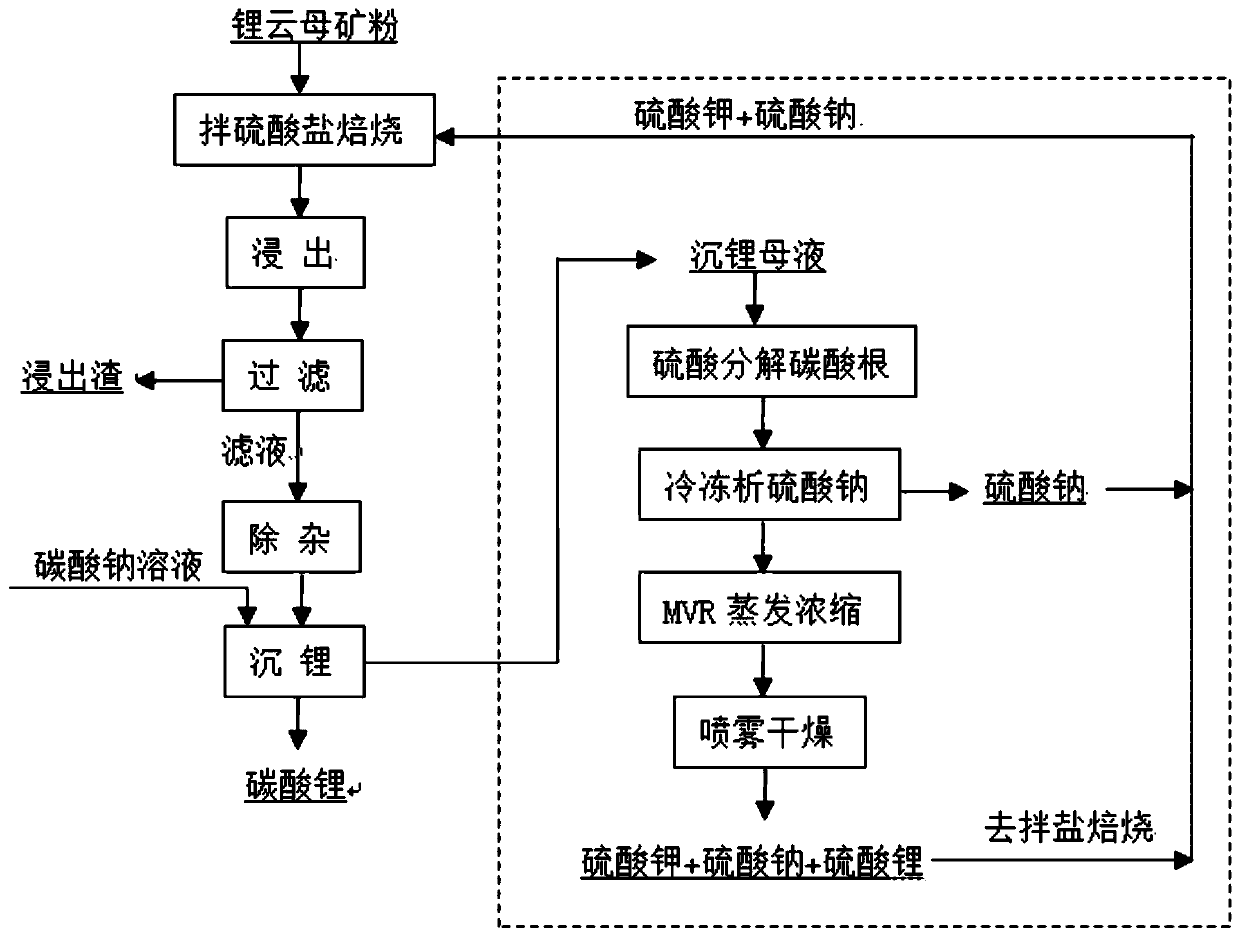

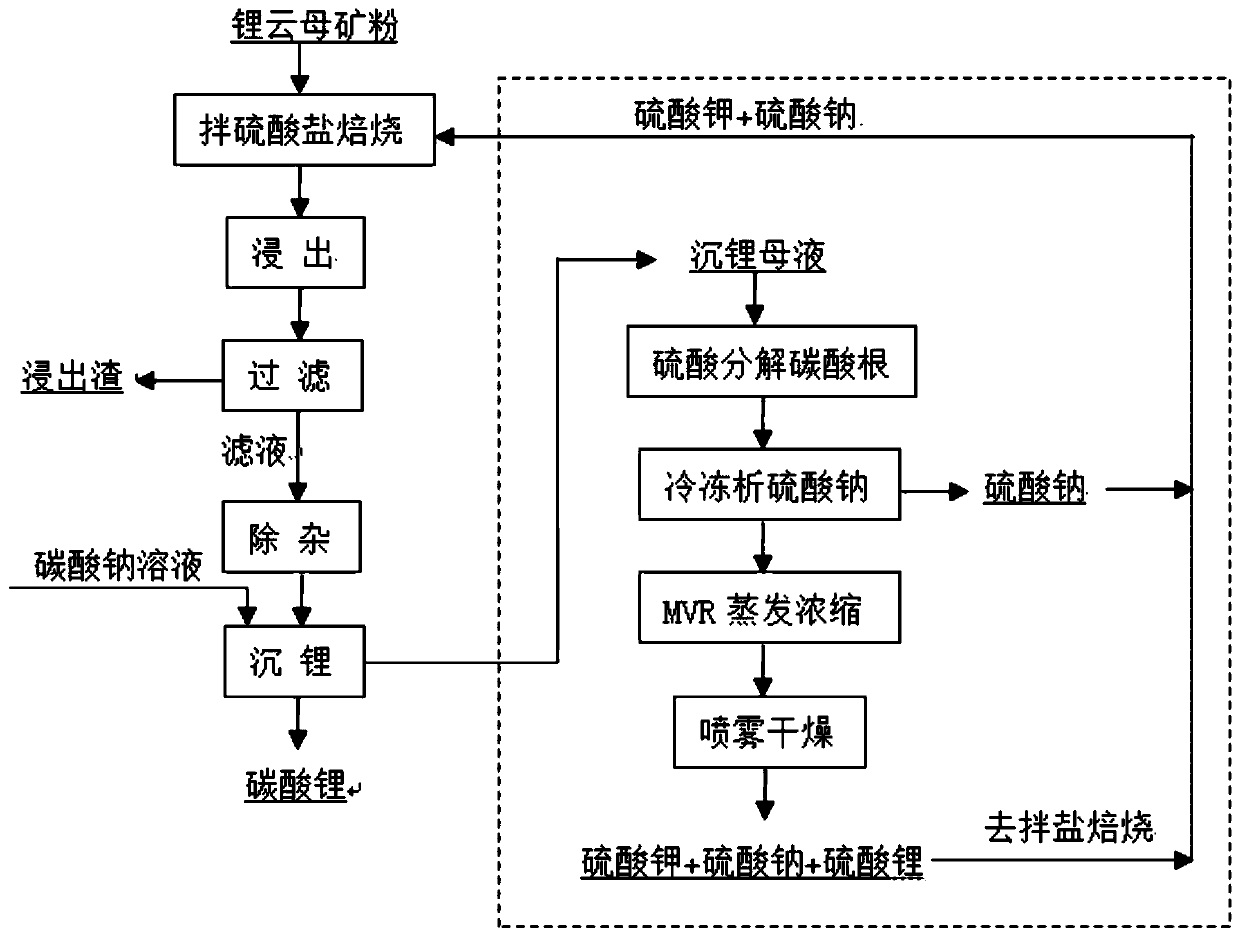

Treatment method of lithium carbonate precipitation mother liquor

A technology of precipitation mother liquor and treatment method, applied in the field of ore extraction of lithium, can solve the problems of scaling and clogging of evaporation and concentration equipment, inability to obtain concentration and enrichment, low concentration of concentrated lithium, etc. The effect of continuous and stable operation and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Measure the lithium carbonate precipitation mother liquor in 1000ml table 1, operate as follows:

[0045] ① Add concentrated sulfuric acid to destroy the remaining CO in the lithium carbonate precipitation mother liquor 3 2- , the final pH value is 8.0;

[0046] ② Freeze the precipitated mother liquor to precipitate sodium sulfate and separate it by filtration. The freezing temperature is 5°C to obtain 855ml mother liquor and 232.4g Na 2 SO 4 10H 2 O;

[0047] ③ In the beaker, evaporate and concentrate the mother liquor after freezing and analyzing sodium, and when concentrated to a volume of 300ml, a small amount of sulfate crystals are separated out;

[0048] ④Put the beaker containing the concentrated solution into an oven for drying and dehydration at a drying temperature of 105°C to obtain a mixed salt of potassium sulfate, sodium sulfate and lithium sulfate, which contains 65g of potassium sulfate, 82g of sodium sulfate, and 13g of lithium sulfate;

[0049] ...

Embodiment 2

[0051] Take 10m from Table 1 3 Lithium carbonate precipitation mother liquor, operate as follows:

[0052] ① Add concentrated sulfuric acid to destroy the remaining CO in the lithium carbonate precipitation mother liquor 3 2- , the terminal pH value is 7.5;

[0053] ②The precipitated mother liquor was frozen to precipitate sodium sulfate and separated by filtration. The freezing temperature was 0°C to obtain 8.4m 3 Mother liquor and 2534kg Na 2 SO 4 10H 2 O;

[0054] ③ Evaporate and concentrate the mother liquor after freezing and separating out sodium in the MVR to a volume of 2.7m 3 , a small amount of sulfate crystals precipitated;

[0055] ④Pump the concentrate into a spray dryer for drying and dehydration at a drying temperature of 150°C to obtain a mixed salt of potassium sulfate, sodium sulfate and lithium sulfate, which contains 646kg of potassium sulfate, 785kg of sodium sulfate, and 131kg of lithium sulfate;

[0056] ⑤All the sodium sulfate, potassium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com