Method for controlling metering system having plurality of metering valves

A technology of metering system and metering valve, which is applied in the direction of electric control of exhaust gas treatment device, exhaust gas treatment, mechanical equipment, etc., can solve problems such as the rise of liquid level controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

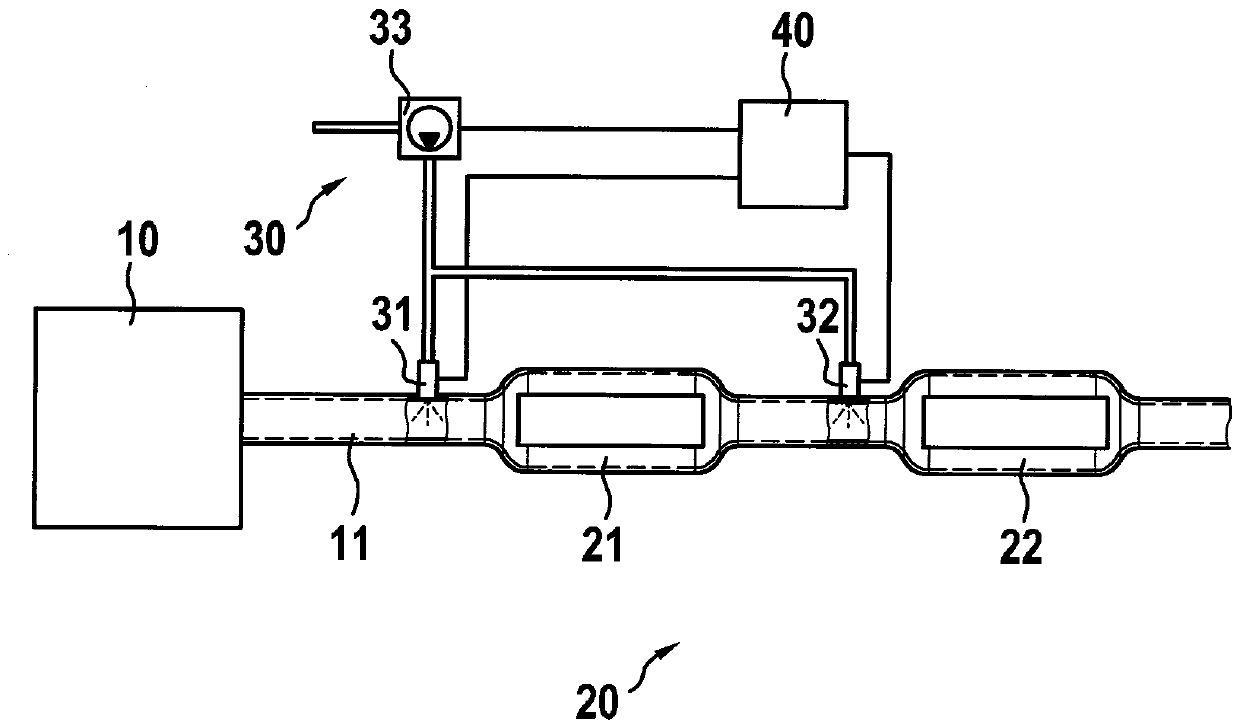

[0016] The internal combustion engine 10 has in its exhaust system 11 an SCR catalytic converter system 20 which is located in the figure 1 is shown in . It has two SCR catalytic converters 21 , 22 , wherein the catalytic converter material of the first SCR catalytic converter 21 is arranged on a particle filter (SCR on filter; SCRF). A metering system 30 is provided for metering the aqueous urea solution into the exhaust system 11 . It has a first metering valve 31 upstream of the first SCR catalytic converter 21 and a second metering valve 32 between the two SCR catalytic converters 21 , 22 . The delivery pump 33 delivers the aqueous urea solution from a reducing agent tank (not shown). In this case, the aqueous urea solution is conveyed via a reducing agent line which branches off downstream of a feed pump 33 into two metering valves 31 , 32 . The first metering valve 31 has a structurally relevant first maximum metering quantity dm max,31 , and the second metering valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap