Multifunctional flexible electronic device, application and preparation method

A multi-functional and flexible technology, applied in cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, circuits, etc., can solve the difficulties of multi-functional flexible electronic light-emitting devices, low-cost patterned light-emitting is difficult to achieve, Complicated weaving methods and other problems, to achieve the effect of rich raw materials, low cost, and solve uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The average length of silver nanowires used in this example is 20 μm.

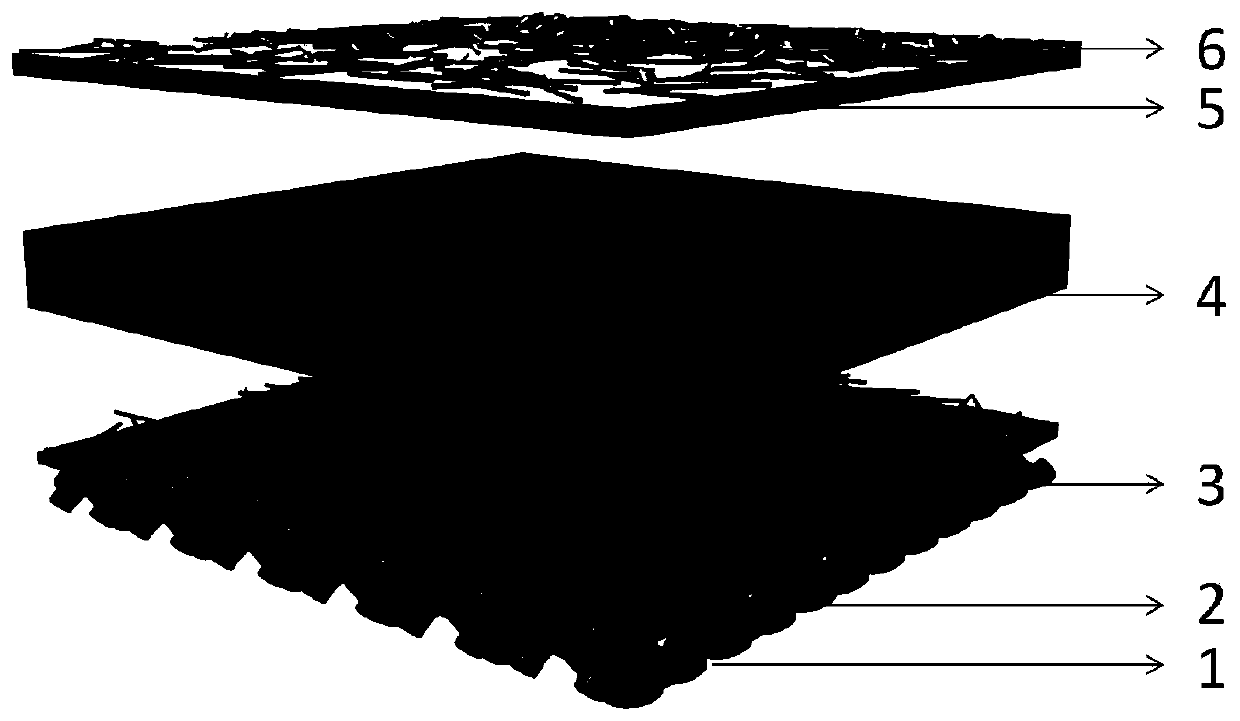

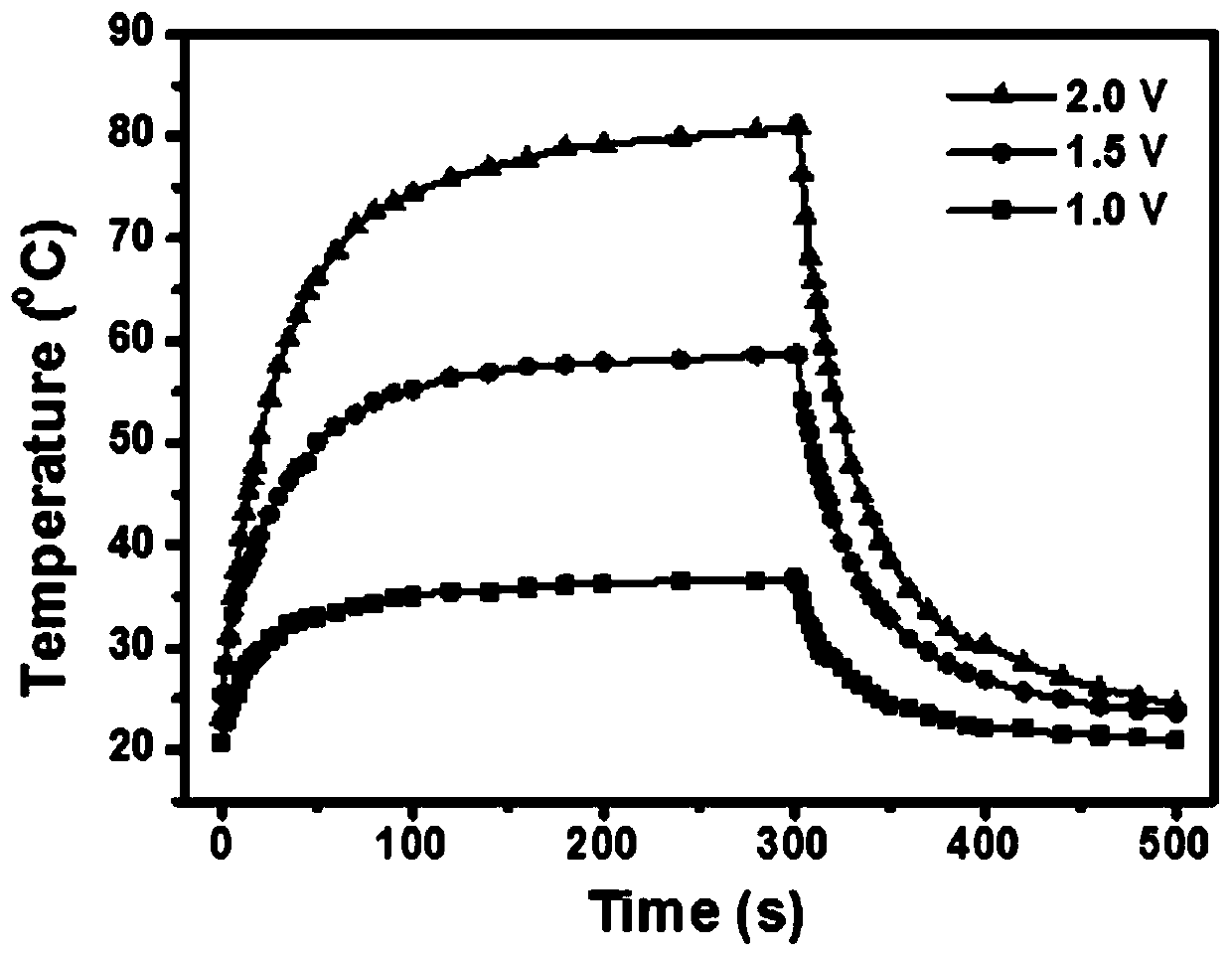

[0040] 1) Preparation of the first electrode layer: Spray silver nanowires on the base of a plastic petri dish to prepare a conductive film. The average length of the silver nanowires used is 20 μm, the sheet resistance of the film is 10Ω / sq, and the light transmittance is 55%. The conductive film has both the functions of the inner electrode in the light-emitting mode and the heating layer in the heating mode. Then drop-coat NOA63 on the conductive film as an adhesive and cover the fabric on NOA63, and peel it off from the substrate after the whole is completely cured.

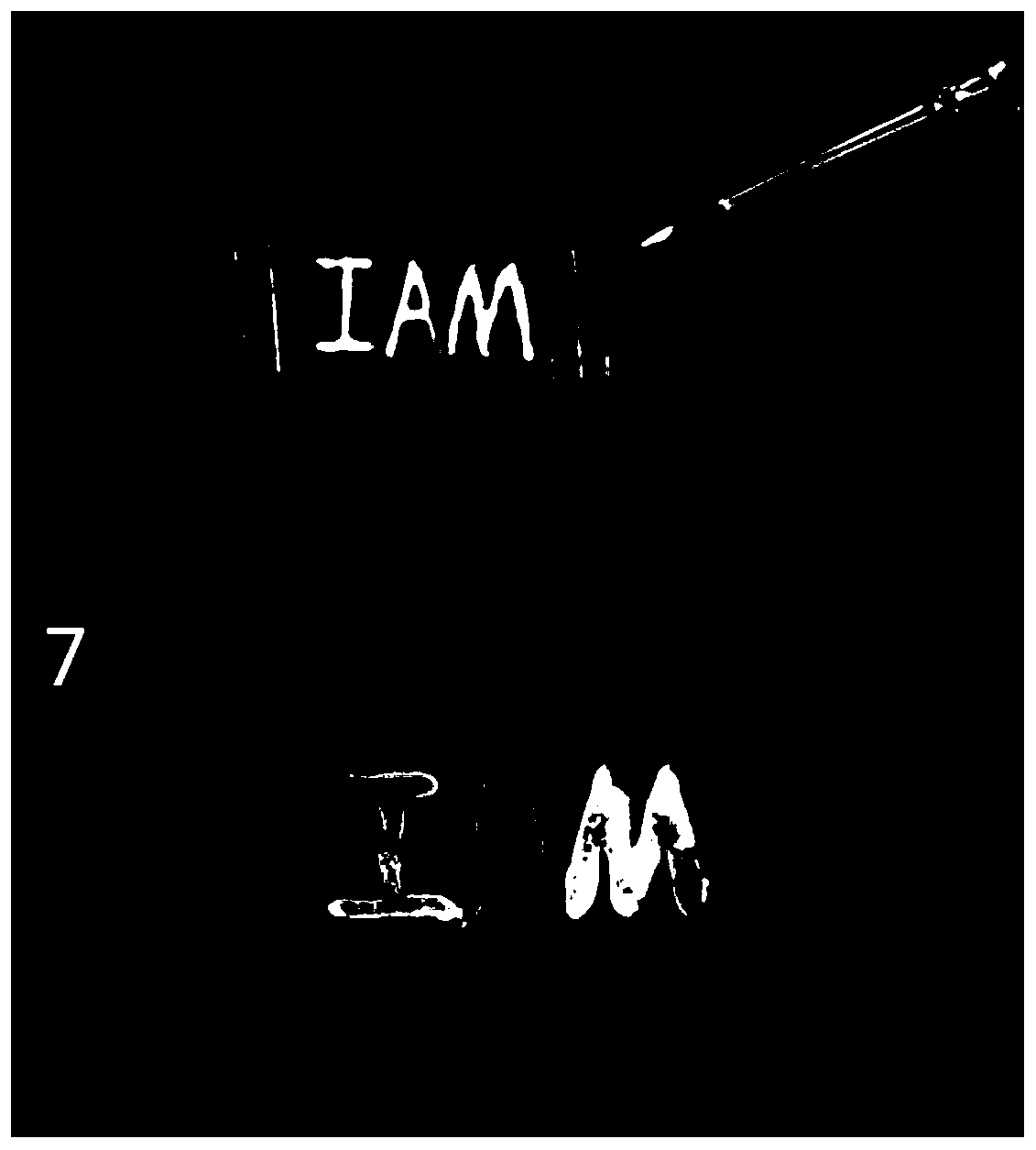

[0041] 2) Prepare the luminescent functional layer: fully mix the ZnS phosphor and the insulating polymer (PB, ie polybutadiene) to prepare the luminescent layer solution, wherein for the blue luminescent functional layer material, the phosphor added is ZnS: Cu; orange light-emitting functional layer material, the phosphor powder ...

Embodiment 2

[0050] The silver nanowires used in this example have an average length of 10 μm.

[0051] 1) Preparation of the first electrode layer: Spray silver nanowires on the base of a plastic petri dish to prepare a conductive film. The average length of the silver nanowires used is 10 μm, the sheet resistance of the film is 1Ω / sq, and the light transmittance is 20%. The conductive film has both the functions of the inner electrode in the light-emitting mode and the heating layer in the heating mode. Then drop-coat NOA63 on the conductive film as an adhesive and cover the fabric on NOA63, and peel it off from the substrate after the whole is completely cured.

[0052] 2) Preparation of luminescent functional layer: fully mix ZnS phosphor and insulating polymer (PB) to prepare a luminescent layer solution, wherein for the blue luminescent functional layer material, the phosphor powder added is ZnS:Cu, and spin-coated A large-area luminescent layer was obtained by spin coating and drie...

Embodiment 3

[0062] The average length of silver nanowires used in this example is 200 μm.

[0063] 1) Preparation of the first electrode layer: Spray silver nanowires on the base of a plastic petri dish to prepare a conductive film. The average length of the silver nanowires used is 200 μm, the sheet resistance of the film is 100Ω / sq, and the light transmittance is 90%. With the function of inner electrode in light-emitting mode and heating layer in heating mode, the density of silver nanowires should be as high as possible to obtain good conductivity. Then drip-coat NOA63 as an adhesive on the conductive film and cover the fabric on NOA63, and peel it off from the substrate after the whole is completely cured.

[0064] 2) Preparation of luminescent functional layer: fully mix ZnS:Cu phosphor with insulating polymer (PB) to prepare a luminescent layer solution with a mass ratio of 1:1. Select the Chinese zodiac seal with the "pig" pattern, press a small amount of luminescent layer soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com