Rare earth-doped halide glass ceramics and preparation method thereof

A glass-ceramic and rare earth doping technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of low luminous intensity of fluorescent glass, avoid aging and discoloration, increase the possibility of practical use, and enhance Effect of fluorescence output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0029] The raw material composition of Example 1-8# fluorozirconate glass ceramics is shown in Table 1:

[0030] Weighing:

[0031]

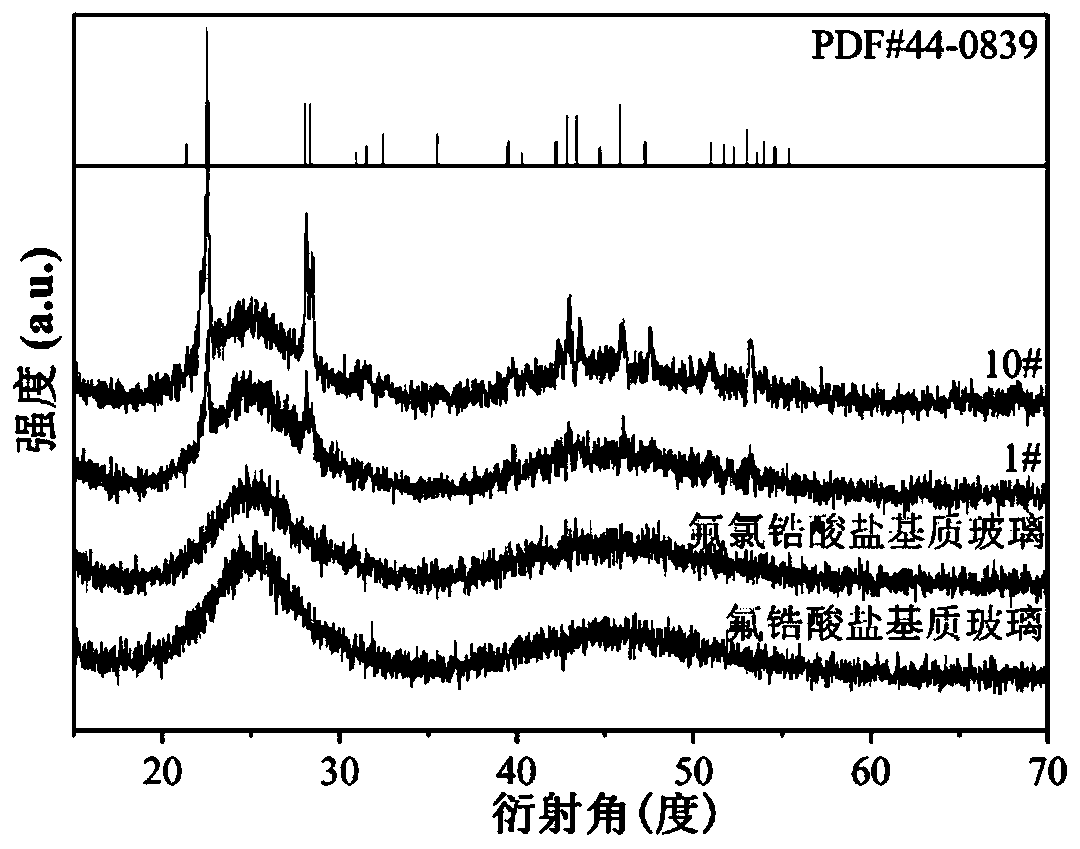

[0032] The preparation process of the fluorozirconate matrix glass: the weighed raw materials are mixed and ground to obtain the mixture. The mixture is placed in a covered platinum crucible, melted and clarified in a high-temperature electric furnace above 910℃, and the molten glass is poured in On the preheated stainless steel mold, the glass block was transferred to an annealing furnace at 330°C for annealing, kept for 6 hours, and then reduced to 100°C at a rate of 10°C / h. The furnace was cooled to room temperature, and the glass sample was taken out after complete cooling. Pr 3+ / Ho 3+ Co-doped fluorozirconate matrix glass. The XRD pattern of fluorozirconate matrix glass is as follows figure 1 As shown, the sample has two typical scattering peak packets near 25° and 47°, and no devitrification peak appears. The ultraviolet fluorescence spectru...

Embodiment 1

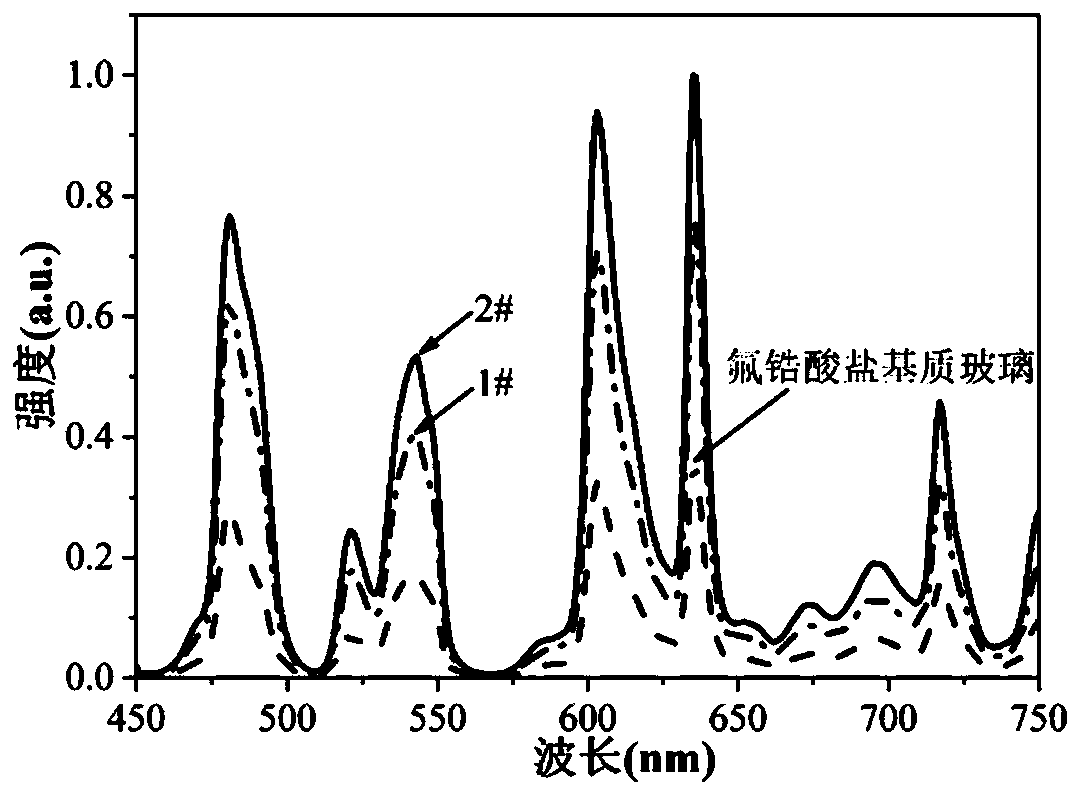

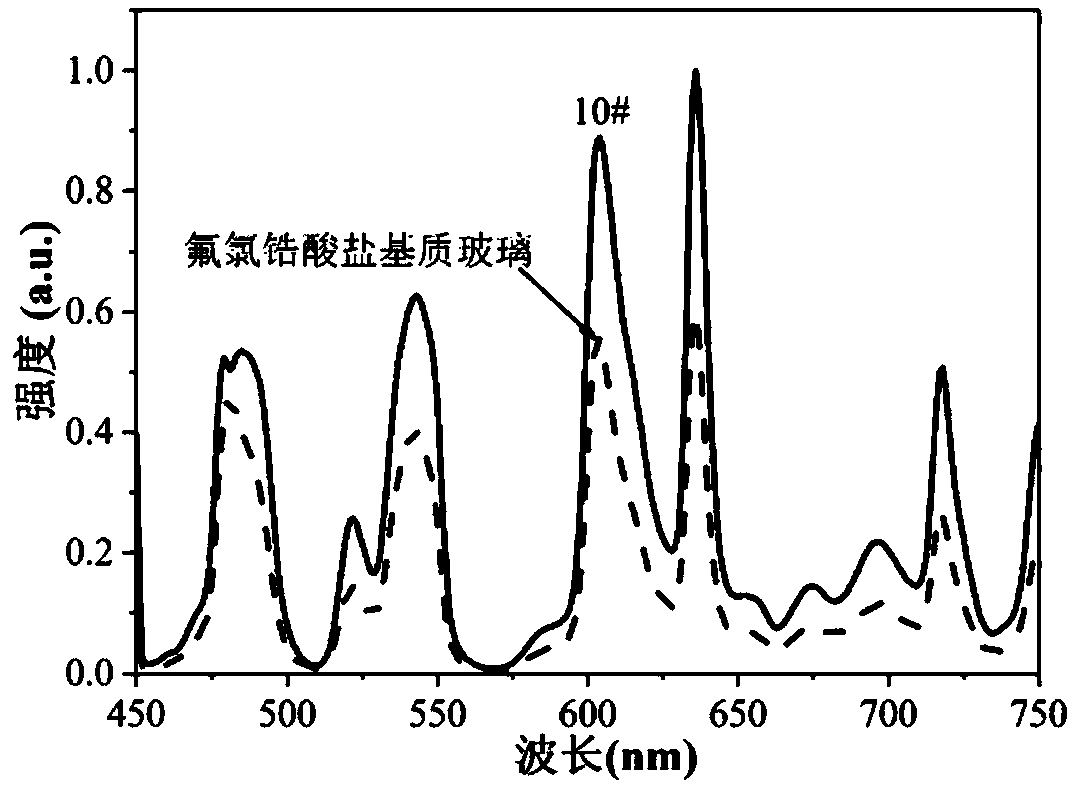

[0034] Heat treatment process: the annealed fluorozirconate matrix glass is placed in a muffle furnace for microcrystalline heat treatment, first heat up to 355°C at a rate of 5°C / min, and then heat up to 395°C at a rate of 2°C / min for 1 hour Treated for 0.25h, and finally cooled to room temperature with the furnace to obtain transparent fluorozirconate glass-ceramics. The XRD pattern of Example 1# of the present invention is as follows figure 1 As shown, there are crystal diffraction peaks, and the analysis is BaZrF 6 Crystal. Example 1# Fluorescence spectra under 445nm blue excitation are as follows figure 2 As shown, the fluorescence intensity of Example 1# is stronger than its fluorozirconate matrix glass. Example 1# Fluorescence spectra under X-ray excitation are as follows Figure 4 As shown in (a), the fluorescence intensity of Example 1# is stronger than that of its fluorozirconate matrix glass.

Embodiment 2

[0036] Heat treatment process: the annealed fluorozirconate matrix glass is placed in a muffle furnace for microcrystalline heat treatment, first heating up to 355°C at a rate of 5°C / min, and then heating up to 395°C at a rate of 2°C / min for 1 hour Treated for 0.75h, and finally cooled to room temperature with the furnace to obtain transparent glass-ceramics. The fluorescence spectrum of Example 2# of the present invention under the excitation of 445nm blue light is as follows figure 2 As shown, the fluorescence intensity of Example 2# is about 3 times that of fluorozirconate matrix glass. The fluorescence spectrum of Example 2# of the present invention under X-ray excitation is as follows Figure 4 As shown in (a), the fluorescence intensity of Example 2# is about 2.6 times that of the fluorozirconate matrix glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com