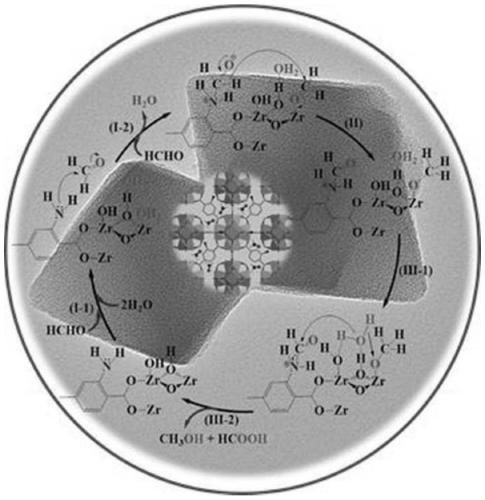

UiO-66 based MOF (metal organic framework) material for indoor formaldehyde purification at room temperature and application of material

An organic framework, uio-66 technology, applied in other chemical processes, chemical instruments and methods, gas treatment, etc., to achieve the effect of high speed, conducive to diffusion transfer, and rapid adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

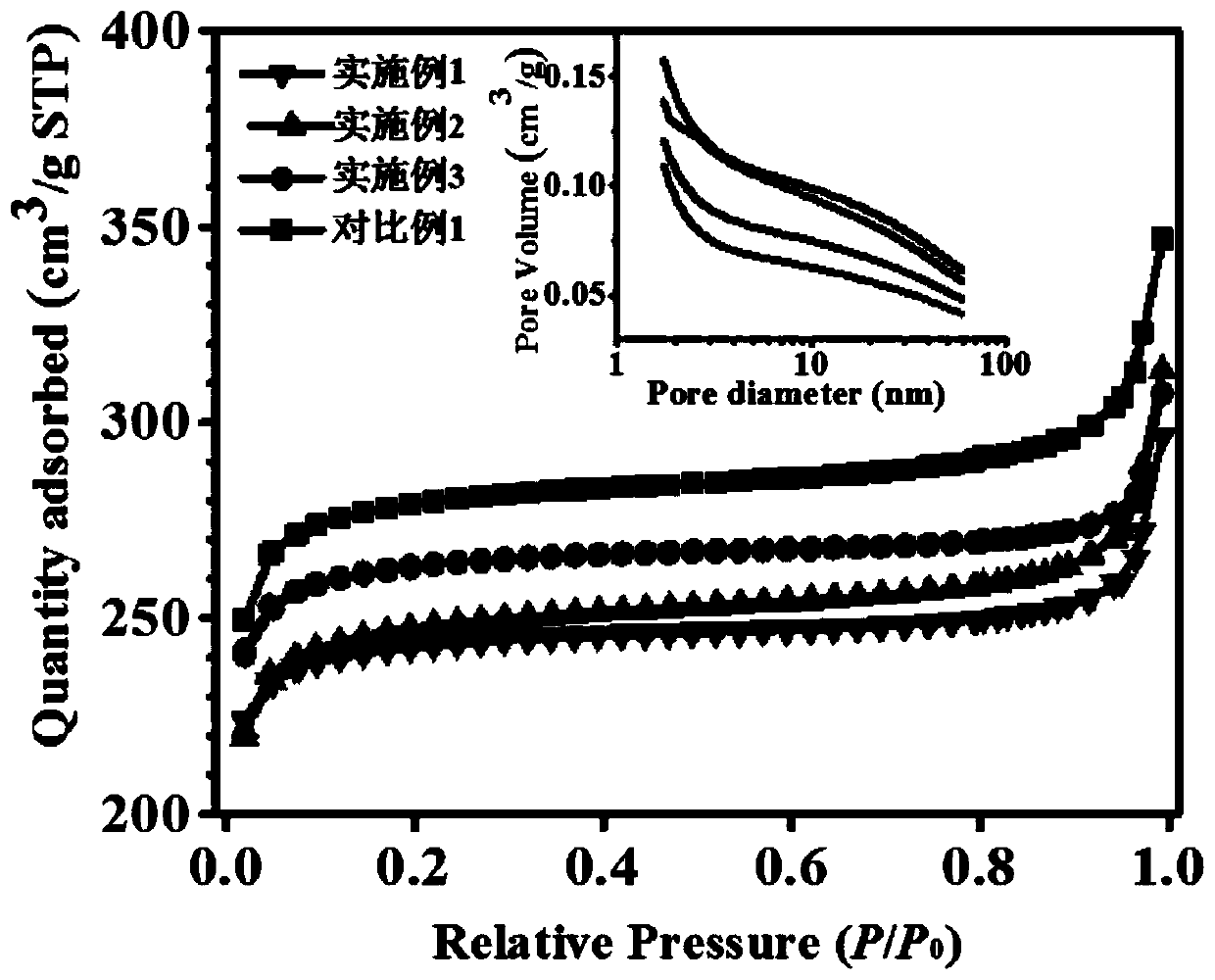

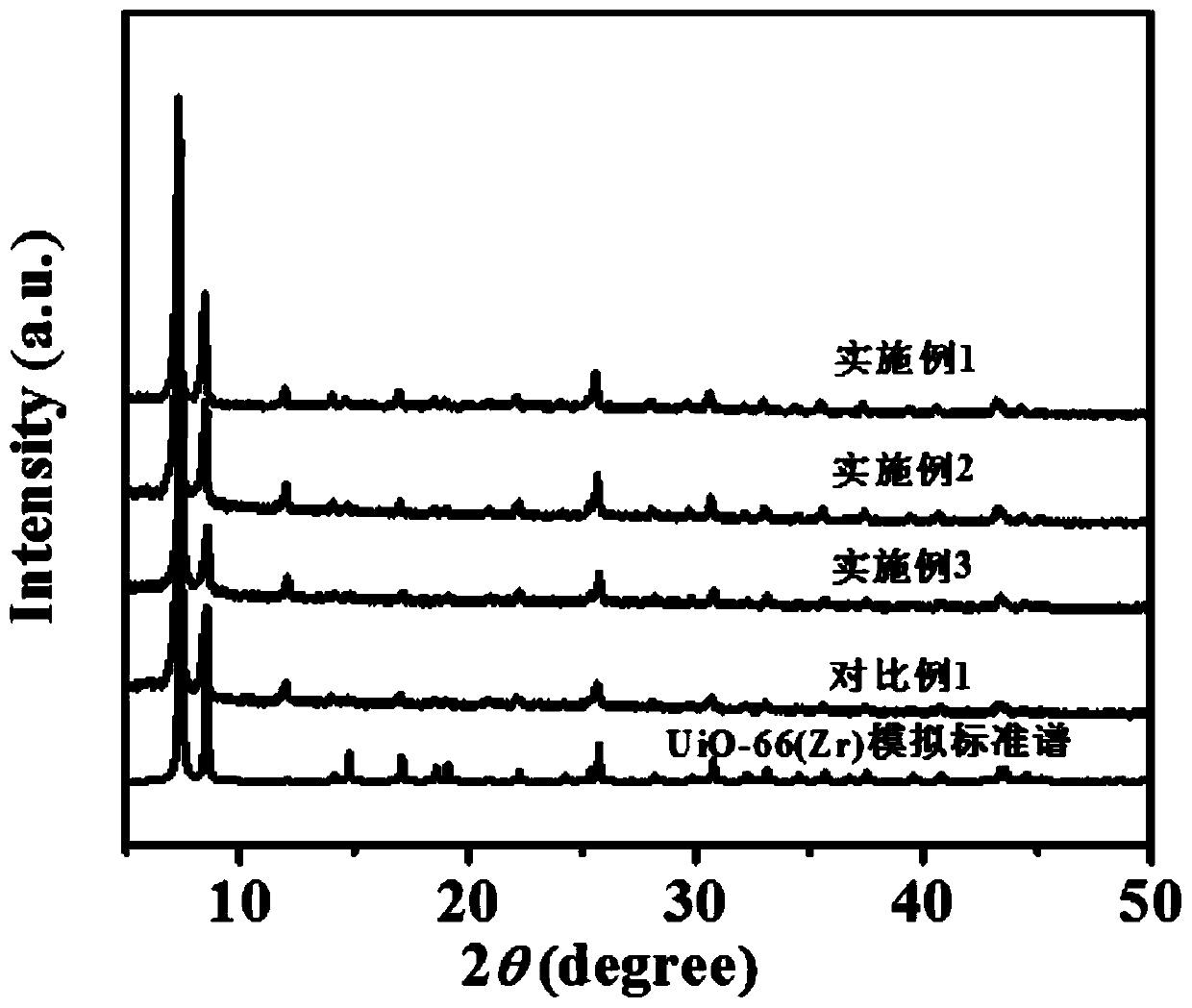

Embodiment 1

[0064] Example 1 Preparation of a multi-defective amine functionalized metal-organic framework material

[0065] Amine-functionalized metal-organic frameworks were prepared according to the following method:

[0066] S1. At room temperature, 233mg (1mmol) zirconium tetrachloride (ZrCl 4 ) was stirred and dissolved in 50mL of N,N-dimethylformamide (DMF) solvent;

[0067] S2. Add 181 mg (1 mmol) of 2-aminoterephthalic acid (ATA) into the S1 mixture, and stir at a constant speed until the solute is completely dissolved, and the solution is clear and transparent;

[0068] S3. After step S2, the mixed solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene with a volume of 100ml, reacted at 120°C for 48h, and then naturally cooled to room temperature;

[0069] S4. After step S3, filter to obtain a solid product, wash with DMF and anhydrous methanol three times respectively, and freeze-dry, that is, the freeze-drying parameters are: freezin...

Embodiment 2

[0070] Example 2 Preparation of a multi-defect amine functionalized metal-organic framework material

[0071] Amine-functionalized metal-organic frameworks were prepared according to the following method:

[0072] S1. At room temperature, 233mg (1mmol) zirconium tetrachloride (ZrCl 4 ) was stirred and dissolved in 50mL of N,N-dimethylformamide (DMF) solvent;

[0073] S2. Add 92mg (0.5mmol) of 2-aminoterephthalic acid (ATA) and 83mg (0.5mmol) of terephthalic acid (BDC) into the S1 mixture, stir at a constant speed until the solute is completely dissolved, and the solution is clear and transparent shape;

[0074] S3. After step S2, the mixed solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene with a volume of 100ml, reacted at 120°C for 48h, and then naturally cooled to room temperature;

[0075] S4. After step S3, filter to obtain a solid product, wash with DMF and anhydrous methanol three times respectively, and freeze-dry, that ...

Embodiment 3

[0076] Example 3 Preparation of a multi-defective amine functionalized metal-organic framework material

[0077] Amine-functionalized metal-organic frameworks were prepared according to the following method:

[0078] S1. At room temperature, 233mg (1mmol) zirconium tetrachloride (ZrCl ) was stirred and dissolved at a constant speed in 50mL of N,N-dimethylformamide (DMF) solvent;

[0079] S2. Add 45.25 mg (0.25 mmol) of 2-aminoterephthalic acid (ATA) and 124.5 mg (0.75 mmol) of terephthalic acid (BDC) into the S1 mixture, stir at a constant speed until the solute is completely dissolved, and the solution is clear and transparent;

[0080] S3. After step S2, the mixed solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene with a volume of 100ml, reacted at 120°C for 48h, and then naturally cooled to room temperature;

[0081] S4. After step S3, filter to obtain a solid product, wash with DMF and anhydrous methanol three times respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com