Waterproof coating glue and tarpaulin treatment method

A waterproof coating and pretreatment technology, applied in the field of coating adhesive, can solve the problems of poor wetting of polyester, high surface tension, poor coating adhesion, etc., and achieve good waterproof performance, reliable connection, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

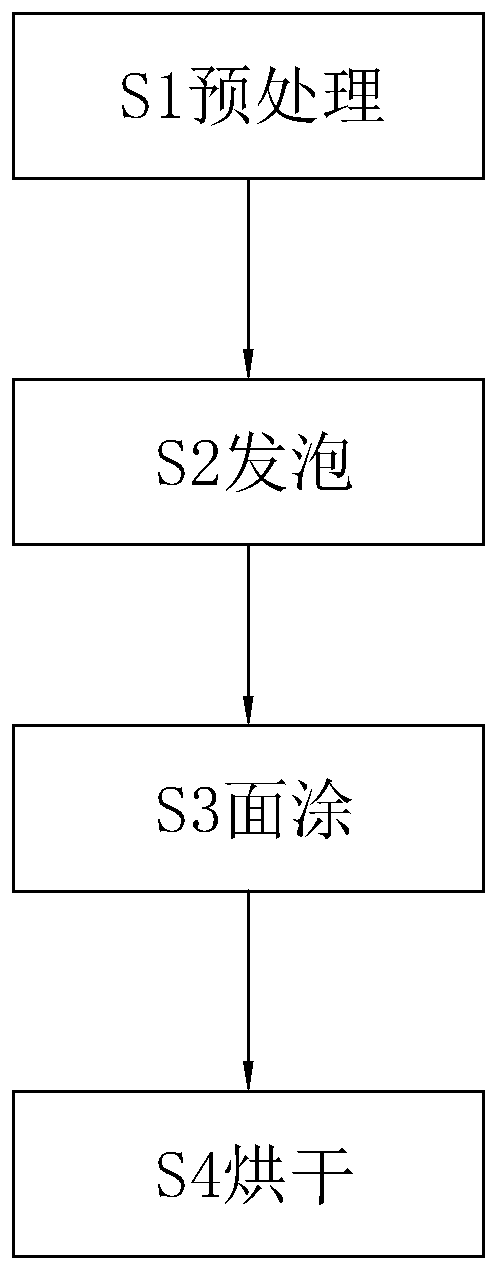

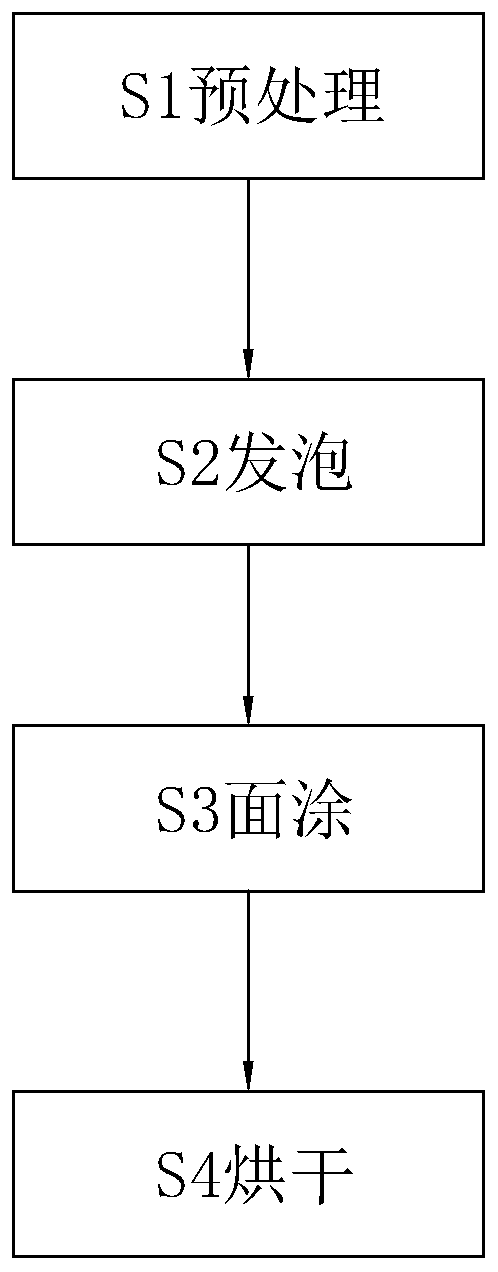

Image

Examples

Embodiment 1

[0045] A waterproof coating glue, comprising the following components by weight:

[0046] 90 parts of aqueous polyurethane emulsion;

[0047] Sodium bicarbonate 0.6 part;

[0048] 3 parts carboxymethyl cellulose

[0049] Nano titanium dioxide 1.2 parts

[0050] Dispersant NNO 0.48 parts

[0051] 1.6 parts of citric acid.

[0052] The preparation process of aqueous polyurethane emulsion is as follows:

[0053] Step 1, in parts by weight, mix 60 parts of PTMG-1000 and 20 parts of PCDL-1000 and stir evenly, heat to 105°C for 3 hours and then cool to room temperature;

[0054] Step 2, add 30 parts of IPDI, 0.08 parts of dibutyltin dilaurate, and 0.08 parts of stannous octoate, pass through nitrogen protection, stir evenly and heat to 85°C, and continue to react for 120 minutes;

[0055] Step 3: After the reaction is completed, add 4 parts of 2,2-dimethylolpropionic acid and 10 parts of 1,4-butanediol, heat to 70°C, and react for 3 hours;

[0056] Step 4: After the reaction,...

Embodiment 2

[0063] A waterproof coating glue, comprising the following components by weight:

[0064] 80 parts of aqueous polyurethane emulsion;

[0065] 0.4 parts of sodium bicarbonate;

[0066] Carboxymethylcellulose 2.4 parts

[0067] Nano titanium dioxide 0.8 parts

[0068] Dispersant NNO 0.42 parts

[0069] 1.2 parts of citric acid.

[0070] The preparation process of aqueous polyurethane emulsion is as follows:

[0071] Step 1: In parts by weight, mix 55 parts of PTMG-1000 and 17 parts of PCDL-1000 and stir evenly, heat to 100°C for 2 hours and then cool to room temperature;

[0072] Step 2, add 25 parts of IPDI, 0.06 parts of dibutyltin dilaurate, and 0.06 parts of stannous octoate, pass through nitrogen protection, stir evenly and heat to 80°C, and continue to react for 100 minutes;

[0073] Step 3: After the reaction is completed, add 3 parts of 2,2-dimethylolpropionic acid and 8 parts of 1,4-butanediol, heat to 60°C, and react for 2 hours;

[0074] Step 4: After the react...

Embodiment 3

[0081] A waterproof coating glue, comprising the following components by weight:

[0082] 85 parts of aqueous polyurethane emulsion;

[0083] 0.5 parts of sodium bicarbonate;

[0084] Carboxymethylcellulose 2.7 parts

[0085] Nano titanium dioxide 1 part

[0086] Dispersant NNO 0.45 parts

[0087] 1.4 parts of citric acid.

[0088] The preparation process of aqueous polyurethane emulsion is as follows:

[0089] Step 1: In parts by weight, mix 58 parts of PTMG-1000 and 18 parts of PCDL-1000 and stir evenly, heat to 103°C for 2.5 hours and then cool to room temperature;

[0090] Step 2, add 28 parts of IPDI, 0.07 parts of dibutyltin dilaurate, and 0.07 parts of stannous octoate, pass through nitrogen protection, stir evenly and heat to 82°C, and continue the reaction for 110 minutes;

[0091] Step 3: After the reaction is completed, add 3.5 parts of 2,2-dimethylolpropionic acid and 9 parts of 1,4-butanediol, heat to 65°C, and react for 2.5 hours;

[0092] Step 4: After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com