A quality improver for recombined products of round toe crab meat and its preparation method

A quality improver, crab meat technology, applied in the direction of food ingredients as taste improver, food ingredients as thickeners, food ingredients as antifreeze, etc. Changes, economic losses and other problems, to achieve the effect of low production equipment requirements, improved gel properties, and improved texture properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

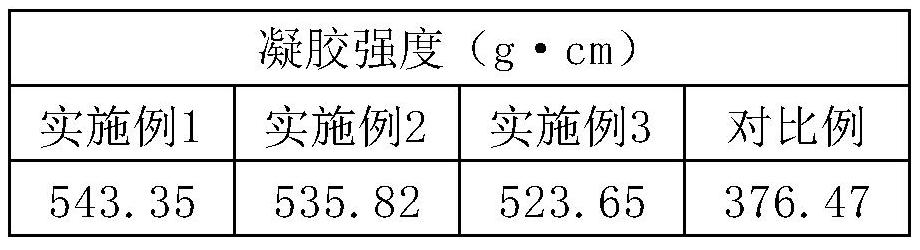

Examples

Embodiment 1

[0021] (1) Preparation of oxidized tea polyphenol modified konjac glucomannan: first dissolve konjac glucomannan in water to prepare a konjac glucomannan solution with a mass concentration of 2%, then add appropriate amount of ascorbic acid and stir evenly, then add The tea polyphenol solution with a mass concentration of 0.5% was stirred evenly, and the added volume of the tea polyphenol solution was 15% of the volume of the konjac glucomannan solution, ultrasonicated for 2 hours at 25±5° C., and finally added with a mass concentration of 5%. Hydrogen peroxide solution, the added volume of hydrogen peroxide solution is 4% of the volume of konjac glucomannan solution, stirred for 30min, and freeze-dried;

[0022] (2) Mixing: Add cornstarch into water and stir evenly to make a slurry. The mass ratio of cornstarch to water is 20:100. The slurry is ground and passed through a 100-mesh sieve. After sieving, it is centrifugally settled and dried. Obtain pretreated cornstarch; press...

Embodiment 2

[0024] (1) Preparation of oxidized tea polyphenol modified konjac glucomannan: first dissolve konjac glucomannan in water to prepare a konjac glucomannan solution with a mass concentration of 1.5%, then add an appropriate amount of ascorbic acid and stir evenly, then add The tea polyphenol solution with a mass concentration of 0.4% is stirred evenly, the added volume of the tea polyphenol solution is 12% of the volume of the konjac glucomannan solution, ultrasonicated for 1.5h at 25±5°C, and finally added with a mass concentration of 4% Hydrogen peroxide solution, the added volume of hydrogen peroxide solution is 3% of the volume of konjac glucomannan solution, stirred for 25min, and freeze-dried;

[0025] (2) Mixing: Add cornstarch into water and stir evenly to make a slurry. The mass ratio of cornstarch to water is 10:100. The slurry is ground and passed through a 100-mesh sieve. After the sieve, it is centrifugally settled and dried. Obtain pretreated cornstarch; press 6kg ...

Embodiment 3

[0027] (1) Preparation of oxidized tea polyphenol modified konjac glucomannan: first dissolve konjac glucomannan in water to prepare a konjac glucomannan solution with a mass concentration of 1%, then add an appropriate amount of ascorbic acid and stir evenly, then add The tea polyphenol solution with a mass concentration of 0.3% is stirred evenly, the added volume of the tea polyphenol solution is 10% of the volume of the konjac glucomannan solution, ultrasonicated for 1 h at 25±5° C., and finally added with a mass concentration of 3%. Hydrogen peroxide solution, the added volume of the hydrogen peroxide solution is 2% of the volume of the konjac glucomannan solution, stirred for 20 minutes, and freeze-dried;

[0028] (2) Mixing: Add cornstarch into water and stir evenly to make a slurry. The mass ratio of cornstarch to water is 9:100. The slurry is ground and passed through a 100-mesh sieve. After the sieve, it is centrifugally settled and dried. Obtain pretreated cornstarch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com