Preparation method of carbon quantum dots

A technology of carbon quantum dots and mass fraction is applied in the field of preparation of carbon quantum dots, which can solve the problems of low utilization rate of urban sludge resources, and achieve the effects of good economic benefits, low production cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

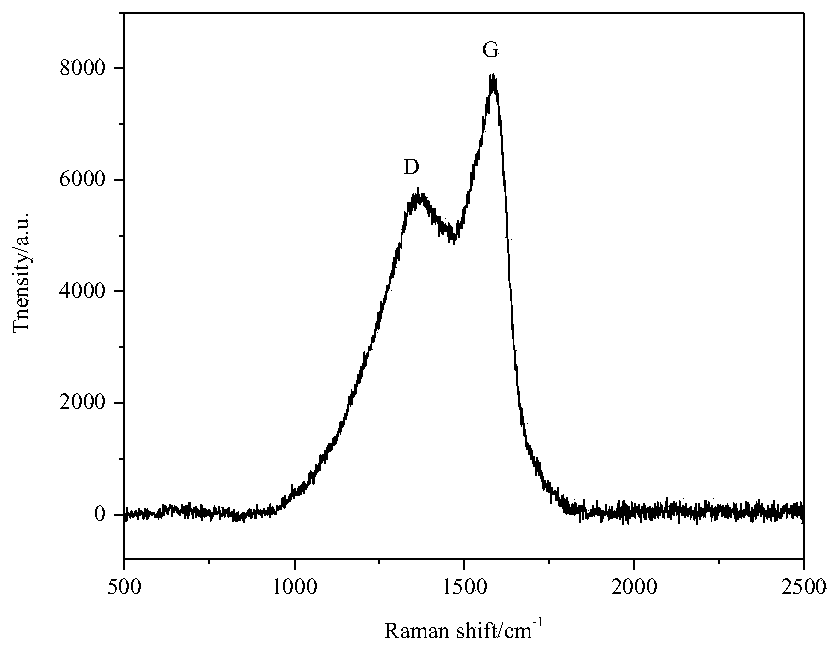

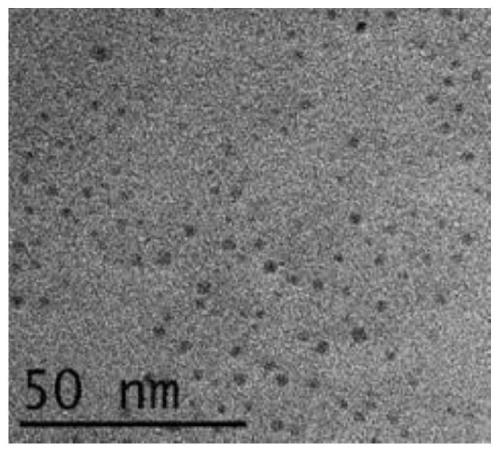

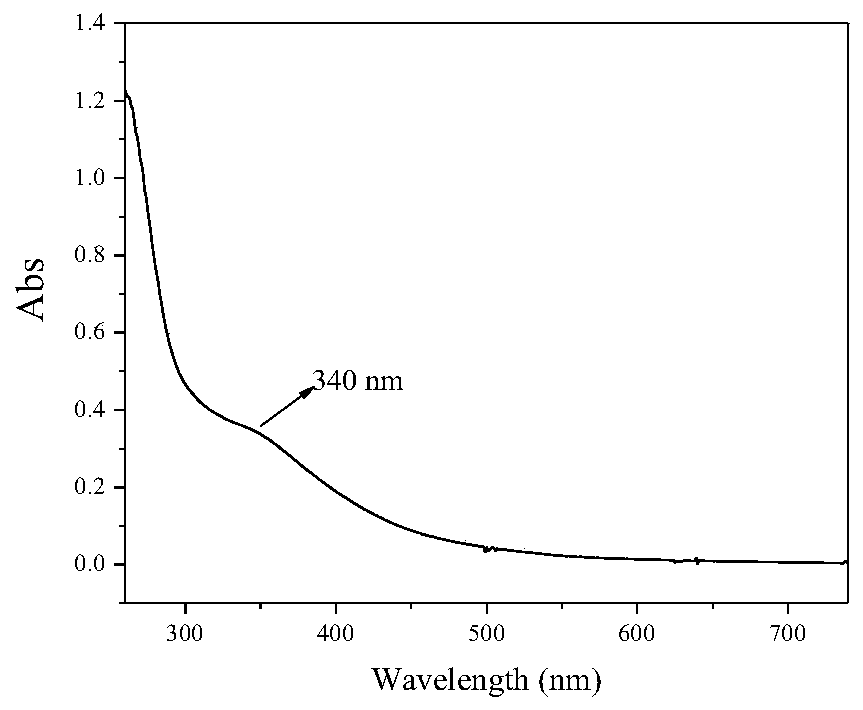

Image

Examples

Embodiment 1

[0028] a. Select urban sludge with a water content of 83%, carbonize the ground urban sludge at 500°C for 5 hours at high temperature to obtain a black solid, grind the black solid again to make its particle size 200 mesh, and obtain a black solid Powder;

[0029] b. Weigh 0.2 g of the black powder obtained in step a and place it in a flask, then add 40 g of nitric acid with a mass fraction of 65%, and ultrasonicate the mixed solution for 140 min at 30 KHz to obtain solution I, and then The solution I was heated to reflux at 140°C for 15 hours, and cooled to room temperature to obtain solution II;

[0030] c. Filtrate the solution II to obtain a filtrate; centrifuge the filtrate at 8000r / min for 35min, take the supernatant and dialyze for 28h to obtain an aqueous solution of carbon quantum dots.

Embodiment 2

[0032] a. Select municipal sludge with a water content of 80%, and carbonize the ground municipal sludge at 200° C. for 8 hours to obtain a black solid. Grind the black solid again to make its particle size 500 mesh to obtain a black solid. Powder;

[0033] b. Weigh 0.1 g of the black powder obtained in step a and place it in a flask, then add 40 g of nitric acid with a mass fraction of 60%, and ultrasonicate the mixed solution for 260 min at 28 KHz to obtain solution I, and then The solution I was heated to reflux at 140°C for 5 hours, and cooled to room temperature to obtain solution II;

[0034] c. Filtrate the solution II to obtain a filtrate; centrifuge the filtrate at 4000 r / min for 60 min, take the supernatant and dialyze for 8 h to obtain an aqueous solution of carbon quantum dots.

Embodiment 3

[0036] a. Select municipal sludge with a water content of 85%, carbonize the ground municipal sludge at 800°C for 2 hours at high temperature to obtain a black solid, grind the black solid again to make its particle size 50 mesh, and obtain a black solid Powder;

[0037] b. Weigh 0.1 g of the black powder obtained in step a and place it in a flask, then add 10 g of nitric acid with a mass fraction of 68%, ultrasonicate the mixed solution for 20 min at 40 KHz to obtain solution I, and then The solution I was heated to reflux at 60°C for 24 hours, and cooled to room temperature to obtain solution II;

[0038] c. Filtrate the solution II to obtain a filtrate; centrifuge the filtrate at 12000 r / min for 15 minutes, take the supernatant and dialyze for 48 hours to obtain an aqueous solution of carbon quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com