Heat preservation box, water tank, heat collecting box, flat plate heat collector and flat plate solar water heater

A technology of flat-plate heat collectors and incubators, which is applied to solar heat collector heat insulation, solar thermal energy, solar thermal power generation, etc. It can solve the problems of high raw material and production costs, large thermal expansion and cold contraction, and high raw material costs. Achieve the effect of low processing cost, low cost and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

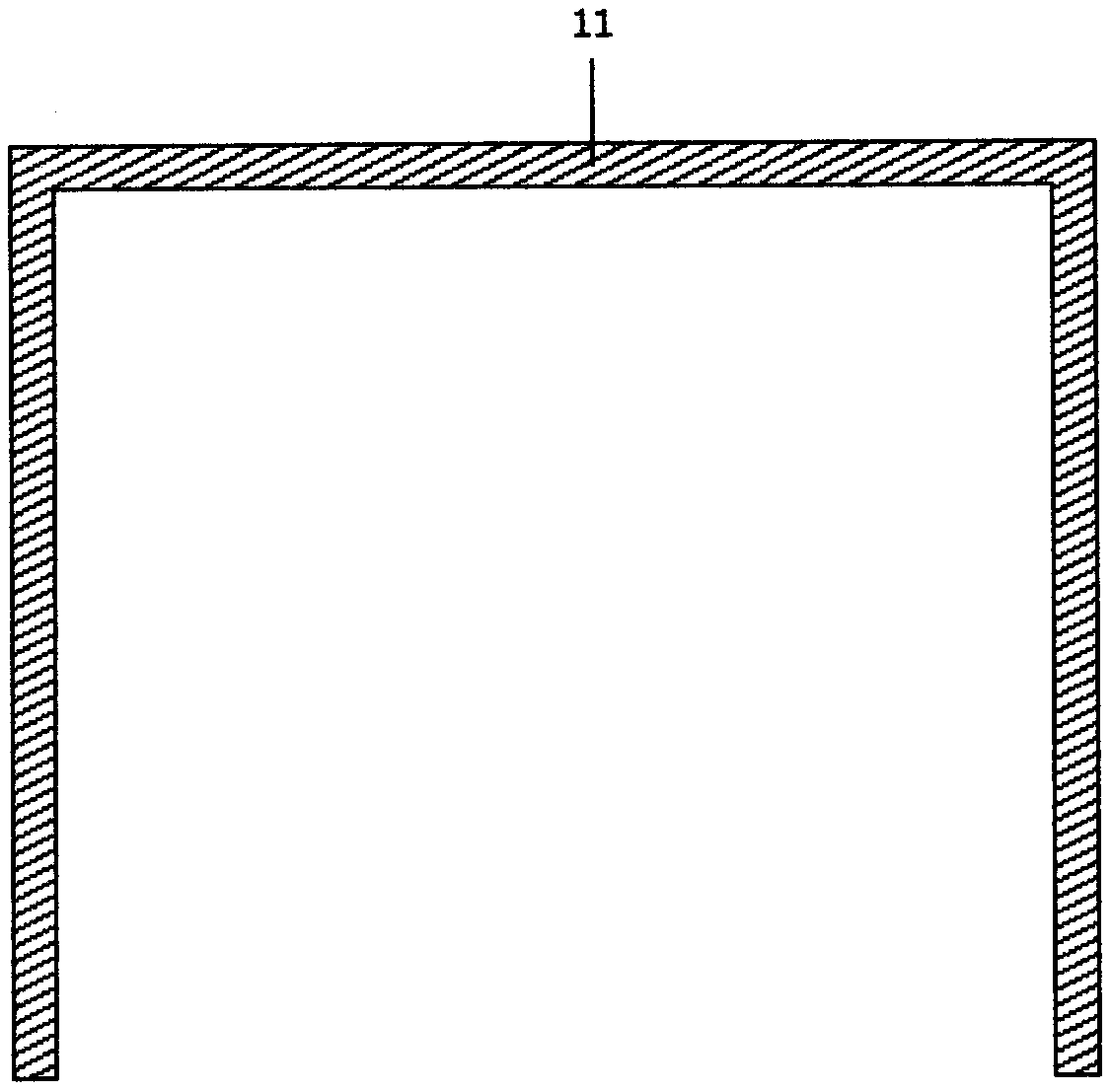

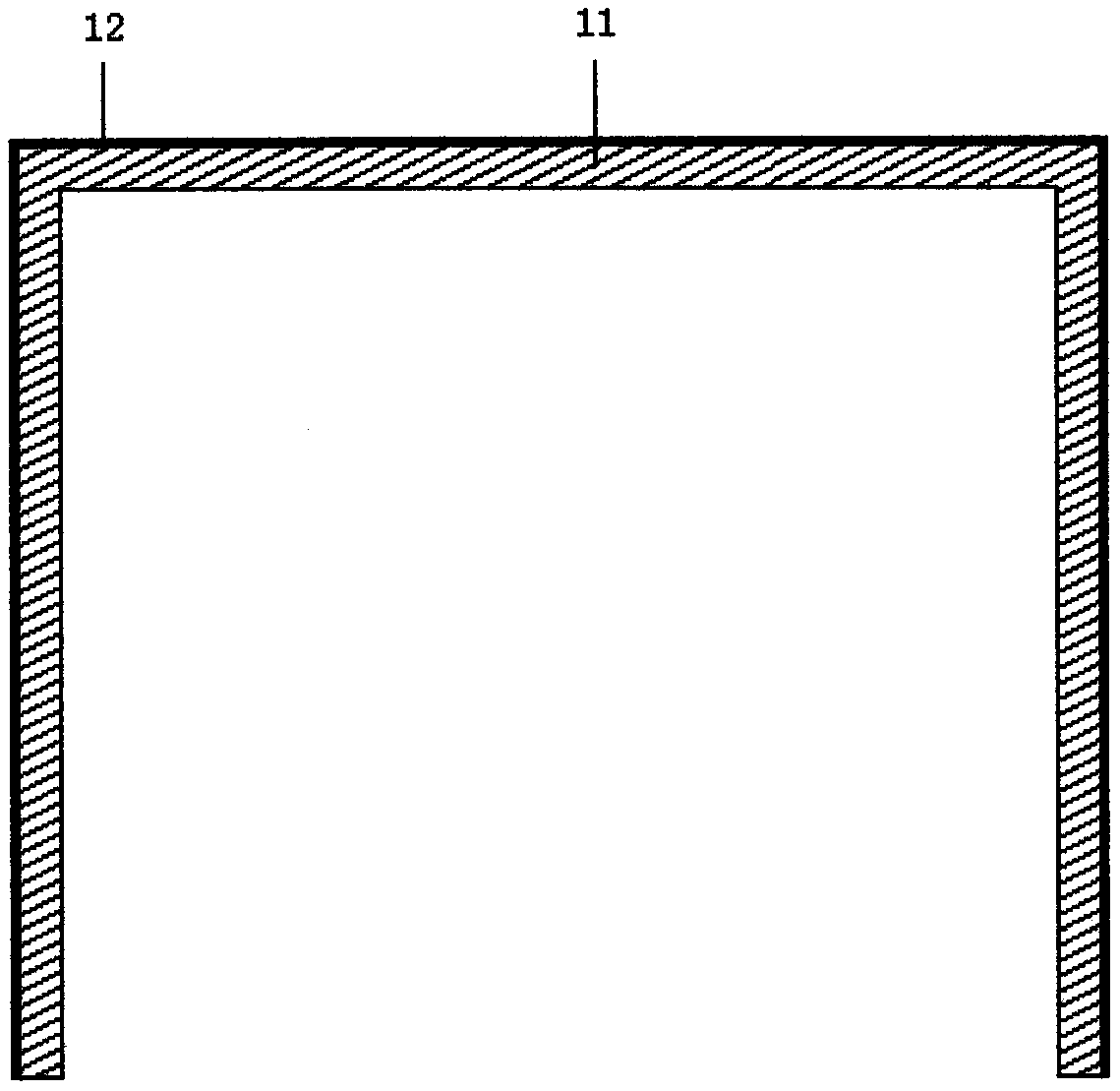

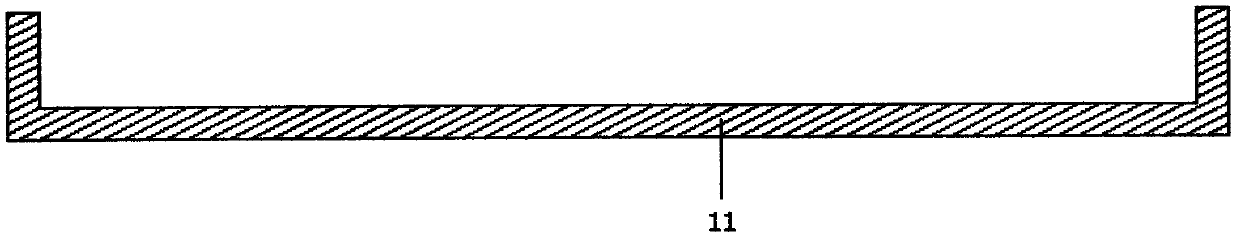

Embodiment 1

[0028] Such as Figure 1-4 Shown, the incubator of the present invention is the extruded board square box 11 of four side walls and top or bottom. For weather resistance and anti-ultraviolet rays, the outer surface that is exposed to the sun, that is, the outer side and the outer top surface, has a good exterior wall latex paint or EVA or weather-resistant adhesive or aluminum foil or other weather-resistant protective layer 12 with white. figure 1 and figure 2 It is a top insulation box, mainly used as the top and side shell of the solar water heater tank, such as Figure 6 and 7 , the outer top surface and the outer side that can be illuminated by the sun have exterior wall latex paint or other weather-resistant protective layers 12 that are preferably white. image 3 and Figure 4 It is a bottom insulation box, mainly used for the shell of the heat collection box of the flat plate collector, such as Figure 10-13 , white exterior wall latex paint or other weather-resi...

Embodiment 2

[0031] Such as Figure 6 Shown, the water tank of the flat solar water heater of the present invention, and background technology such as Figure 5 The shown water tank is the same, and is made up of structural layer 1, insulation layer 2, liner 3, upper circulation pipe 4, lower circulation pipe 5, water inlet pipe 6, water outlet pipe 7 and breathing overflow pipe 8. It is characterized in that: the top and side shells of the water tank are extruded board insulation layer outer cover, that is, the insulation box described in embodiment 1, and the structure layer 1 and the inner tank 3 are in sequence inside. The bottom seam of the incubator and the water tank can be sealed with EVA tape or other adhesives, and it is very convenient to remove and replace. Of course, the insulation layer material at the bottom of the water tank is also preferably extruded board.

Embodiment 3

[0033] This is the preferred technical scheme of embodiment 2. The upper circulation pipe 4, the lower circulation pipe 5, the water inlet pipe 6, the water outlet pipe 7 and the breathing overflow pipe 8 of the water tank are vertically fixed at the bottom of the water tank. Because the upper circulation pipe 4, the lower circulation pipe 5, the water inlet pipe 6, the water outlet pipe 7, and the breathing overflow pipe 8 are mainly fixed by the force of the structural layer 1, the reason why the bottom of the structural layer 1 is kept exposed is to facilitate fixing . Because the bottom of the water tank is fixed vertically, it avoids the phenomenon of pipe bending, poor sealing, rain and weather resistance due to deformation due to its own gravity. Because the exposed mouth of the breathing overflow pipe 8 is at the bottom, it is difficult to dissipate heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com