MEMS microgravity sensor chip with quasi-zero stiffness characteristic preloaded based on electric heating

A sensor chip, quasi-zero stiffness technology, applied in the field of MEMS microgravity sensor chips, can solve the problems of small feature size of the anti-spring structure, high manufacturing process requirements, and reduced quality of the mass block, so as to achieve easy production and simple chip structure. , the effect of increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

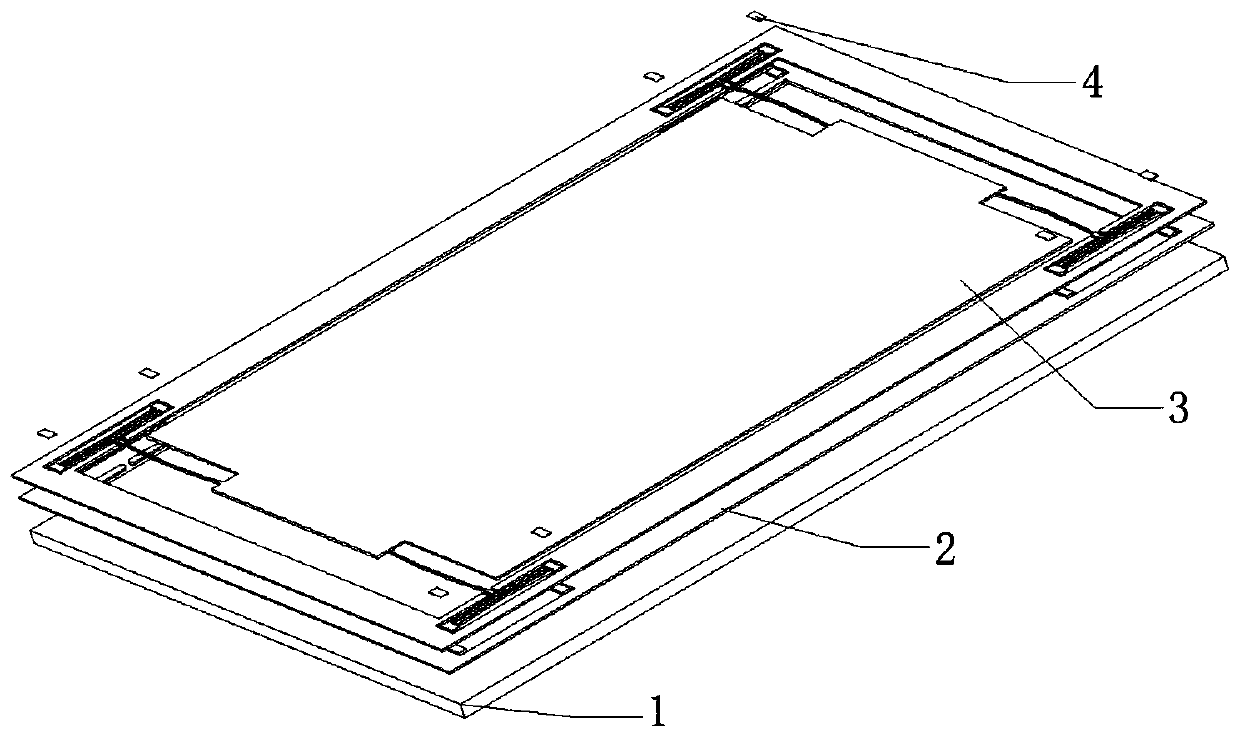

[0026] refer to figure 1 , a MEMS microgravity sensor chip with quasi-zero stiffness characteristics based on electrothermal preloading, comprising a single crystal silicon substrate 1, a silicon dioxide insulating layer 2 is grown on the single crystal silicon substrate 1, and the growth thickness is 2-3 μm, A monocrystalline silicon structural layer 3 is bonded on the silicon dioxide insulating layer 2, a metal electrode layer 4 is deposited on the electrode anchor point 3-2 of the monocrystalline silicon structural layer 3, and a MEMS is fabricated in the monocrystalline silicon structural layer 3. Acceleration sensor chip; the thickness of the monocrystalline silicon structure layer 3 is 40 μm, and the plane size is 13 mm×16 mm.

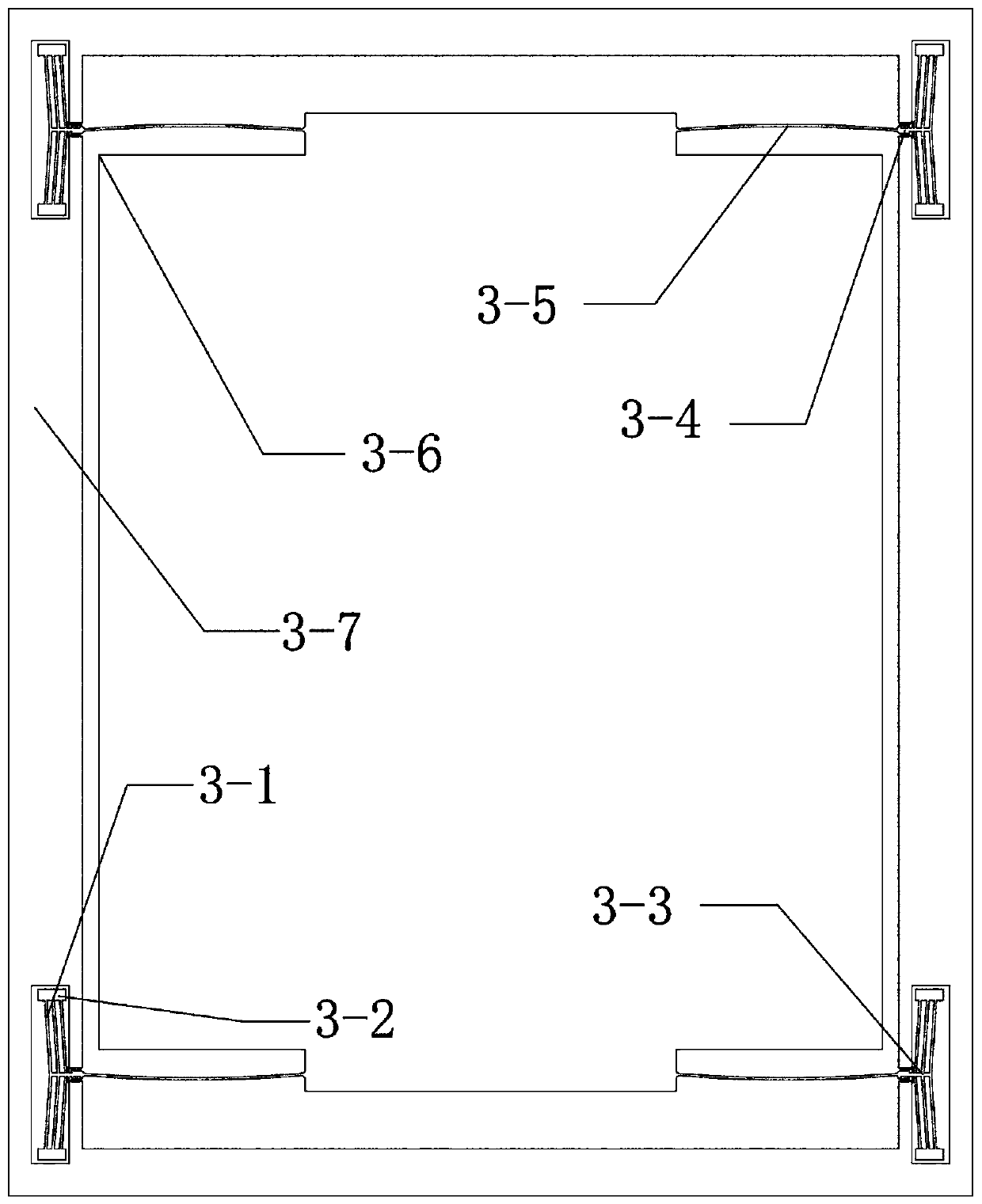

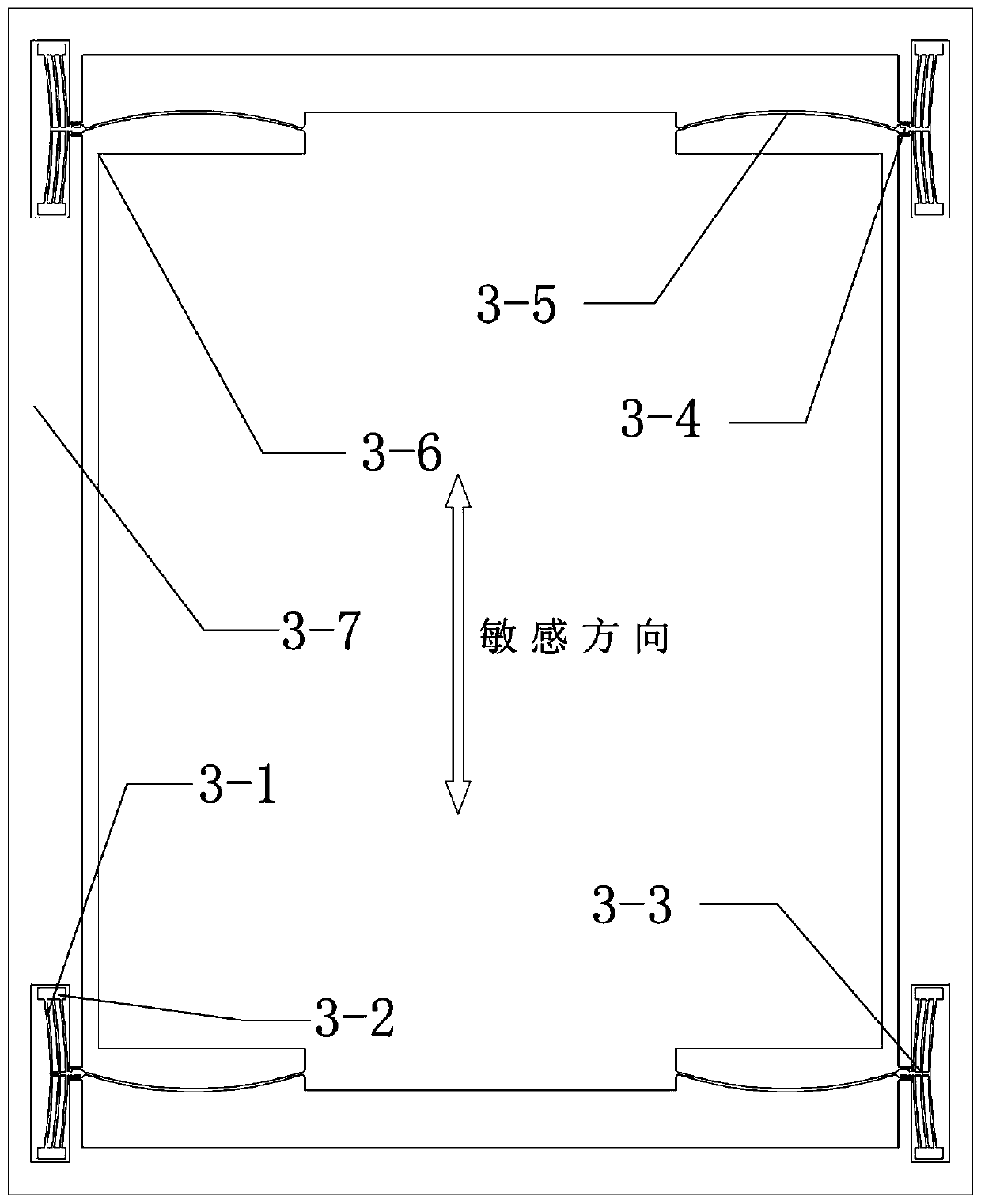

[0027] refer to figure 2 and image 3 , the MEMS acceleration sensor chip includes a chip frame 3-7, and the four ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com