A hot nitrogen assisted steam huff and puff recovery system and method for heavy oil reservoirs

A heavy oil reservoir, hot nitrogen technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

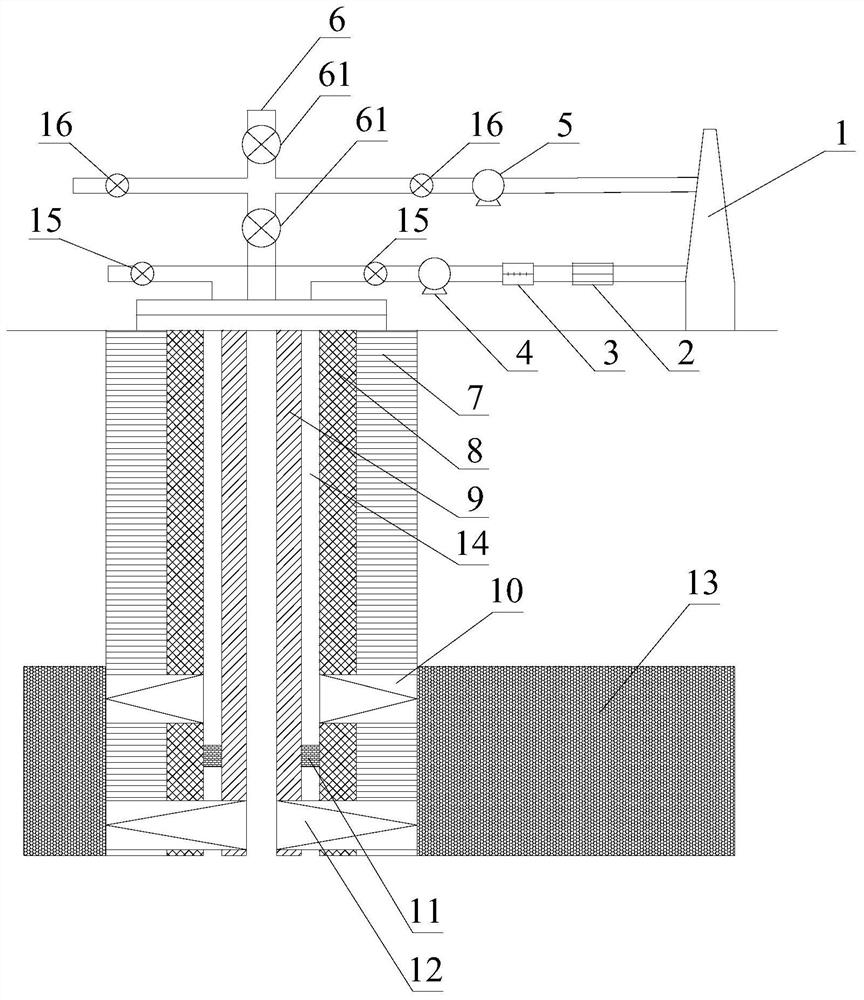

[0086] To exploit heavy oil reservoirs, the specific development steps are as follows:

[0087] (1) Set the packer 11 in the oil jacket annulus 14, the packer 11 is close to the middle of the oil layer 13, and then shoot the casing 8 at the top of the oil layer 13; Perforation operation, the perforation thickness is 4m, forming the casing perforation section 10; performing perforation operation on the tubing 9 at the bottom of the oil layer 13, the perforation thickness is 4m, forming the tubing perforation section 12 .

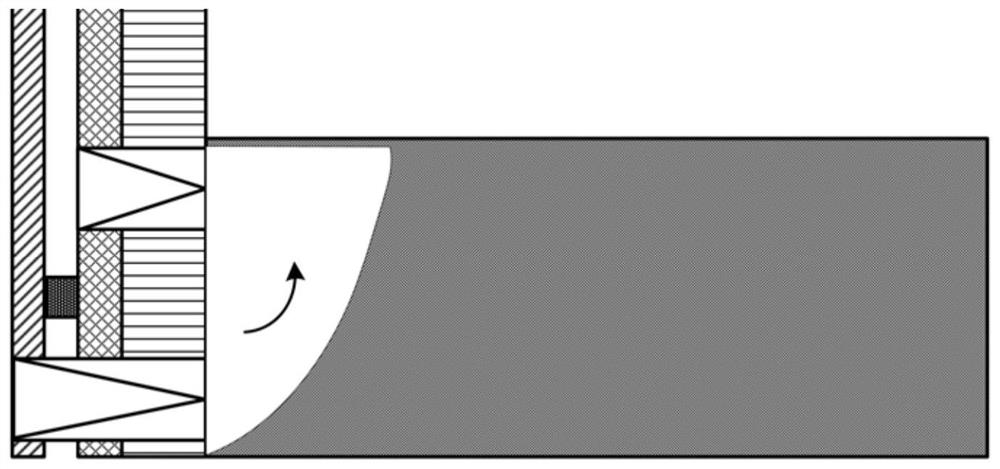

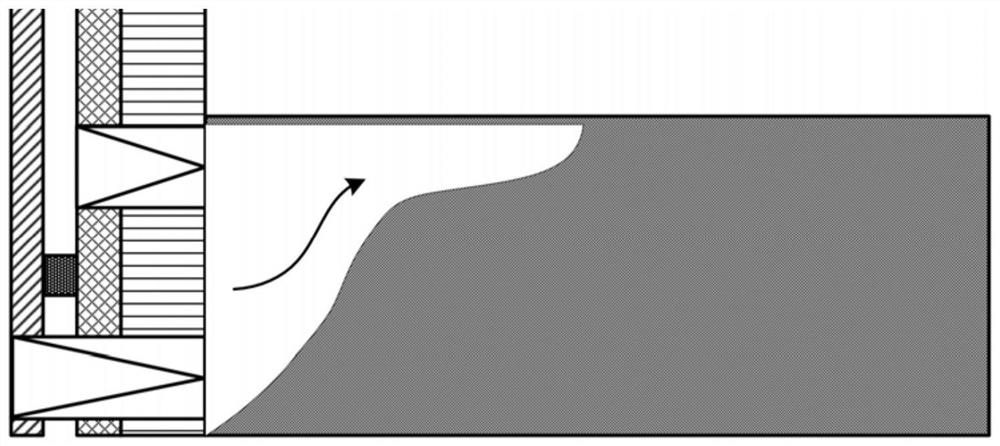

[0088] (2) Hot nitrogen gas injection stage: After the hot nitrogen gas heated up to 300°C by the electric heating device is pressurized by the first booster pump 4, it is injected into the oil jacket annulus area through the Christmas tree 6 14, after the oil-casing annulus 14 is filled with hot nitrogen, continue pressurizing, stop gas injection when the injection pressure of hot nitrogen at the wellhead reaches 1.1 times the original formation pressure, a...

Embodiment 2

[0093] To exploit heavy oil reservoirs, the specific development steps are as follows:

[0094] (1) Set the packer 11 in the oil jacket annulus 14, the packer 11 is close to the middle of the oil layer 13, and then shoot the casing 8 at the top of the oil layer 13; Perforation operation, the perforation thickness is 5m, forming the casing perforation section 10; performing perforation operation on the tubing 9 at the bottom of the oil layer 13, the perforation thickness is 5m, forming the tubing perforation section 12 .

[0095] (2) Hot nitrogen gas injection stage: After the hot nitrogen gas heated up to 300°C by the electric heating device is pressurized by the first booster pump 4, it is injected into the oil jacket annulus area through the Christmas tree 6 14, after the oil-casing annulus 14 is filled with hot nitrogen, continue pressurizing, stop gas injection when the injection pressure of hot nitrogen at the wellhead reaches 1.15 times the original formation pressure, ...

Embodiment 3

[0100] To exploit heavy oil reservoirs, the specific development steps are as follows:

[0101] (1) Set the packer 11 in the oil jacket annulus 14, the packer 11 is close to the middle of the oil layer 13, and then shoot the casing 8 at the top of the oil layer 13; Perforation operation, the perforation thickness is 3m, forming the casing perforation section 10; performing perforation operation on the tubing 9 at the bottom of the oil layer 13, the perforation thickness is 3m, forming the tubing perforation section 12 .

[0102] (2) Hot nitrogen gas injection stage: After the hot nitrogen gas heated up to 300°C by the electric heating device is pressurized by the first booster pump 4, it is injected into the oil jacket annulus area through the Christmas tree 6 14, after the oil-casing annulus 14 is filled with hot nitrogen, continue pressurizing, stop gas injection when the injection pressure of hot nitrogen at the wellhead reaches 1.05 times the original formation pressure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com