Patents

Literature

46results about How to "Difficult to coat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

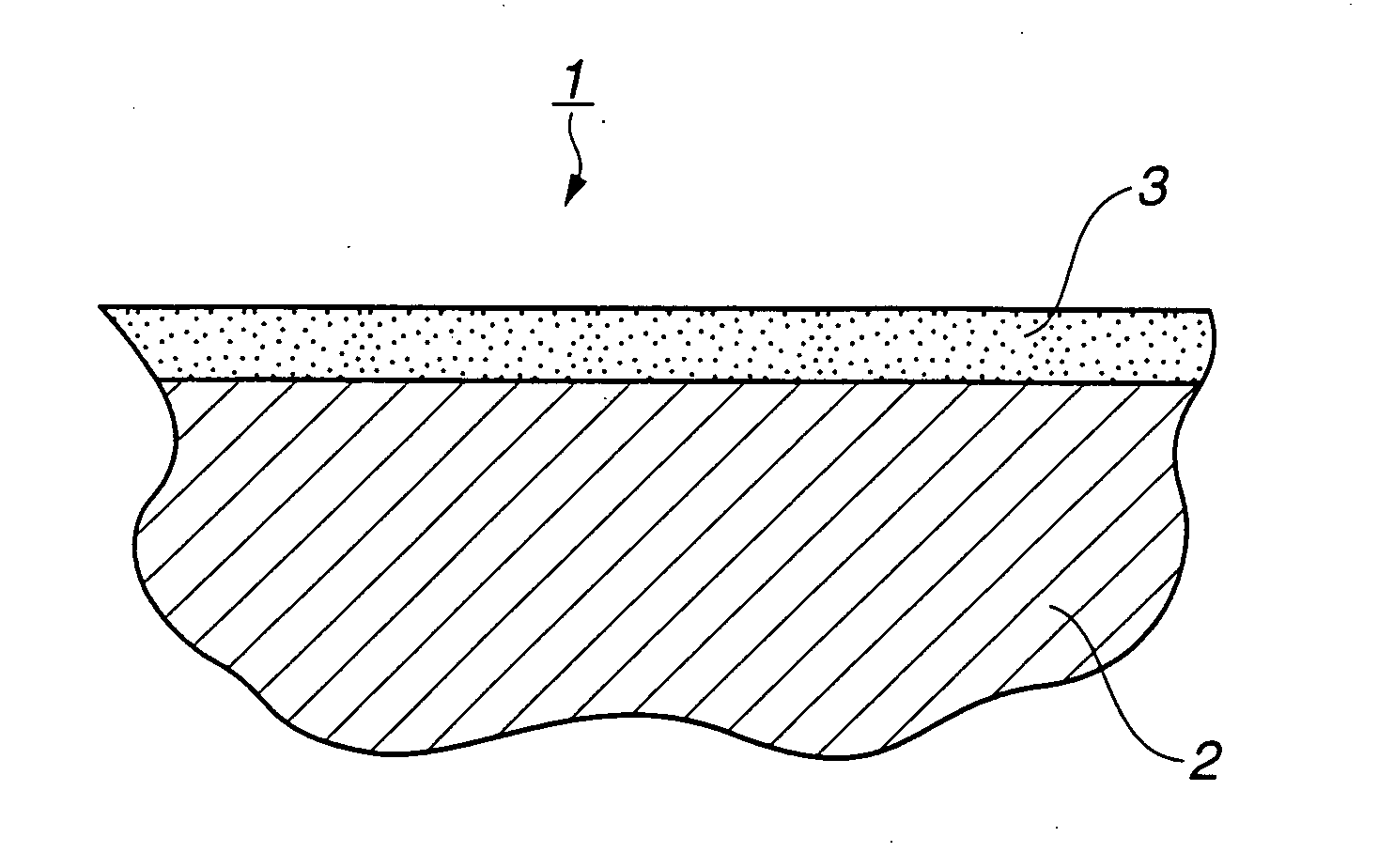

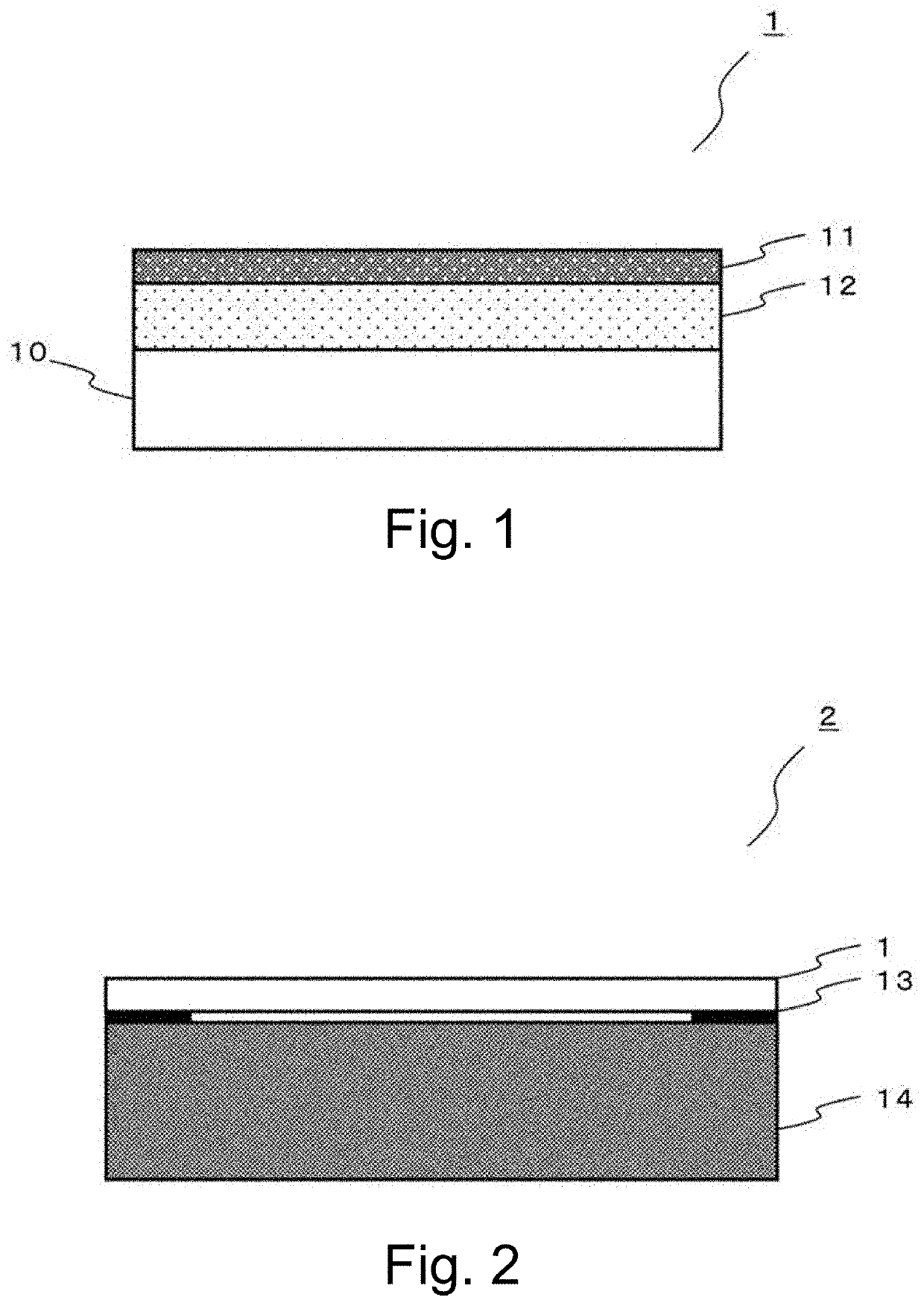

Support film for a transparent conductive thin film

InactiveUS6495253B1Avoid it happening againIncreased durabilitySynthetic resin layered productsElectrical equipmentLiquid-crystal displayTouch panel

An adhesive layer composed of at least an ionizing radiation curable resin binder, a thermoplastic resin binder and two or more matting agents having different average diameters is formed on a transparent polymer film to obtain a support film for a transparent conductive thin film. Alternatively, a transparent hard coat layer containing at least an ionizing radiation curable resin binder and,a matting agent having an average diameter of 1-15 mum, and an adhesive layer containing at least an ionizing radiation curable resin binder, a thermoplastic resin binder and a matting agent having an average diameter of 5-50 nm are formed on a transparent polymer film. The thus obtained support film is excellent in durability when the transparent conductive thin film is formed thereon and prevents occurrence of a Newton-ring, which is produced in a touch panel of the conventional liquid crystal display. The support film, when used in a touch panel of a color liquid crystal display, prevents glare of the color screen and is suitable for use in touch panels of both monochrome and color liquid crystal displays.

Owner:KIMOTO CO LTD

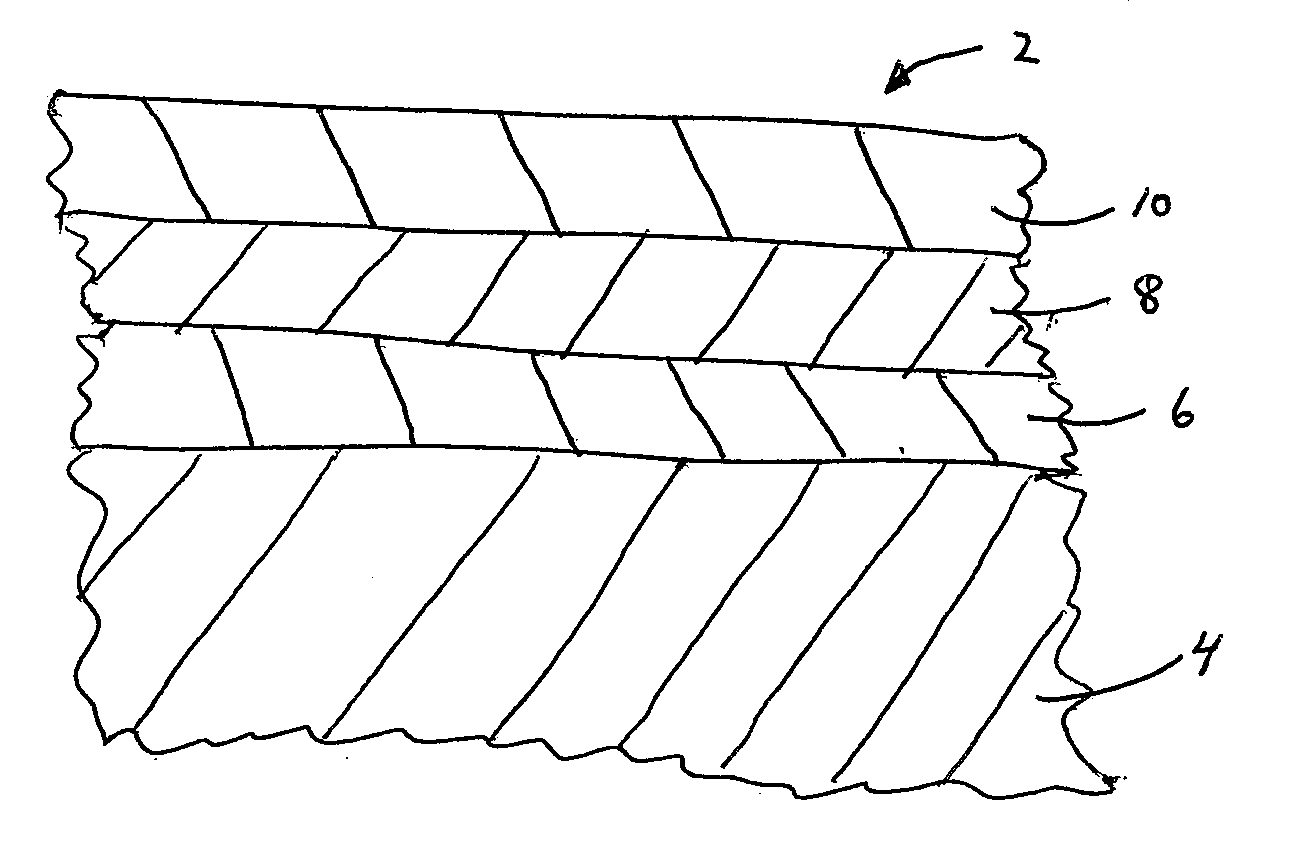

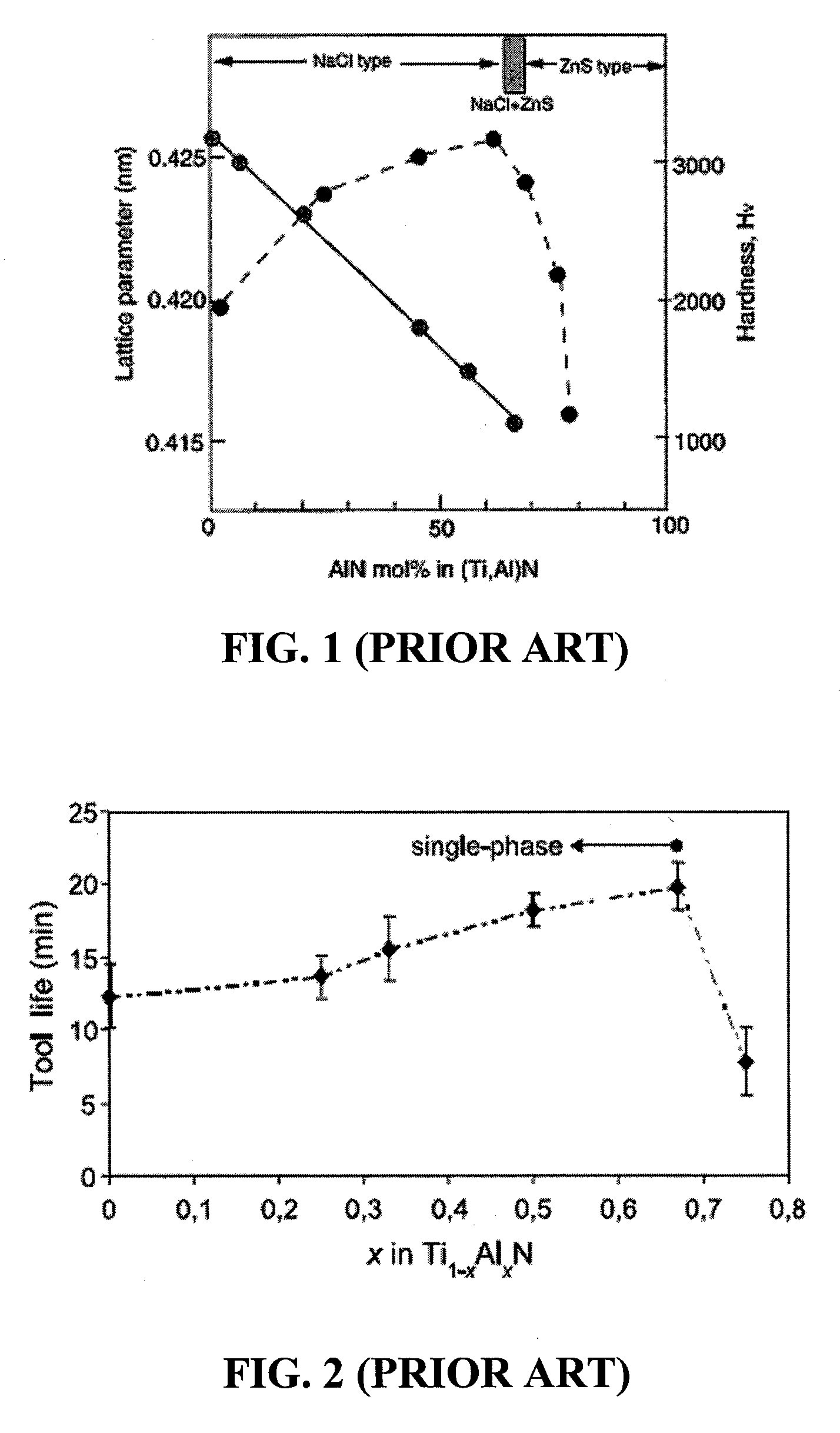

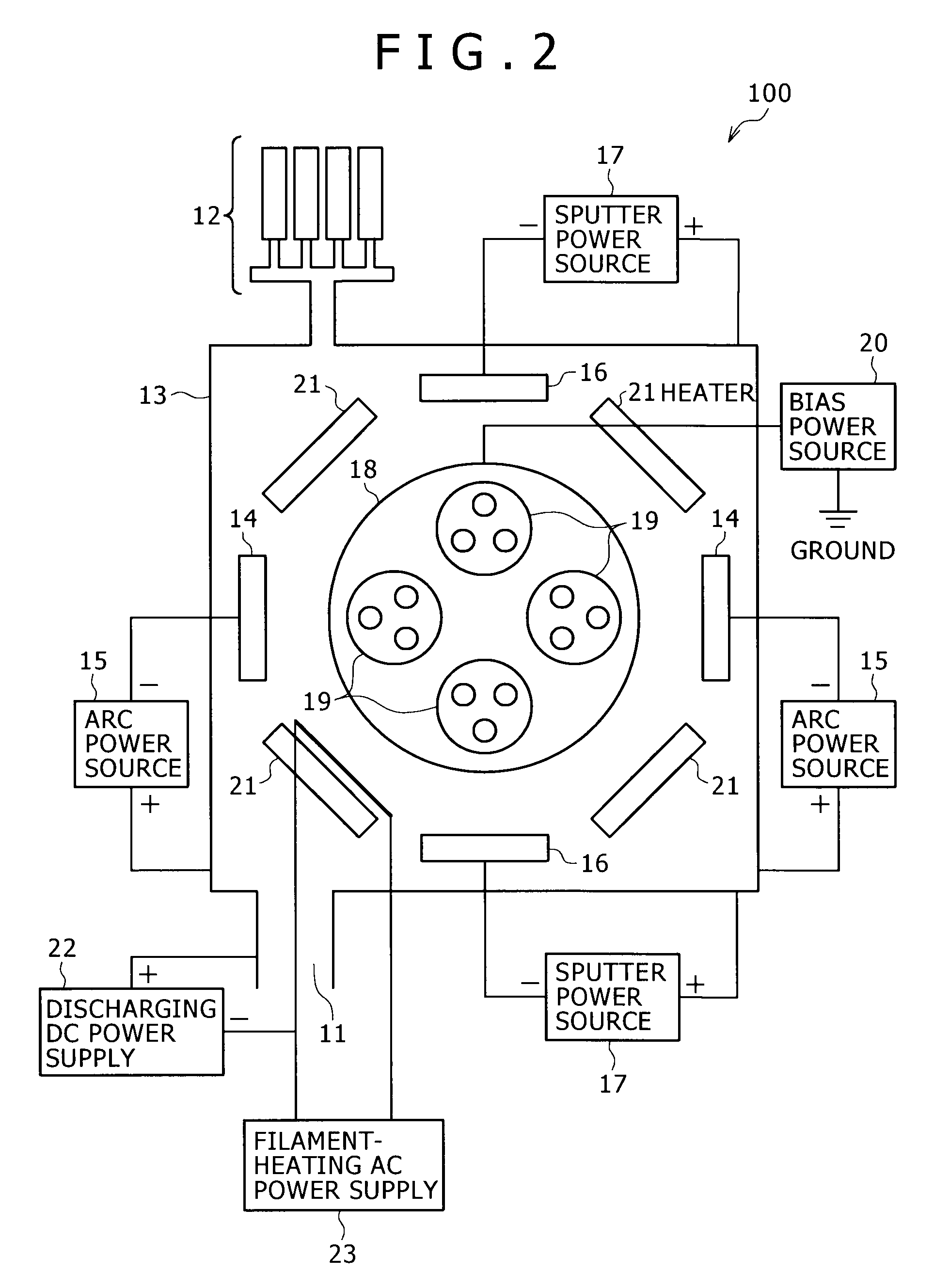

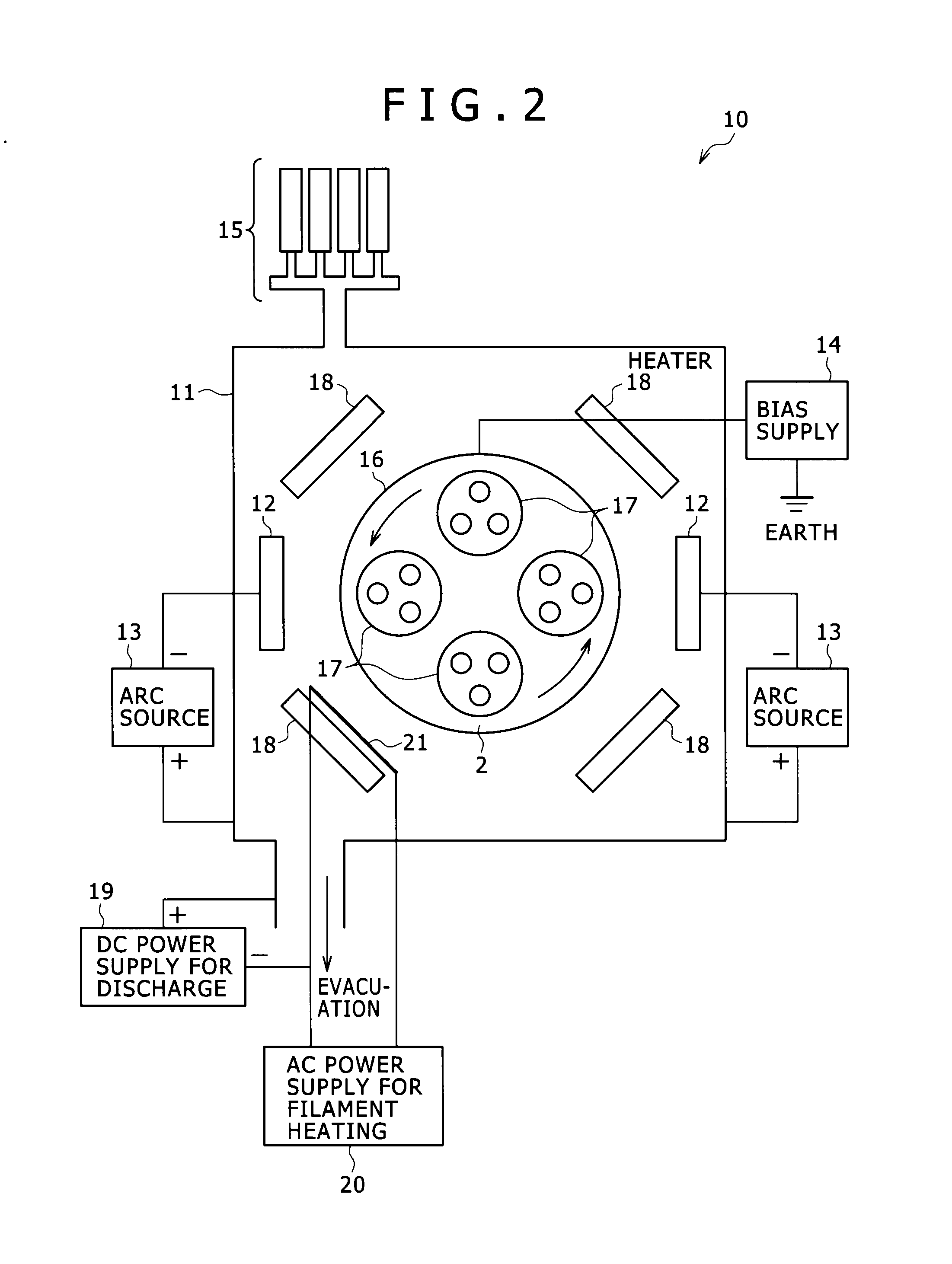

Aluminum Titanium Nitride Coating and Method of Making Same

ActiveUS20110081539A1Improve machinabilityDifficult to coatPigmenting treatmentVacuum evaporation coatingTitanium nitrideHexagonal phase

Hard coatings and methods of making the hard coatings comprising aluminum titanium nitride which are usable on cutting tools are disclosed. The coatings include at least one aluminum titanium nitride layer having between about 0 and about 15 weight percent hexagonal phase and a composition of (AlxTi1-x)N, where x is in the range of about 0.53 to about 0.58 moles.

Owner:KENNAMETAL INC

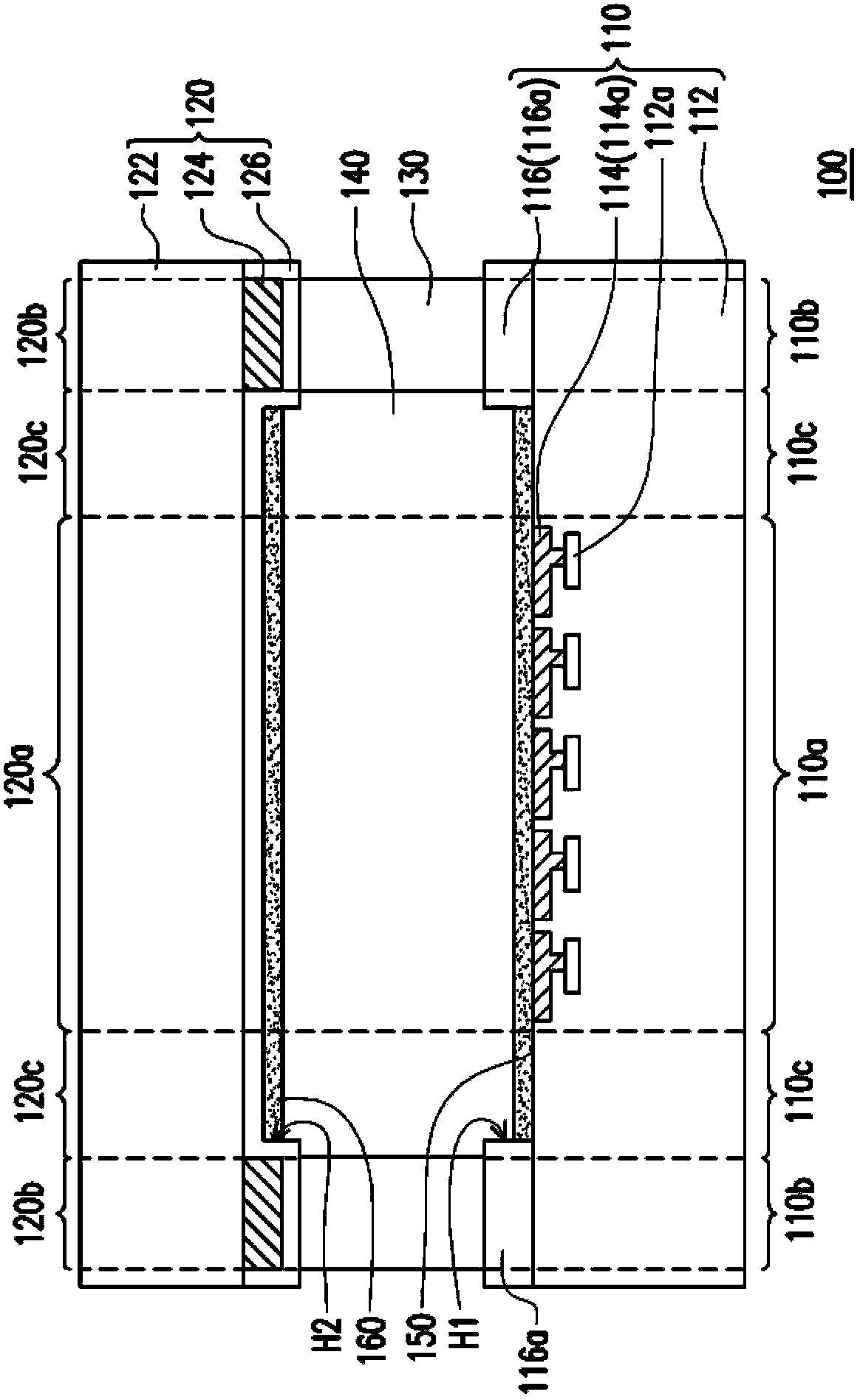

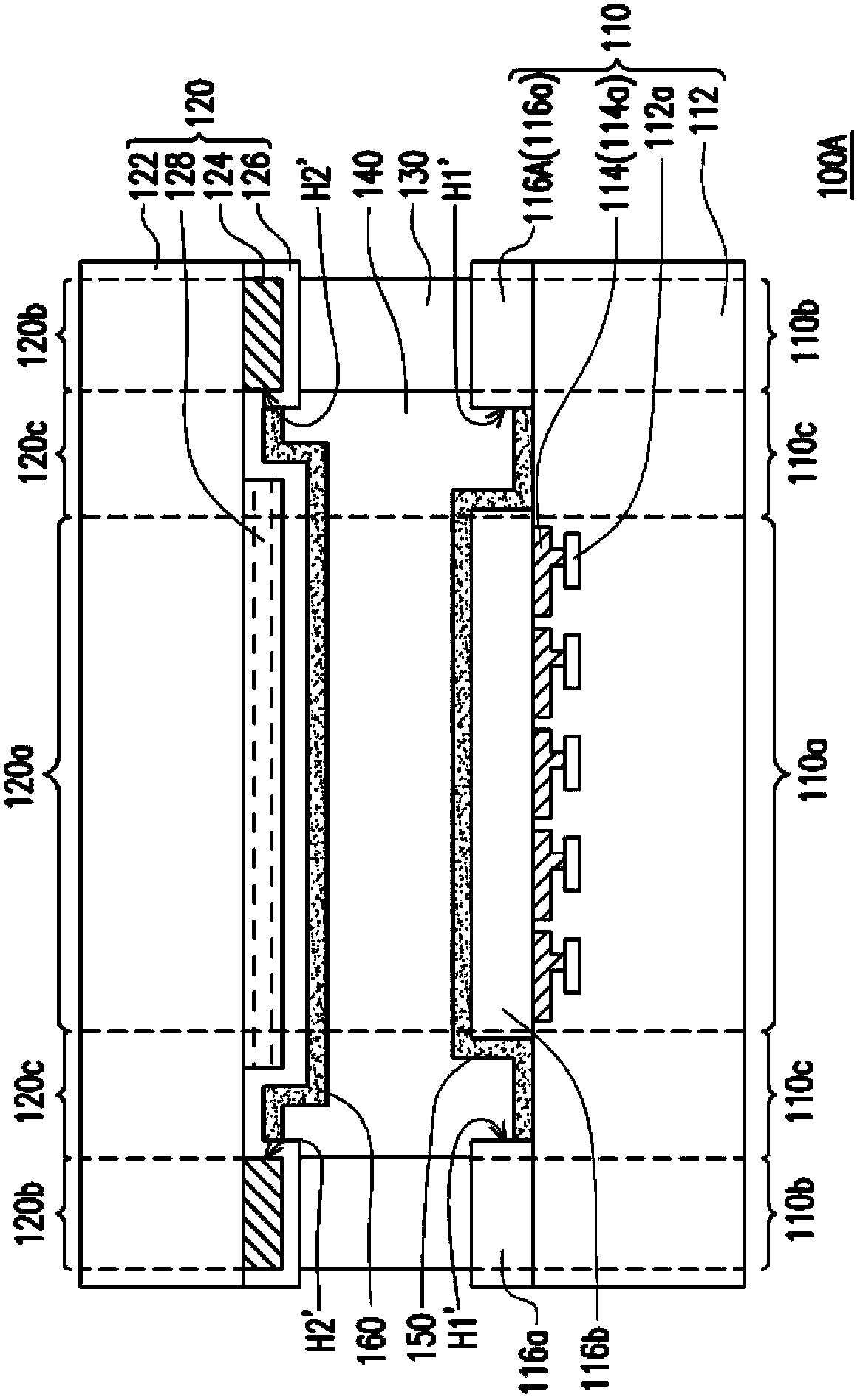

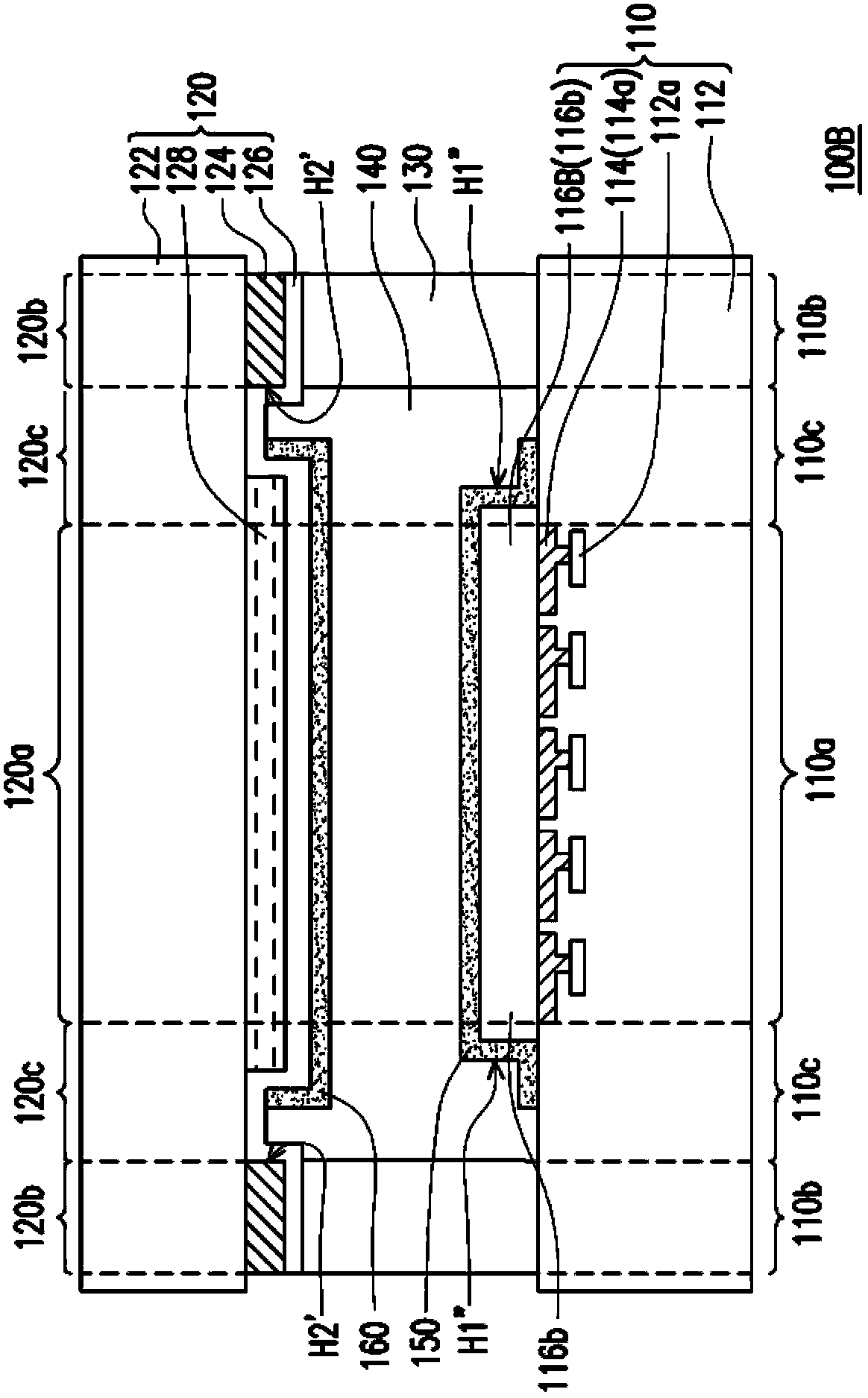

Display

InactiveCN103576390AImprove reliabilitySimplified coating processNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display which comprises a first substrate, a second substrate, frame rubber, a liquid crystal layer and a first alignment film. The first substrate is provided with a first display region, a first frame rubber coating region and first recessions. The first frame rubber coating region encircles the first display region. The first recessions are at least positioned in a region between the first display region and the first frame rubber coating region. The second substrate is opposite to the first substrate. The frame rubber is arranged in the frame rubber coating region and positioned between the first substrate and the second substrate. The first substrate, the second substrate and the frame rubber encircle the liquid crystal layer jointly. The first alignment film is arranged between the first substrate and the liquid crystal layer and filled in the first recessions.

Owner:HIMAX DISPLAY INC

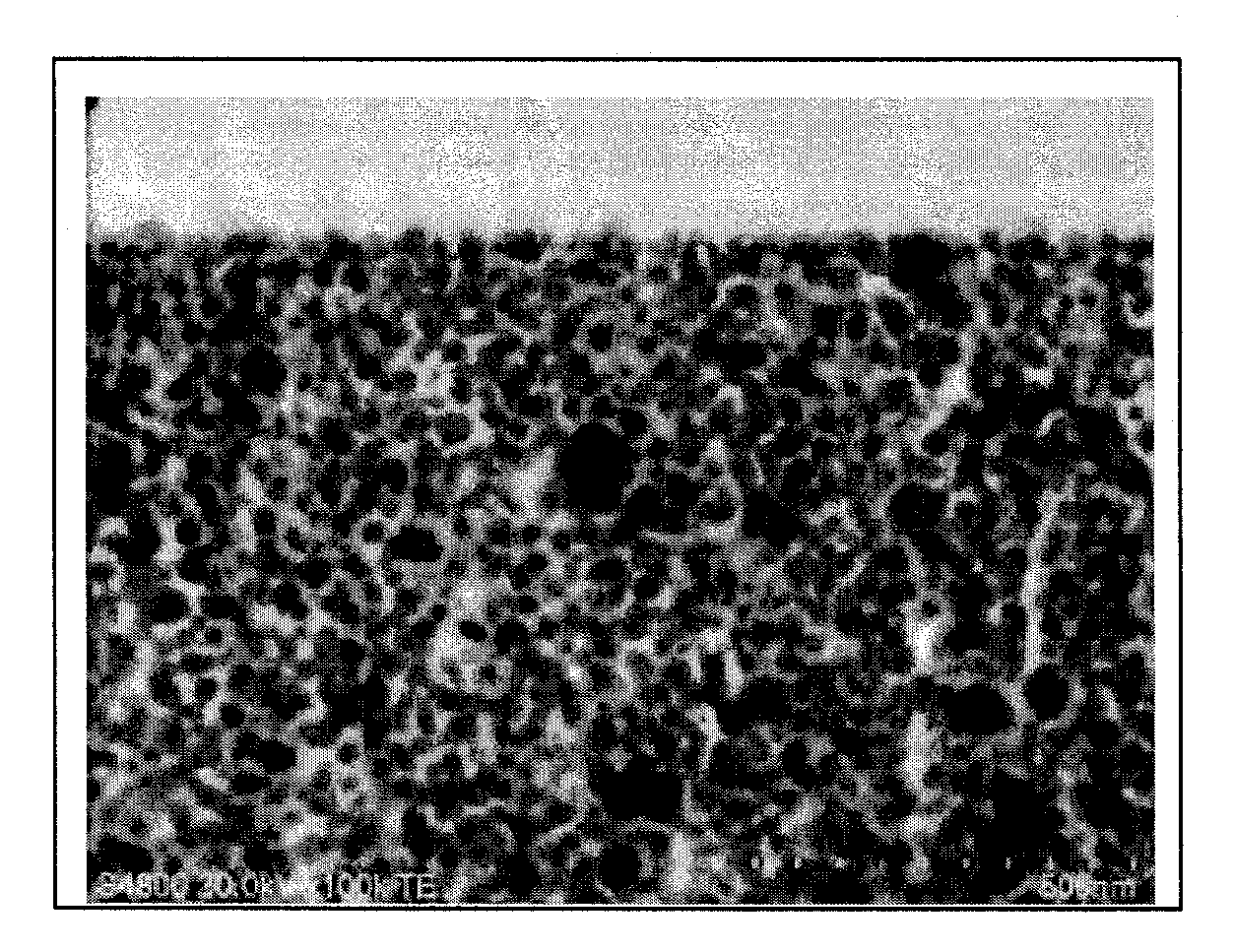

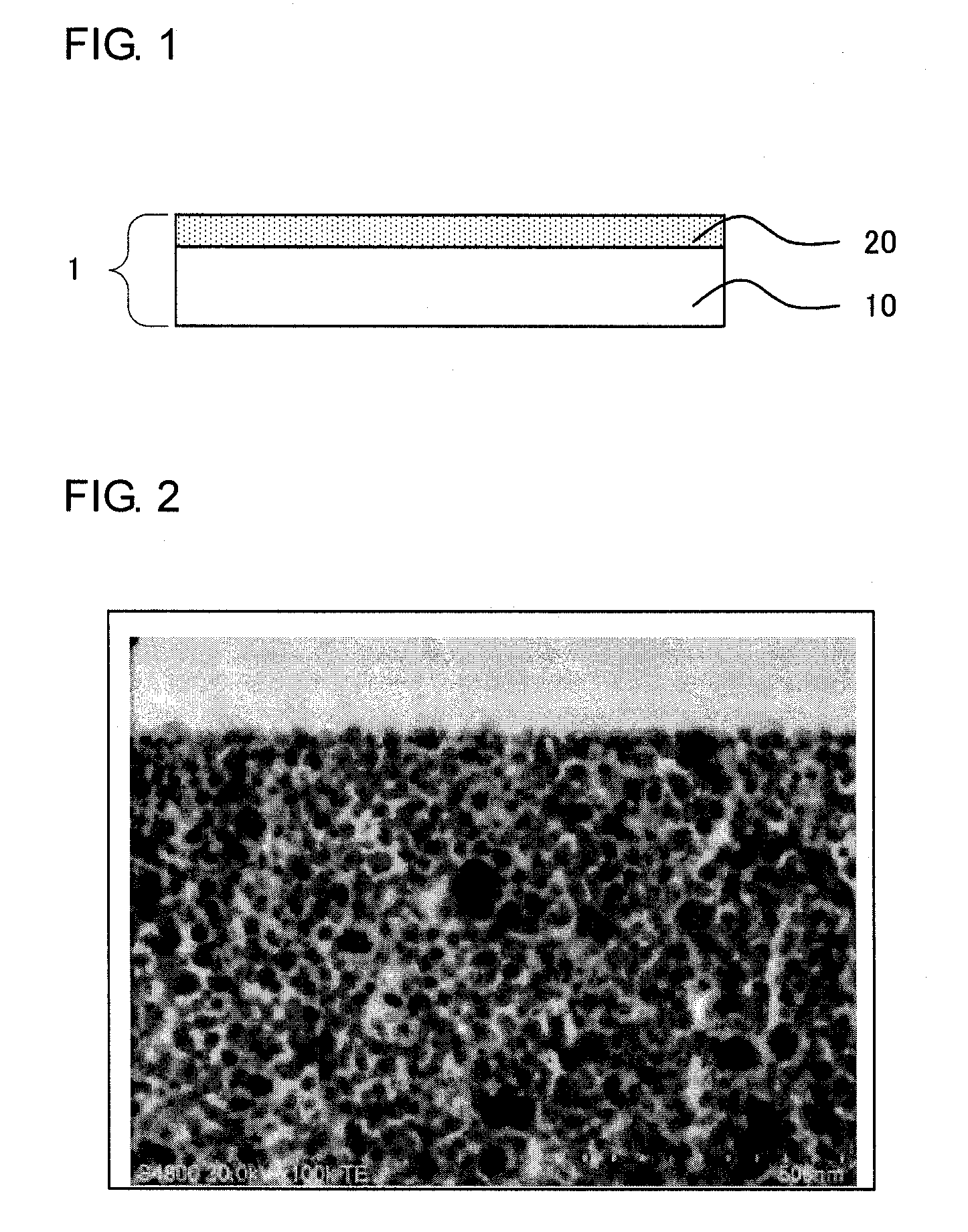

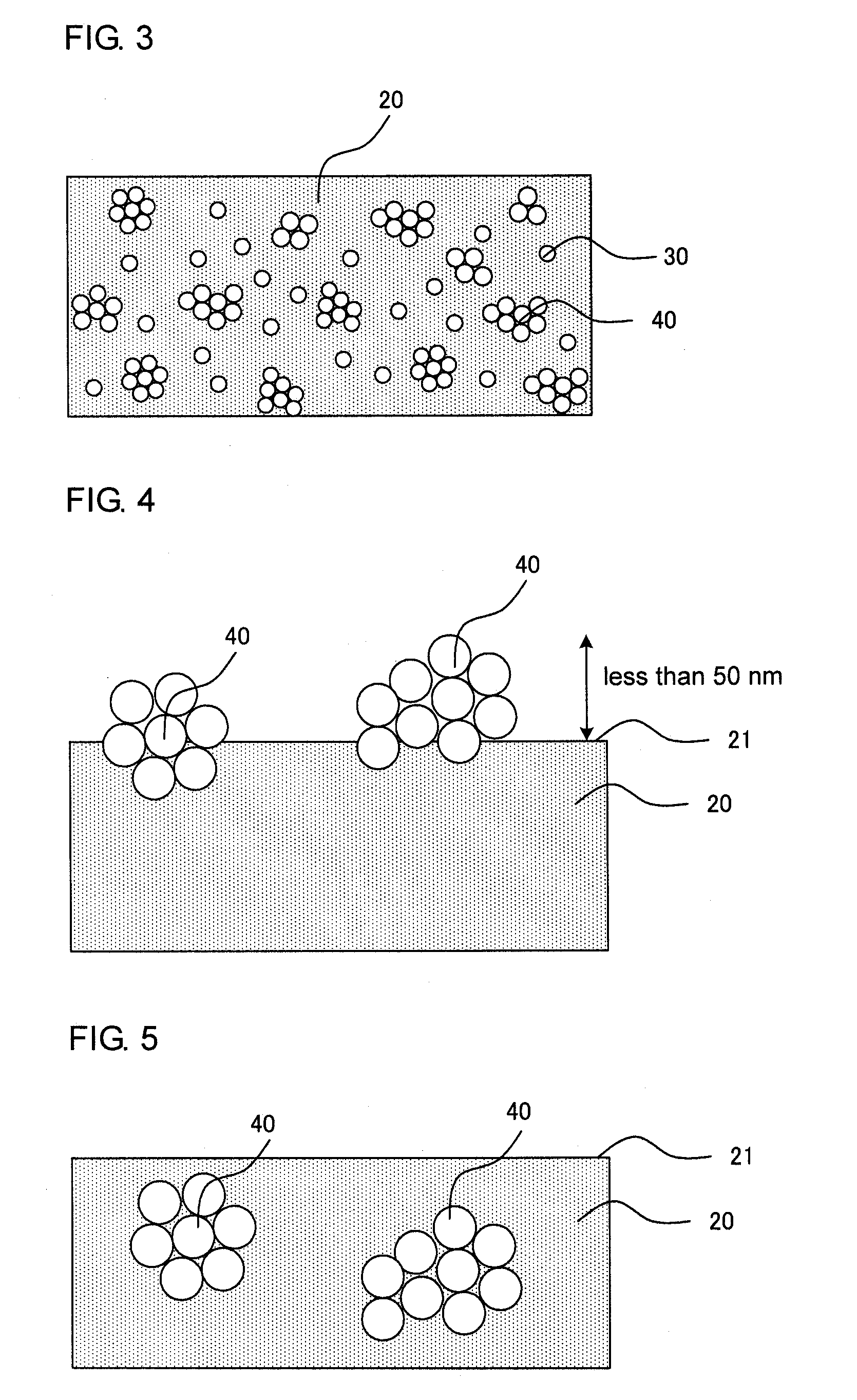

Hard coat film and curable resin composition for hard coat layer

ActiveUS20100104858A1High hardnessIncrease resistanceLayered productsSpecial tyresCross-linkInorganic Chemical

A curable resin composition for a hard coat layer capable of forming a hard coat layer having high hardness even with thin thickness and / or excellent in abrasion resistance and hardness, and a hard coat film using the curable resin composition are provided. A hard coat film in which a hard coat layer is provided on one side of a transparent substrate film, wherein the hard coat layer comprises a matrix in a crosslinked state and an aggregate in which 3 to 100 silica fine particles having an average primary particle diameter of 1 to 100 nm are aggregated, and wherein the aggregate is cross-linked to the matrix, and an irregularly shaped silica fine particle constituted with 3 to 20 silica fine particles having an average primary particle diameter of 1 to 100 nm connected to each other by inorganic chemical bonding is contained as a part of the aggregates. The hard coat layer further contains a silica fine particle preferably.

Owner:DAI NIPPON PRINTING CO LTD

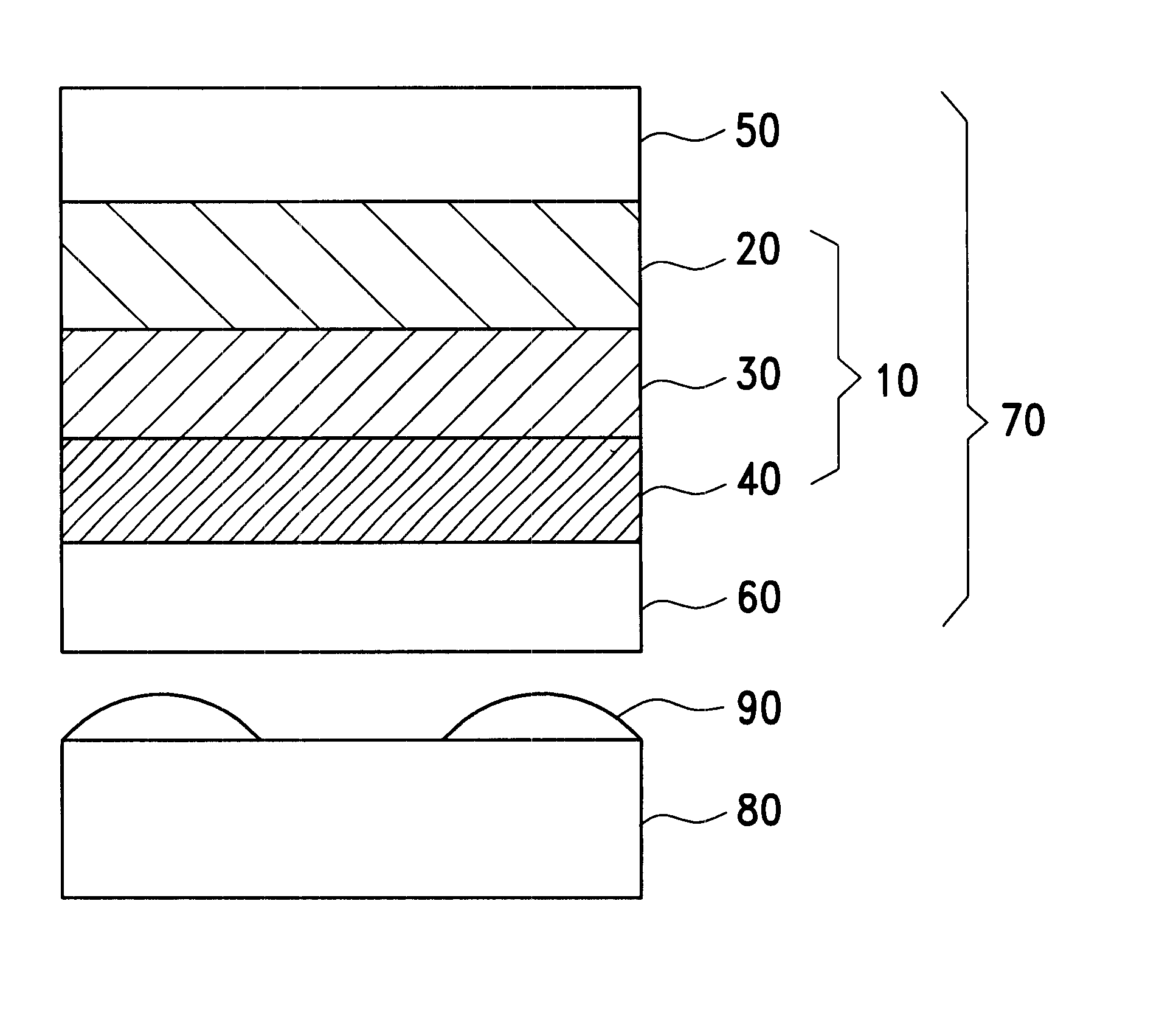

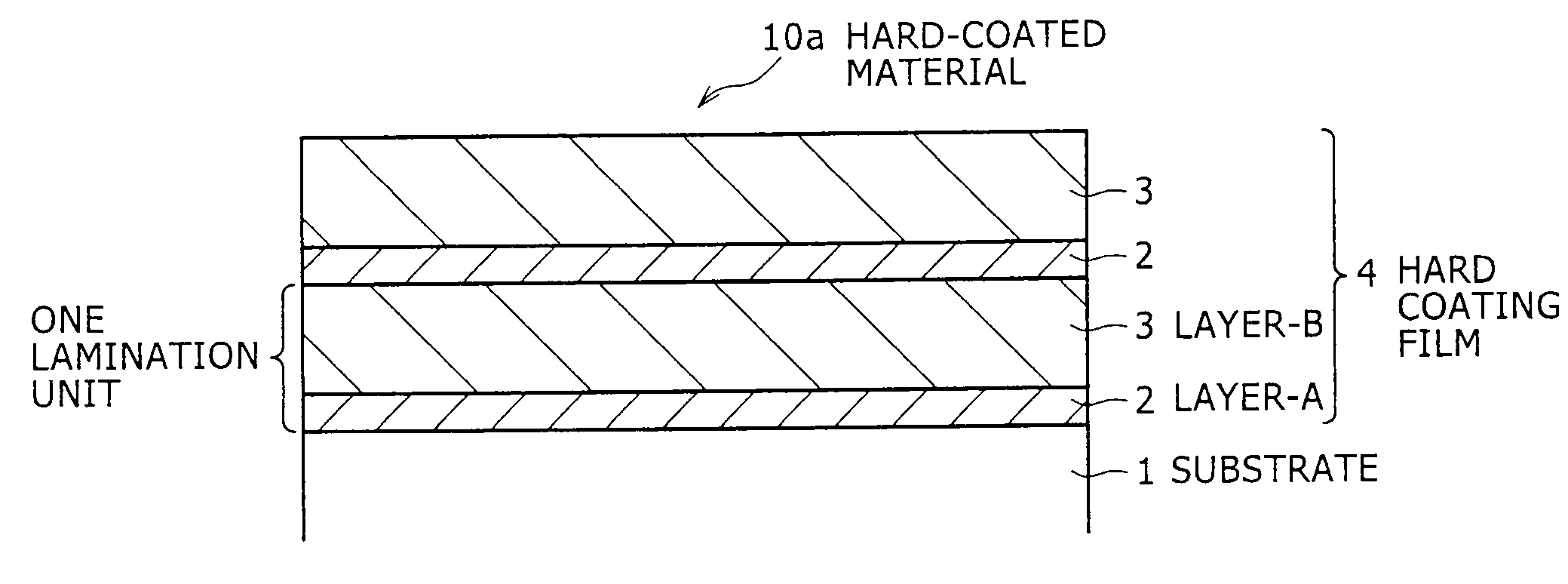

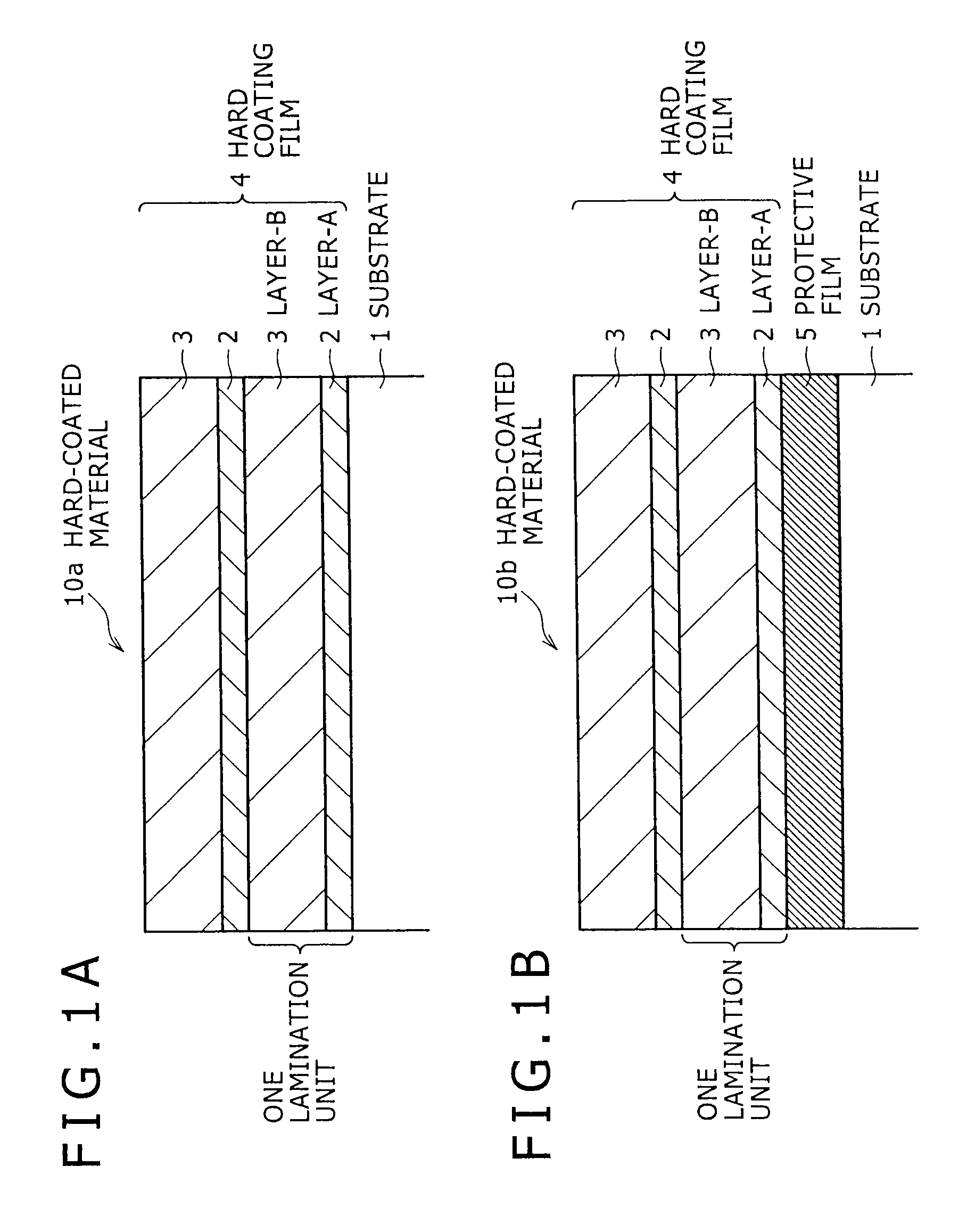

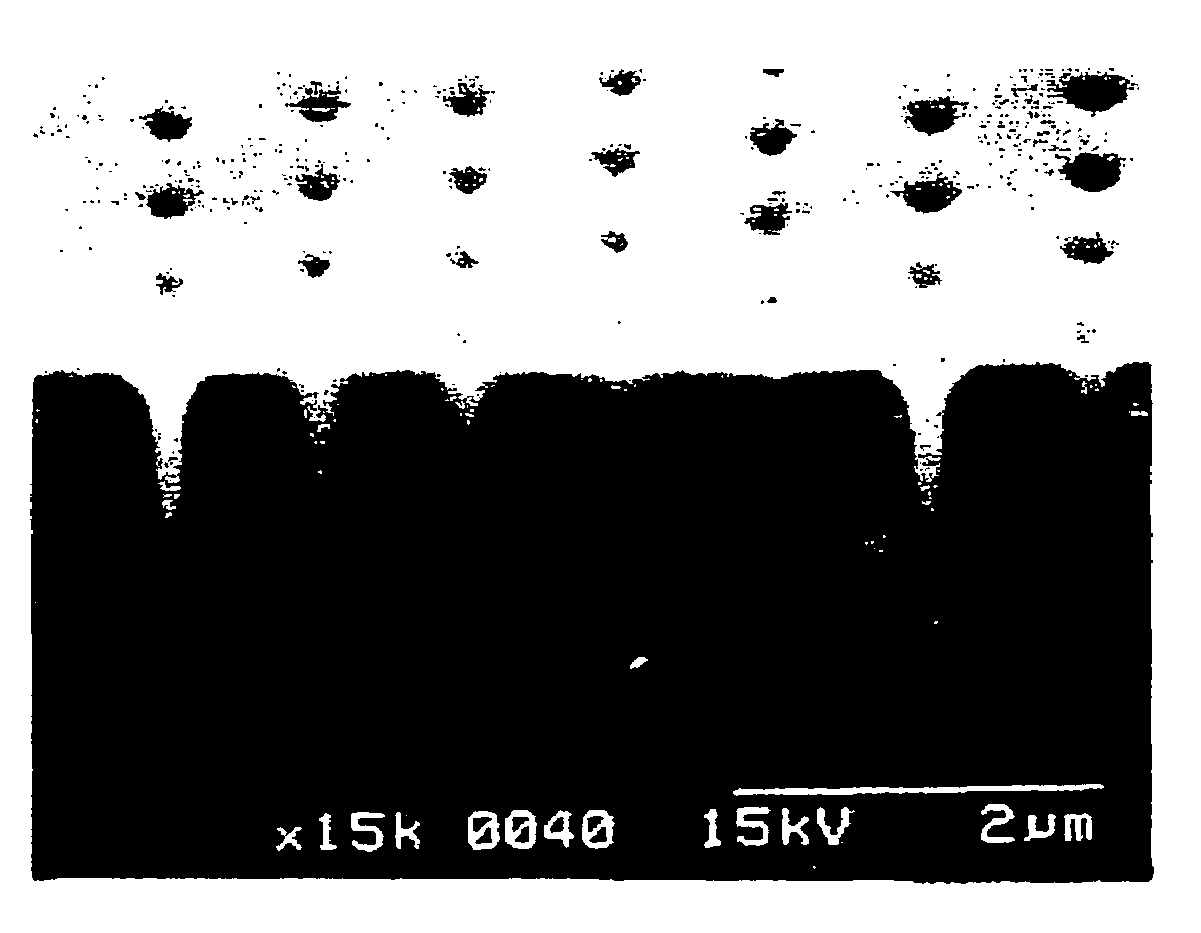

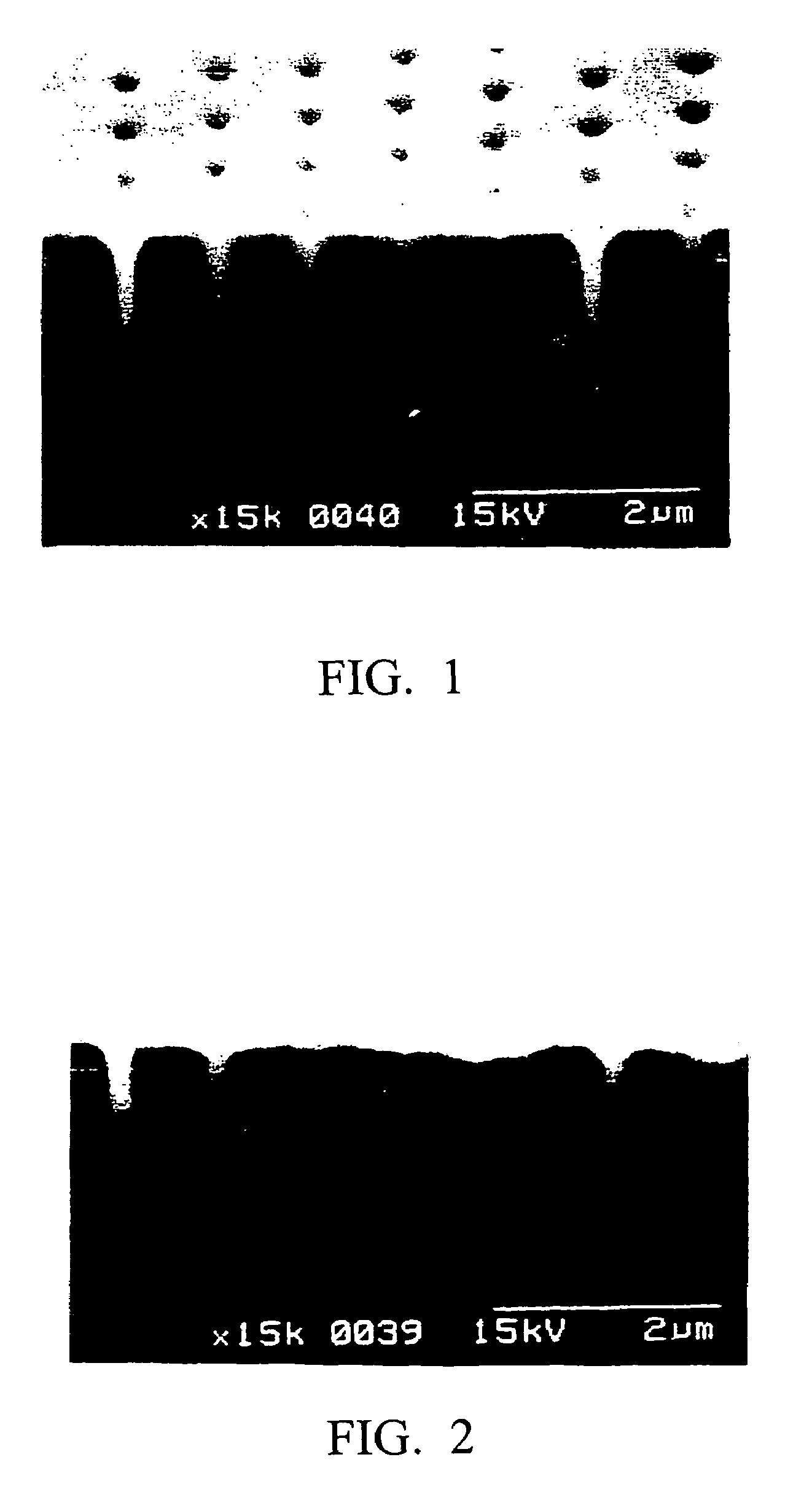

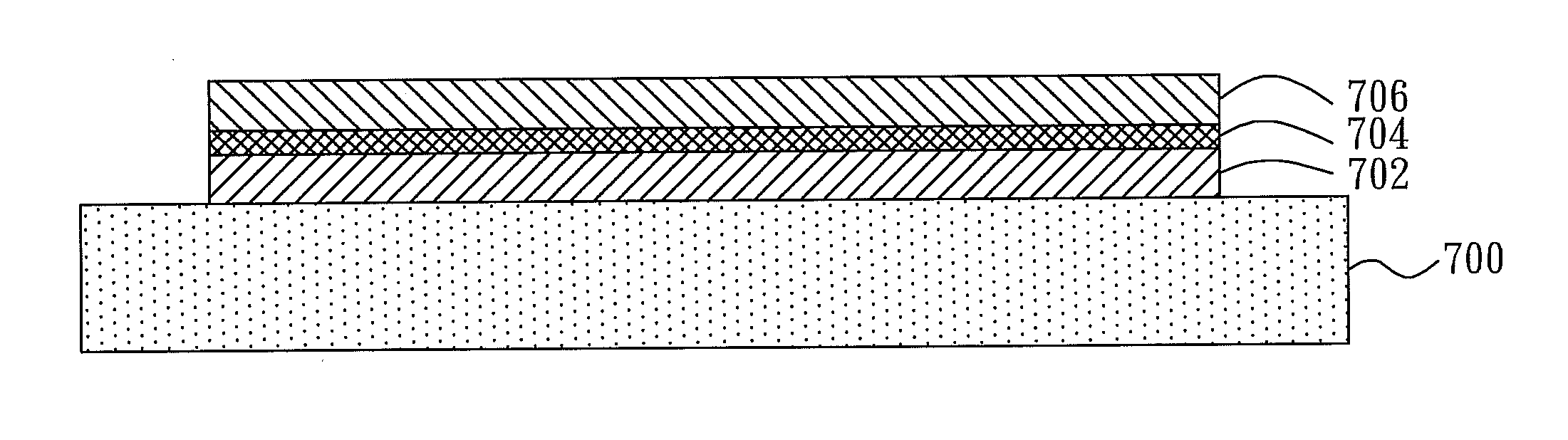

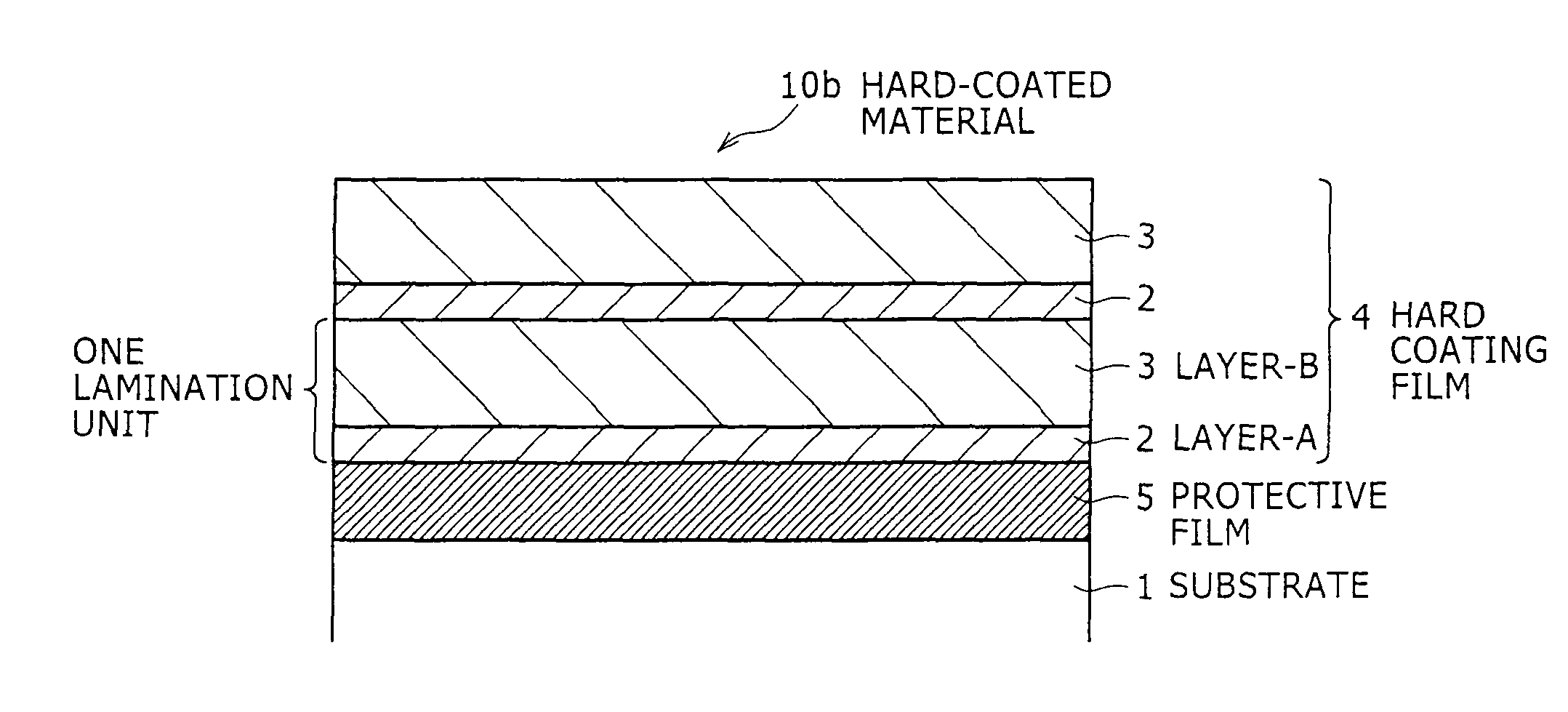

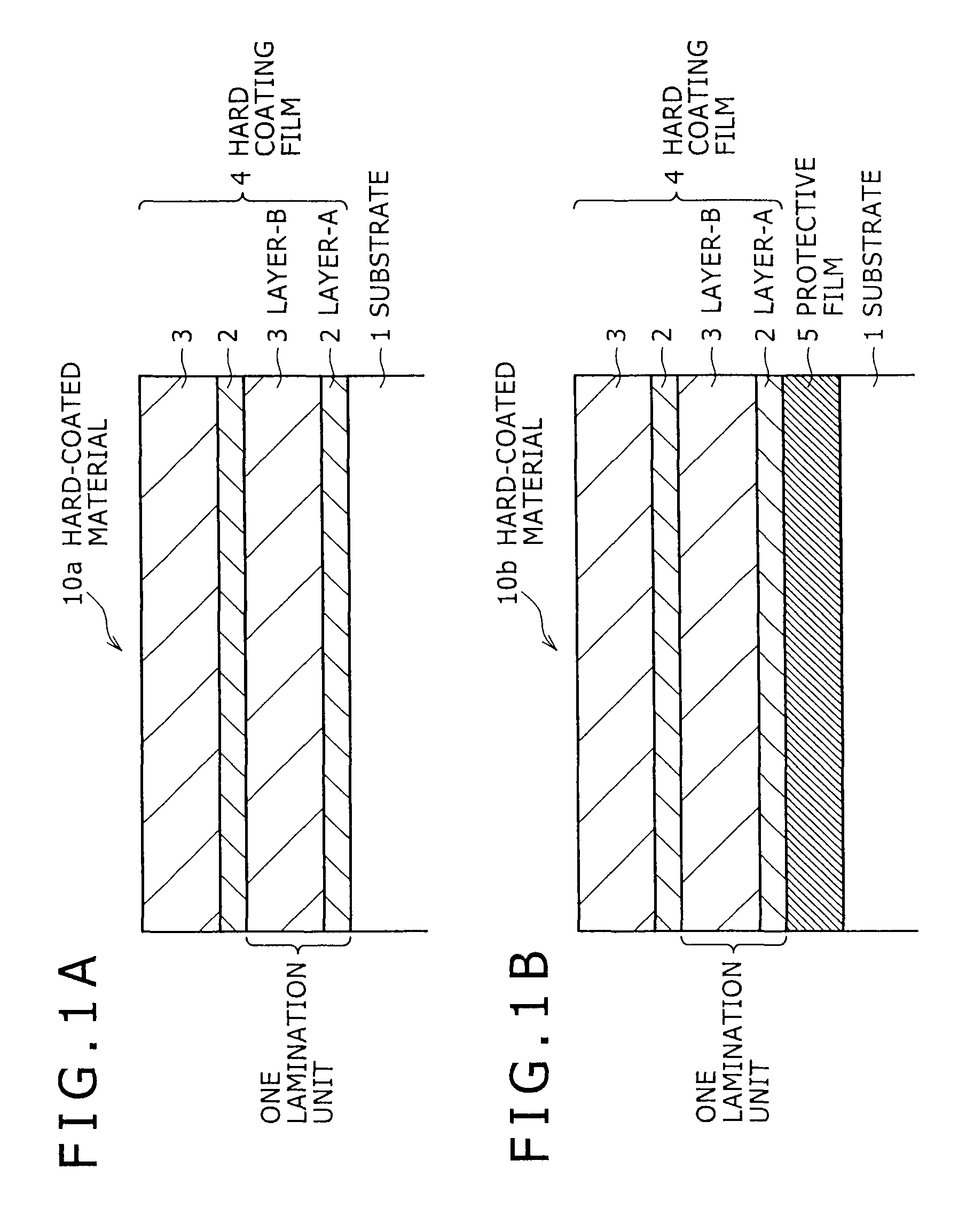

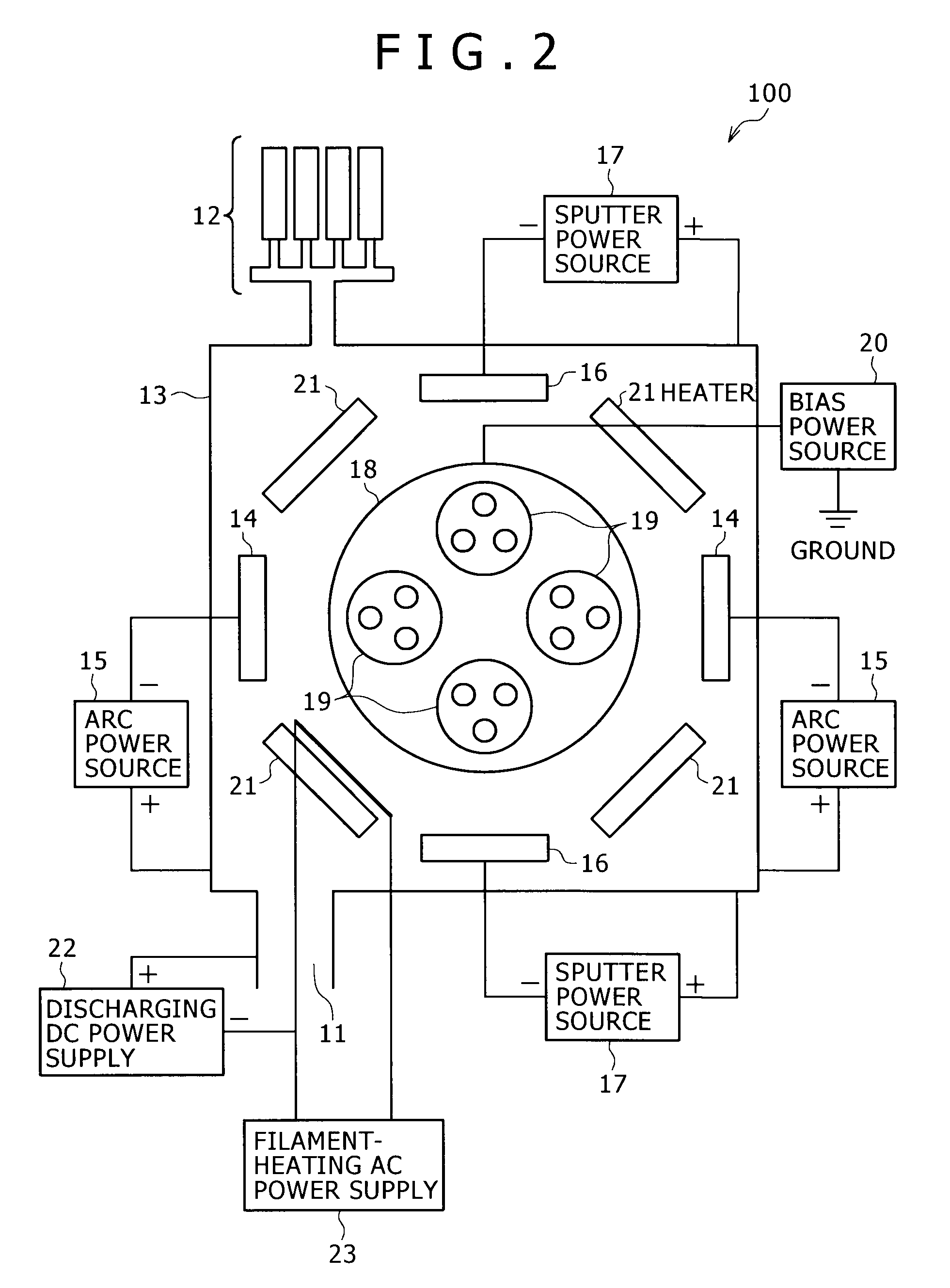

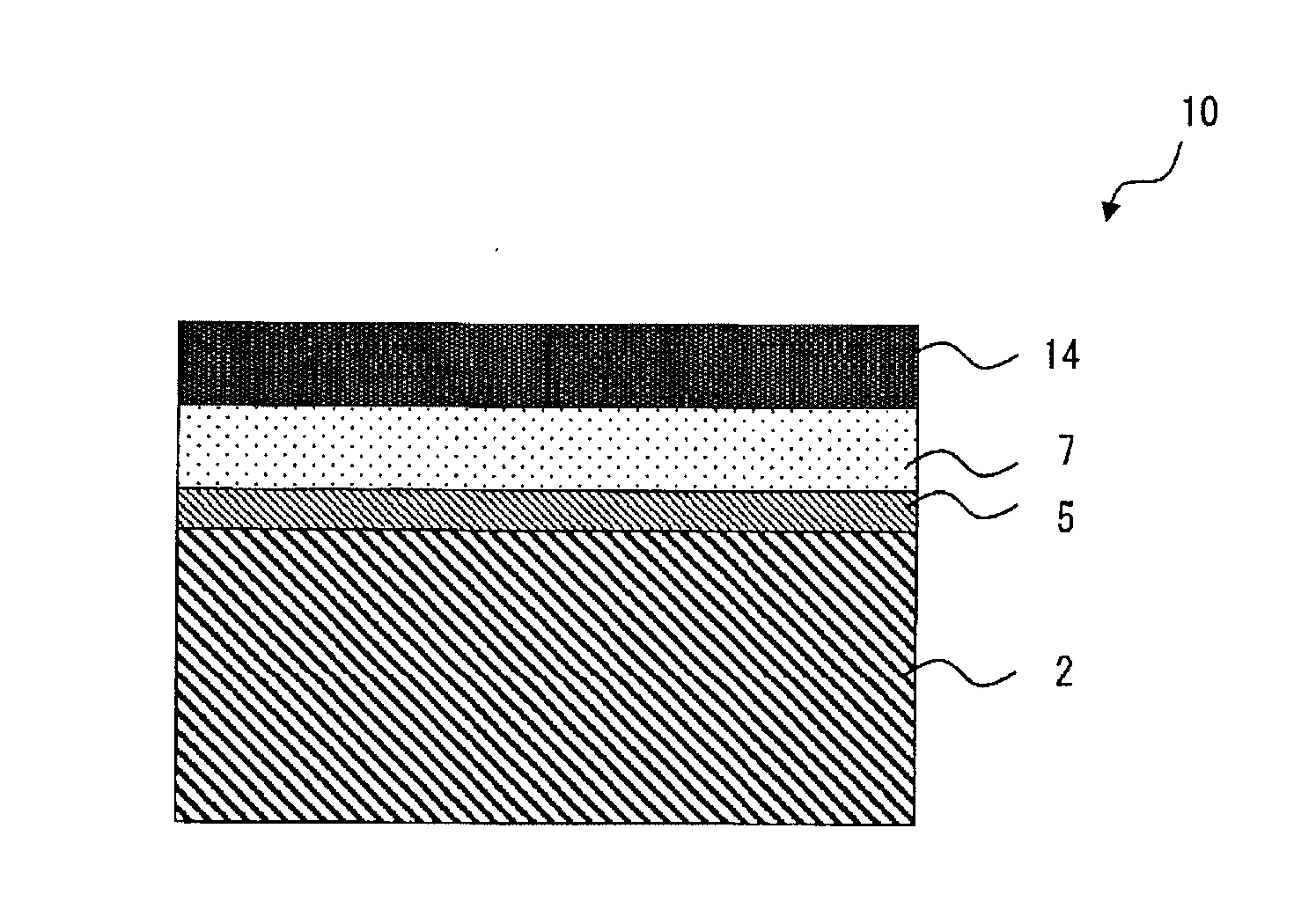

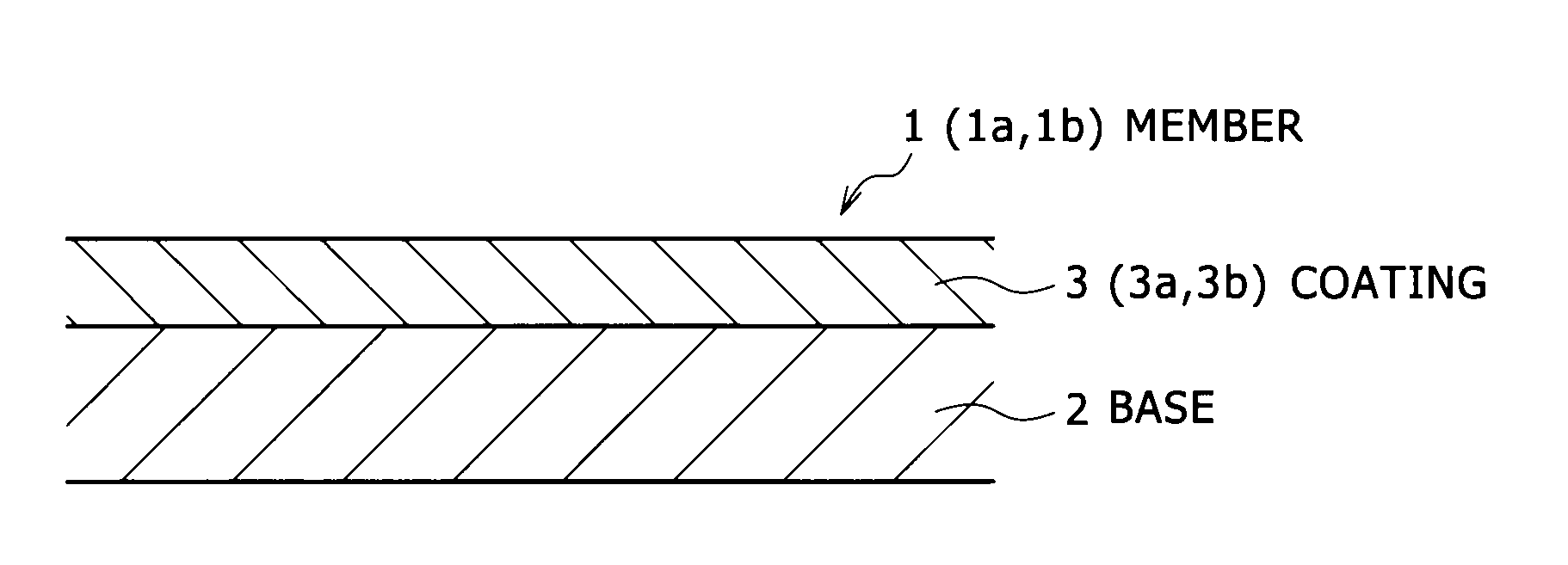

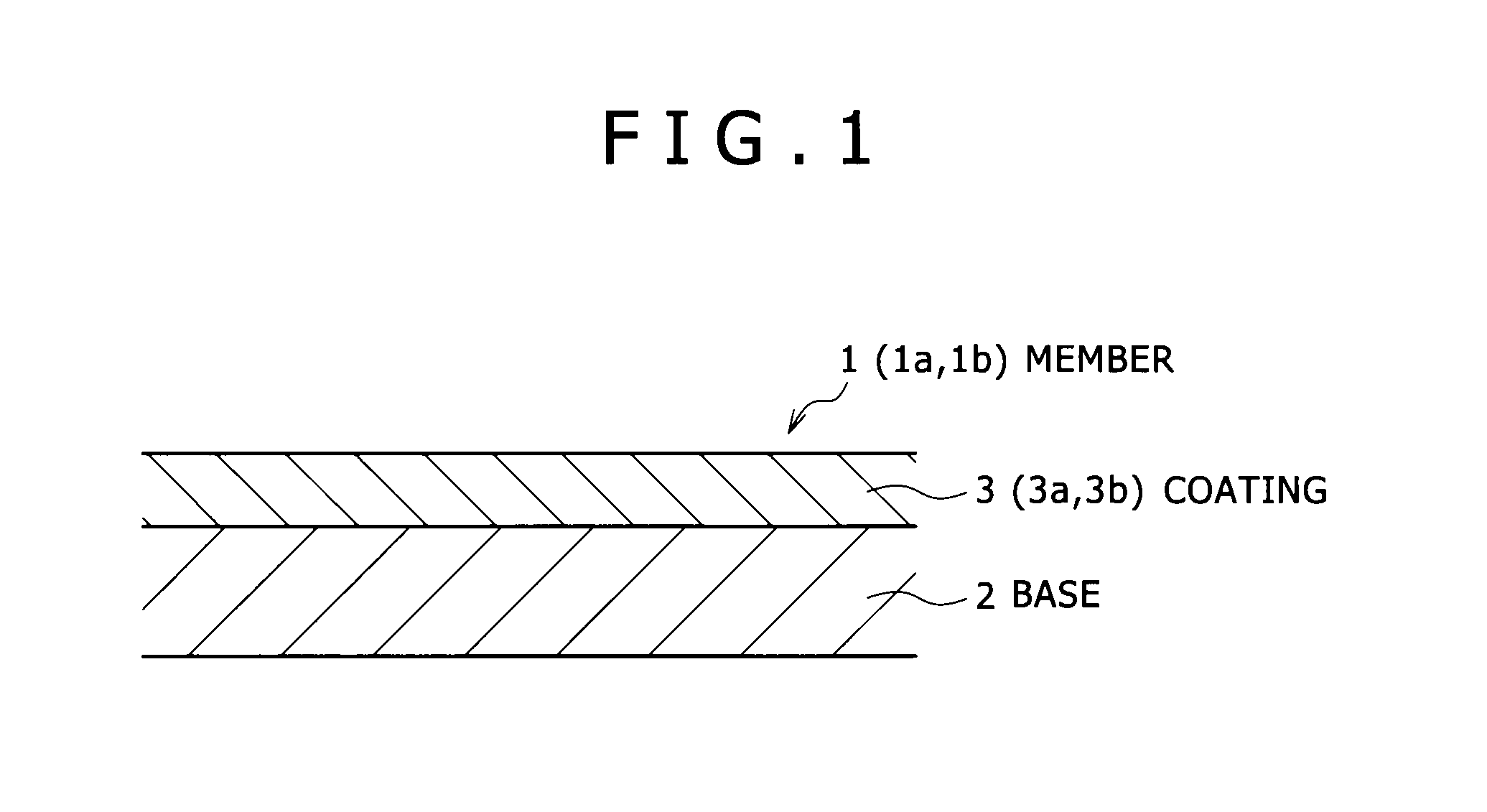

Material with hard coating film formed on substrate surface thereof

ActiveUS20100047545A1Improve wear resistanceImprove removabilitySynthetic resin layered productsVacuum evaporation coatingTotal thicknessWear resistance

There is provided a hard-coated material in which a substrate thereof is coated with a hard coating film that is excellent in wear resistance and also excellent in film removability to allow easy removal thereof once damaged or worn for the purpose of recycled use of the substrate. The hard coating film formed on the substrate comprises a layer-A and a layer-B; wherein the layer-A has a component composition represented by the formula TivM1-v(CxNyOz) (where M denotes at least one species selected from predetermined elements, and the variables v, x, y, and z indicate predetermined ratios of the respective elements); and wherein the layer-B has a component composition represented by the formula TivCrwM1-v-w(CxNyOz) (where M denotes at least one species selected from predetermined elements, and the variables v, w, x, y, and z indicate predetermined ratios of the respective elements). The layer-A and the layer-B are laminated alternately in succession. In terms of lamination units each corresponding to a combination of a singularity of the layer-A disposed at the lower level and a singularity of the layer-B disposed at the upper level, at least two lamination units are provided in laminated structure formation. The ratio in thickness of a singularity of the layer-B to a singularity of the layer-A is at least 2. The thickness of a singularity of the layer-A is within the range of 0.1 to 3 μm both inclusive, the thickness of a singularity of the layer-B is within the range of 1 to 10 μm both inclusive, and the total thickness of a plurality of the layers-B is at least 5 μm.

Owner:KOBE STEEL LTD

Metal plating method, pretreatment agent, and semiconductor wafer and semiconductor device obtained using these

InactiveUS7045461B2Inadequate coverageDifficult to coatPretreated surfacesSemiconductor/solid-state device manufacturingAzoleSemiconductor

Resin cloths, powders, specular bodies and other objects resistant to conventional plating can be plated with metals by a simple method.According to the metal plating method of the present invention, electroless plating is performed after the surface of a object to be plated is treated with a pretreatment agent obtained by reacting or mixing in advance a noble metal compound (catalyst) with a silane-coupling agent having functional groups capable of capturing metals. According to this method, metal plating can be securely applied to powders, resin cloths, semiconductor wafers, and other specular bodies. Moreover, the problem of the insufficient coverage of the seed layer on the inside walls of vias and trenches during the formation of fine wiring can be addressed by applying this method to semiconductor wafers. The silane-coupling agent may be a compound containing azole groups, preferably an imidazole.

Owner:JX NIPPON MINING& METALS CORP

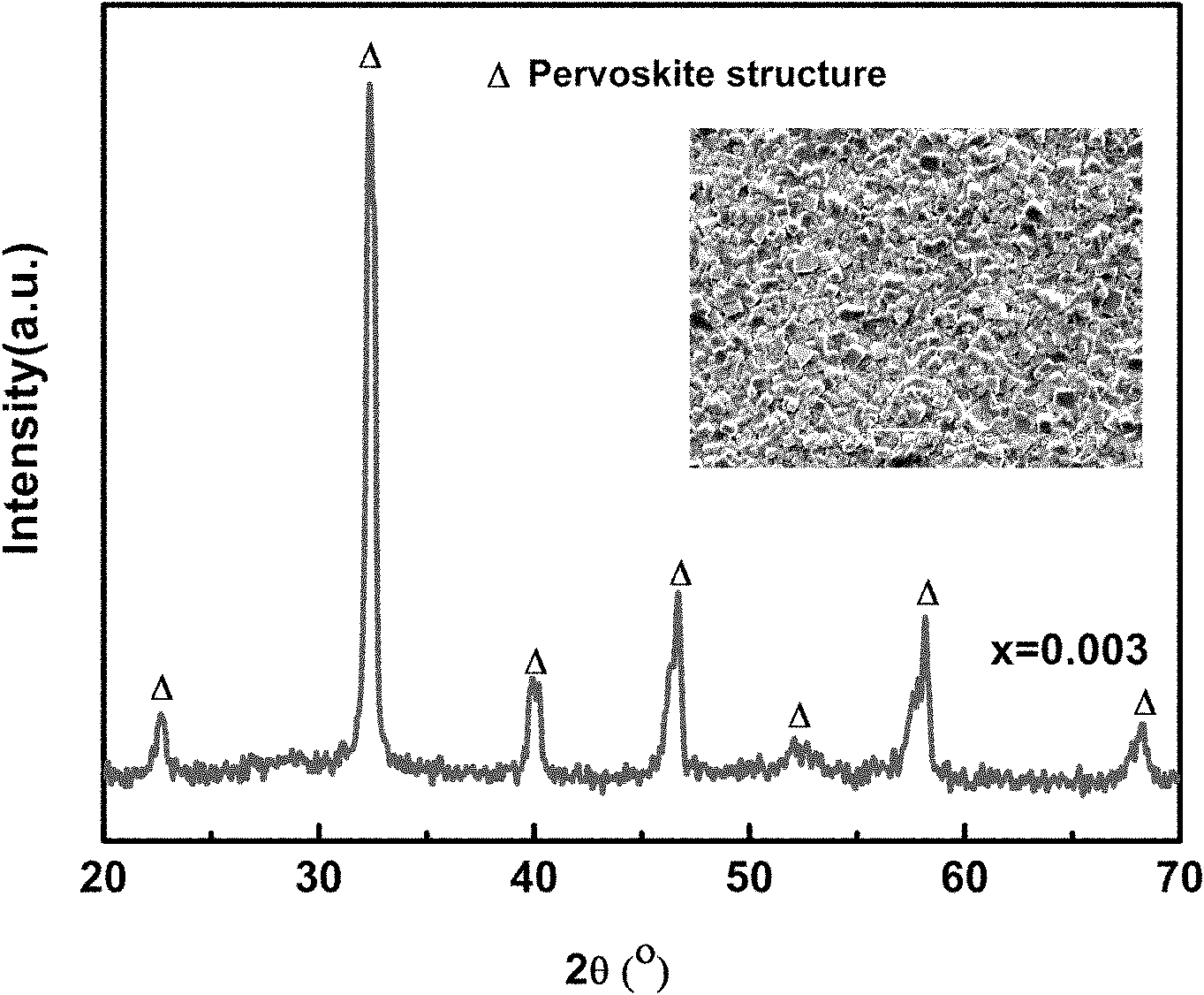

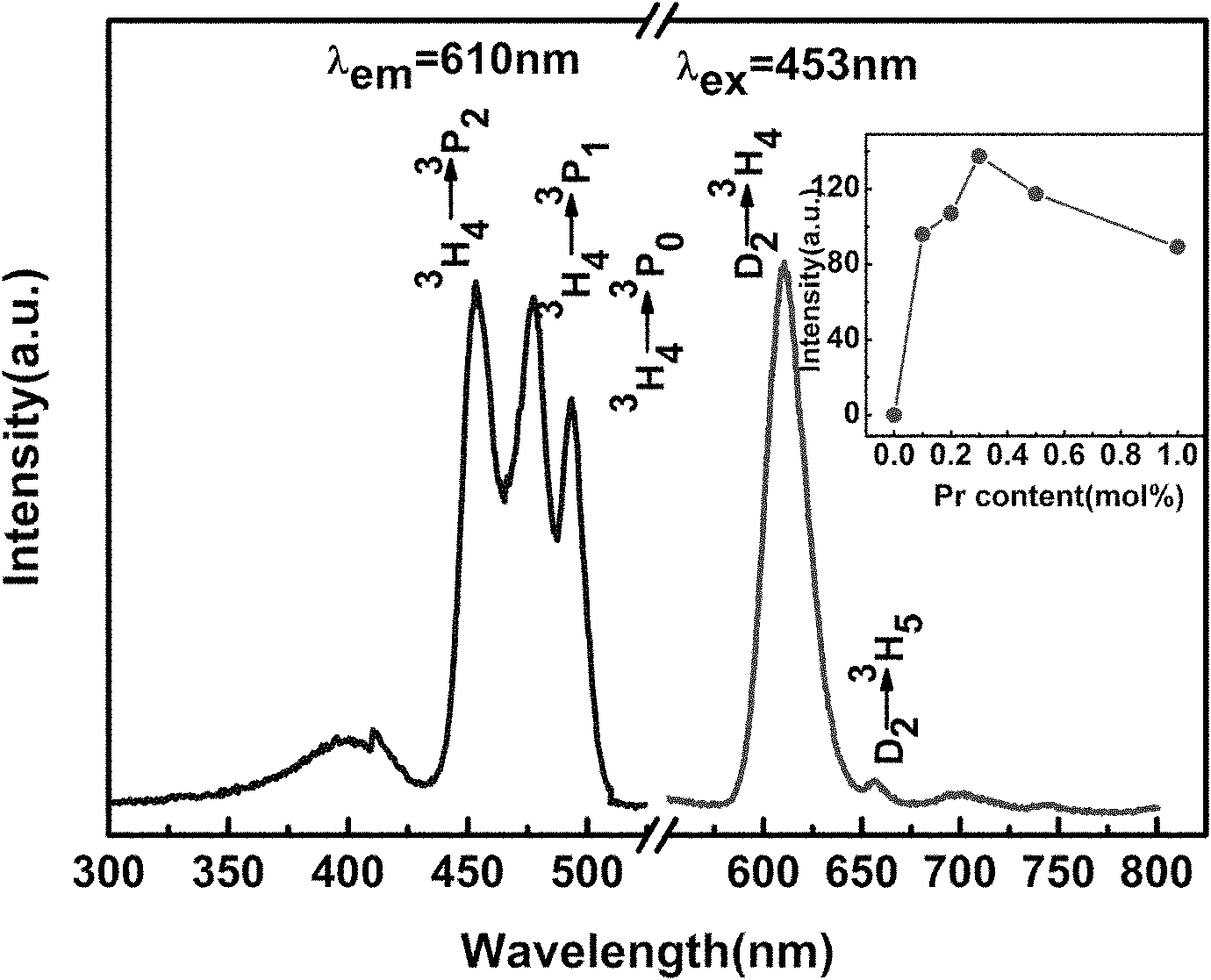

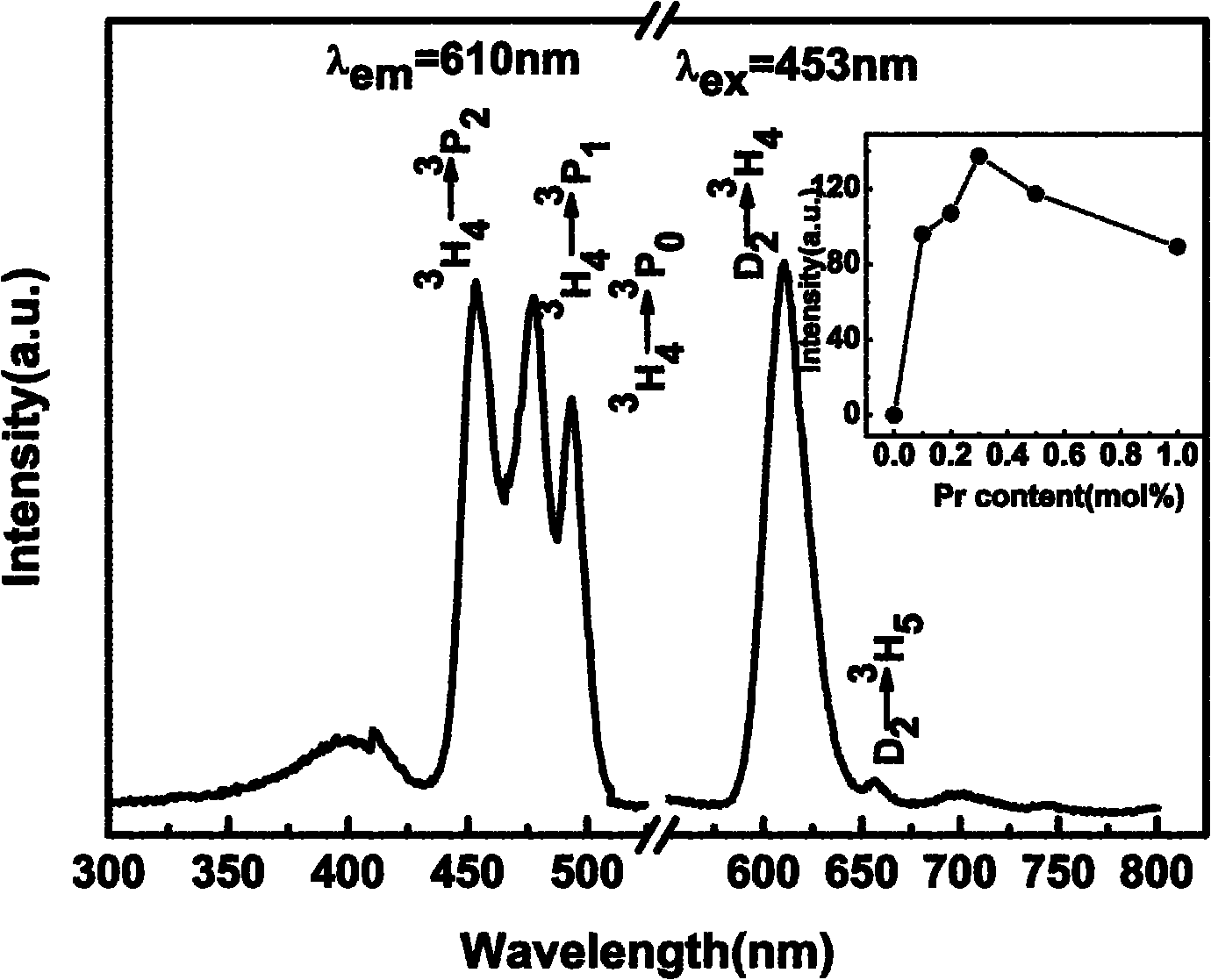

Red fluorescent material and preparation method thereof

InactiveCN102154008AImprove stabilityNot easy to deliquescenceLuminescent compositionsSemiconductor devicesElectricityRare-earth element

The invention relates to a novel blue-light-excited red fluorescent material applied to a white light LED (Light Emitting Diode) technology and a preparation method thereof, belonging to the field of light-emitting materials. The blue-light-excited red fluorescent material has a general formula of Bi0.5+dNa0.5-yAy)1-xRxTiO3:fC, wherein R is selected from one or more than one of rare-earth elements Pr, Sm, Eu and Lu, A is selected from one or more than one of the same group of univalent elements K and Li, C is selected from one or more than one of Li, Na, K, Tl and Ag, 0.001<=x<=0.1, 0<=y<=0.5, 0<=d<=0.1, and 0<=f<=0.1. Blue-light-excited red fluorescent powder provided by the invention has good stability, is not easy to deliquesce, does not need cladding treatment, not only has piezoelectric, ferroelectric and dielectric properties, but also has the characteristic of exciting red light by blue light, belongs to a multifunctional photoelectric material, and can be widely applied to fields such as white light LEDs, photoelectricity integration, micro electro mechanical systems, photoelectricity sensors and the like.

Owner:TONGJI UNIV

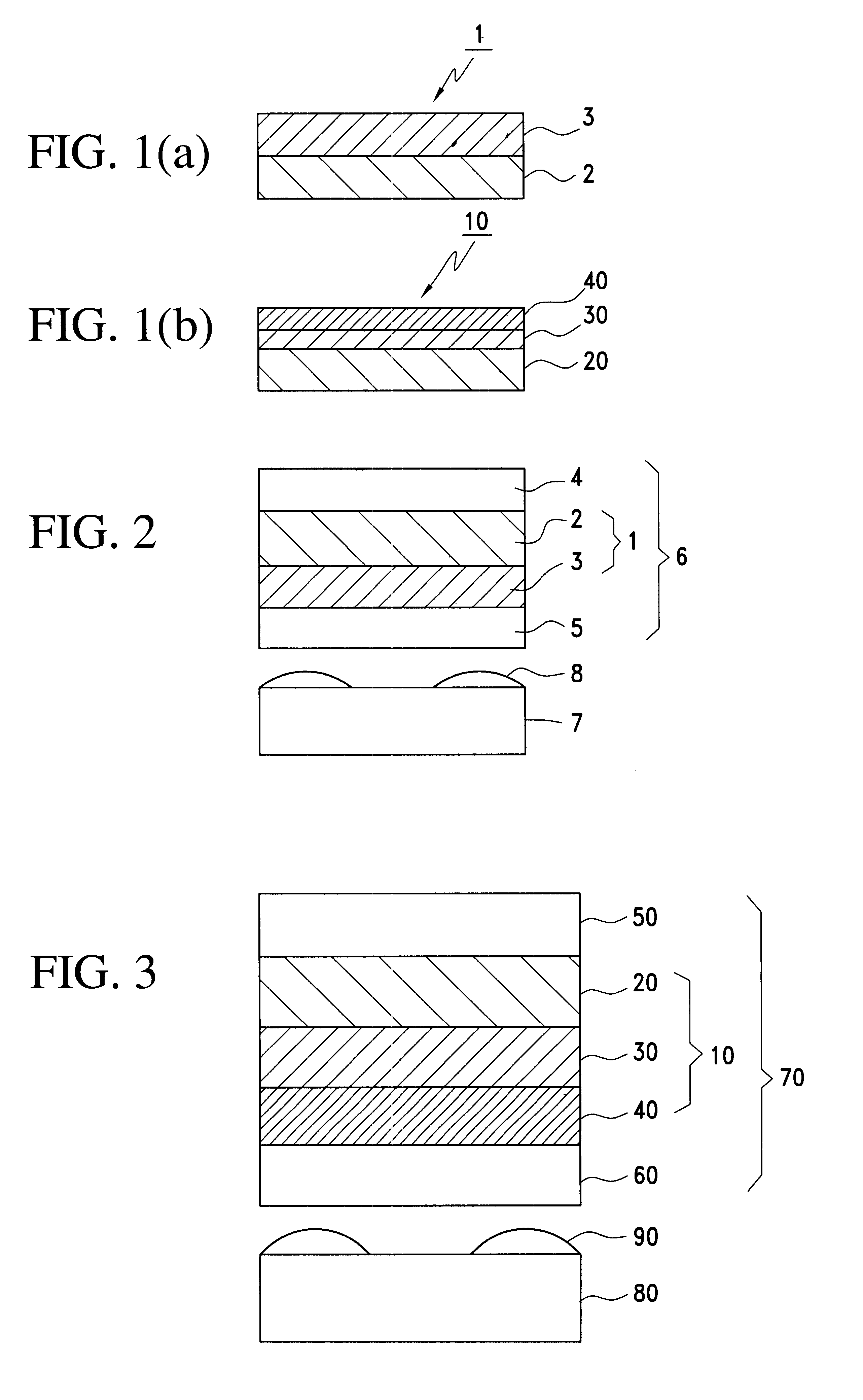

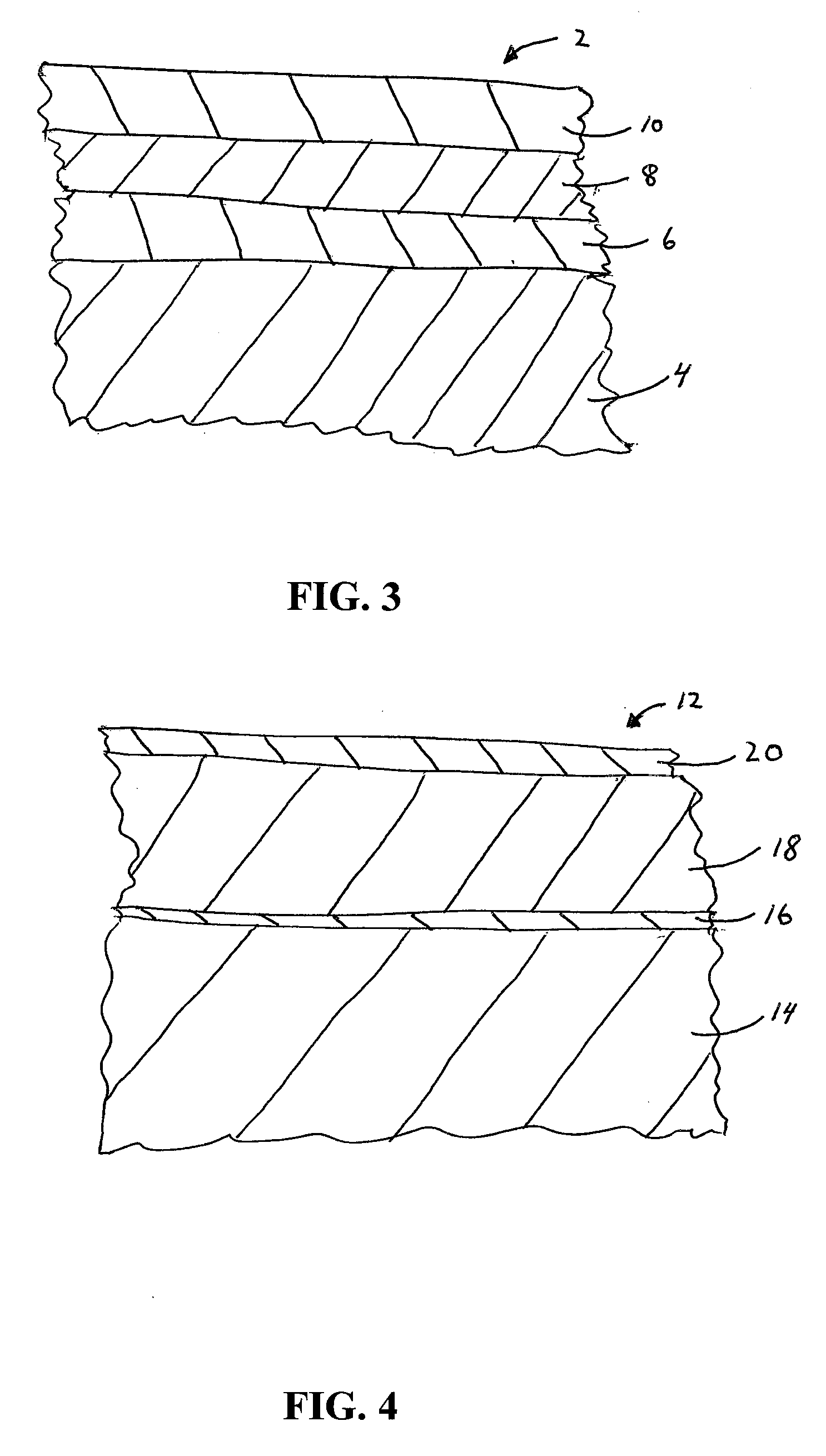

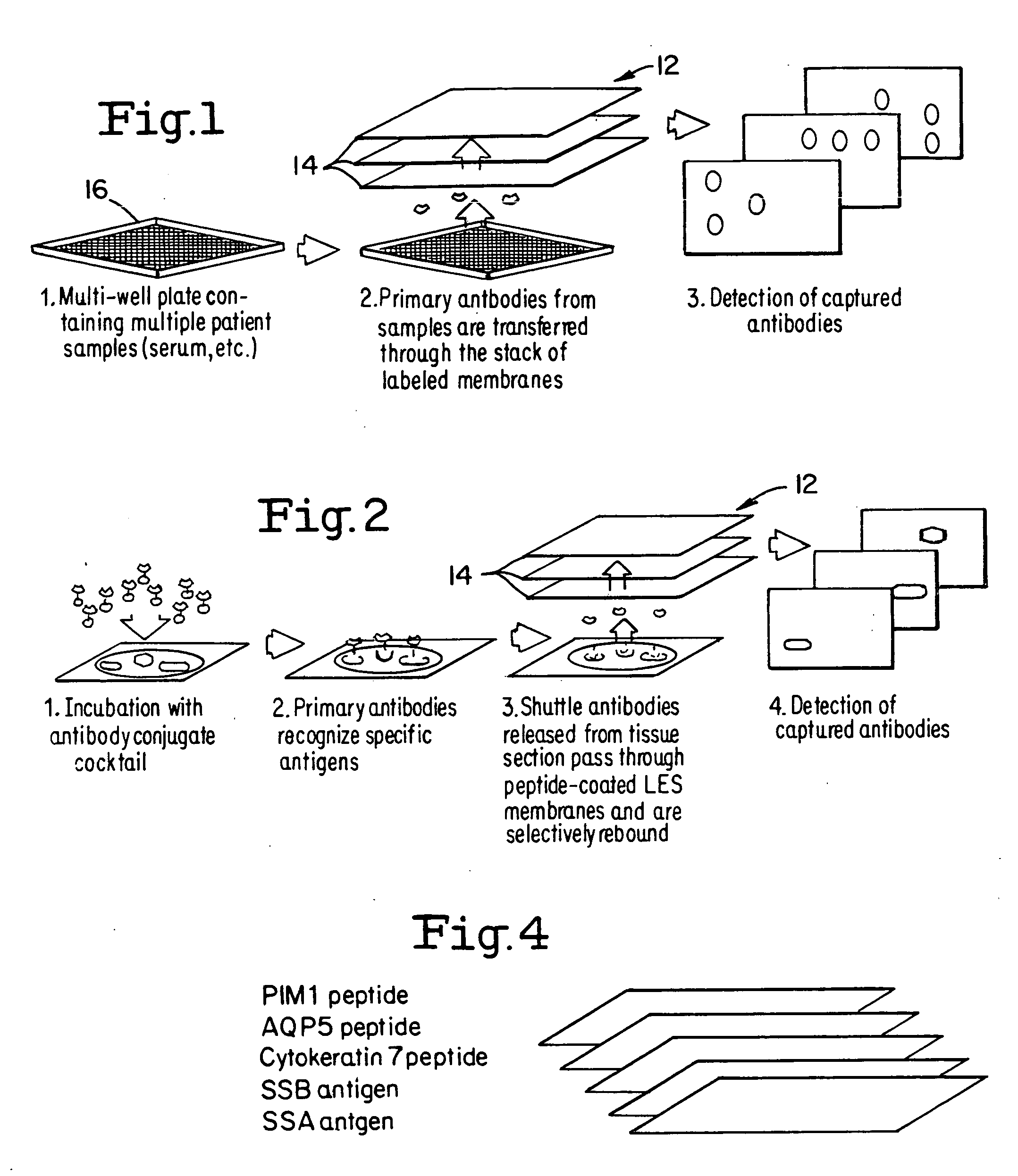

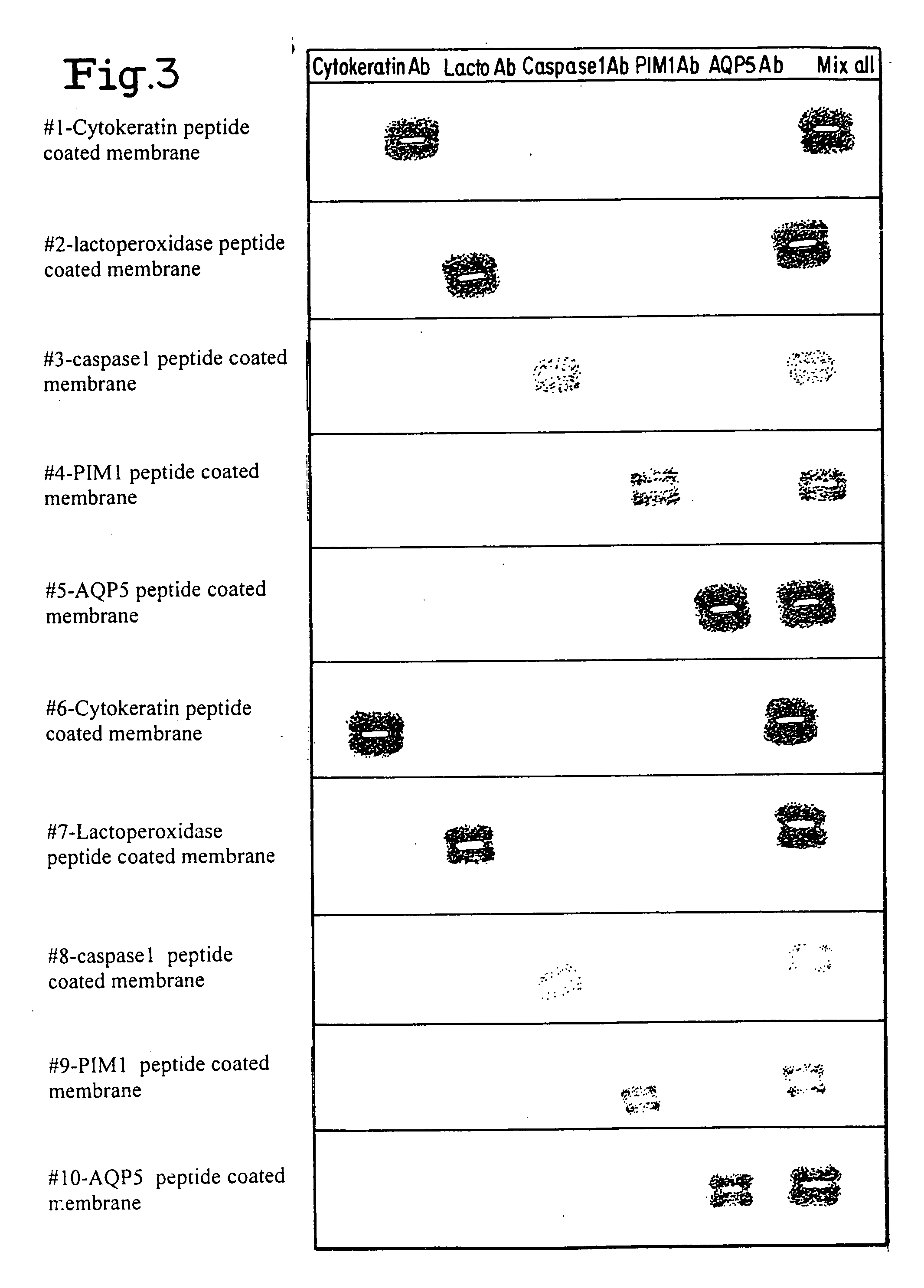

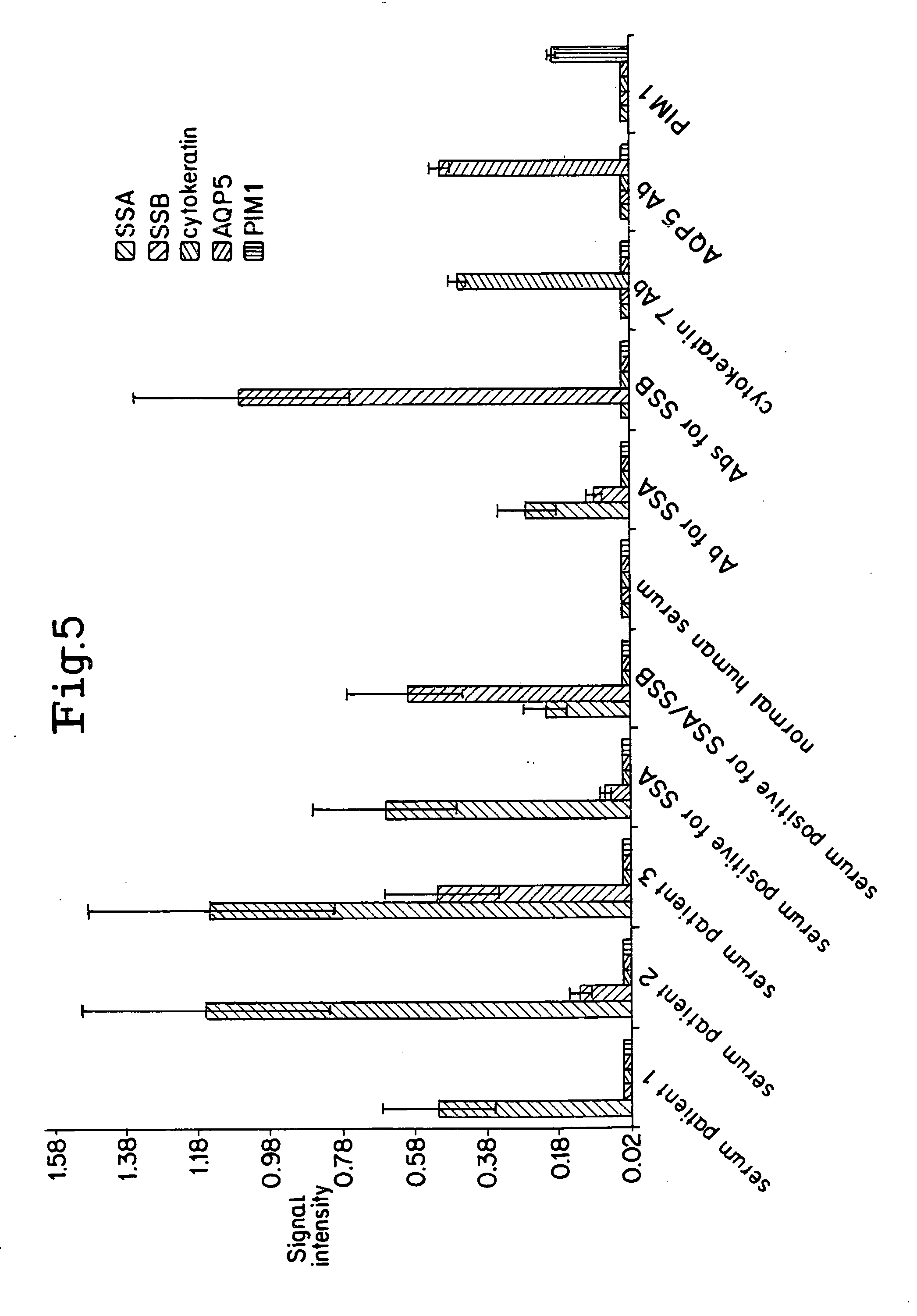

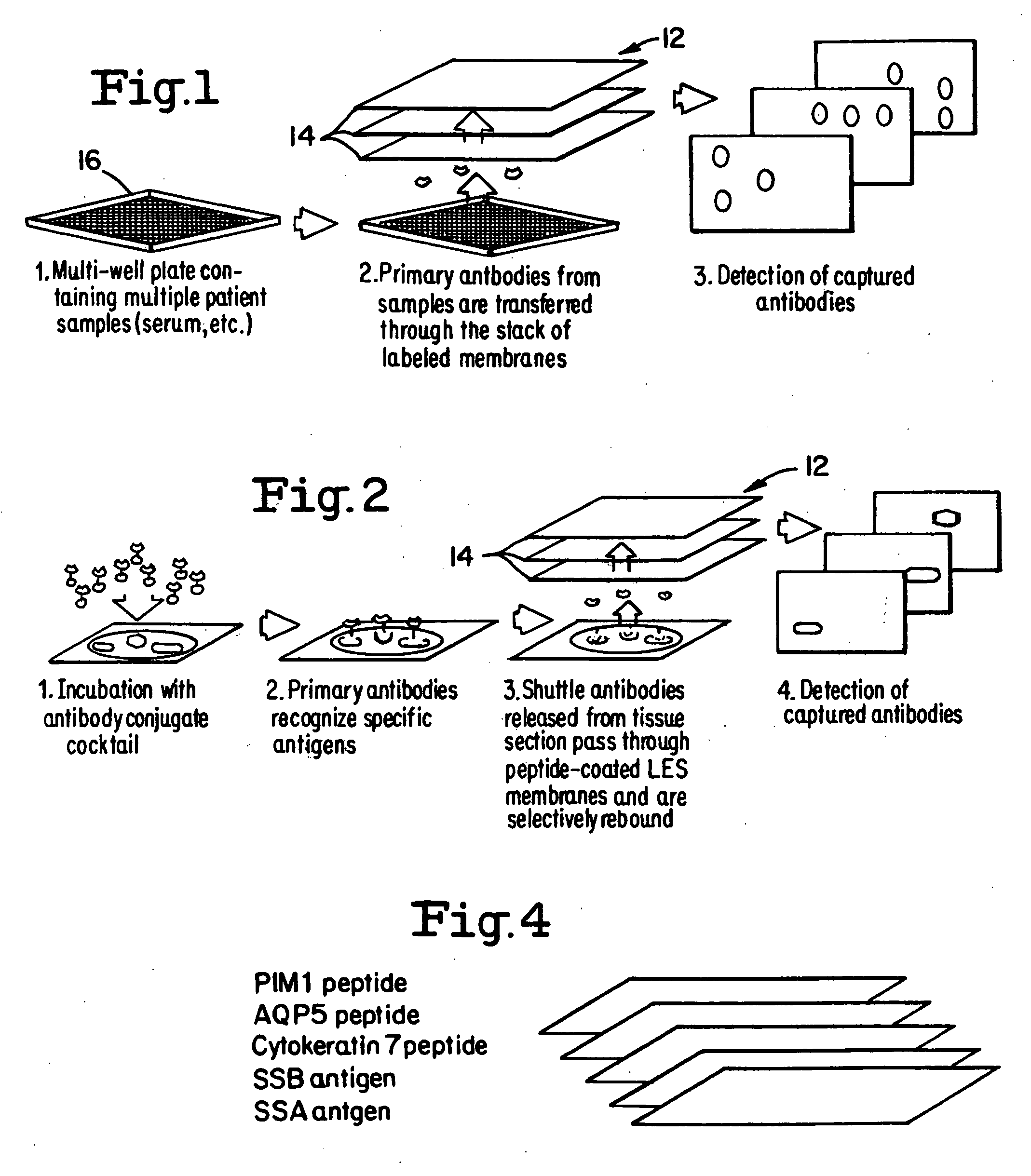

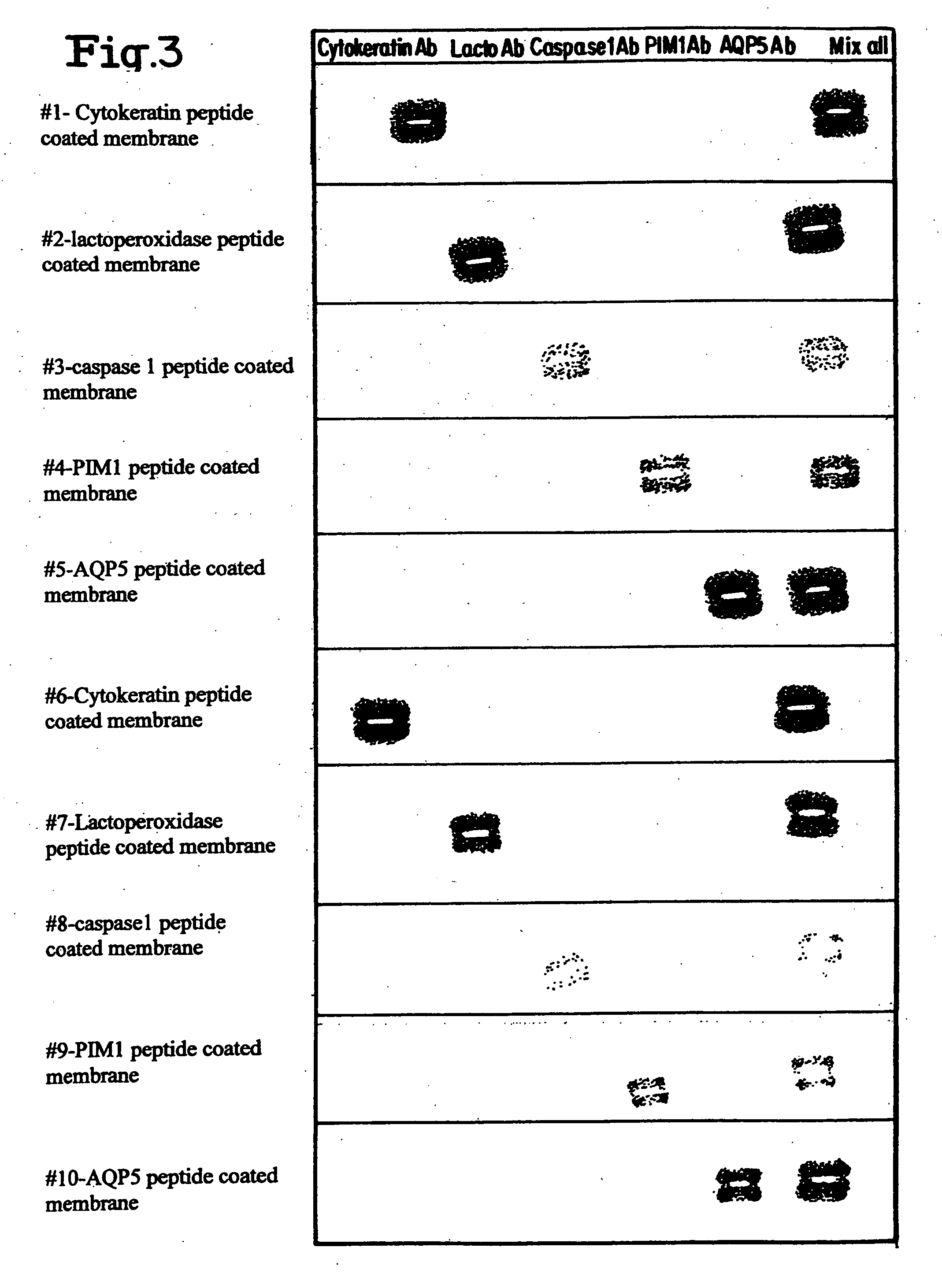

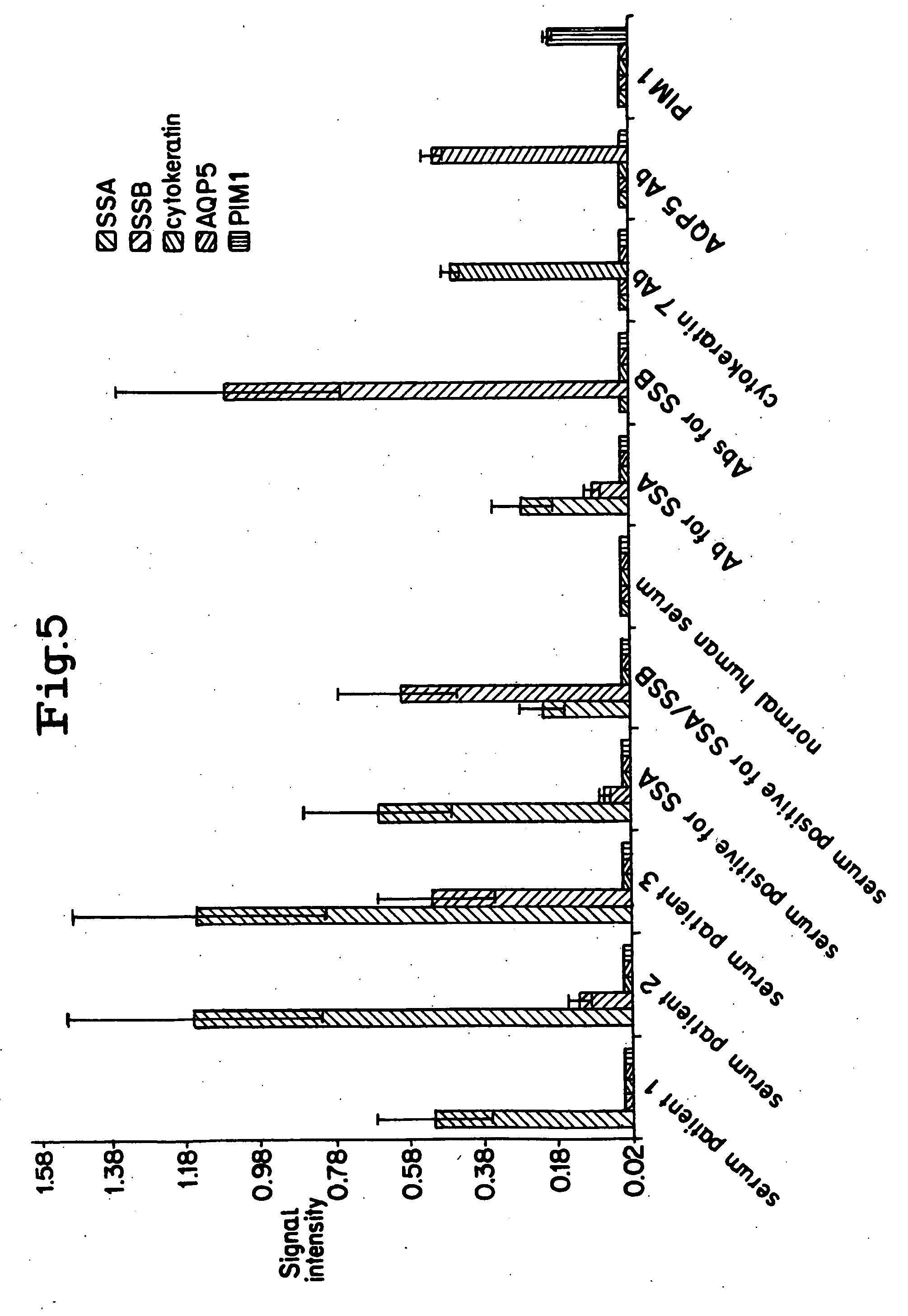

Layered peptide/antigen arrays - for high-throughput antibody screening of clinical samples

InactiveUS20060275851A1Quick and inexpensiveHigh-throughput detectionBioreactor/fermenter combinationsBiological substance pretreatmentsAntibody screeningMembrane configuration

A method and composition for the identification of biomolecule in a sample are disclosed. The method comprises obtaining a coated capture membrane stack comprising a plurality of capture membranes with each capture membrane coated with a different peptide. The membrane stack is exposed to a sample, and, after a given amount of time for the sample to permeate the membrane stack, the membrane stack is removed from the sample carrier and the capture membrane to which the biomolecule adheres is identified.

Owner:EMMERT BUCK MICHAEL R +1

Binder resin emulsion for energy device electrode, and energy device electrode and energy device using the same

InactiveCN101111957AHigh densityExcellent charge and discharge characteristicsElectrolytic capacitorsHybrid capacitor electrodesEmulsionCarboxylic acid

A binder resin emulsion for energy device electrodes is provided that is used in energy device electrodes and more particularly that is used as a binder to dispose an active material on the current collector of such an electrode. An energy device electrode and energy device that use this emulsion are also provided. A binder resin emulsion for energy device electrodes is used that comprises: a copolymer of an alpha,beta-unsaturated carboxylic acid and an alpha-olefin that has been neutralized with a neutralizing agent; and water. Also, an energy device electrode and an energy device that use this binder resin emulsion are utilized.

Owner:HITACHI CHEM CO LTD

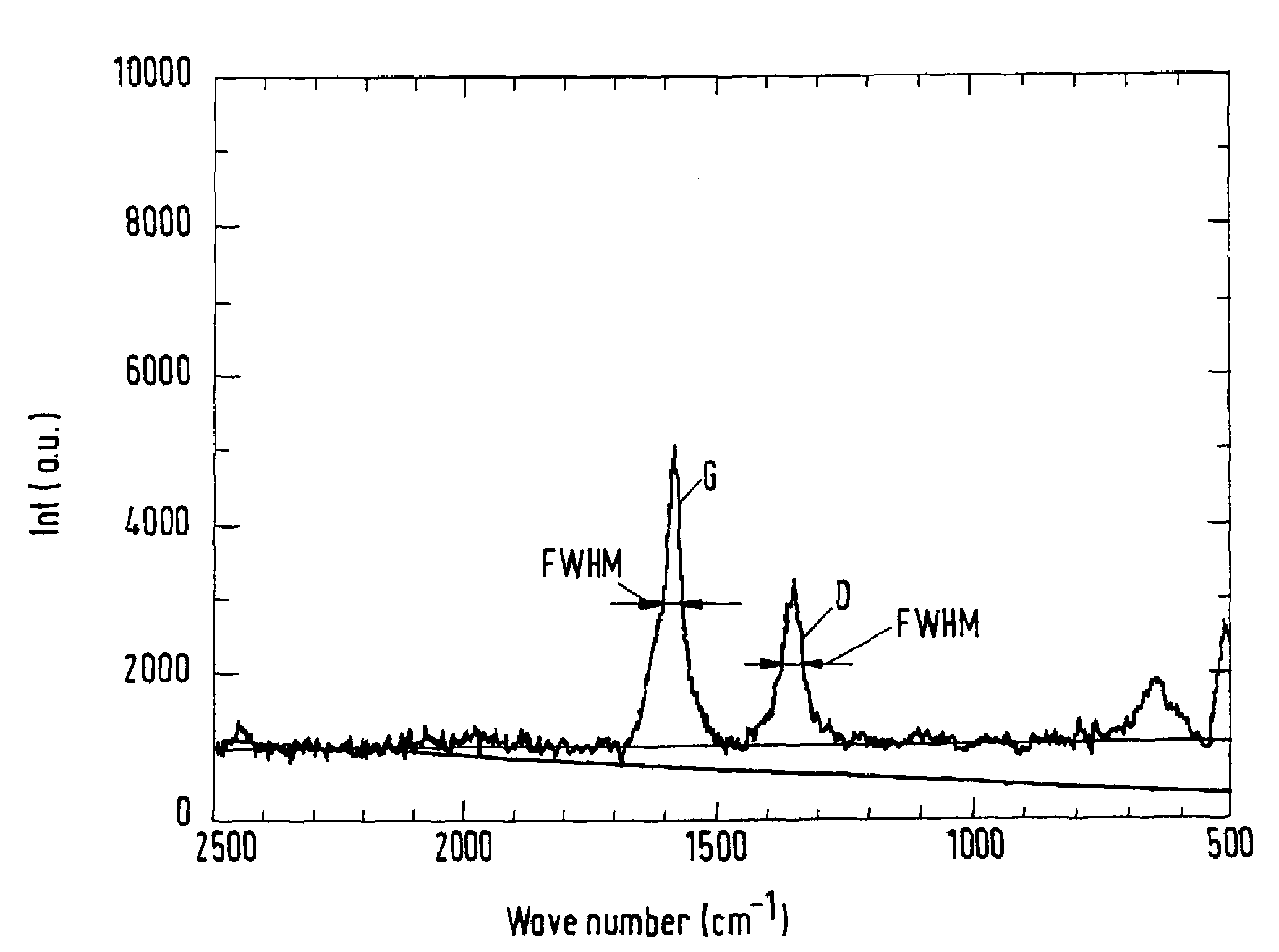

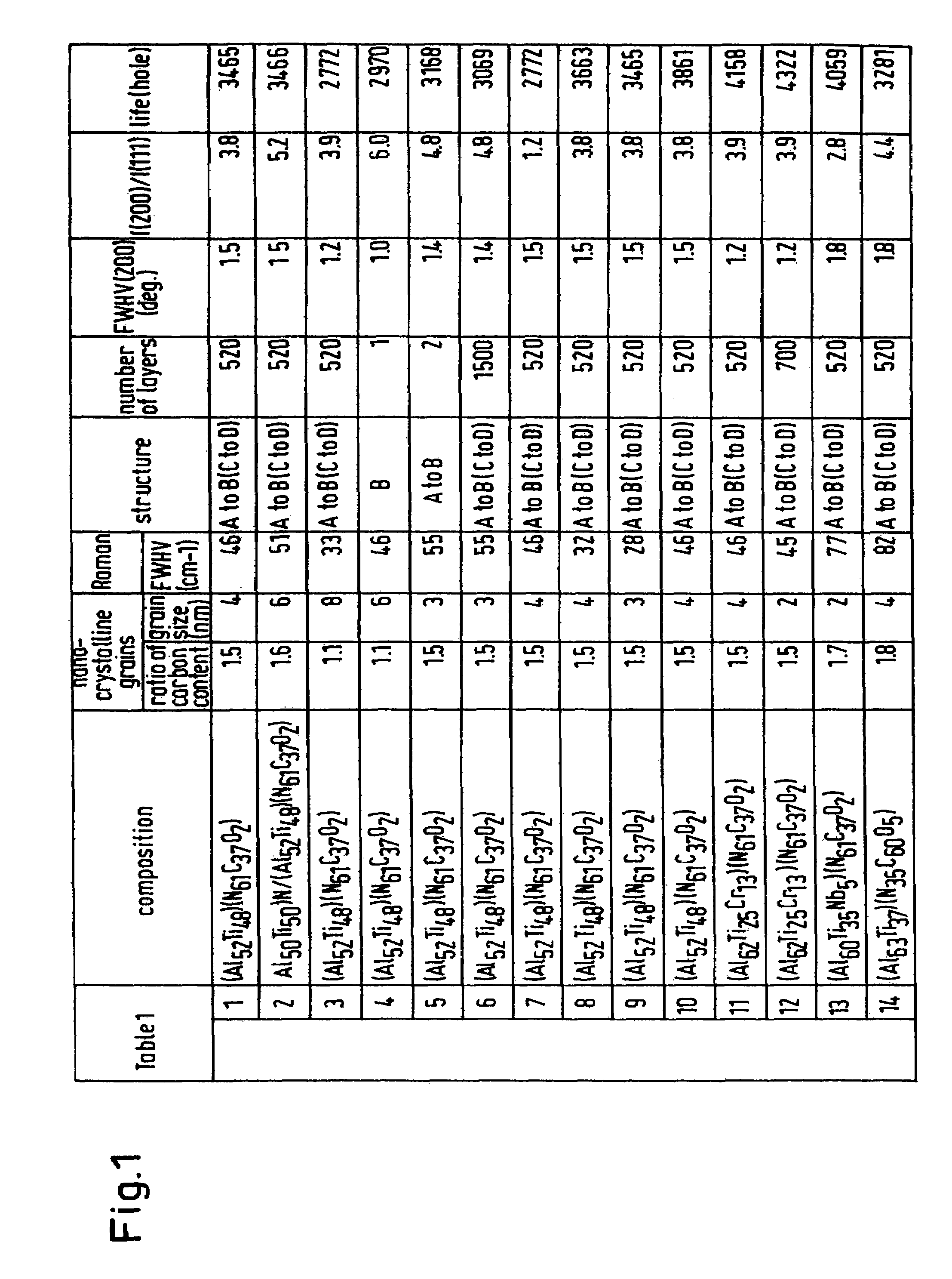

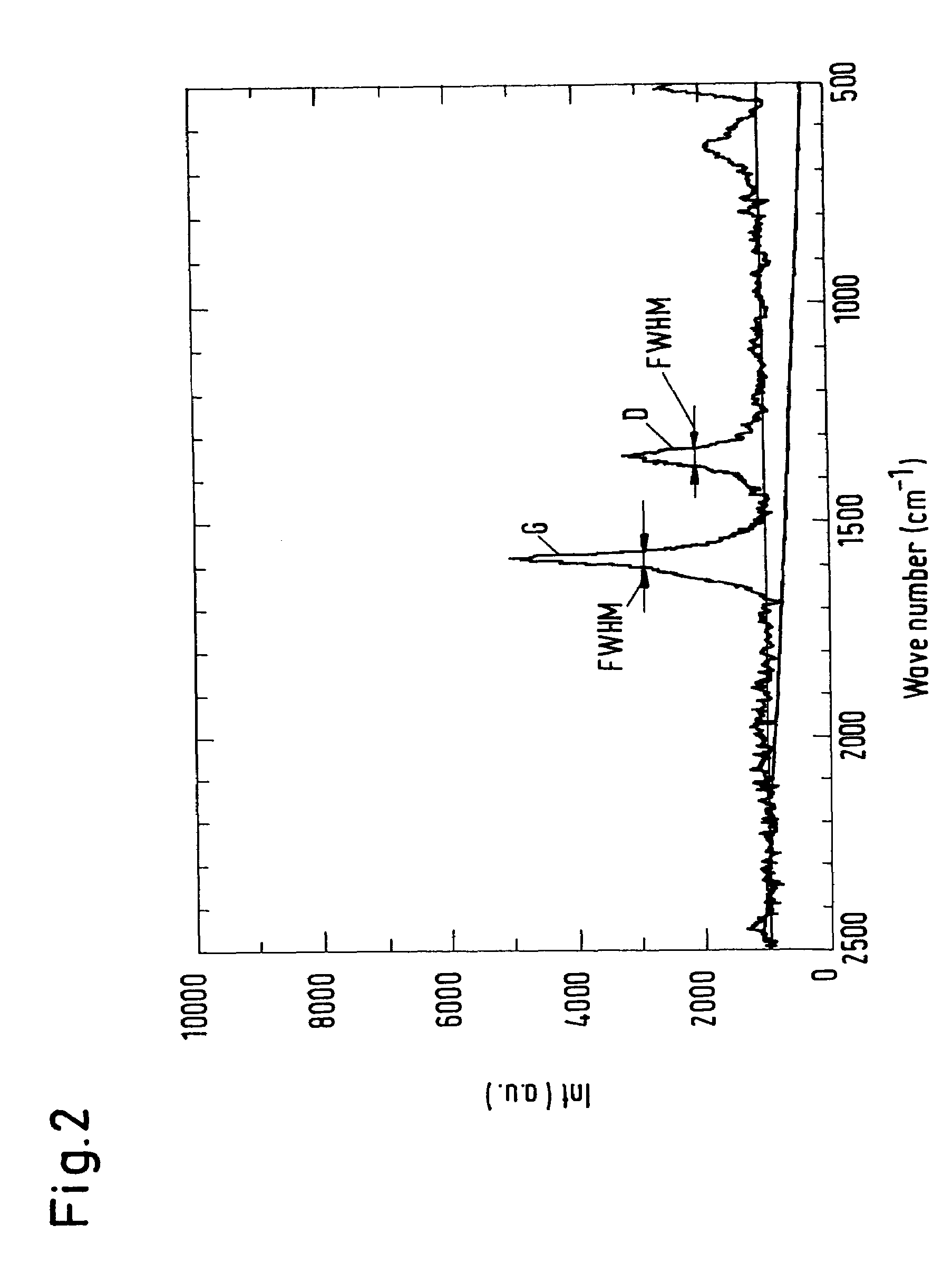

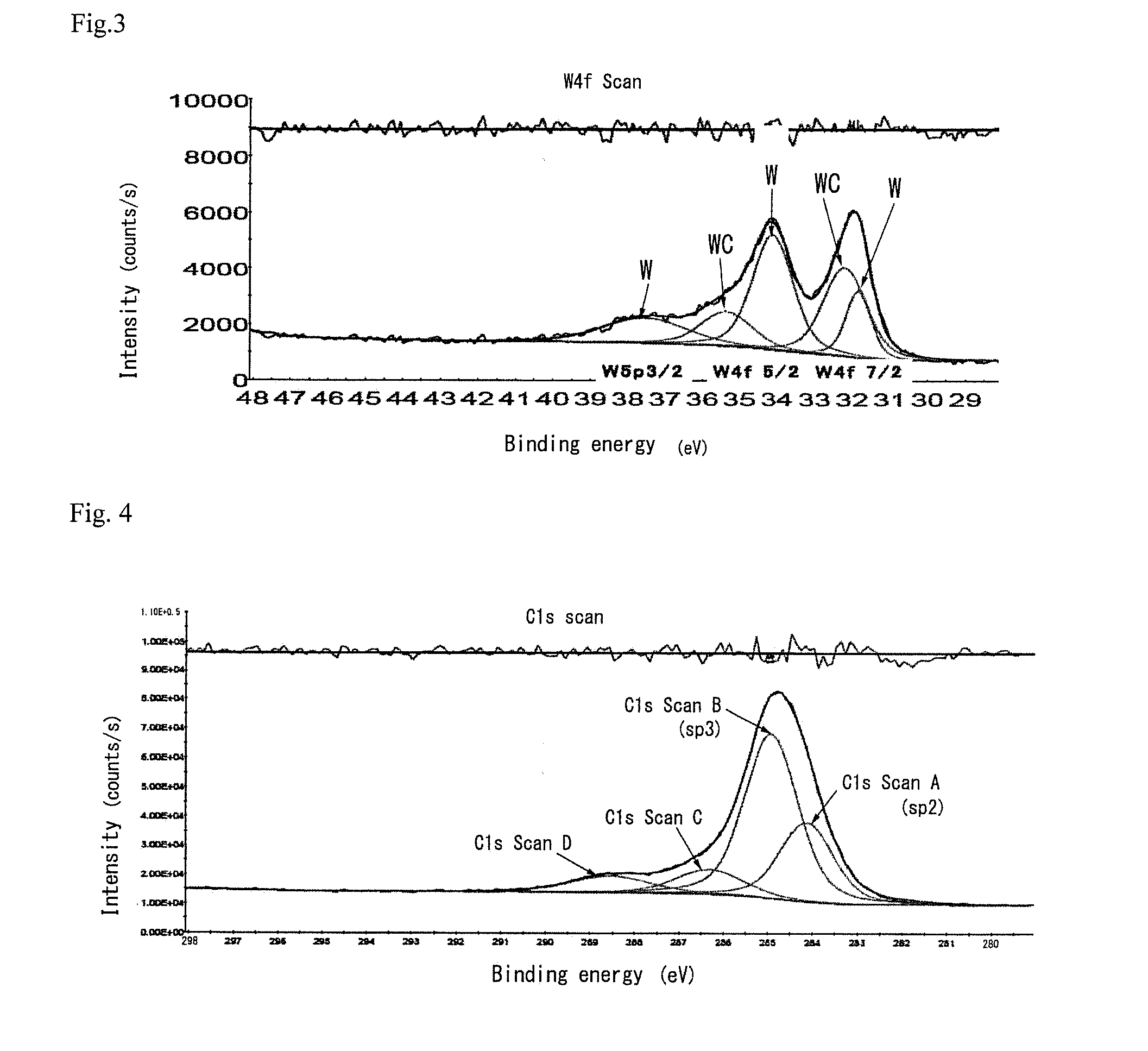

Carbon-containing hard coating and a method for depositing a hard coating onto a substrate

ActiveUS7357975B2Reduce residual stressHigh hardnessMolten spray coatingVacuum evaporation coatingCrystalliteHigh concentration

The carbon-containing hard coating (1) according to the invention comprises nano-crystalline grains being separated from each other by grain boundaries, wherein said hard coating comprises aluminum (Al), at least one additional metal (Me1, Me2), carbon (C) and at least one further element (E1, E2) and has the chemical composition:(AlxMe1yMe2z)CuE1vE2w wherein Me1 is a metal, and Me2 is a metal, with x>0.4 and x+y+z=1 and y,z≧0, and E1 and E2 are further chemical elements with 1>u>0 and u+v+w=1 and v,w≧0. The grain boundaries have a higher concentration of carbon atoms than the nano-crystalline grains.

Owner:SULZER METAPLAS

Modified metal-oxide composite sol, coating composition, and optical member

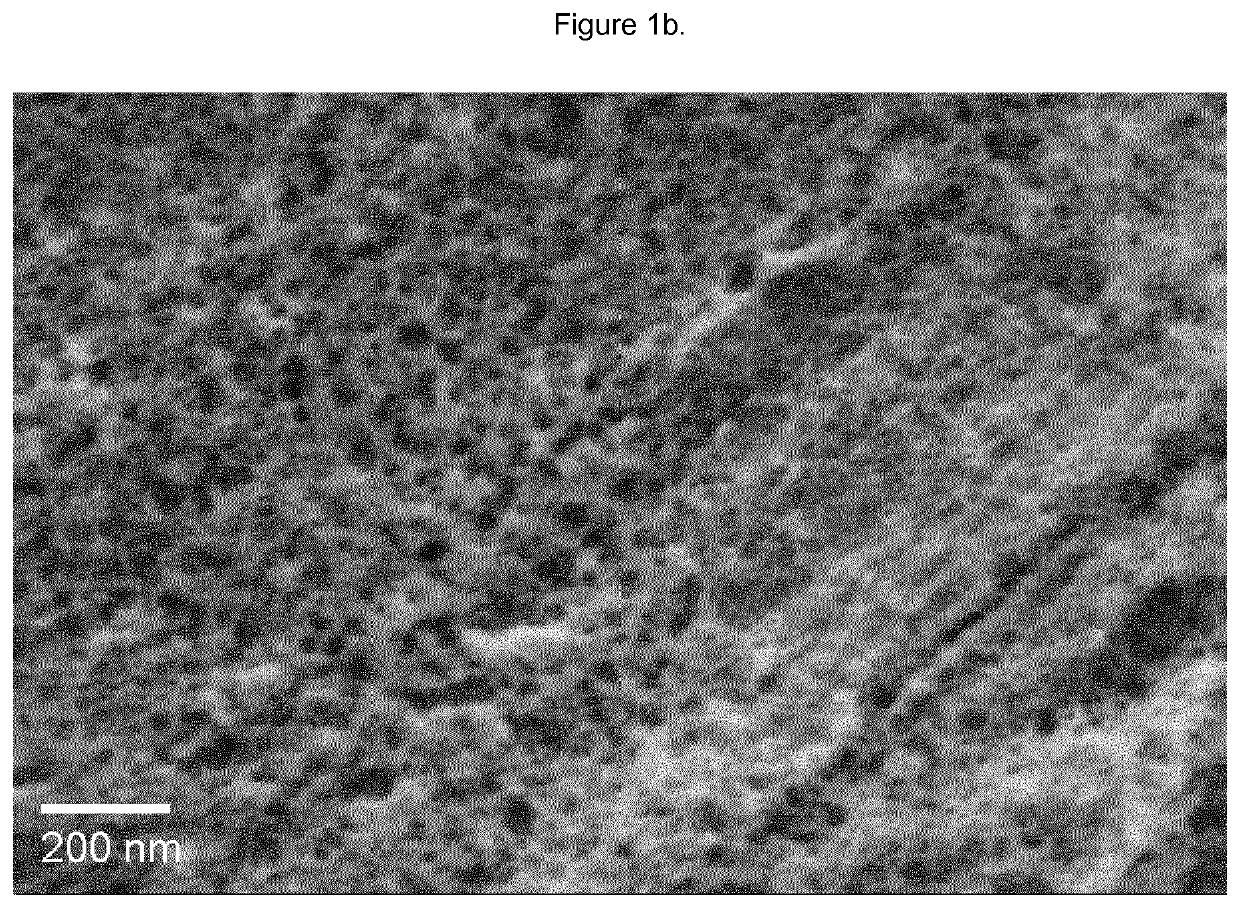

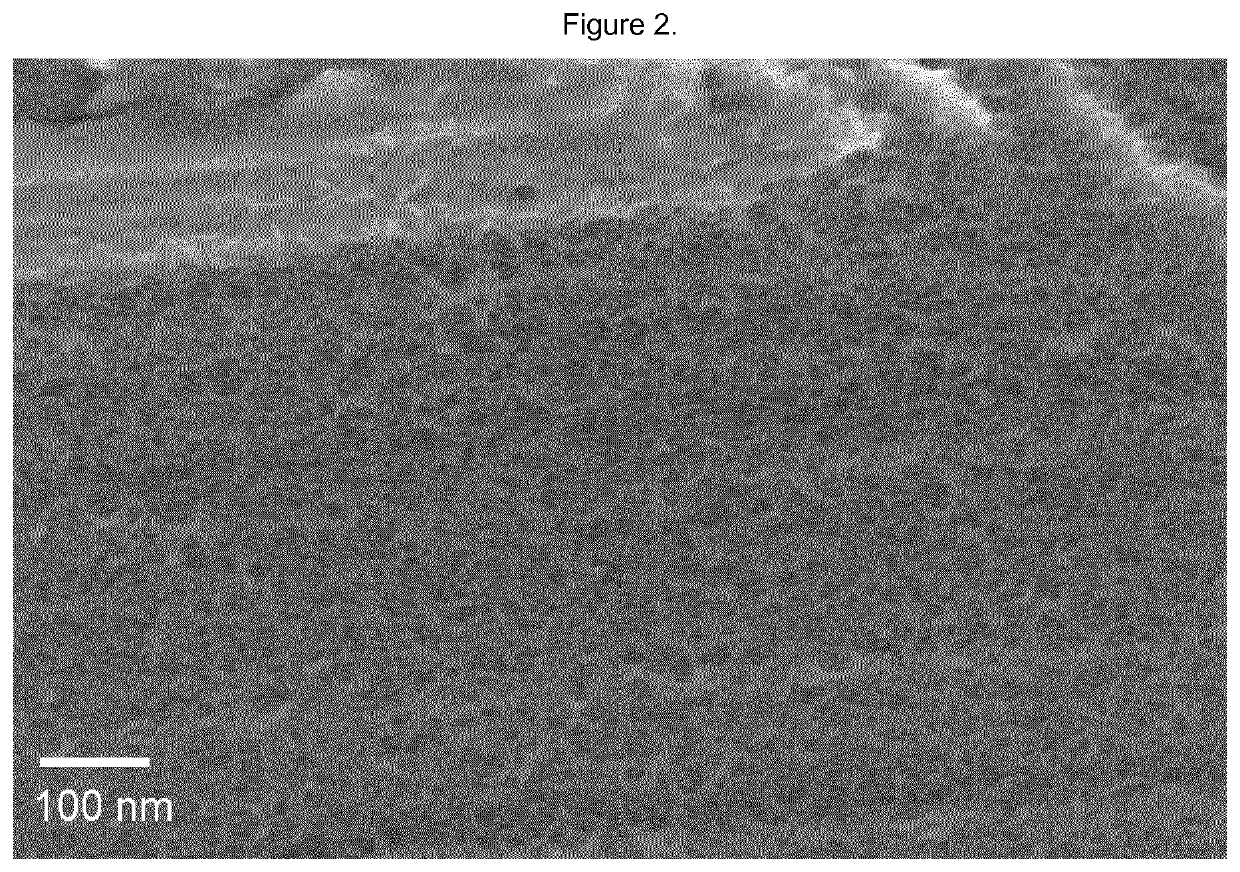

InactiveUS20100221556A1High refractive indexGood dispersionMaterial nanotechnologyPigmenting treatmentWeather resistanceOxide composite

There is provided a sol of modified metal oxide composite colloidal particles including titanium oxide having a high refractive index and excellent light resistance and weather resistance that discoloration of the colloidal particles by photoexcitation is almost completely inhibited. A modified metal oxide composite colloidal particle comprises; a titanium oxide-tin oxide-zirconium oxide-tungsten oxide composite colloidal particle (A) having a primary particle diameter of 2 to 50 nm and having a SnO2 / TiO2 molar ratio of 0.1 to 1.0, a ZrO2 / TiO2 molar ratio of 0.1 to 0.4, and a WO3 / TiO2 molar ratio of 0.03 to 0.15, as a core; and a tungsten oxide-tin oxide-silicon dioxide composite colloidal particle (B) having a primary particle diameter of 1 to 7 nm with which a surface of the core is coated.

Owner:NISSAN CHEM IND LTD

Metal oxide composite sol, coating composition, and optical member

InactiveUS20100239872A1High refractive indexGood dispersibilityPigmenting treatmentMaterial nanotechnologyColloidal particleWeather resistance

There is provided a sol of modified metal oxide composite colloidal particles including titanium oxide having a high refractive index and excellent light resistance and weather resistance that discoloration of the colloidal particles by photoexcitation is almost completely inhibited. A titanium oxide-tin oxide-zirconium oxide-tungsten oxide composite colloidal particle having a primary particle diameter of 2 to 50 nm, and a SnO2 / TiO2 molar ratio of 0.1 to 1.0, a ZrO2 / TiO2 molar ratio of 0.1 to 0.4, and a WO3 / TiO2 molar ratio of 0.03 to 0.15.

Owner:NISSAN CHEM IND LTD

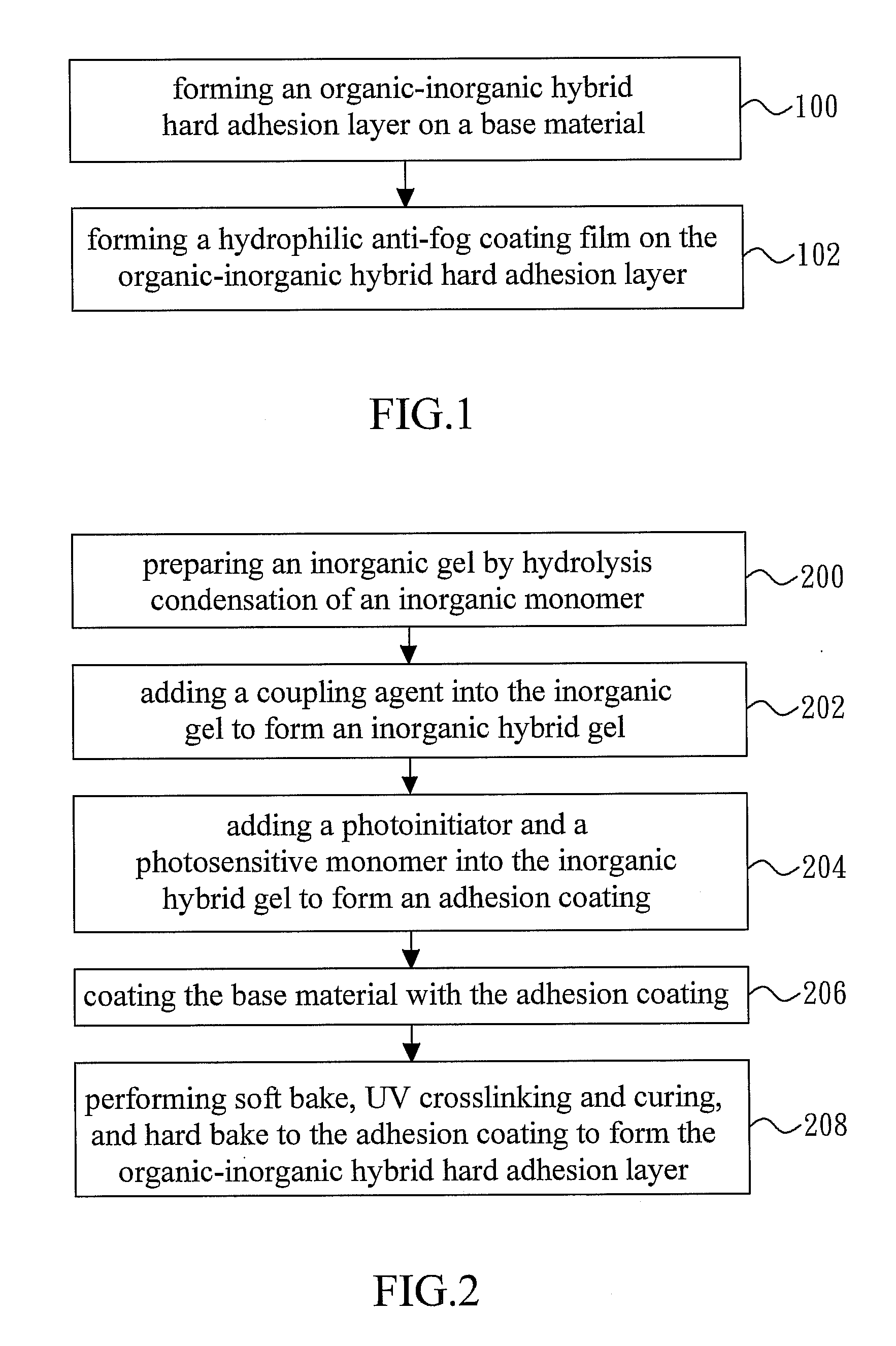

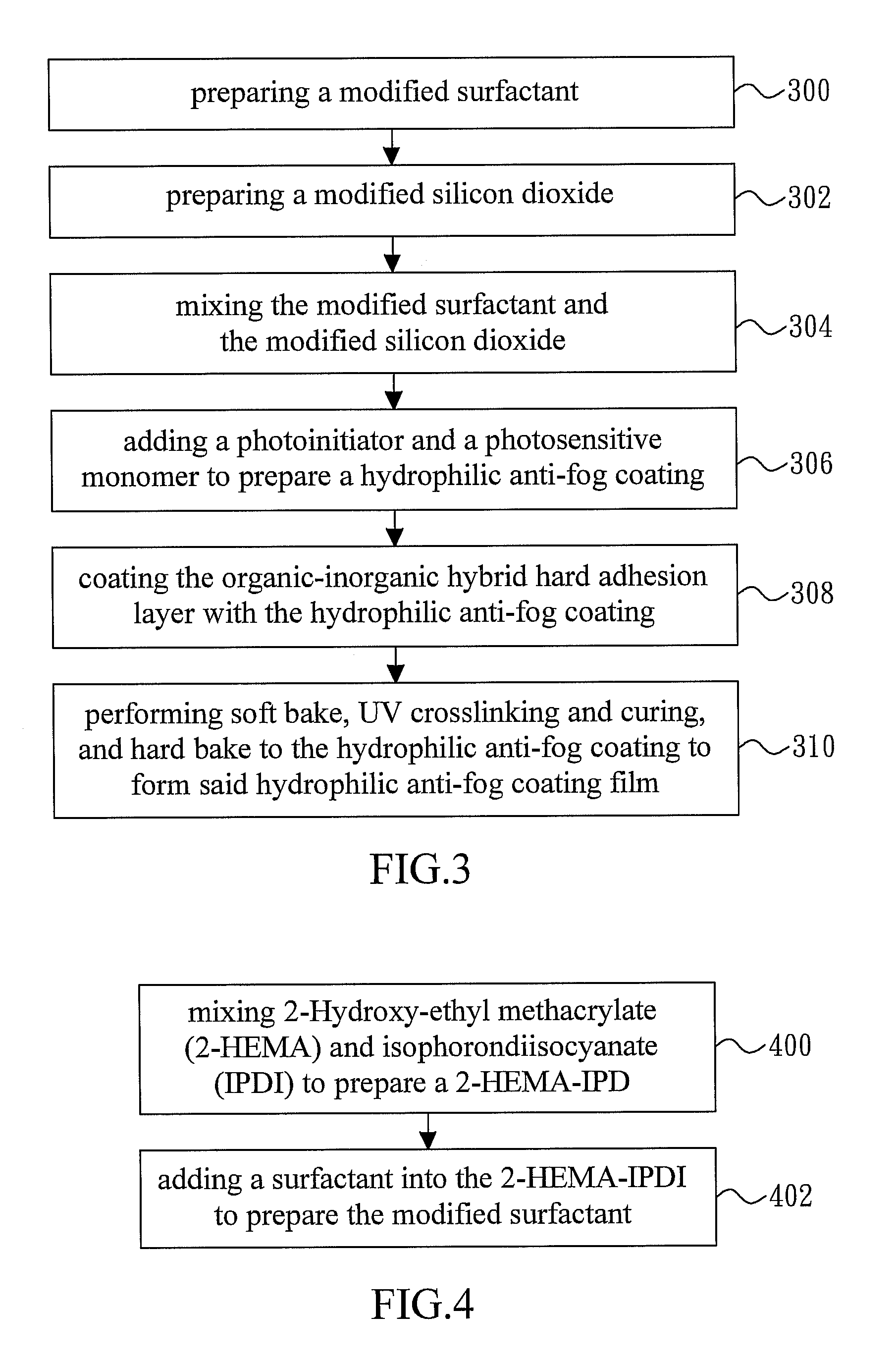

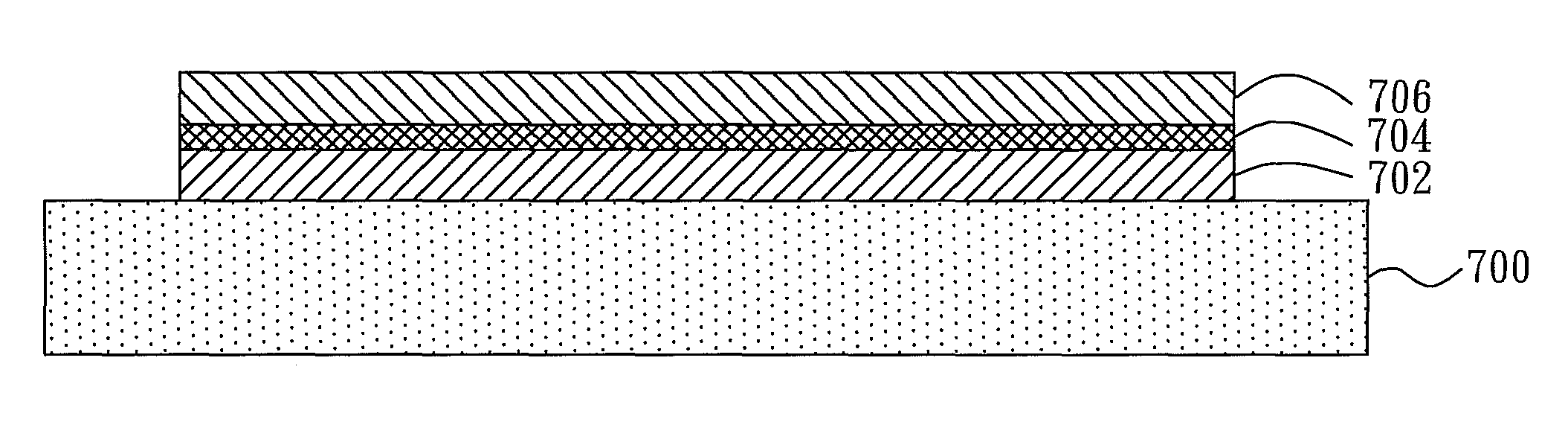

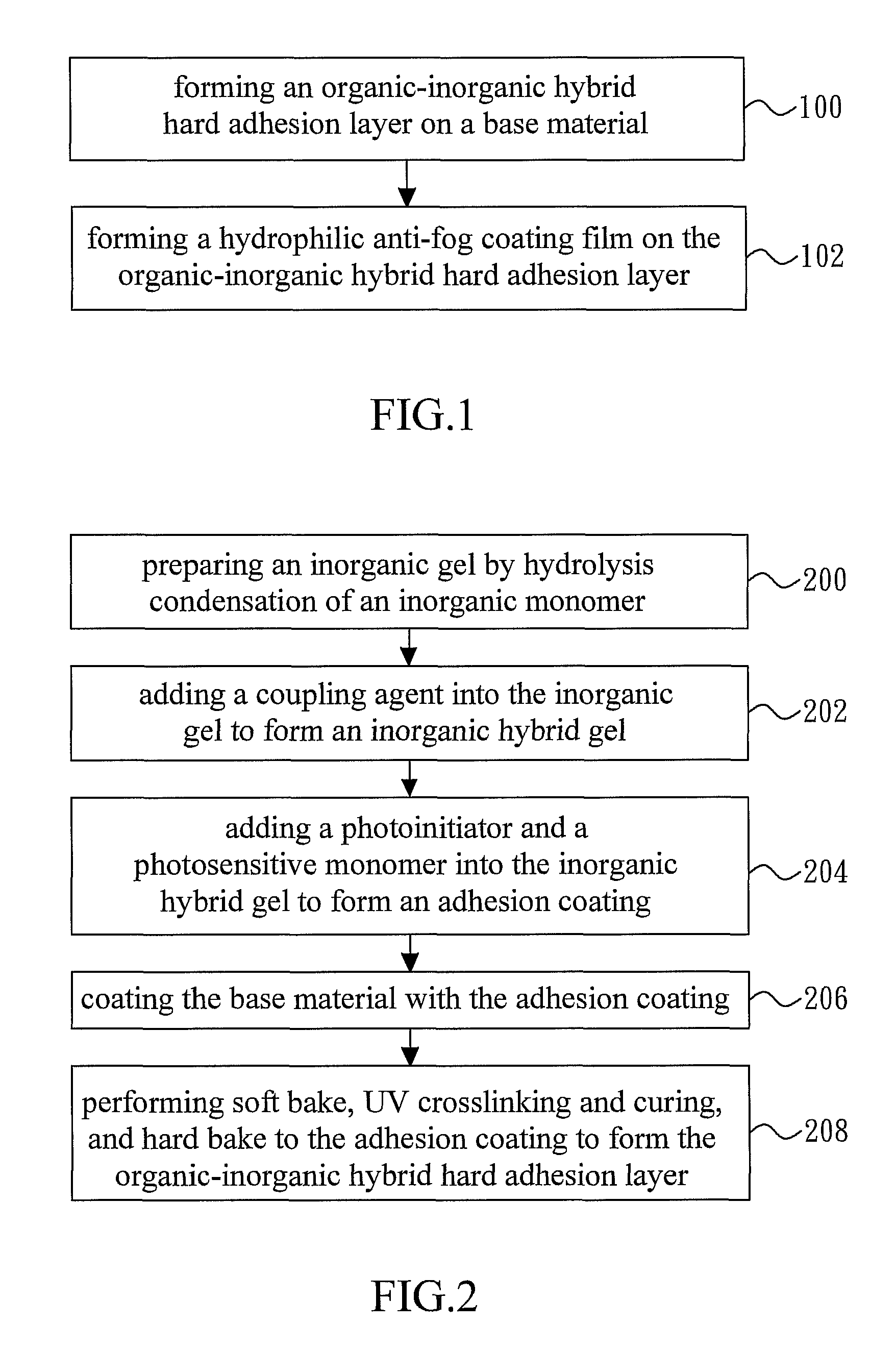

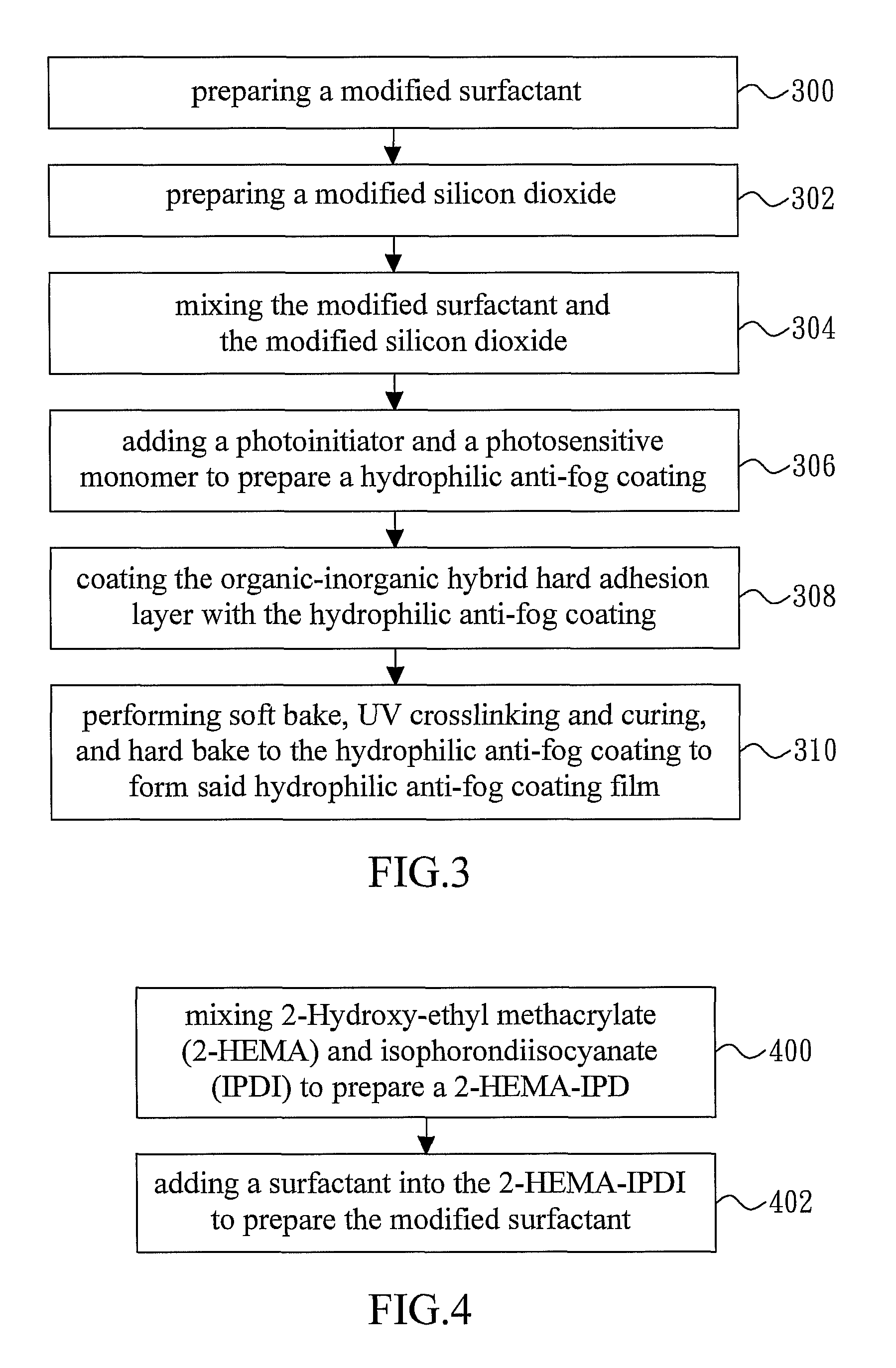

Method for manufacturing a hard, water-resistant Anti-fog coating

InactiveUS20130157066A1Overcomes drawbackGood for plastic materialPretreated surfacesSpecial surfacesPlastic materialsDouble bond

The present invention relates to a method for manufacturing a hard, water-resistant anti-fog coating, and particularly relates to a method for manufacturing a hard, water-resistant anti-fog coating on plastic material. In this method, an organic-inorganic hard adhesion layer and a hydrophilic anti-fog coating film are prepared for manufacturing a hard, water-resistant anti-fog coating. Both of the organic-inorganic hard adhesion layer and the hydrophilic anti-fog coating have C=C double bonds. Therefore, the organic-inorganic hard adhesion layer and the hydrophilic anti-fog coating are adhered to each other tightly. It brings high hardness, high water resistance and good anti-fog effect.

Owner:TAMKANG UNIVERSITY

Hard-carbon coated sliding member

InactiveUS20060093839A1Difficult to coatReduce coefficient of frictionVacuum evaporation coatingSputtering coatingCarbon coatedMetallic Nickel

There is provided a sliding member including a base substrate and a hard carbon coating formed on the base substrate to define at least a surface for sliding contact with an opposing member. The hard carbon coating contains therein at least one of cobalt and nickel in an amount of 1.4 to 39 atomic %.

Owner:NISSAN MOTOR CO LTD +1

Material with hard coating film formed on substrate surface thereof

InactiveUS8025958B2Improve wear resistanceImprove removabilitySynthetic resin layered productsVacuum evaporation coatingWear resistantTotal thickness

Owner:KOBE STEEL LTD

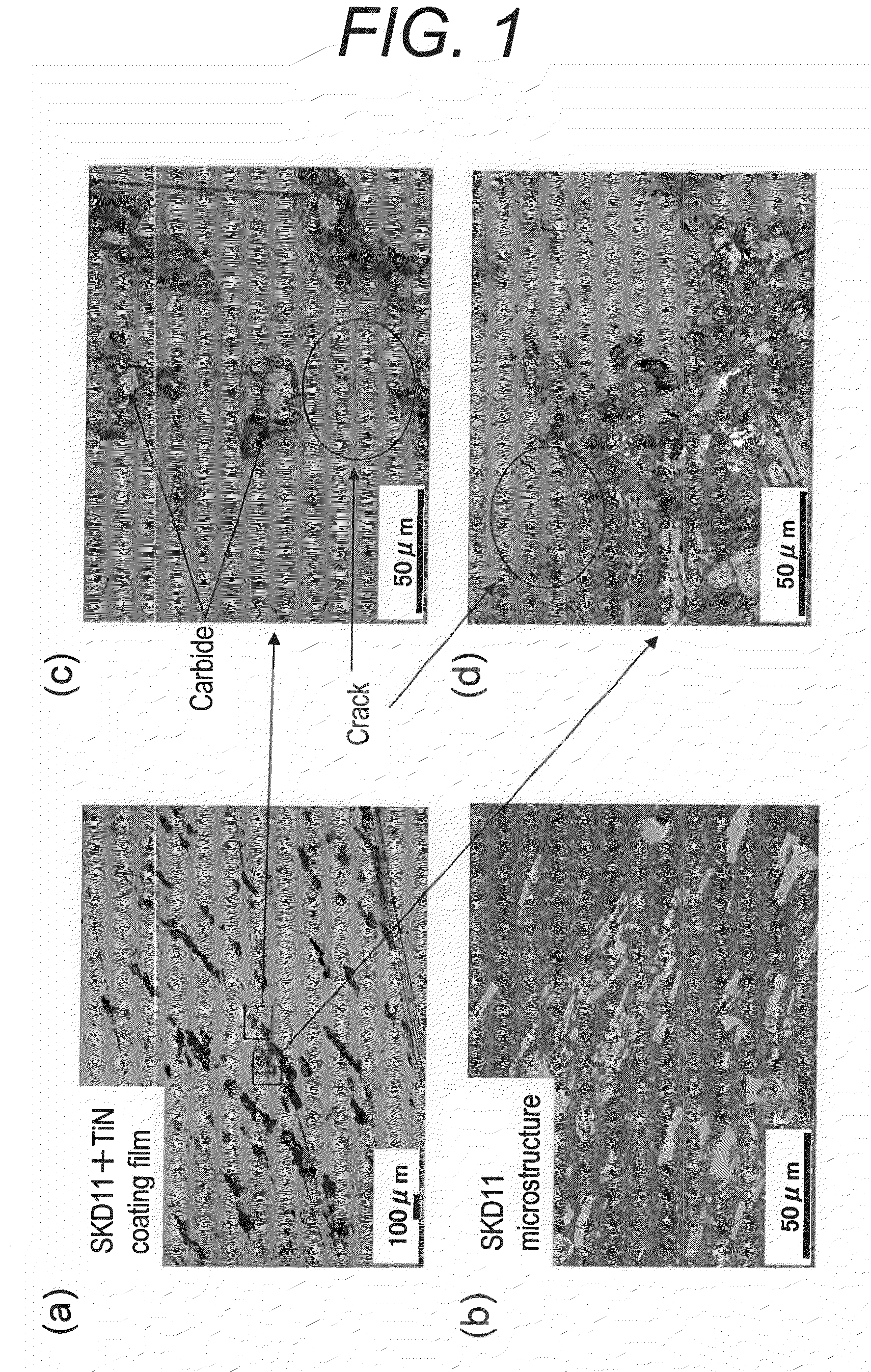

Cold-work die steel and die

InactiveUS20100135844A1High hardness and toughnessExcellent basic propertyShaping toolsFurnace typesNickelMaterials science

The present invention relates to a cold-work die steel, comprising by mass %: 0.5 to 0.7% of C; 0.5 to 2.0% of Si; 0.1 to 2.0% of Mn; 5 to 7% of Cr; 0.01 to 1.0% of Al; 0.003 to 0.025% of N; 0.25 to 1% of Cu; 0.25 to 1% of Ni; 0.5 to 3% of Mo; 2% or less (including 0%) of W; and 0.1% or less (excluding 0%) of S, with a remainder being iron and an unavoidable impurity; wherein the following requirements (1) to (3) are satisfied: (1) [Cr]×[C]≦4; (2) [Al] / [N]: 1 to 30; and (3) [Mo]+0.5×[W]: 0.5 to 3.00%, wherein the bracket means a content (%) of an element written therein.

Owner:KOBE STEEL LTD +1

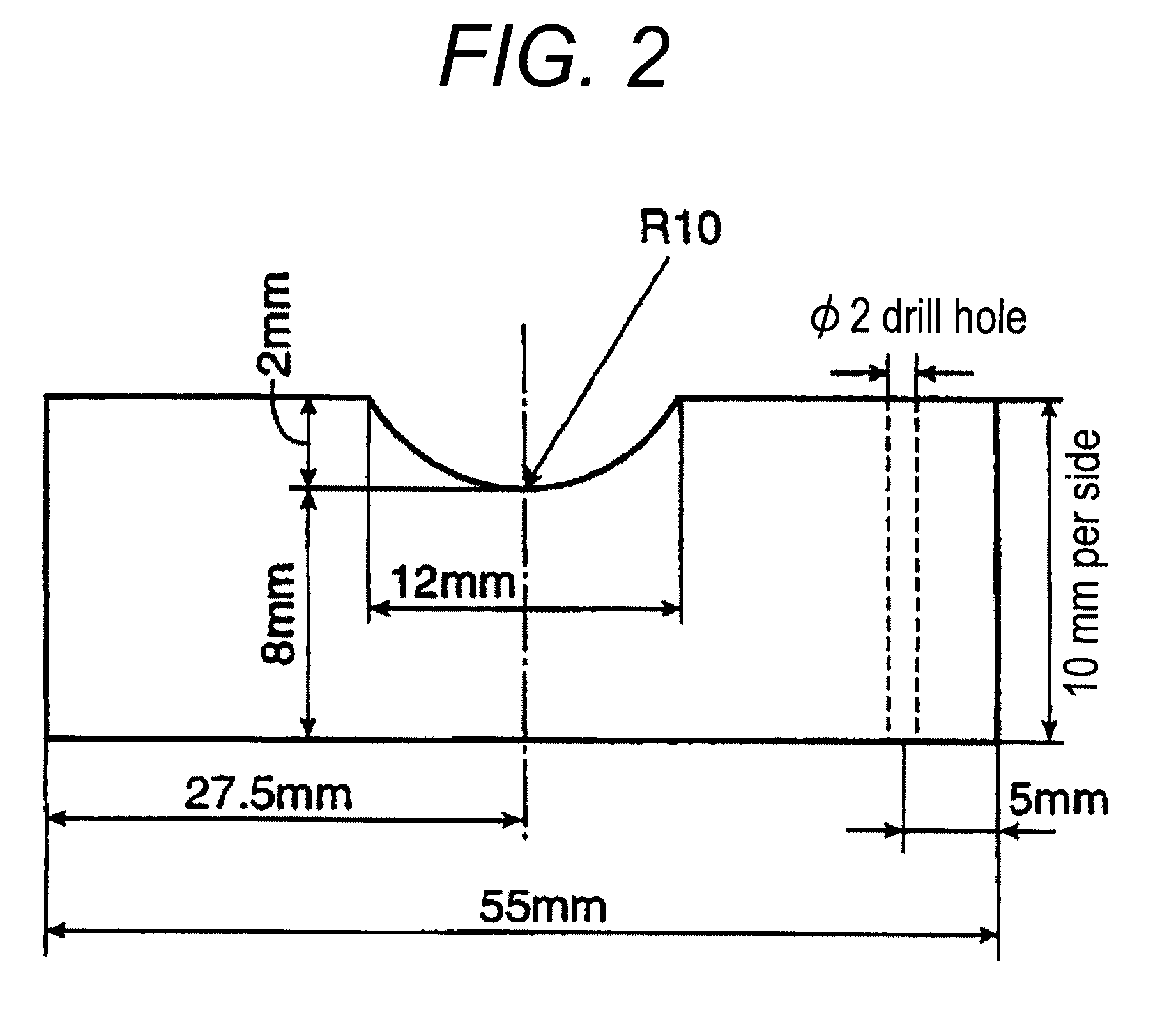

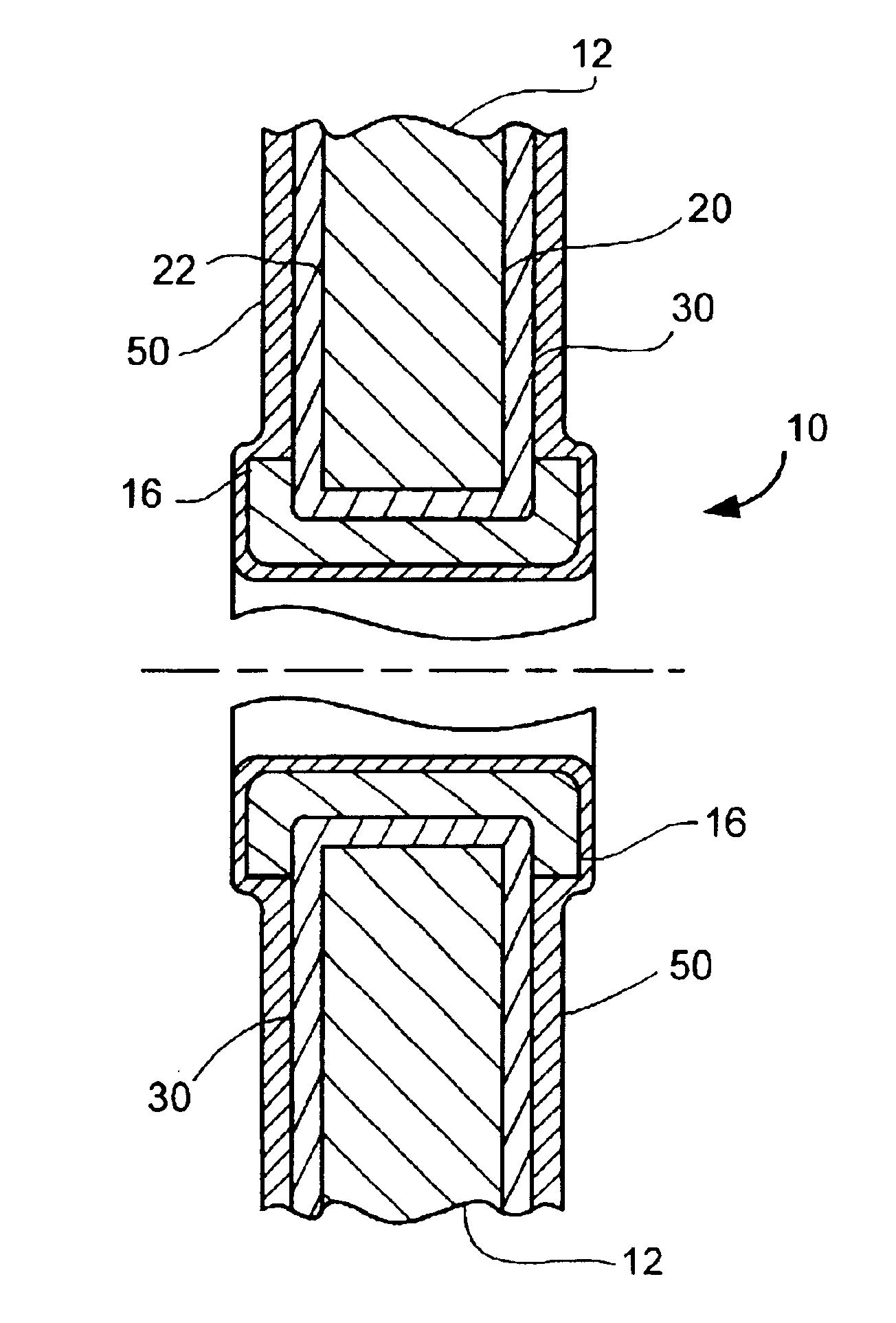

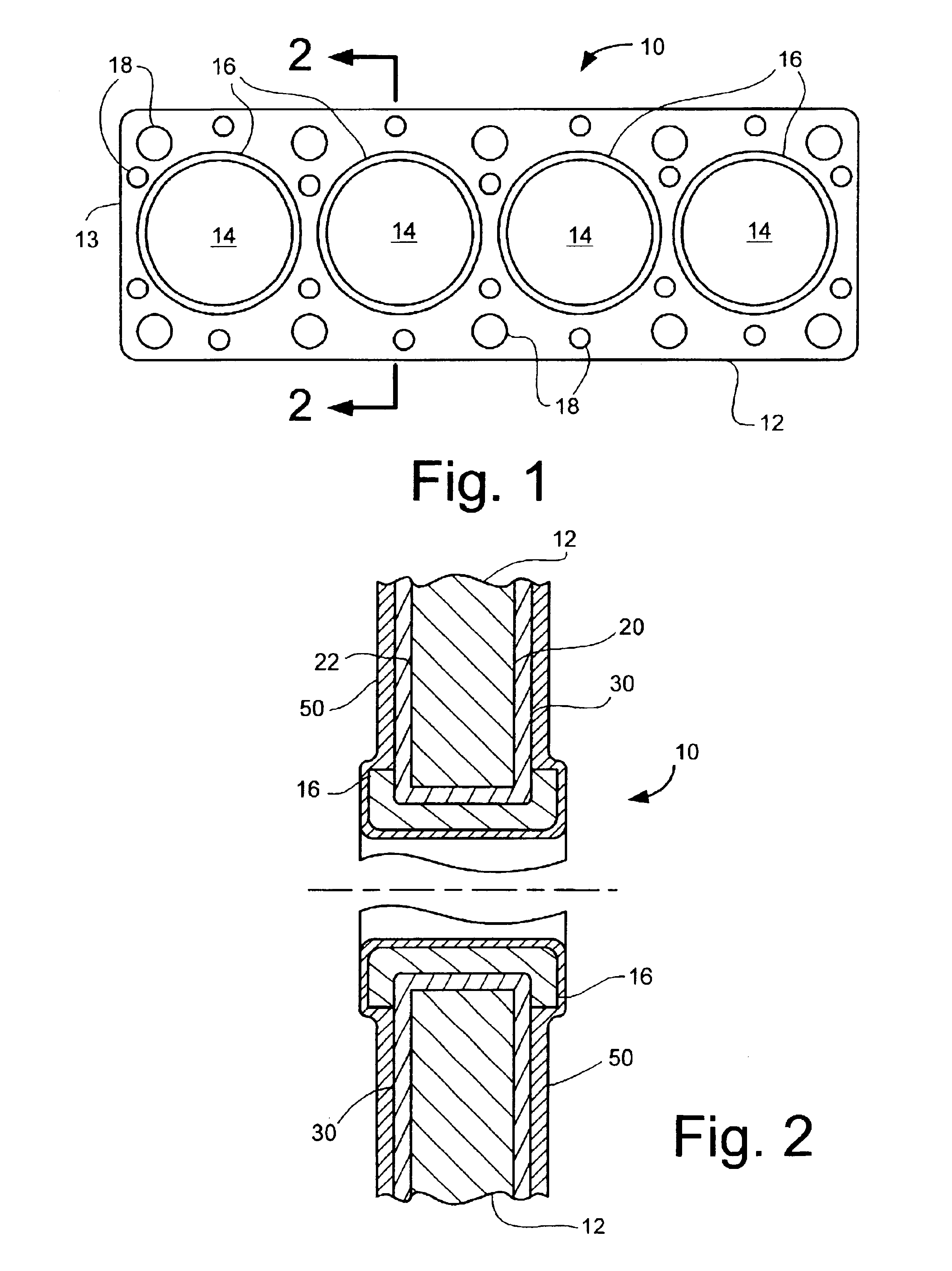

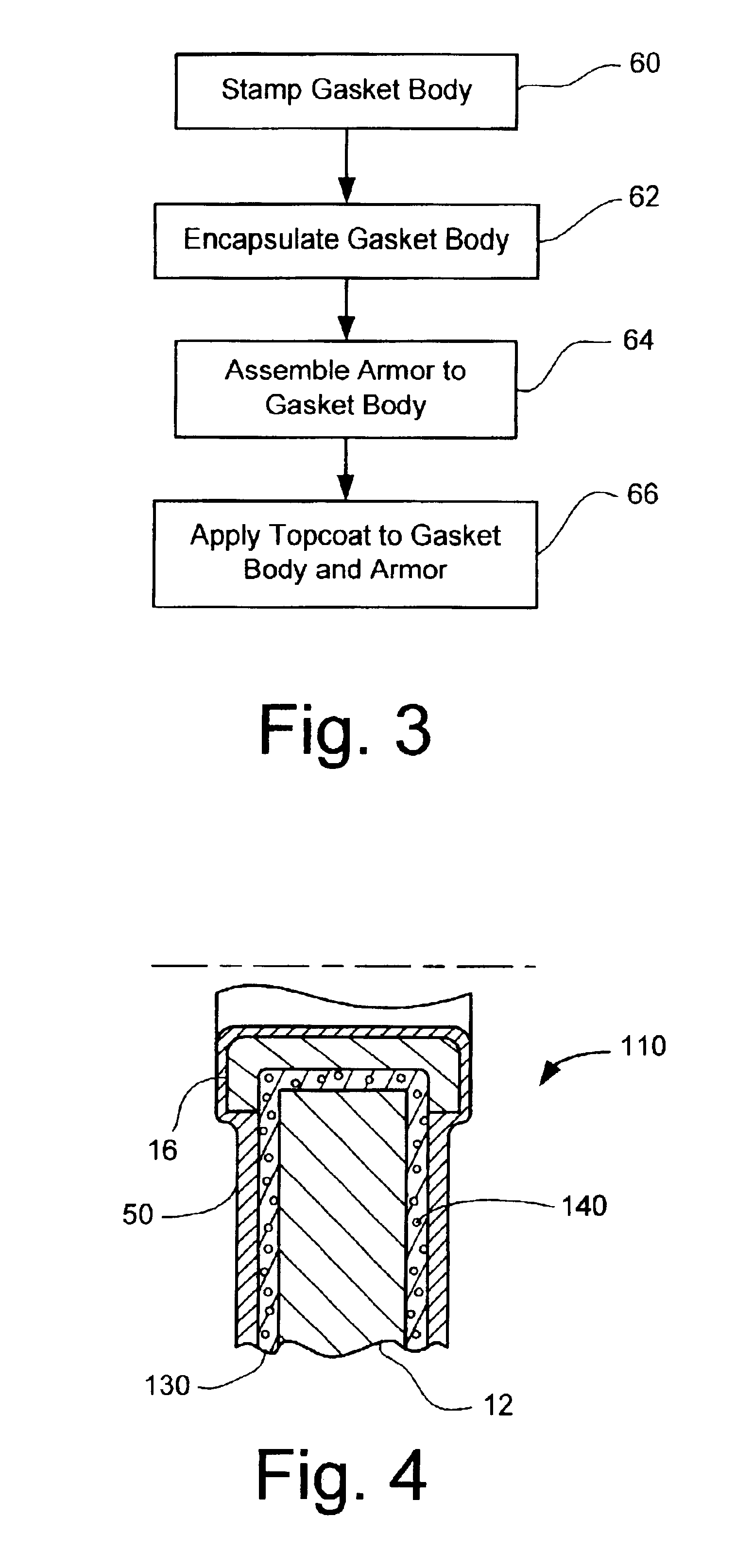

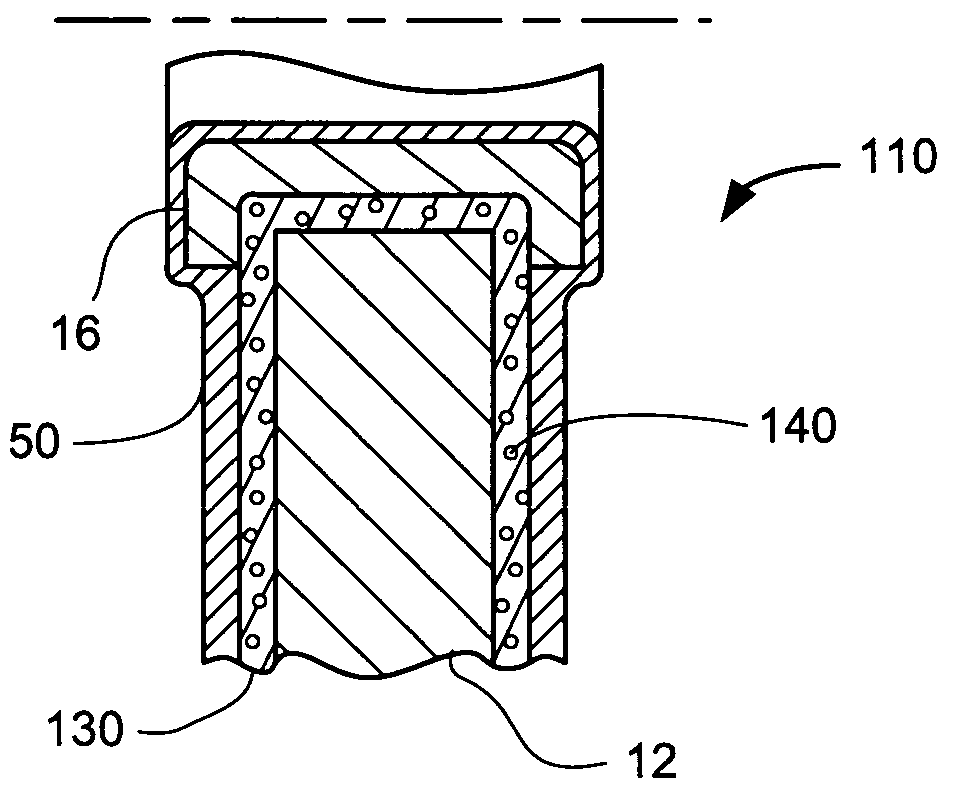

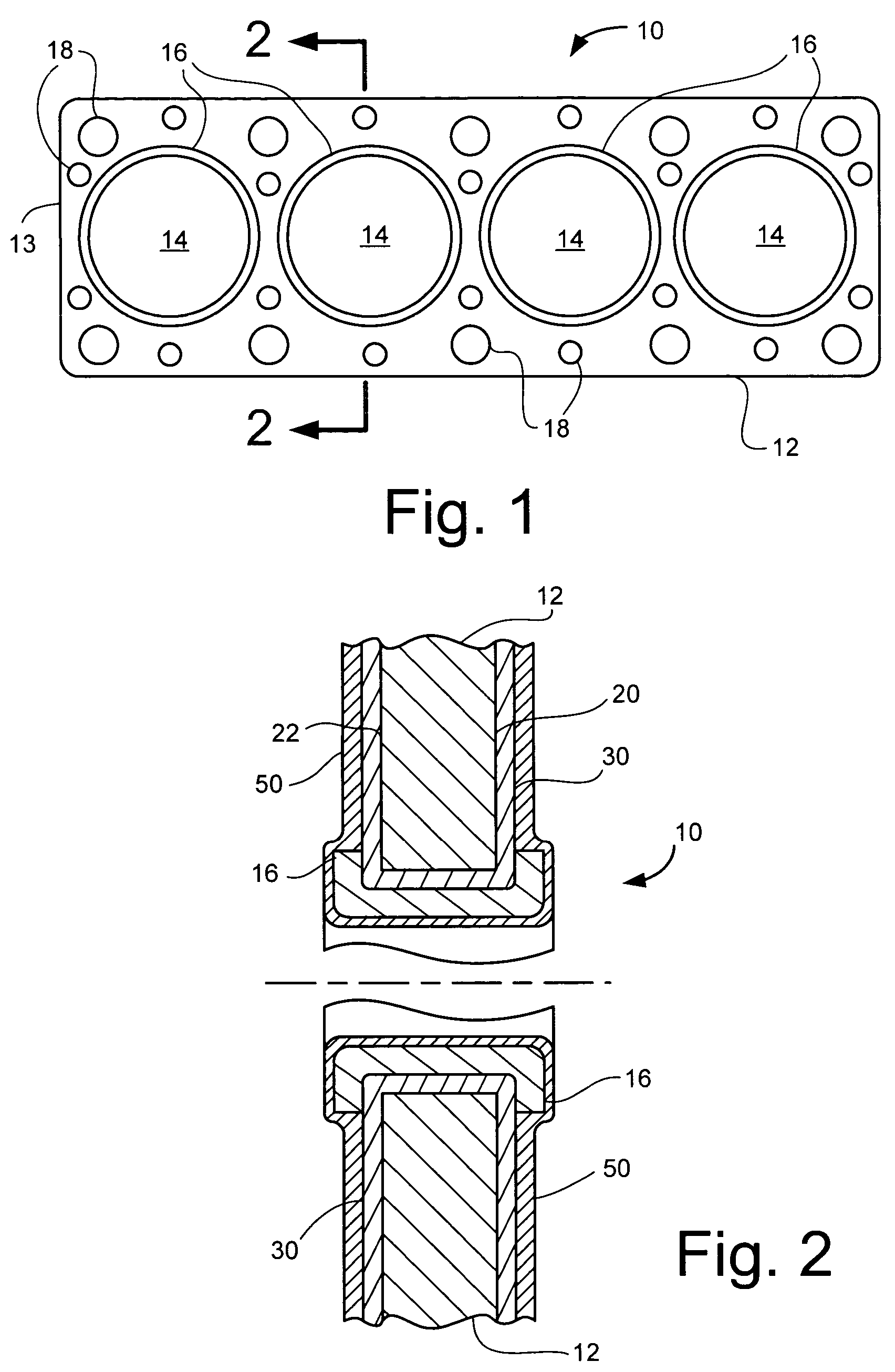

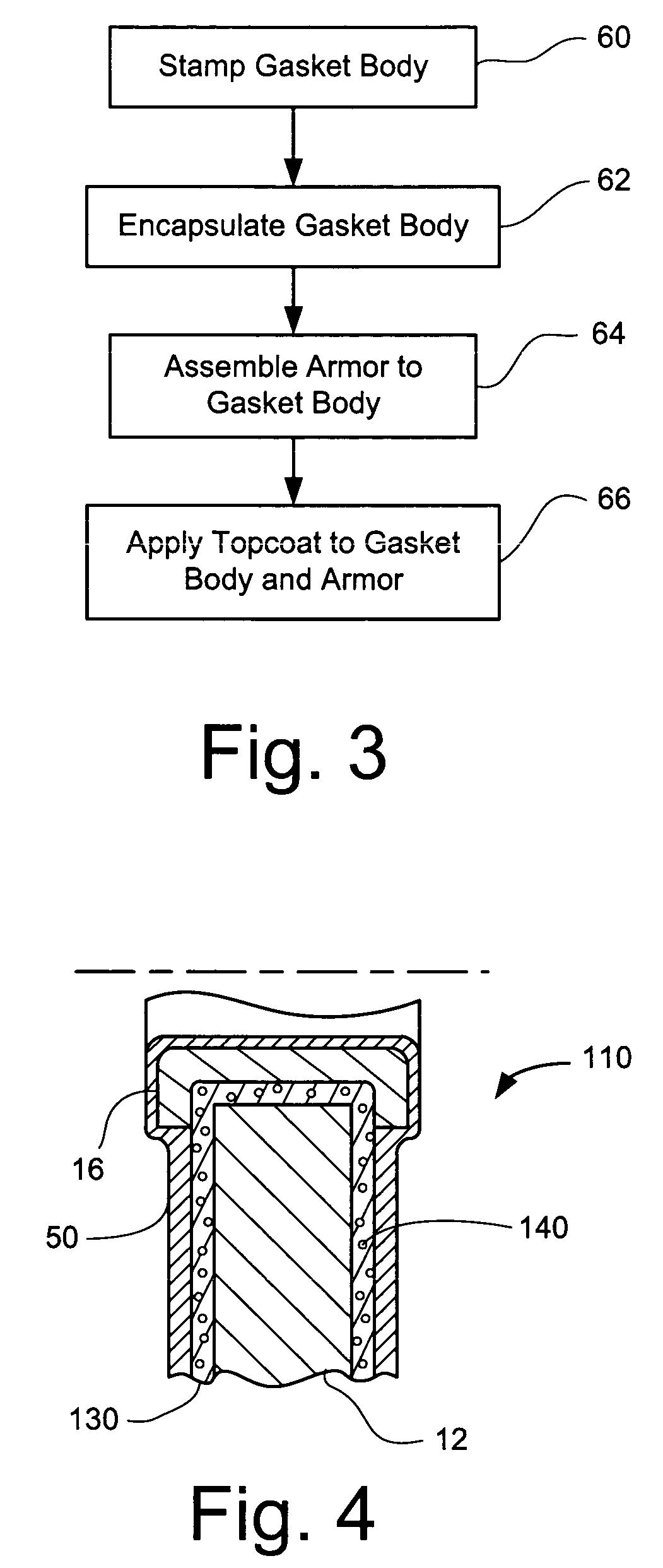

Cylinder head gasket and method of producing

InactiveUS6945538B2Difficult to coatAssembly precisionEngine sealsSealing arrangements for enginesEngineeringSealant

A cylinder head gasket that includes a body that has holes stamped through it and is then coated with an encapsulant before assembling armor to the body of the gasket. A topcoat is coated over the body and armor. The encapsulant is preferably an epoxy primer and the topcoat is preferably a silicone.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Piston ring

ActiveUS20160245407A1Improve wear resistanceReduce wearPiston ringsVacuum evaporation coatingCarbon coatingPiston ring

The present invention provides a piston ring having excellent abrasion resistance to an aluminum alloy cylinder or cylinder liner formed of a mating material and is therefore capable of decreasing abrasion of the mating material. An exemplary piston ring has a hard carbon coating formed on an outer peripheral surface, and the hard carbon coating contains 0.5 atom % or more to less than 5 atom % of tungsten (W).

Owner:RIKEN CO LTD

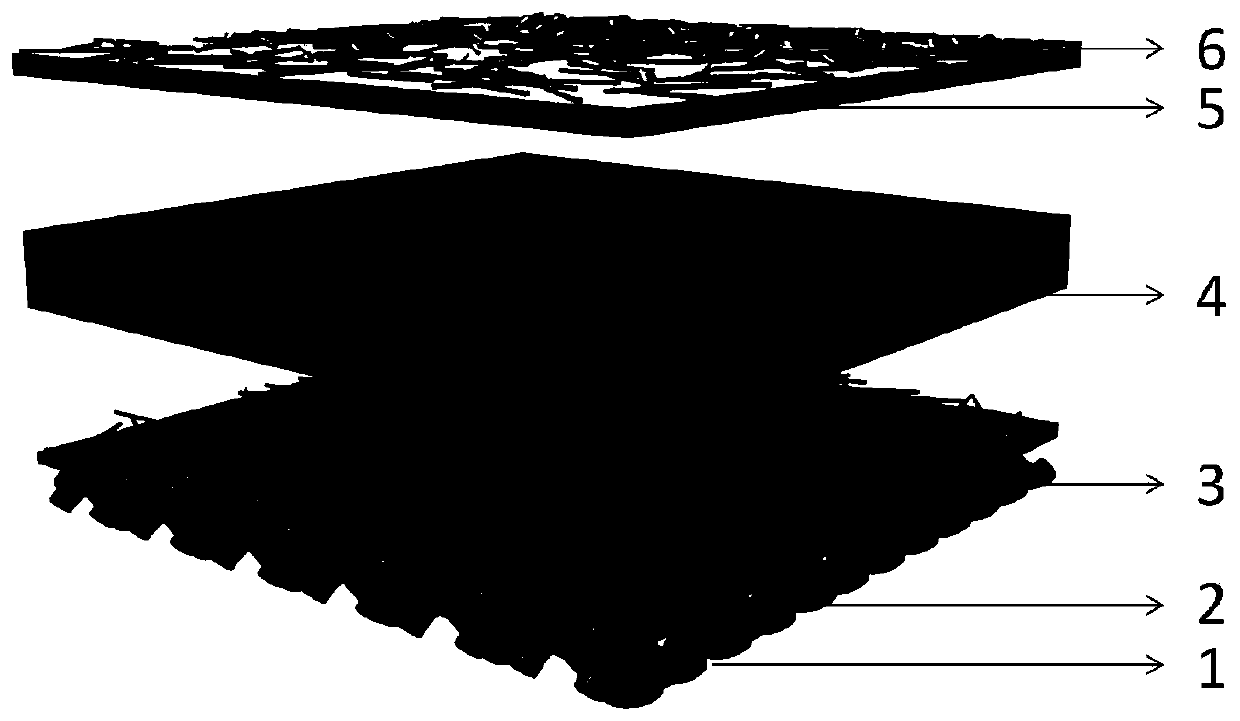

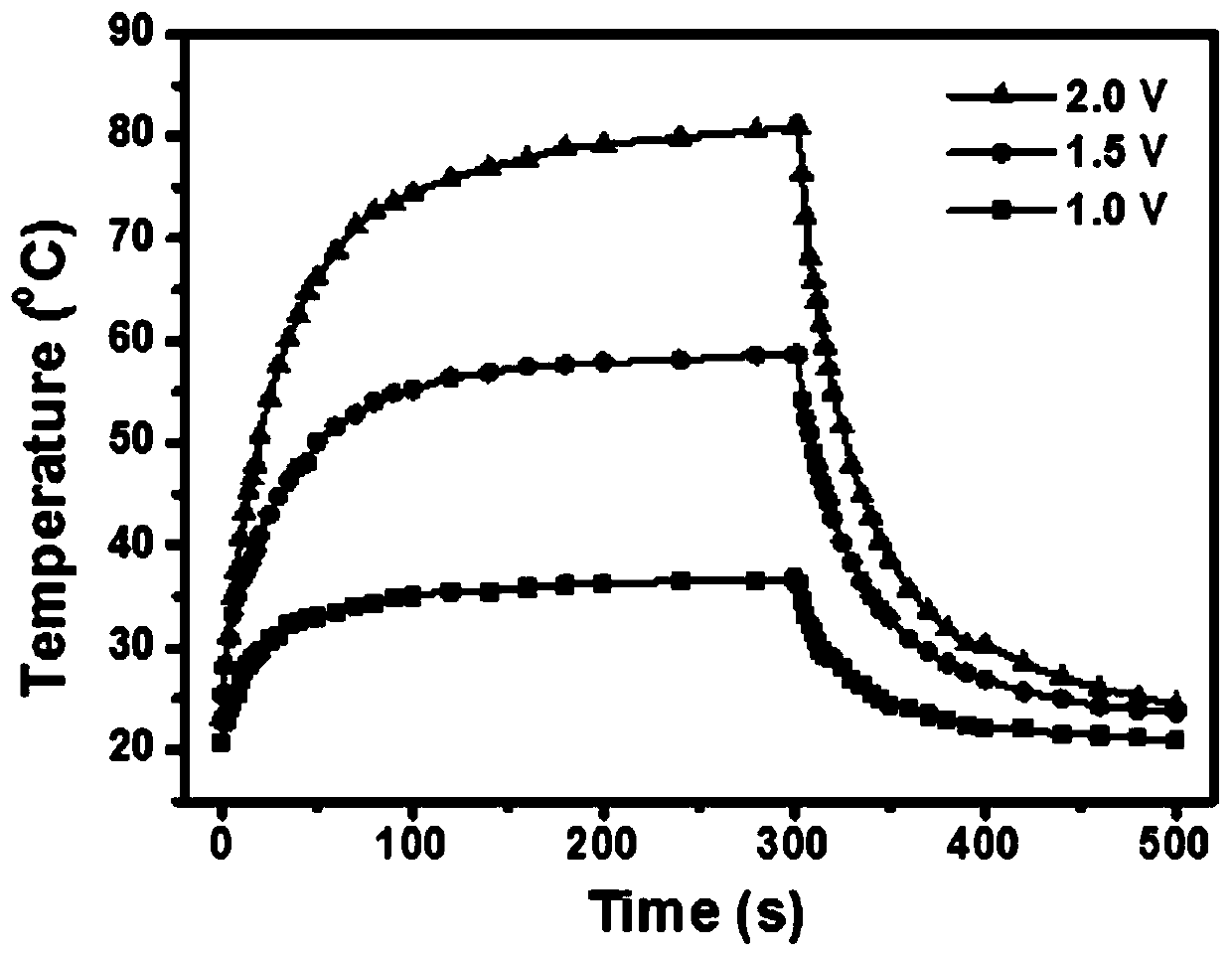

Multifunctional flexible electronic device, application and preparation method

ActiveCN110033880ADifficult to coatDifficult to apply evenlyConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersFlexible electronicsJoule

The invention discloses a multifunctional flexible electronic device, an application and a preparation method. Specifically the multifunctional flexible electronic device comprises a first electrode layer (a), a light-emitting functional layer (b), a dielectric layer (c) which is a transparent or semitransparent insulating polymer, a second electrode layer (d), and an insulating protective layer (e) which is the transparent or semitransparent insulating polymer. The invention further discloses an application and a preparation method of the flexible electronic device. The multifunctional flexible electronic device is directly prepared on a common fabric; the raw materials are rich, the cost is low, the integrity is high, and the implementation is easy; a patterned flexible electronic deviceis prepared innovatively by handwriting, imprinting and other ways; Joule heat is generated by utilizing electrodes so as to obtain a flexible heatable device; and the patterned flexible electronic device and the flexible heatable device are combined to obtain the multifunctional flexible electronic device based on the common fabric.

Owner:NANJING UNIV OF TECH

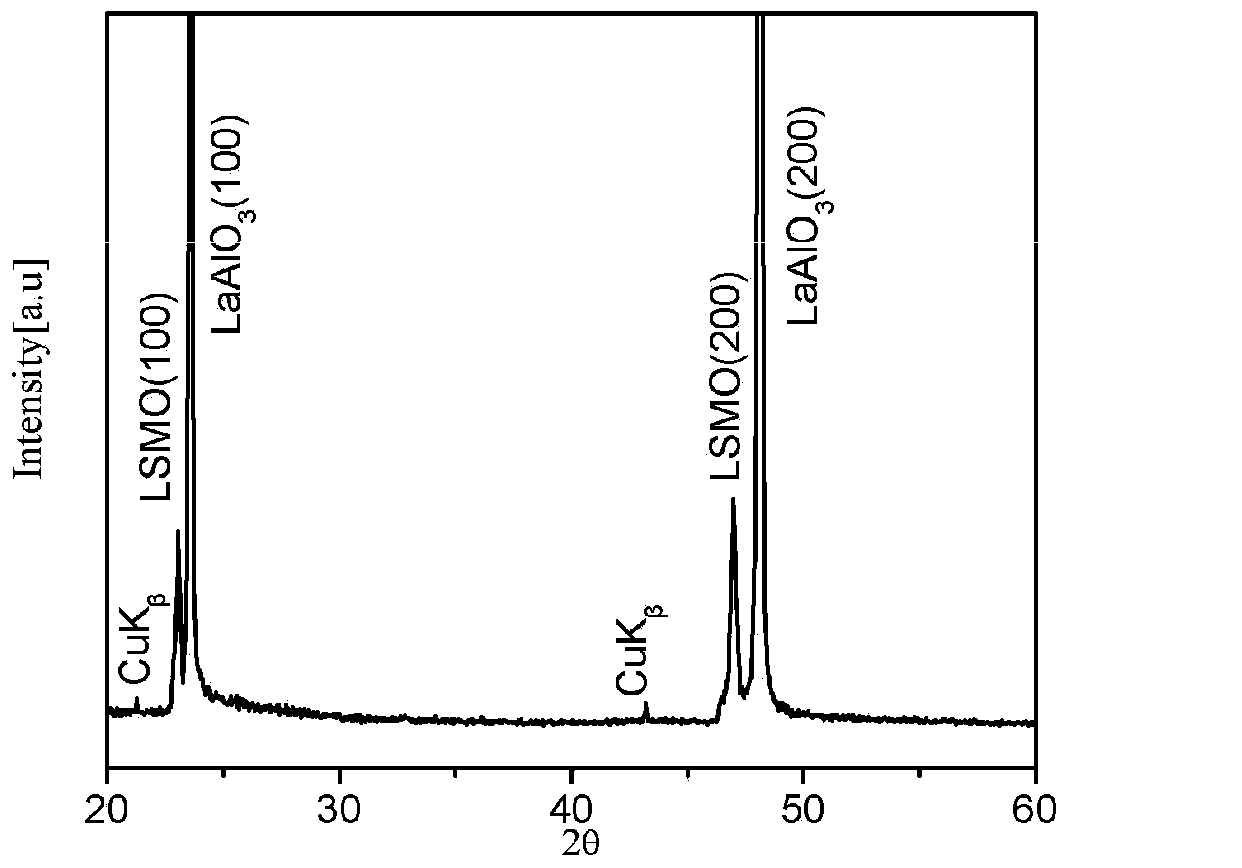

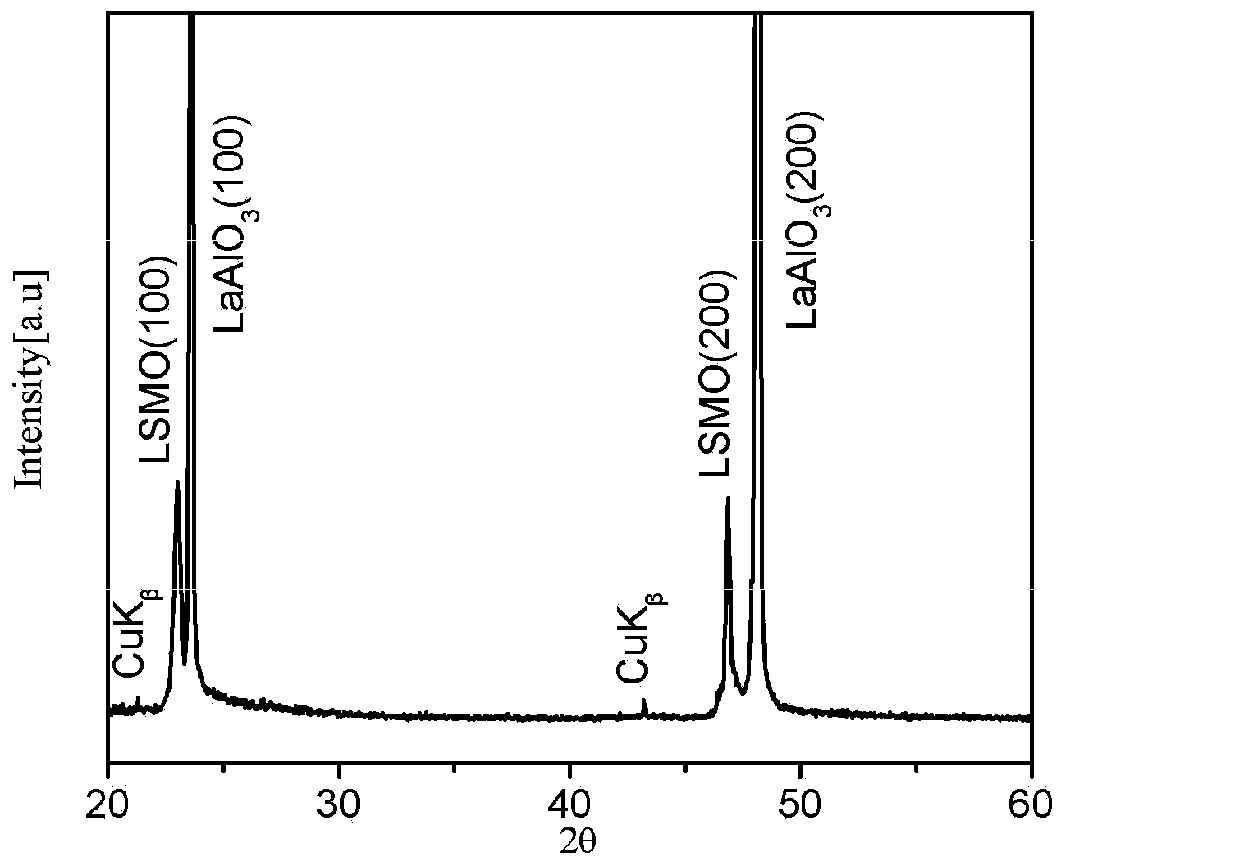

Preparation method of high temperature superconducting coated conductor La0.7Sr0.3MnO3 buffer layer thin film

ActiveCN103515026ADecompose fullyAvoid formingCable/conductor manufactureElectrical conductorThermal insulation

The invention discloses a preparation method of a high temperature superconducting coated conductor La0.7Sr0.3MnO3 buffer layer thin film. The preparation method mainly comprises the steps of a, lanthanum nitrate, strontium nitrate and manganese nitrate are dissolved in N, N-dimethyl formamide to form an anhydrous solution, wherein the number ratio of lanthanum ions, strontium ions and manganese ions is 7:3:10; b, polyvinylpyrrolidone K30 is added into the anhydrous solution of step a to form colloid; c, the colloid prepared by step b is coated on a lanthanum aluminum oxide substrate, and then drying in an infrared drying box is carried out; and d, a substrate plate which is dried by step c is placed in a tube type furnace, undergoes thermal insulation at the temperature of 160 to 220 DEG C, is slowly heated to the temperature of 500 to 540 DEG C for thermal insulation, and finally undergoes annealing at the temperature of 830 to 870 DEG C. According to the method, a good LSMO thin film with a smooth surface can extends and grows on the lanthanum aluminum oxide (LaAlO3) substrate; and the method has the advantages of low preparation cost and less environment pollution, and is suitable for mass production.

Owner:四川中创登峰科技有限公司

Method for manufacturing a hard, water-resistant anti-fog coating

InactiveUS9103977B2Adhesion can be improved and increasedHardness can be improved and increasedLayered productsPretreated surfacesPlastic materialsHardness

The present invention relates to a method for manufacturing a hard, water-resistant anti-fog coating, and particularly relates to a method for manufacturing a hard, water-resistant anti-fog coating on plastic material. In this method, an organic-inorganic hard adhesion layer and a hydrophilic anti-fog coating film are prepared for manufacturing a hard, water-resistant anti-fog coating. Both of the organic-inorganic hard adhesion layer and the hydrophilic anti-fog coating have C═C double bonds. Therefore, the organic-inorganic hard adhesion layer and the hydrophilic anti-fog coating are adhered to each other tightly. It brings high hardness, high water resistance and good anti-fog effect.

Owner:TAMKANG UNIVERSITY

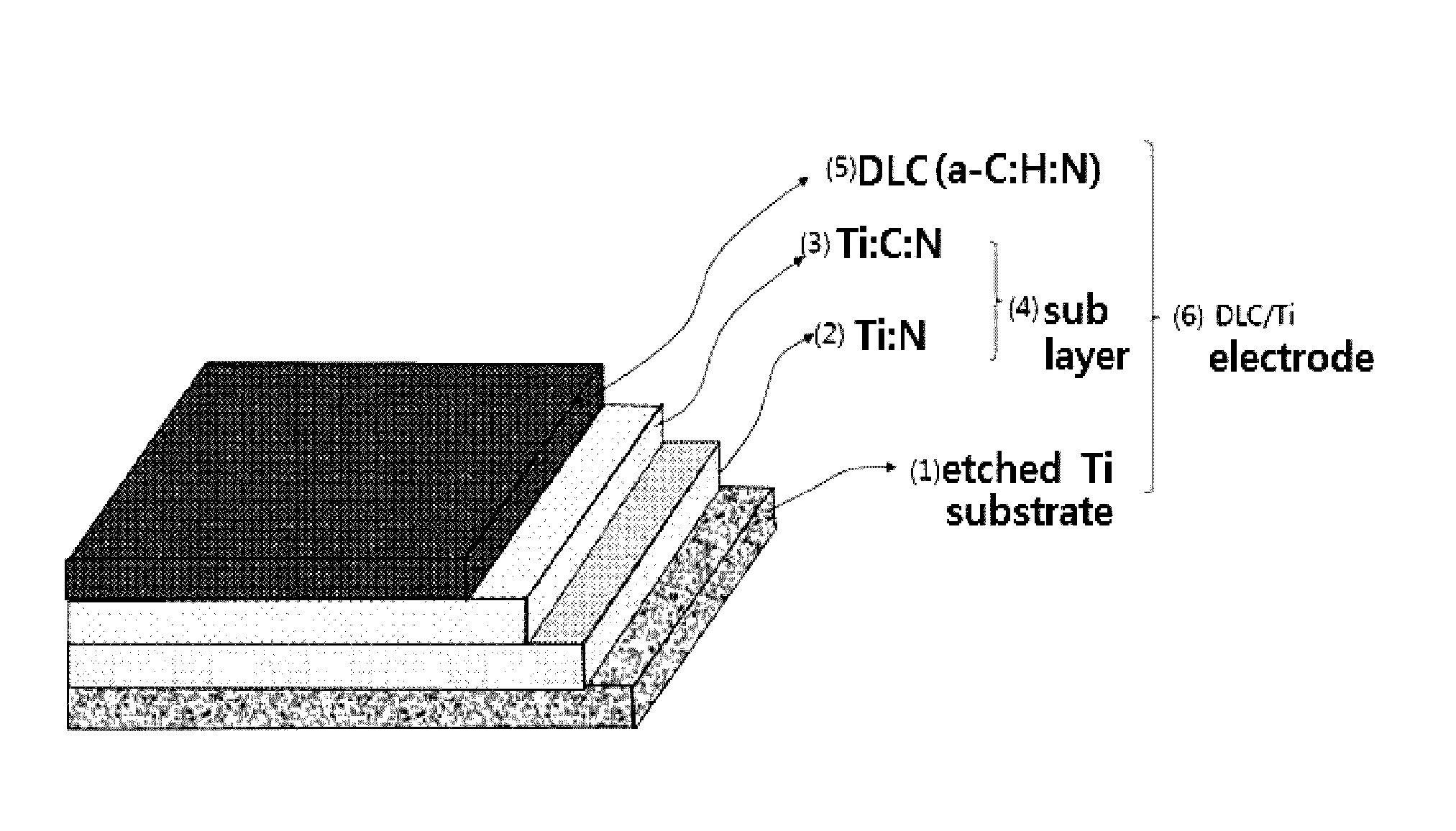

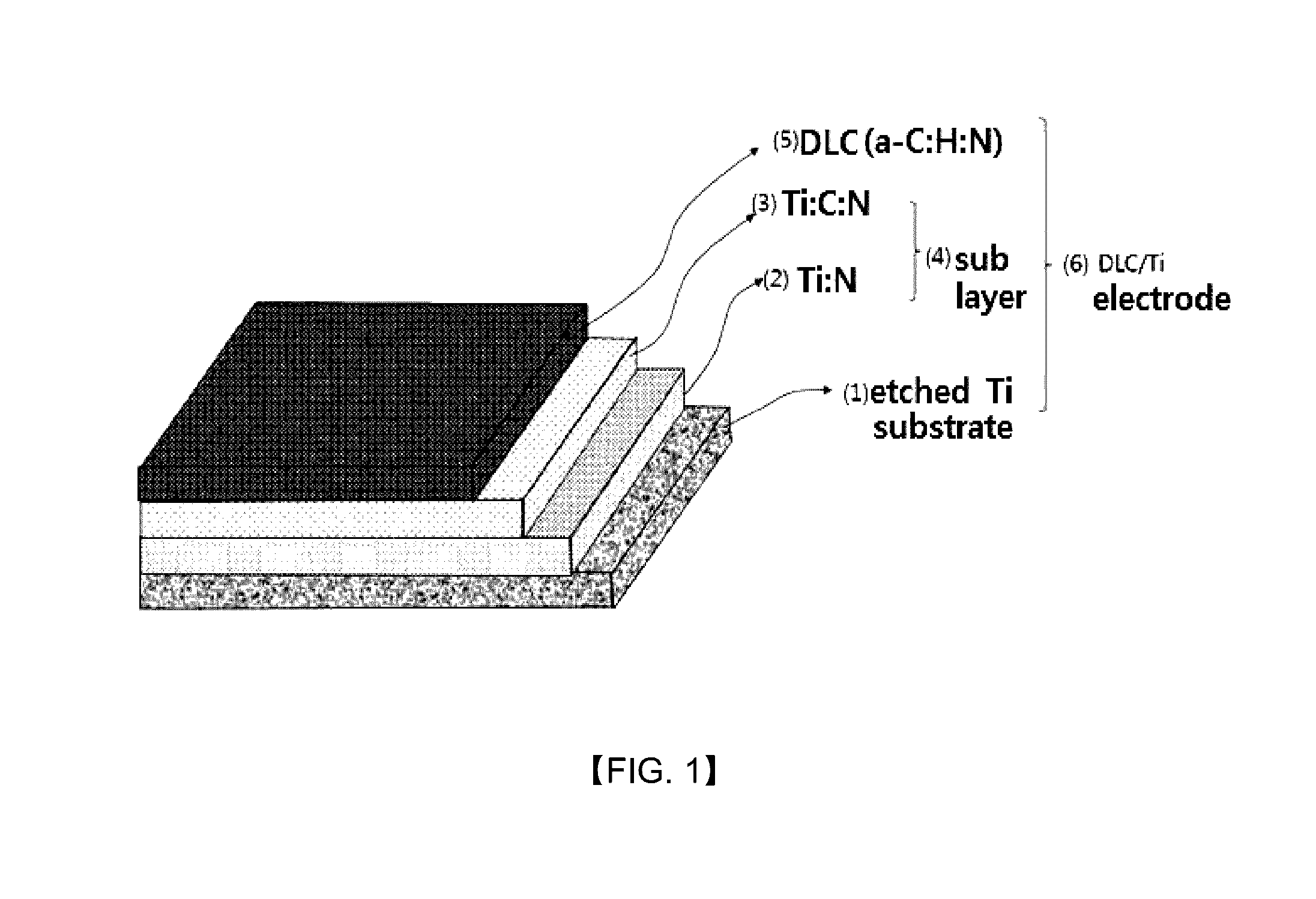

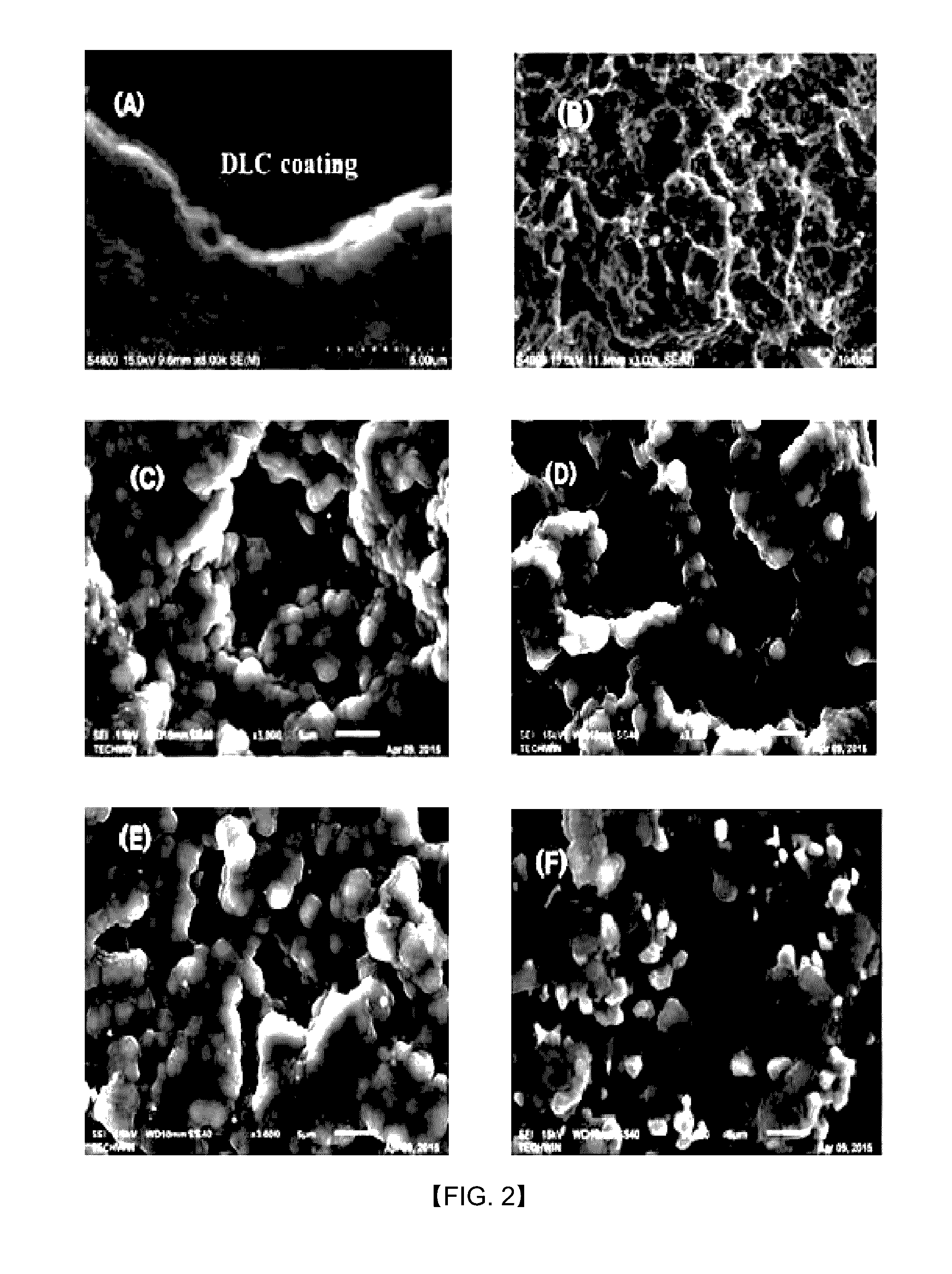

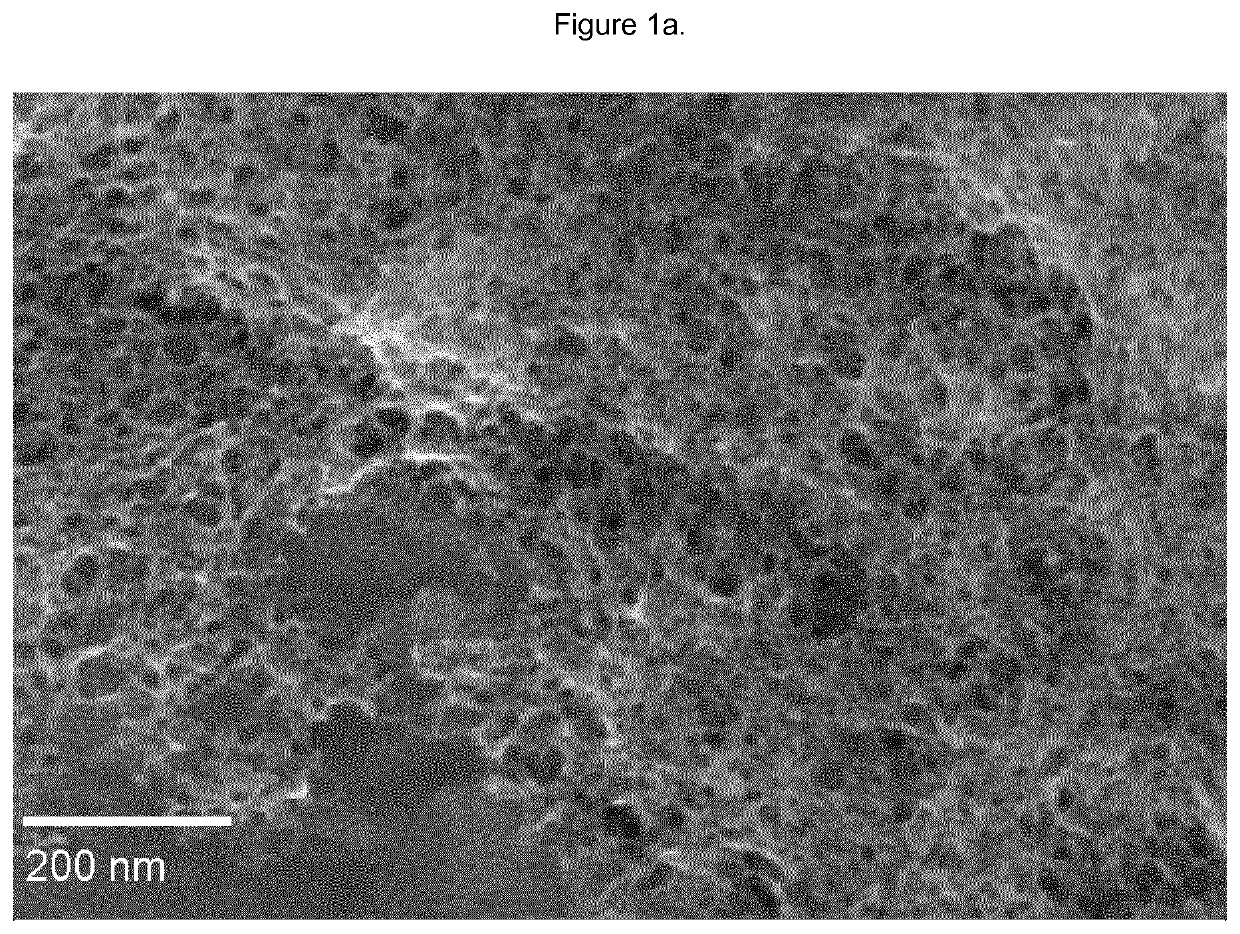

Fabrication method of DLC/Ti electrode with multi-interface layers for water treatment

InactiveUS20160351290A1High hardnessStrong adhesion of the DLC layerNon-conductive material with dispersed conductive materialWide areaSurface resistivity

In this layer, the Ti:N, Ti:C:N sublayer is formed on the etched Ti substrate, and DLC is coated, and afterwards, the proportion of the sp2 carbon structure and the sp3 carbon structure is changed to lower the surface specific resistance, and by having electrochemical traits, the trait of enhancing the adhesion of the Ti substrate and the DLC layer is caused to have high durability and electrochemical traits, providing wide-area water-treatment DLC / Ti electrode manufacture method.

Owner:GLOBAL FRONTIER HYBRID INTERFACE MATERIALS

Zirconium and titanium phosphate coatings for implants and other substrates

PendingUS20210030921A1Improves tissue integrationDifficult to coatDental implantsPharmaceutical delivery mechanismMedicineTitanium phosphate

This invention is directed to coated substrates, wherein the coating comprises titanium phosphate and / or zirconium phosphate. In certain embodiments the substrate is an implant for use in vivo. The invention is also directed to methods for forming coatings comprising or consisting of titanium phosphate and / or zirconium phosphate on the surface of a substrate.

Owner:PROMIMIC

Antistatic hardcoat layer-forming composition, optical film, production method of optical film, polarizing plate and image display device

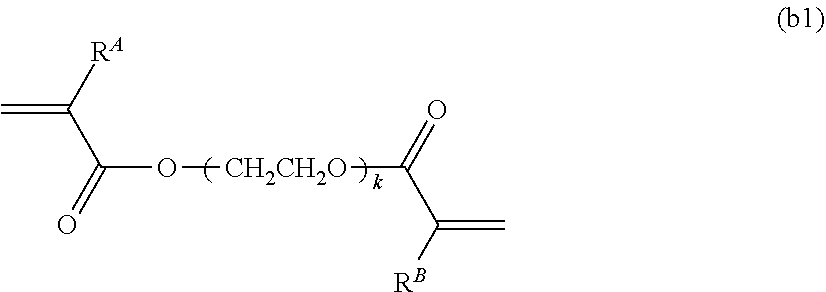

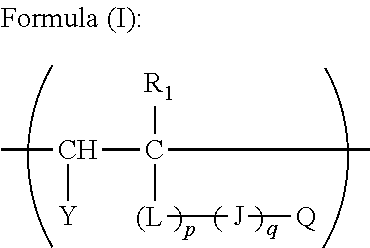

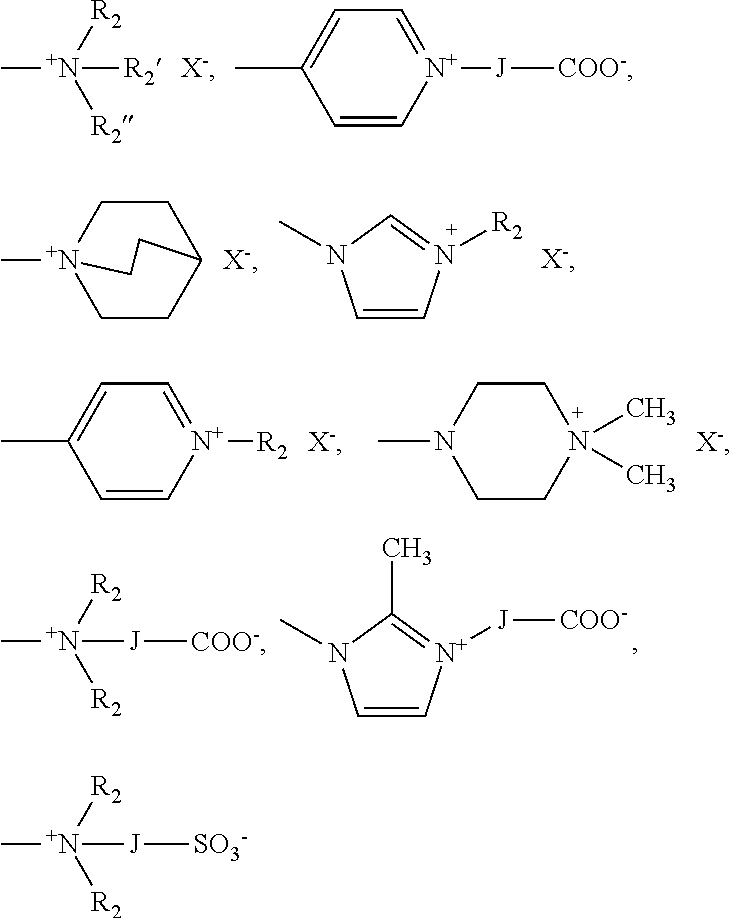

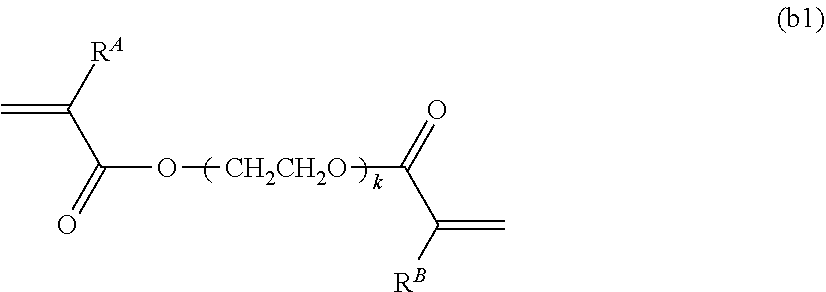

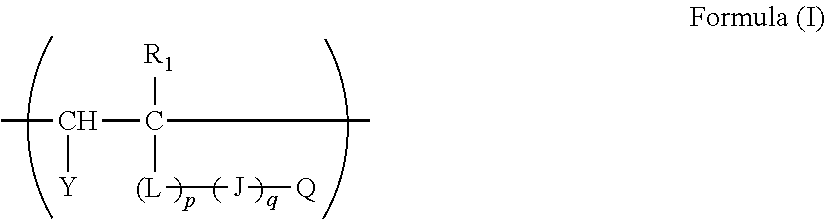

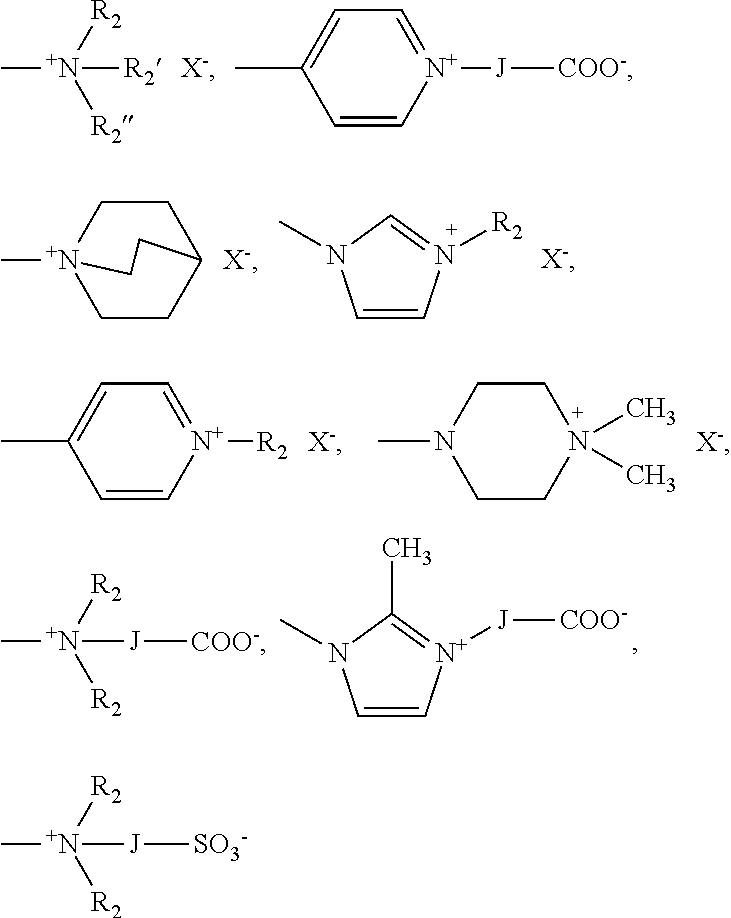

ActiveUS20120077047A1Excellent pencil hardnessImprove antistatic performanceOrganic chemistryMixing methodsPolyethylene oxideDisplay device

A antistatic hard coat layer-forming composition having the following (a), (b), (c) and (d): (a) an ion-conducting compound, (b) a polyethylene oxide compound having one or more photopolymerizable groups, having no hydroxyl group, and having a —(CH2CH2O)k— structure (wherein k represents a number of 1 to 50), (c) a compound having an unsaturated double bond, and (d) a photopolymerization initiator.

Owner:FUJIFILM CORP

Antistatic hardcoat layer-forming composition, optical film, production method of optical film, polarizing plate and image display device

ActiveUS8697246B2Improve antistatic performanceDifficult to coatSynthetic resin layered productsCellulosic plastic layered productsPolyethylene oxideDouble bond

A antistatic hard coat layer-forming composition having the following (a), (b), (c) and (d): (a) an ion-conducting compound, (b) a polyethylene oxide compound having one or more photopolymerizable groups, having no hydroxyl group, and having a —(CH2CH2O)k— structure (wherein k represents a number of 1 to 50), (c) a compound having an unsaturated double bond, and (d) a photopolymerization initiator.

Owner:FUJIFILM CORP

Light colored cylinder head gasket and method of producing

InactiveUS7128322B2Difficult to coatAssembly precisionEngine sealsSealing arrangements for enginesEngineeringSealant

Owner:FREUDENBERG NOK GEN PARTNERSHIP

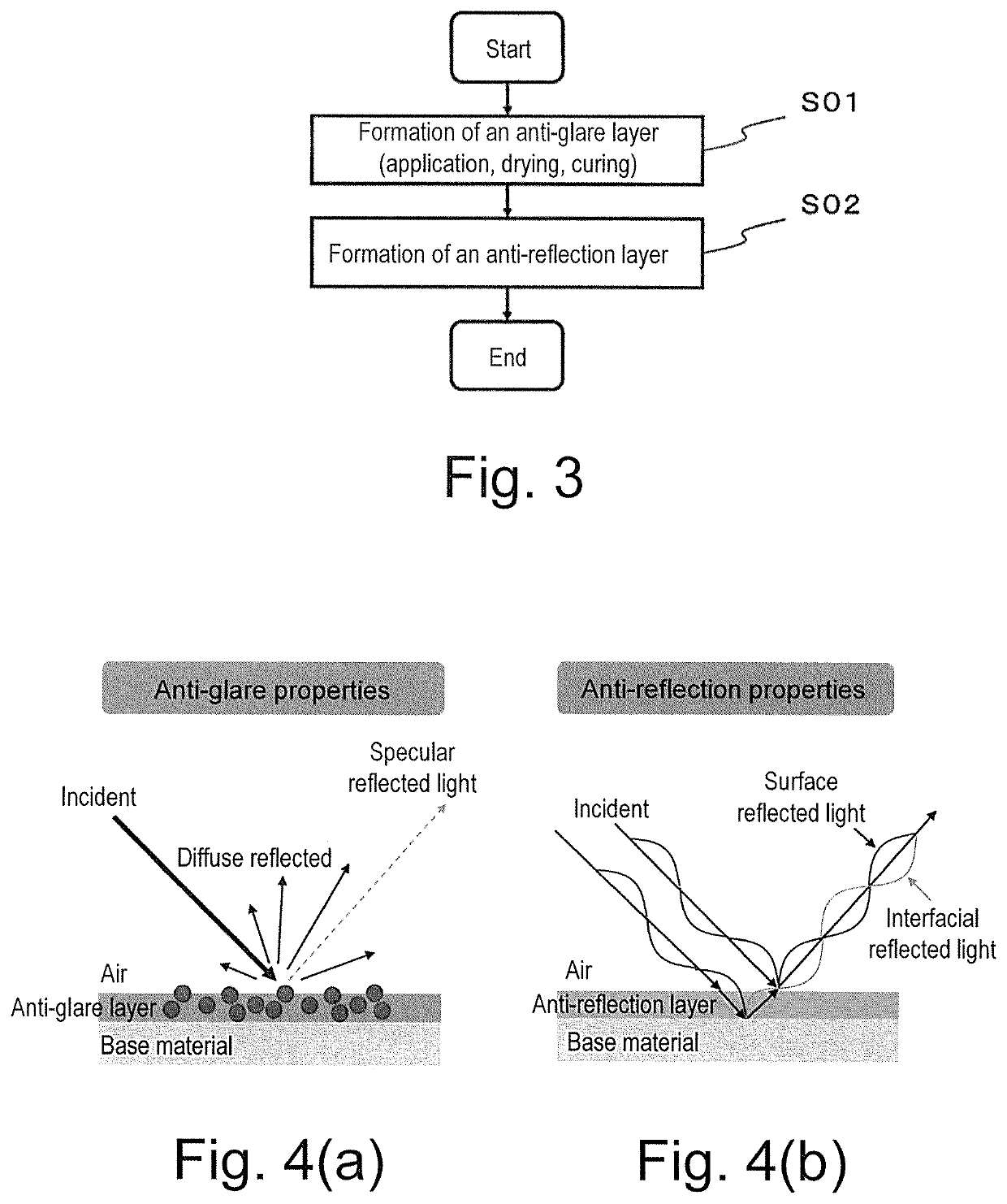

Anti-glare Anti-reflection hard coating film, image display device, and method for producing Anti-glare Anti-reflection hard coating film

InactiveUS20200033506A1Good suppressionSuppress reflected and reflectionDiffusing elementsSynthetic resin layered productsSilica particleDisplay device

The present invention is an anti-glare anti-reflection hard coating film which is capable of providing excellent anti-glare properties and anti-reflection properties, while being suppressed in glare if used in various displays, thereby enabling the achievement of good visibility, and which is also applicable as a film for surface protection. An anti-glare anti-reflection hard coating film includes a substrate in the form of a transparent film; and an anti-glare layer and an anti-reflection layer, which are sequentially arranged on one surface of the substrate in this order from the substrate side. The anti-glare layer has a thickness of 3-15 μm; and the anti-reflection layer has a thickness of 50-150 nm. The anti-glare layer is a cured product obtained by curing a resin composition that contains an active energy ray-curable resin; and the resin composition contains silica particles that have a volume average particle diameter of 0.3-0.9 μm.

Owner:JNC CORP

Curable coating composition

UV curable coating composition includes a non hydrolyzed epoxy- alkoxy-silane, polyfunctional acrylate and / or epoxy compounds and a cationic and / or free-radical photo-initiator; with polyfunctional acrylate and / or epoxy compounds representing more than 40 weight % of the total dry matter and the composition being without any hydrolyzed epoxy-alkoxy-silane. This composition is coated and cured on an optical substrate.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Layered peptide/antigen arrays - for high-throughput antibody screening of clinical samples

InactiveUS20090215073A1Quick and inexpensiveHigh-throughput detectionBiological testingAntibody screeningMembrane configuration

Owner:UNITED STATES OF AMERICA

Hard-coating-coated member, tool, and target

InactiveUS20110197786A1Easily and simply formedImprove wear resistancePigmenting treatmentVacuum evaporation coatingWear resistanceCoating

A member covered with a hard coating having good wear resistance, a tool using the member, and a target for forming the hard coating are provided. A hard-coating-coated member has a hard coating on a substrate, in which the hard coating has a composition of (TiaCrbAlcSidYeRf)(CyNz), the R being at least one element selected from Ho, Sm, Dy and La, and when the subscripts a, b, c, d, e, f, y and z denote atomic ratios respectively, 0.05≦a≦0.3, 0.05≦b≦0.3, 0.4≦c≦0.65, 0≦d≦0.05, 0≦e≦0.05, 0.005≦f≦0.05, a+b+c+d+e+f=1, 0≦y≦0.3, 0.7≦z≦1, and y+z=1 are satisfied.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com