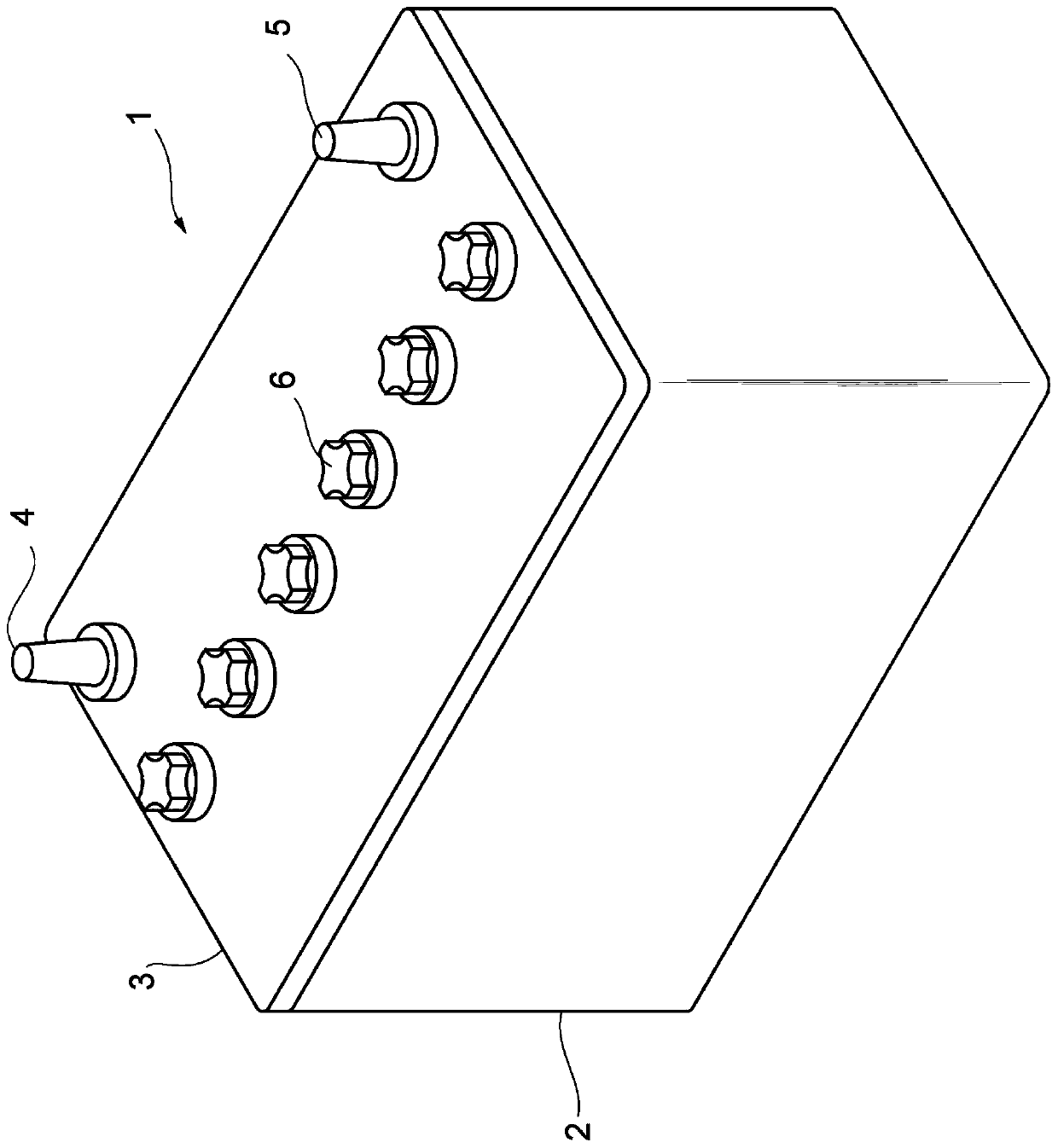

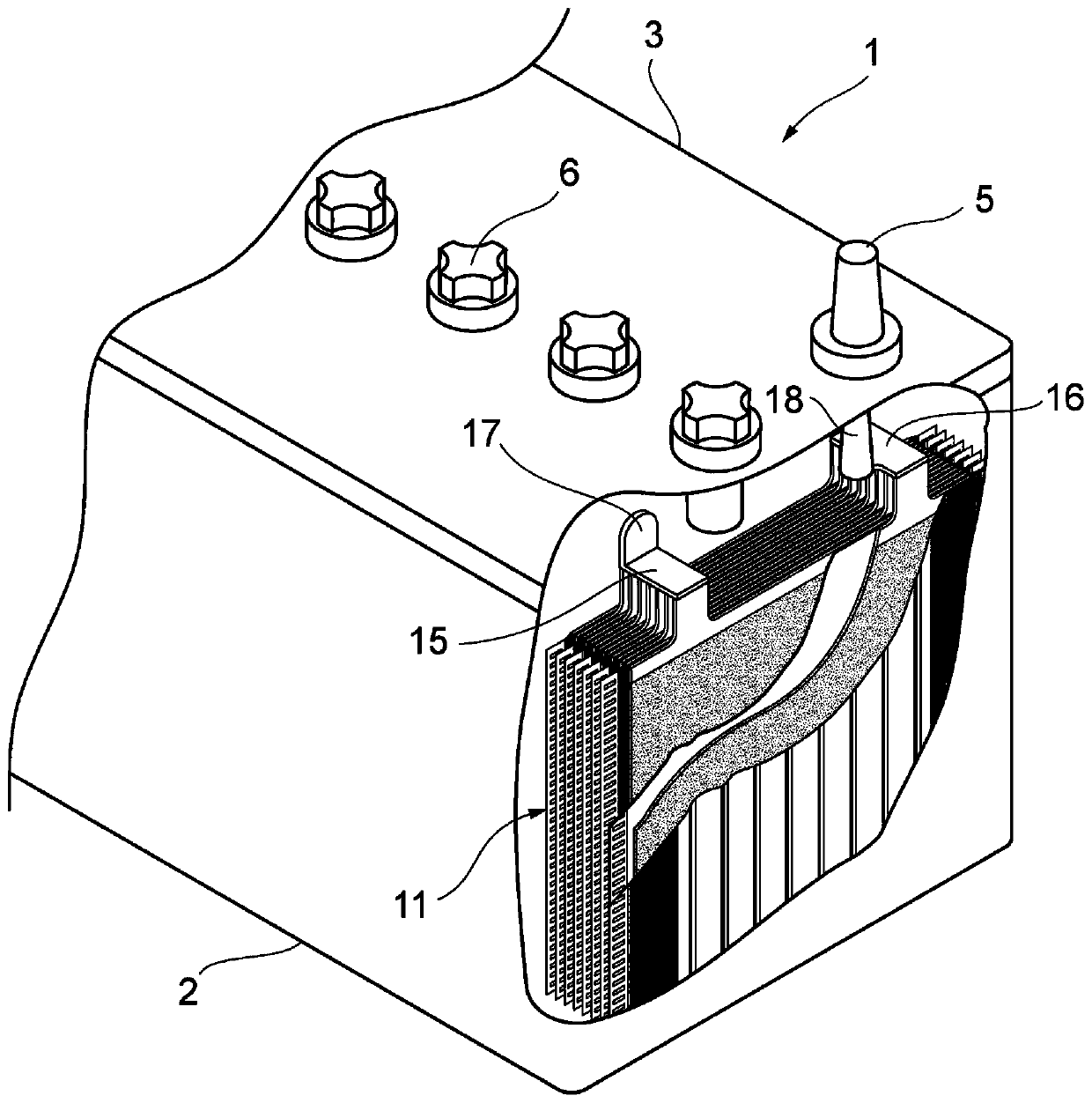

Lead acid storage battery

A technology of lead-acid battery and electrolyte, which is applied in the direction of lead-acid battery, lead-acid battery construction, battery, etc. It can solve the problems of broken ears and inability to output, and achieve the effect of excellent liquid reduction performance and excellent cycle life performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095]

[0096] [Production of positive plate]

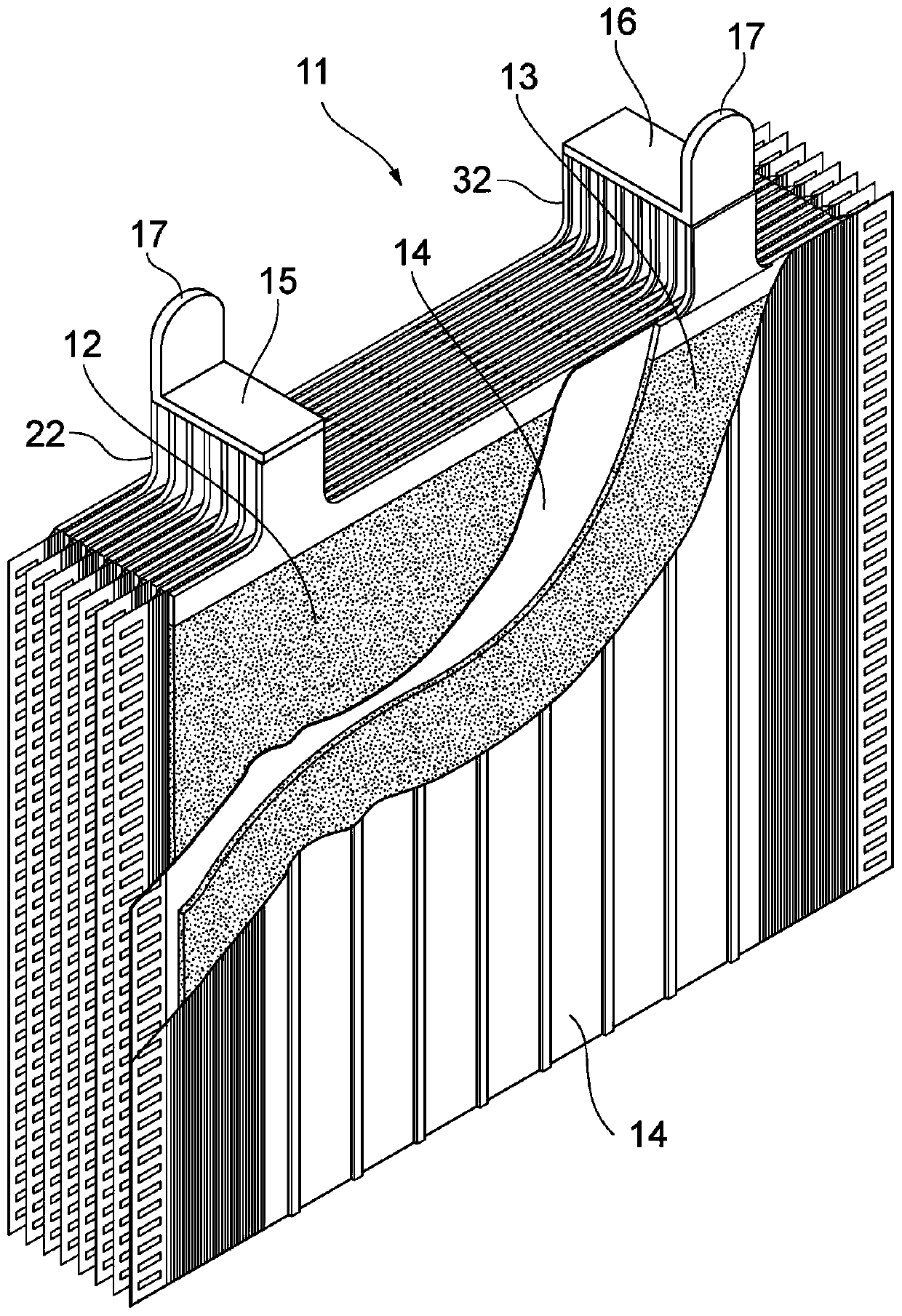

[0097] As the positive electrode current collector, a plate-shaped lead-calcium-tin alloy (calcium content: 0.05% by mass, tin content: 0.5% by mass) is prepared to cut a slit and stretch it so that the slit is enlarged. Expand the grid. 0.07% by mass of acrylonitrile fibers and 0.01% by mass of sodium sulfate were added to the lead powder prepared by the ball mill method as reinforcing short fibers, and dry-mixed to obtain a mixture containing the lead powder. The compounding quantity of acrylonitrile fiber and sodium sulfate is the compounding quantity based on the total mass of lead powder. Next, with respect to above-mentioned mixture containing lead powder, add 10 mass % water and 9 mass % dilute sulfuric acid (specific gravity 1.28) and carry out kneading, thereby make positive electrode material paste (water and dilute sulfuric acid each compounding amount is with lead powder The total mass of the standard compounding...

Embodiment 2~4

[0109] Except having adjusted the filling quantity of a positive electrode material and the filling quantity of a negative electrode material so that M2 / M1 may be the value shown in Table 1, it carried out similarly to Example 1, and obtained the lead acid storage battery of Examples 2-4. The content of the positive electrode active material (based on the total mass of the positive electrode material) and the content of the negative electrode active material (based on the total mass of the negative electrode material) after the chemical conversion in the lead accumulators of embodiments 2 to 4 are the same as that of the embodiment 1 is the same.

Embodiment 5~9

[0111] When producing the negative electrode current collector, the thickness D (thickness of the rolled sheet) of the negative electrode lug and the thickness d of the surface layer were rolled in such a manner that the values shown in Table 1 were carried out, except that it was the same as in Example 1. According to the operation, the lead storage batteries of Examples 5-9 were obtained. In addition, the lead-calcium-tin alloy and the metal sheet used in Example 1 were used for the lead-calcium-tin alloy and the metal sheet. The content of the positive electrode active material (based on the total mass of the positive electrode material) and the content of the negative electrode active material (based on the total mass of the negative electrode material) after the chemical conversion in the lead storage battery of embodiments 5 to 9 are the same as those of the examples 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com