High-efficiency synthesis method of 2-cyanophenol

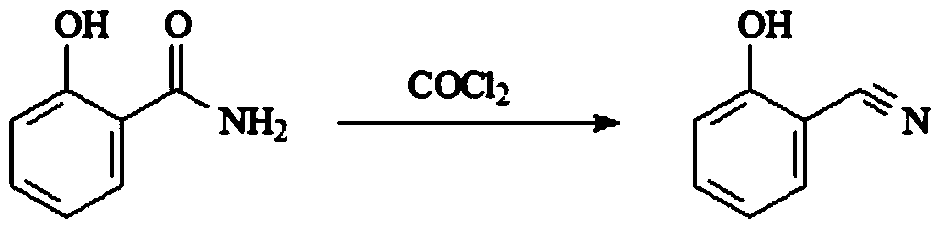

A technology of o-hydroxybenzonitrile and o-hydroxybenzamide, which is applied in the field of organic synthesis, can solve problems such as o-hydroxybenzonitrile that have not yet been seen, achieve continuous production methods, improve safety and environmental protection, and improve conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

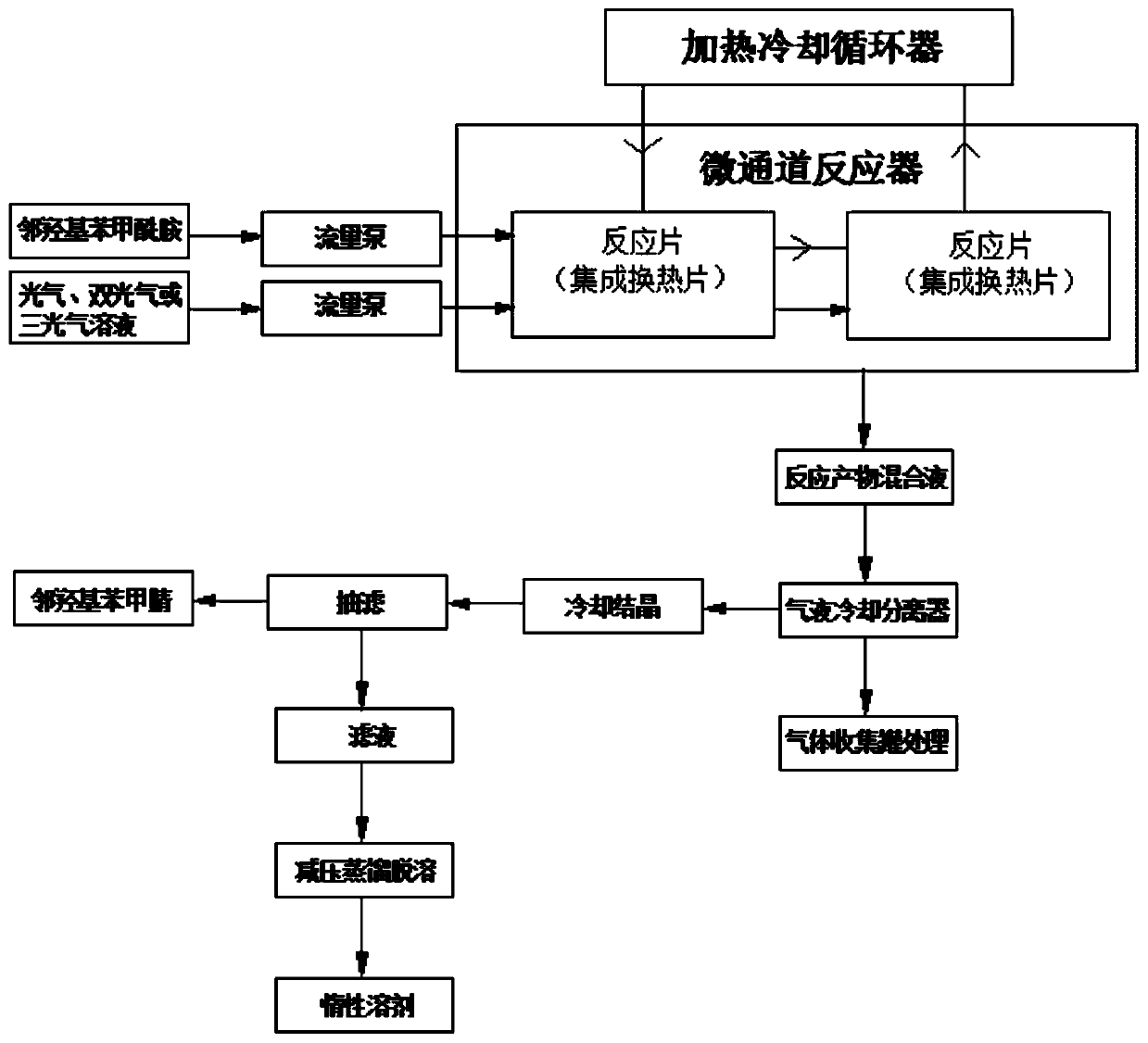

[0027] Adopt the method for synthesizing o-hydroxybenzonitrile with microchannel reactor of the present invention, take o-hydroxybenzamide and phosgene as reactant raw material to synthesize o-hydroxybenzonitrile, comprise the steps:

[0028] S1: Pretreatment of reactants, dissolving 50 g (0.36 mol) of o-hydroxybenzamide in toluene to prepare 167 g of o-hydroxybenzamide solution with a mass concentration of 30%;

[0029] S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator sets the reaction temperature of the microchannel reactor;

[0030] S3: Synthesis of o-hydroxybenzonitrile, using o-hydroxybenzamide solution with a mass concentration of 30% and phosgene with a purity of 98% as raw materials...

Embodiment 2

[0033] Adopt the method for synthesizing o-hydroxybenzonitrile with microchannel reactor of the present invention, take o-hydroxybenzamide and phosgene as reactant raw material to synthesize o-hydroxybenzonitrile, comprise the steps:

[0034] S1: Pretreatment of reactants, dissolving 50 g (0.36 mol) of o-hydroxybenzamide in xylene to prepare 250 g of o-hydroxybenzamide solution with a mass concentration of 20%;

[0035]S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator sets the reaction temperature of the microchannel reactor;

[0036] S3: Synthesis of o-hydroxybenzonitrile, using o-hydroxybenzamide solution with a mass concentration of 40% and phosgene with a purity of 95% as raw materials, ...

Embodiment 3

[0039] The method for synthesizing o-hydroxybenzonitrile using a microchannel reactor of the present invention uses o-hydroxybenzamide and diphosgene as reactant raw materials to synthesize o-hydroxybenzonitrile, comprising the following steps:

[0040] S1: Pretreatment of reactants, dissolving 50 g (0.36 mol) of o-hydroxybenzamide in xylene to form 500 g of o-hydroxybenzamide solution with a mass concentration of 10%;

[0041] S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator sets the reaction temperature of the microchannel reactor;

[0042] S3: Synthesis of o-hydroxybenzonitrile, using o-hydroxybenzamide solution with a mass concentration of 10% and diphosgene with a purity of 98% as raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com