Method for preparing European type interlocked tiles by using high-silicon tailings

A technology for interlocking tiles and tailings, applied in applications, household appliances, clay products, etc., can solve the problems of high cost and low product performance, and achieve the effects of low system resistance, reliable operation up to the standard, and strong load adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

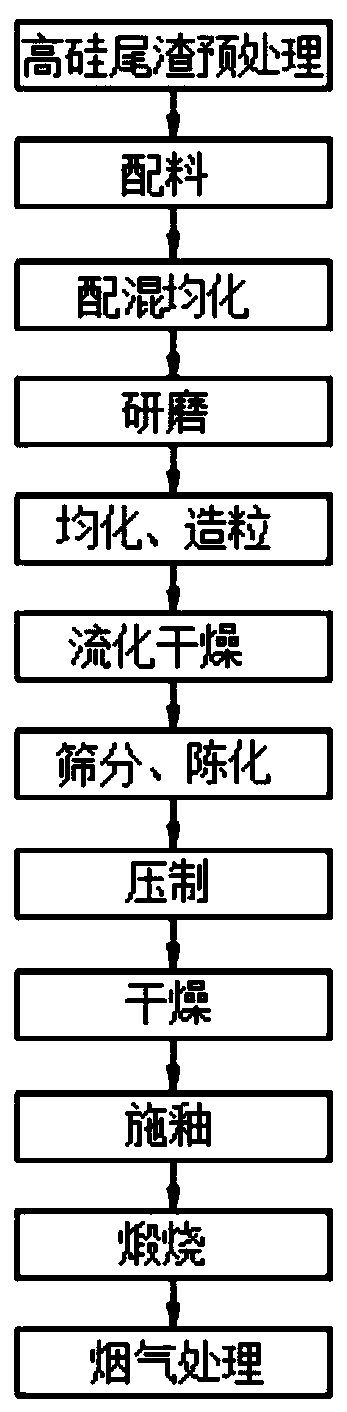

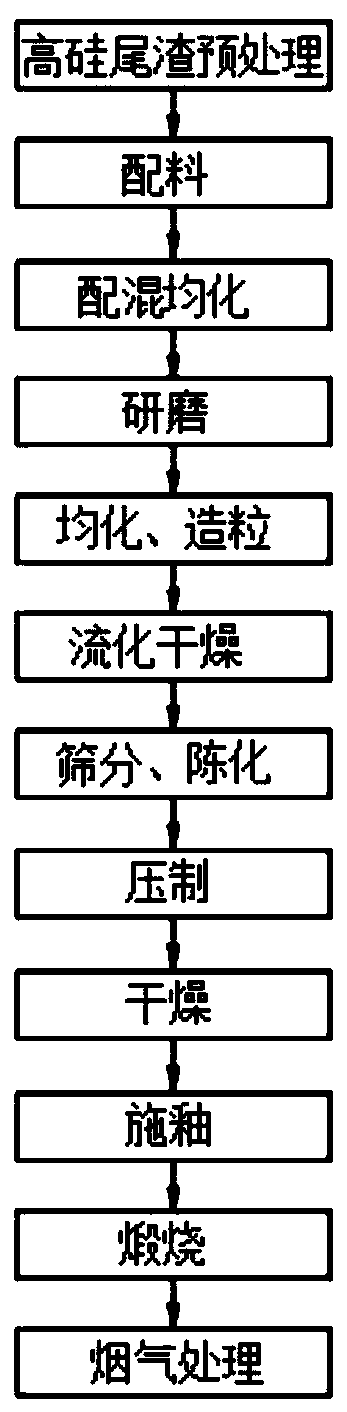

[0028] see figure 1 , in an embodiment of the present invention, a method for preparing European-style interlocking tiles using high-silicon tailings, comprising the following steps:

[0029] Step 1), high-silicon tailings pretreatment: Extrude the high-silicon tailings with a moisture content of 25% into mud sticks with an impurity removal extrusion machine, place them in a horizontal dryer to dry, and reduce the moisture to below 15%. Make it finalized, and then send the tailings to the pre-homogenization shed for homogenization;

[0030] Step 2), batching: put the raw material in the feeder, and set it through the computer according to the proportion of the process formula;

[0031] Step 3), blending and homogenization: After the blended raw materials are evenly mixed by the mixer, they are transported to the transfer warehouse by the belt for homogenization, and the blended raw materials are homogenized again by sliding down through the cross section during unloading;

...

Embodiment 2

[0048] Repeat Example 1 according to the same steps, and the difference from Example 1 is: step 11), calcining: the embryo body after glazing is placed in a roller kiln for firing, and the temperature is controlled at 1350 degrees.

Embodiment 3

[0050]Repeat Example 1 according to the same steps, and the difference between Example 1 and Example 2 is: step 11), calcining: the embryo body after glazing is placed in a roller kiln for firing, and the temperature is controlled at 1400 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com