Spiral-flow type flue gas fly ash sampling pipe

A sampling tube and swirling flow technology, applied in the field of airflow fly ash sampling device, can solve the problems of cumbersome electrical system, airflow leakage, inconvenient operation, etc., and achieve the effects of saving time and human resources, preventing gas leakage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

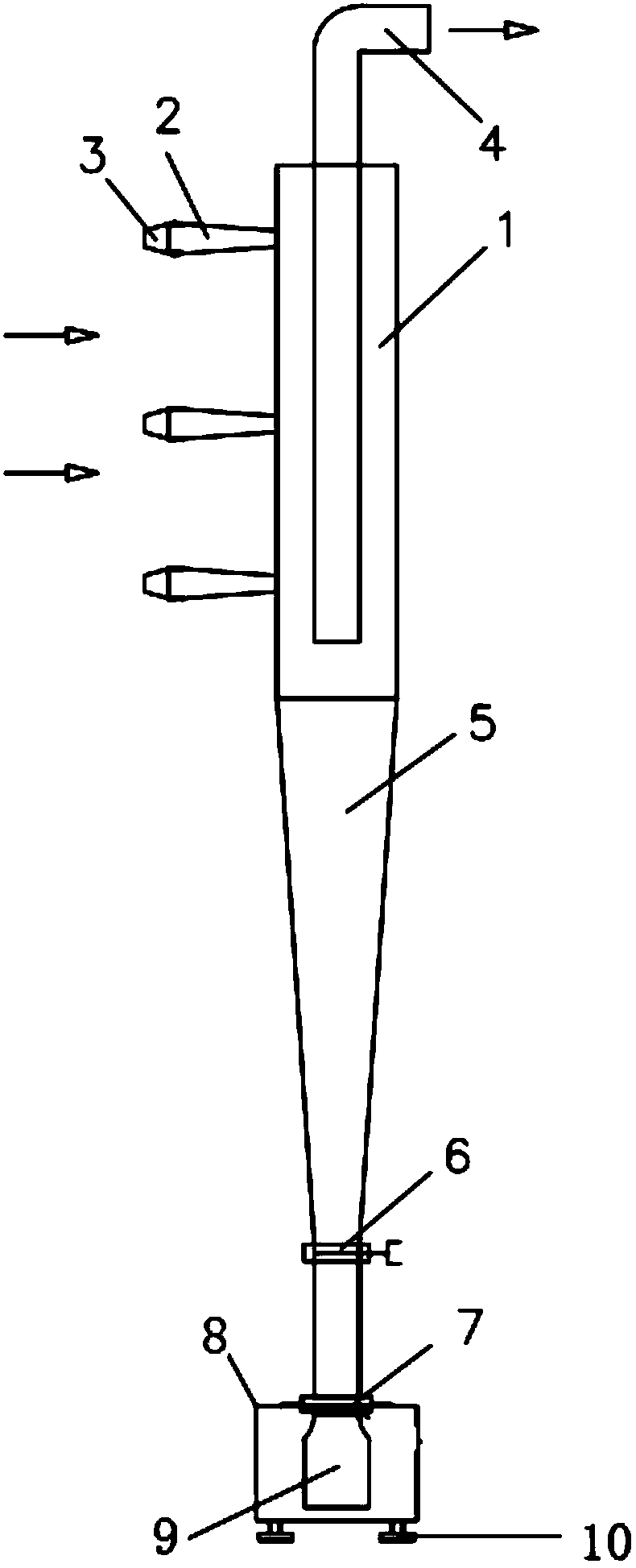

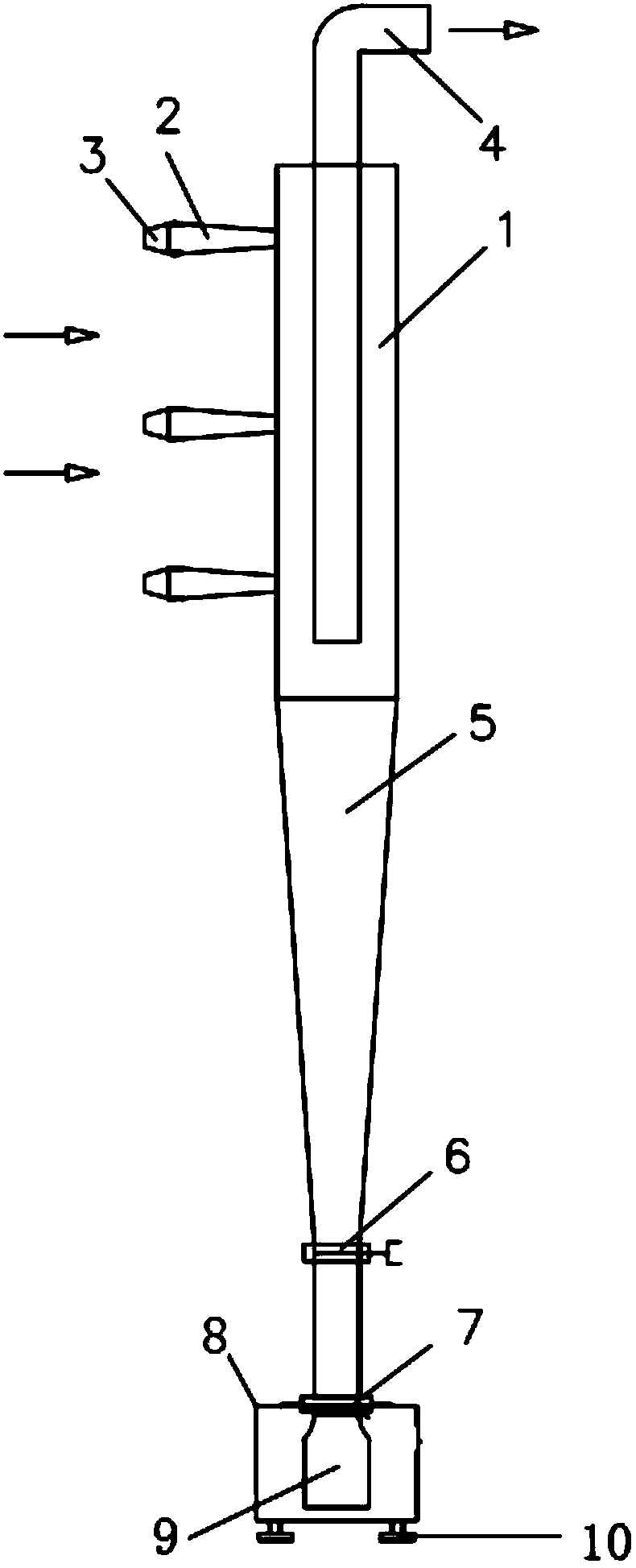

[0020] Embodiment 1: as figure 1 as shown,

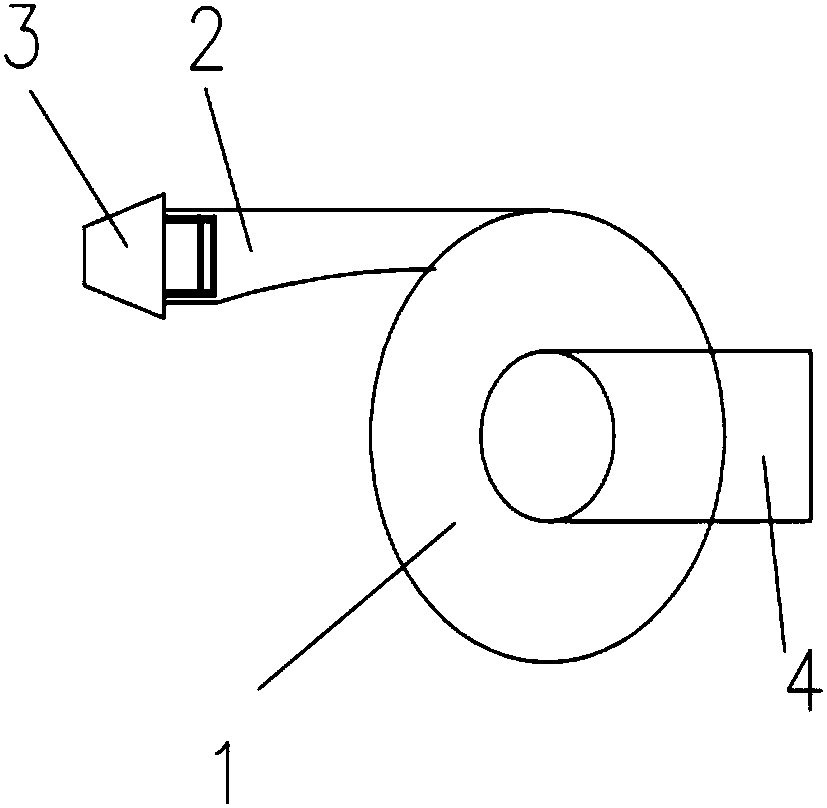

[0021] A swirling flue gas fly ash sampling pipe, comprising an exhaust pipe 4, a sampling pipe, a swirling air inlet pipe 2 and a sealed support box 9, the sampling pipe includes a straight pipe section 1 and a sampling pipe tapered pipe section 5, the sampling pipe tapered pipe section 5. The diameter gradually decreases from top to bottom. The diameter of the swirl air inlet pipe 2 gradually decreases from the front end to the rear end. A plurality of swirl air inlet pipes 2 are arranged longitudinally on the side wall of the straight pipe section 1 of the sampling pipe. The swirl air inlet pipe 2. The rear end is connected tangentially to the side wall of the straight section 1 of the sampling pipe, and the swirl air inlet pipe 2 is perpendicular to the wall of the straight section 1 of the sampling pipe. The front end of the swirl air inlet pipe 2 is screwed with a sampling nozzle 3; The pipe 4 is L-shaped, and its longer pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com