A method for removing mist droplets in gas by combining expanded bed of glass spheres with coalescer

An expanded bed and coalescer technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as poor purification efficiency of fine mist droplets, and achieve fast and efficient adsorption, high environmental friendliness, and corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

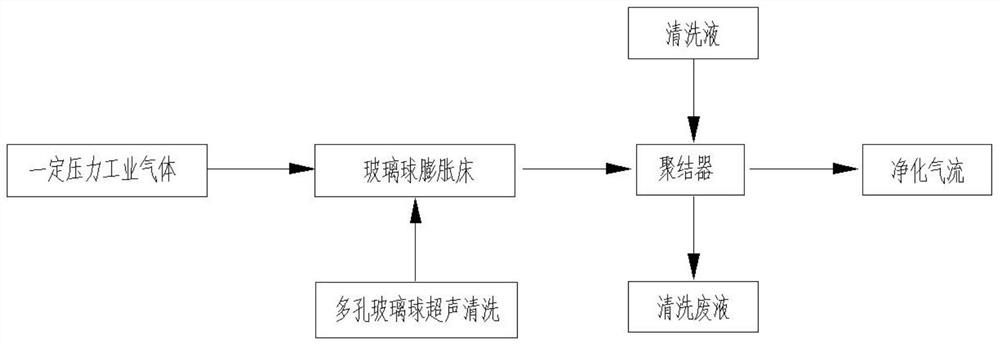

[0027] Such as figure 1 Shown, the present invention utilizes glass sphere expanded bed in conjunction with coalescer to carry out the implementation steps of the purifying method that removes mist droplet in gas as follows:

[0028] (1) Pass the industrial airflow (synthetic waste gas from organosilicon monomer) containing droplet size of 1-10 μm and concentration of 200-500ppm into the expanded bed of glass spheres filled with porous glass spheres, and carry out Preliminary adsorption to obtain a preliminary purified gas flow; among them, the velocity of the industrial gas flow in the glass bead expanded bed is at the critical fluidization velocity, so that the glass bead expanded bed is in a slightly expanded state; the glass bead expanded bed is distributed in three layers from bottom to top Porous glass spheres of different particle sizes, the particle diameters of the porous glass spheres are 5mm, 3mm and 1mm respectively, and the corresponding filling heights account fo...

Embodiment 2

[0031] Such as figure 1 Shown, the present invention utilizes glass sphere expanded bed in conjunction with coalescer to carry out the implementation steps of the purifying method that removes mist droplet in gas as follows:

[0032](1) Pass the industrial airflow (synthetic waste gas from organosilicon monomer) containing droplet size of 1-10 μm and concentration of 200-500ppm into the expanded bed of glass spheres filled with porous glass spheres, and carry out Preliminary adsorption to obtain a preliminary purified gas flow; among them, the velocity of the industrial gas flow in the glass bead expanded bed is at the critical fluidization velocity, so that the glass bead expanded bed is in a slightly expanded state; the glass bead expanded bed is distributed in three layers from bottom to top Porous glass spheres of different particle sizes, the particle diameters of the porous glass spheres are 5mm, 3mm and 1mm respectively, and the corresponding filling heights account for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com