Device and method for metal roof rust removal and renovation, anti-seepage and anti-corrosion, snow melting and deicing

A metal roof and snow melting technology, which is applied in snow melting and deicing devices, metal roof rust removal and renovation, anti-seepage and anti-corrosion fields, can solve the problems of limited coverage, low work efficiency, high operation risk, etc., to reduce operation risk and roof Collapse, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

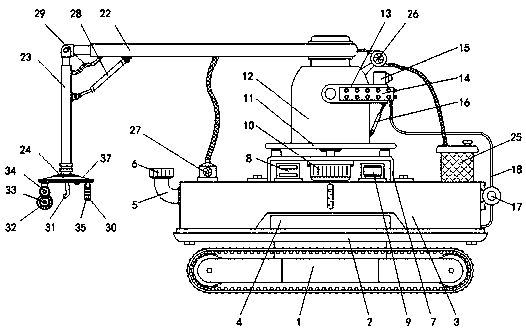

[0038]The embodiment of the present invention provides a device and method for metal roof derusting and renovation, anti-seepage and anti-corrosion, and snow melting and deicing. All-round cleaning and painting treatment of the metal roof, while the coverage is relatively limited.

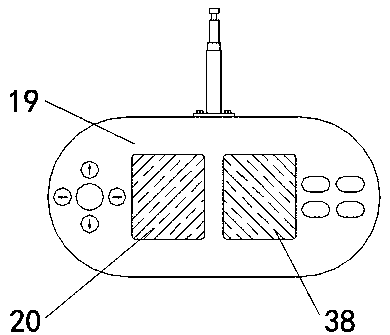

[0039] By adopting the remote control mechanism, when the metal roof needs to be processed, the remote control car 1 is placed on the top of the metal roof as a whole, and the remote control car 1 can be controlled to move through the remote control 19. This remote control operation structure is both The occurrence of personnel falling and roof collapse is reduced, and the operation risk is reduced. At the same time, the remote-controlled cleaning and painting structure improves the efficiency of metal roof cleaning and painting.

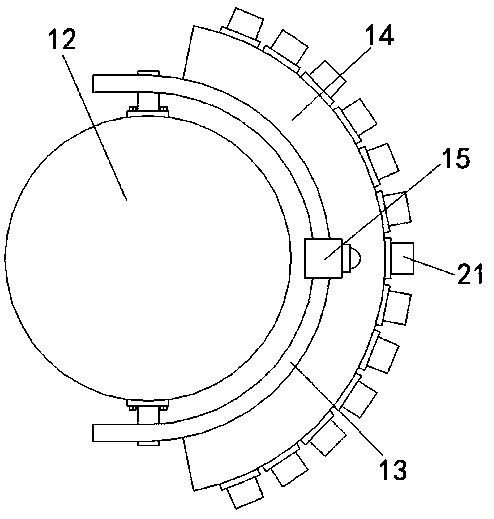

[0040] By adopting an all-round rotation mechanism, a servo motor 10 is provided at the center of the bottom of the mounting frame 7, and the servo motor 10 can drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com