Patents

Literature

31results about How to "Improve texture properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

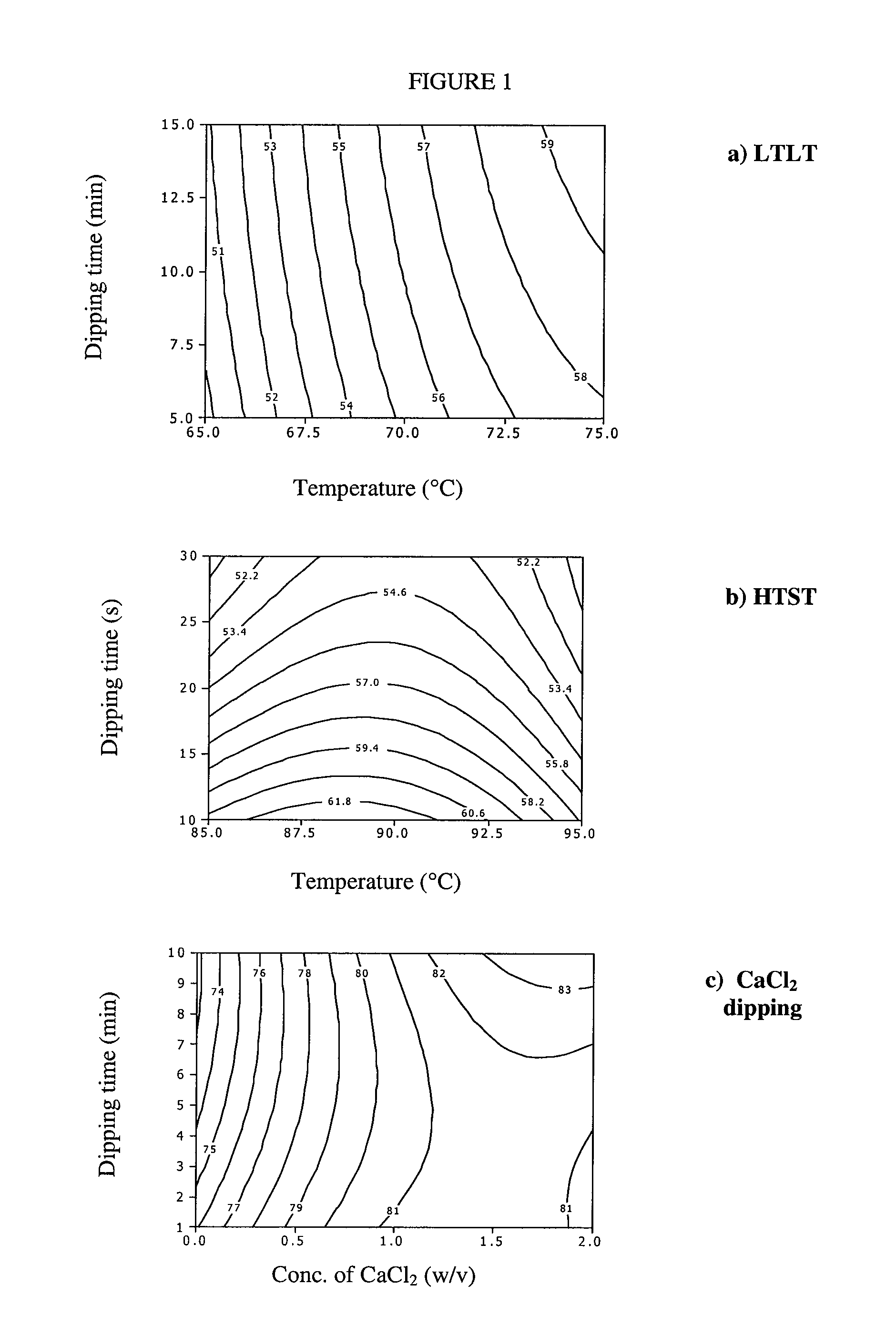

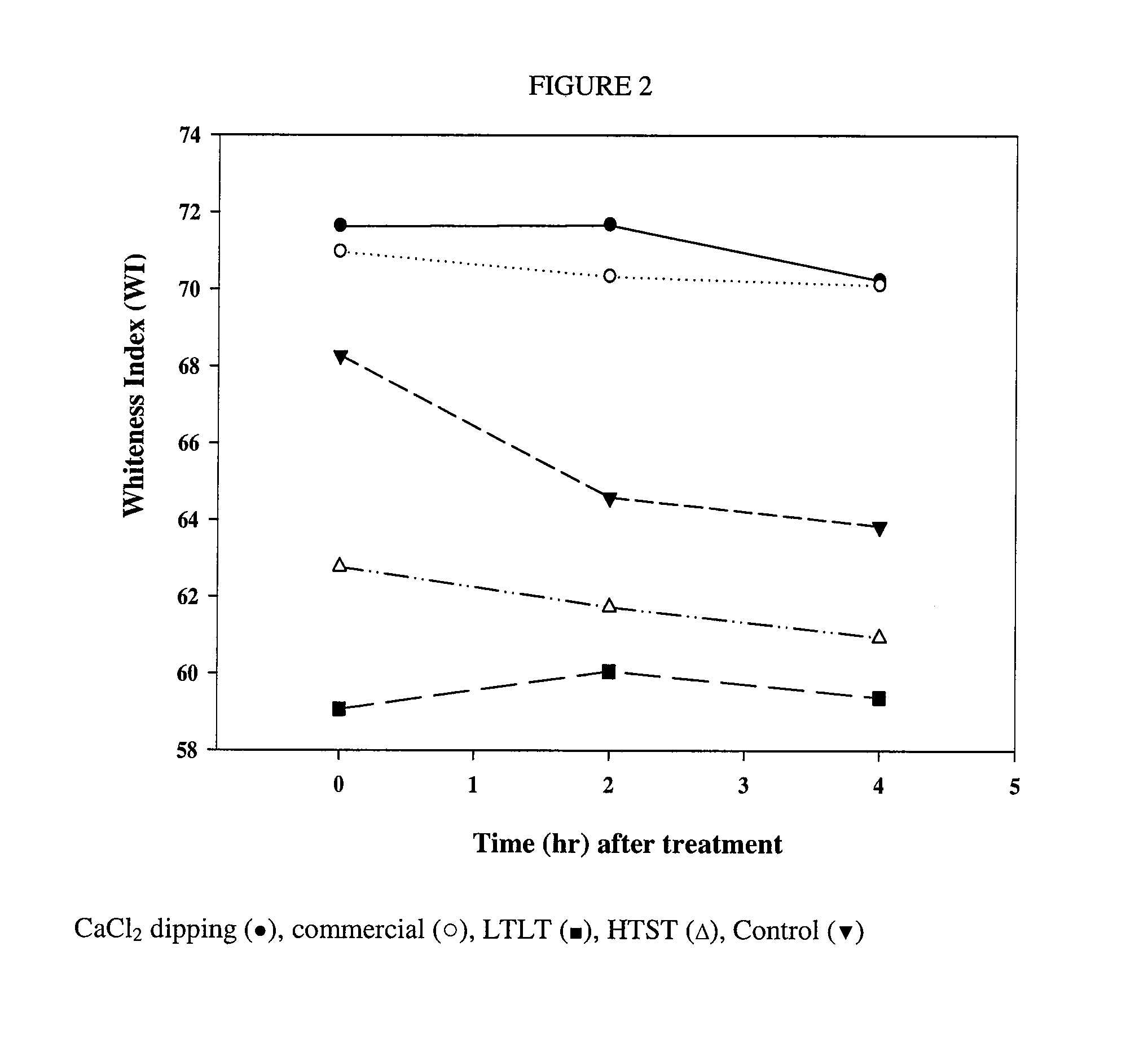

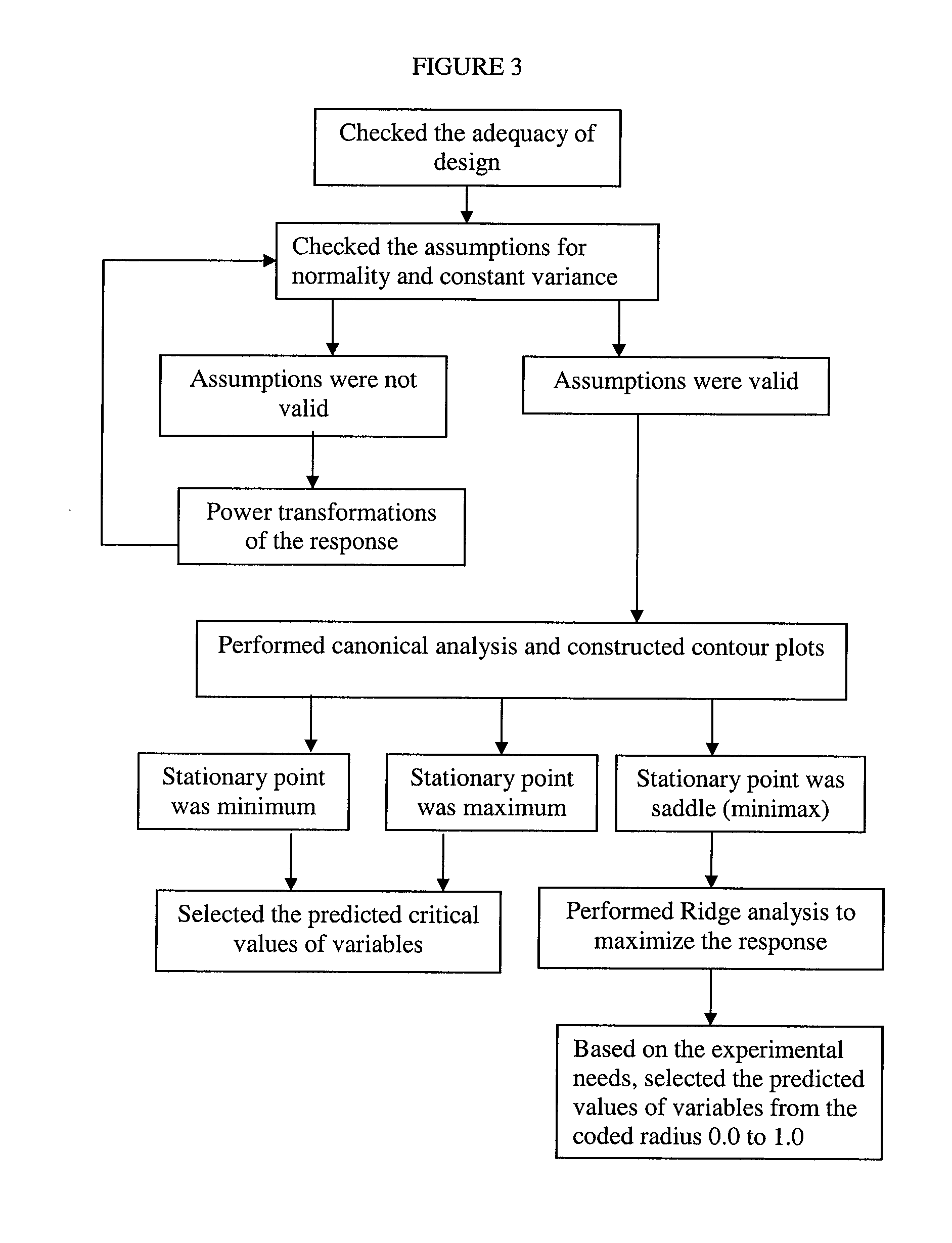

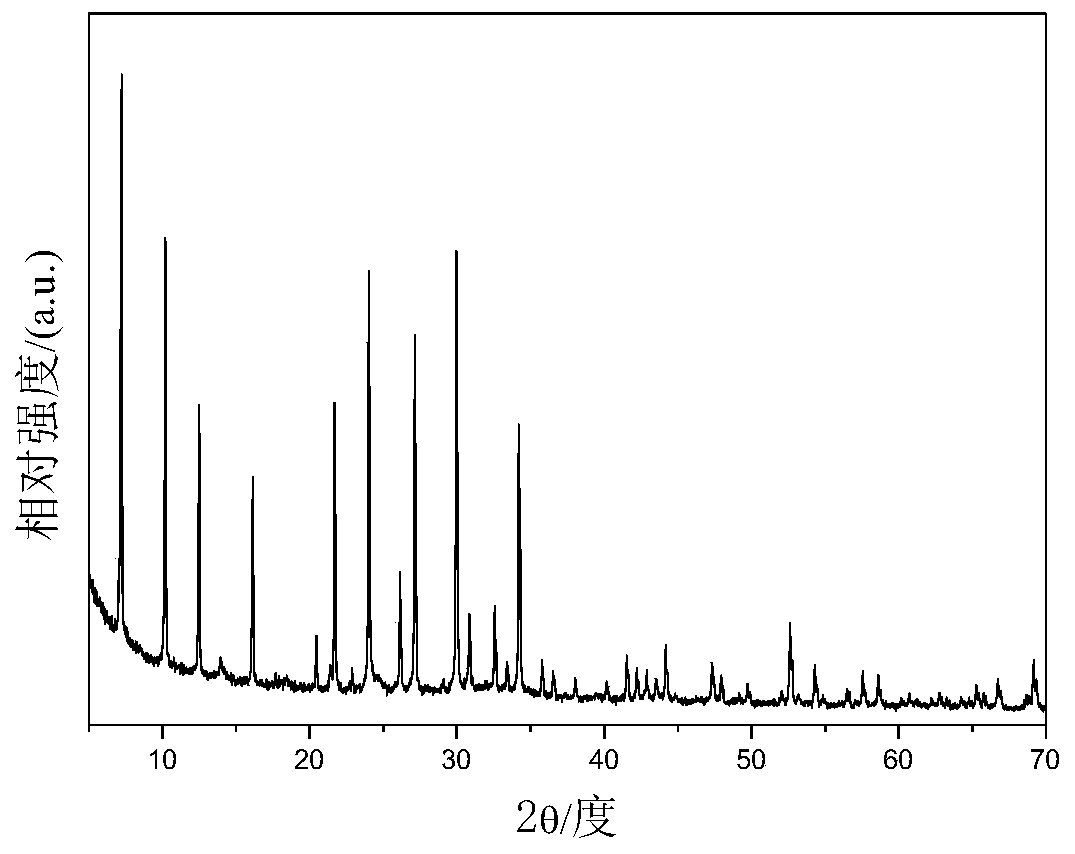

Non-fried apple food products and processes for their preparation

InactiveUS20100159082A1Improve sensory attributeImprove nutritional qualityAnimal feeding stuffFruits/vegetable preservation by coatingDeep fryingFood products

The present disclosure relates to value-added non-fried, crispy apple food products and a consumer-friendly process for manufacturing these products that does not use deep-frying in oil.

Owner:HER MAJESTY THE QUEEN IN RIGHT OF THE PROVINCE OF NOVA SCOTIA AS REPRESENTED BY THE NOVA SCOTIA AGRI COLLEGE NSAC ON BEHALF OF THE MINIST OF AGRI

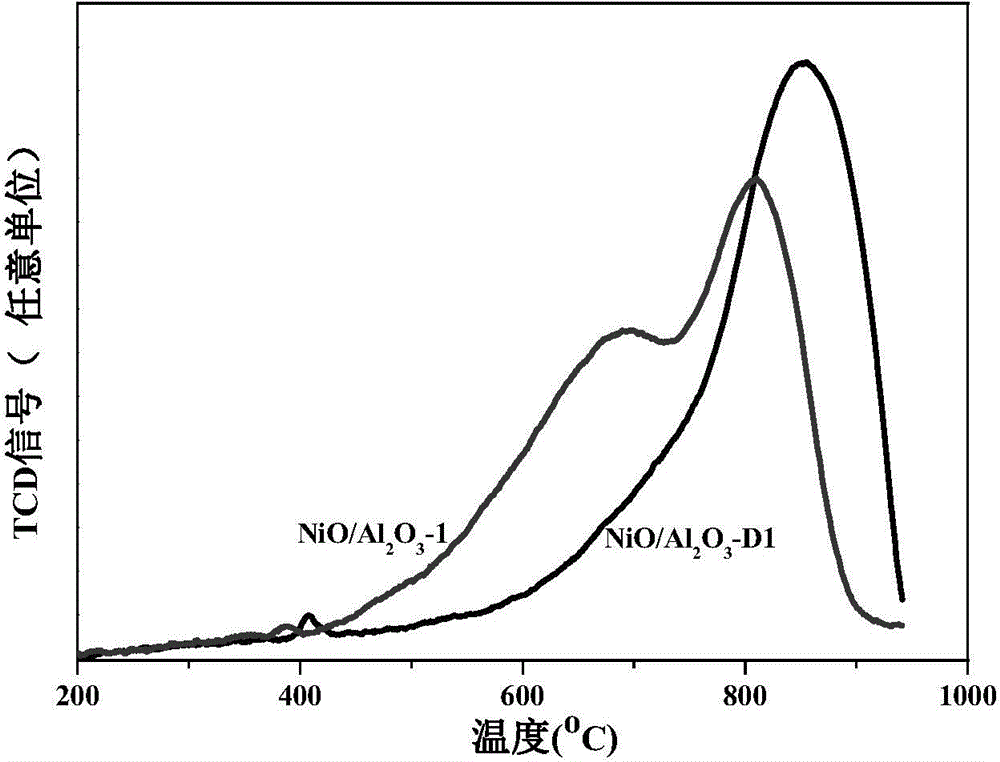

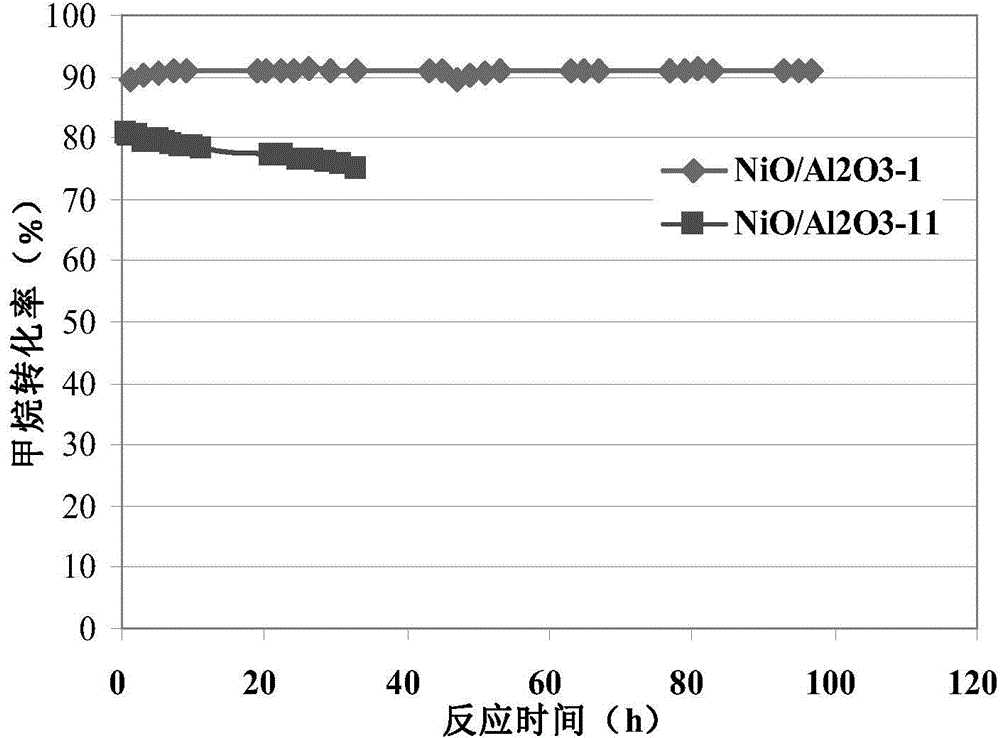

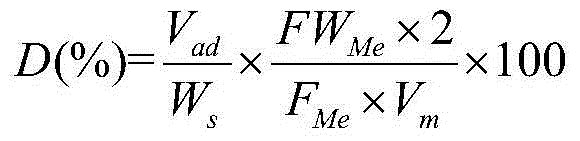

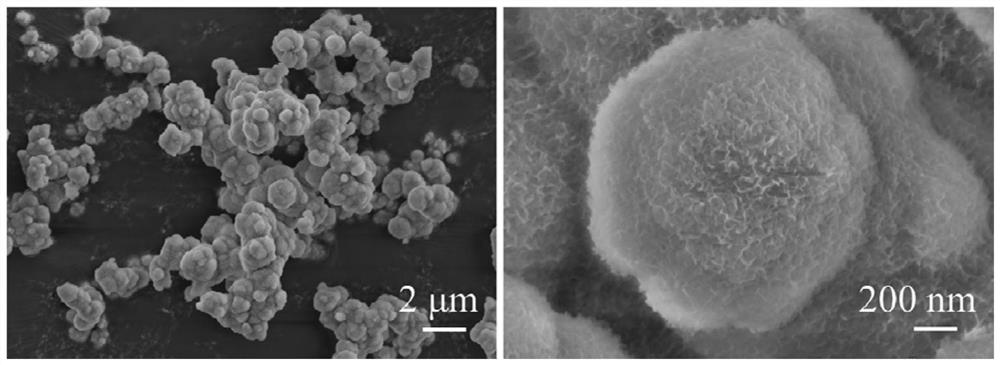

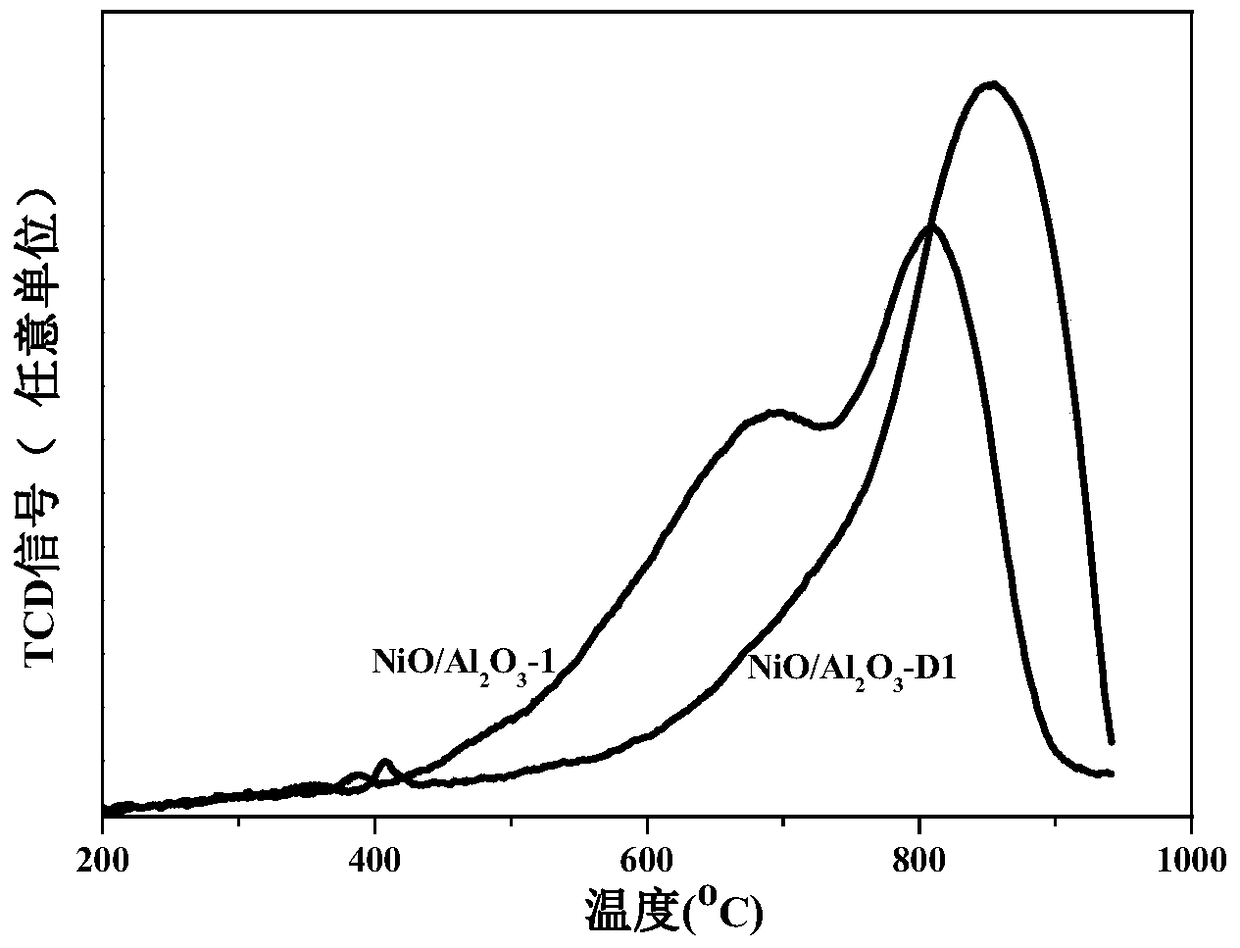

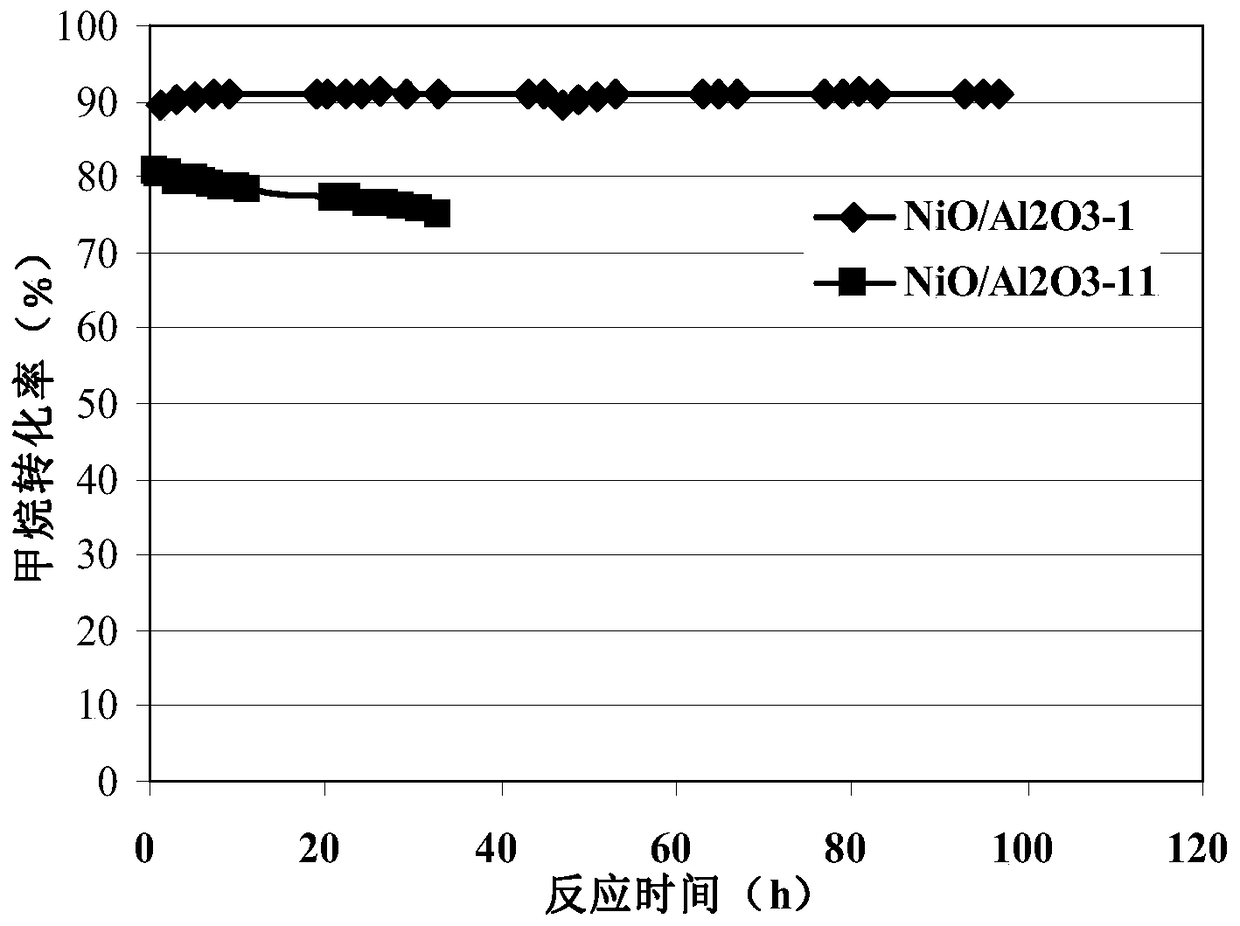

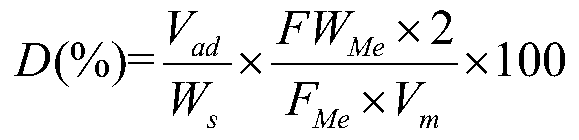

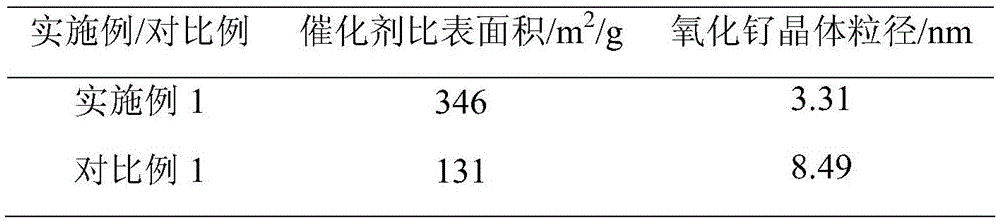

Catalyst carrier and supported catalyst and their preparation methods and use and method for producing synthetic gas through dry reforming of methane

ActiveCN105562113ASimple processReduce manufacturing costHydrogenCatalyst carriersSolventCatalyst support

The invention relates to a preparation method of a catalyst carrier, a preparation method of a supported catalyst, the supported catalyst, a use of the supported catalyst and a method for producing synthetic gas through dry reforming of methane through the supported catalyst. According to the preparation method of the catalyst carrier, a sale carrier precursor such as pseudo-boehmite as a raw material is used, a carrier modification assistant is directly added into a glue solvent such as a dilute nitric acid solution, simultaneously, a pore forming agent and an extrusion aid are added into the solution, the mixture is mixed and is extruded to form strips and the strips are dried and roasted. The carrier is roasted once so that the carrier has excellent texture properties, has a large specific surface area and is conducive to active metal uniform dispersion. The carrier carries an active metal Ni to form the supported catalyst and the supported catalyst is used for a methane dry reforming catalytic reaction. Compared with the same type of the existing catalyst, the supported catalyst has higher catalytic activity and better resistance to carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

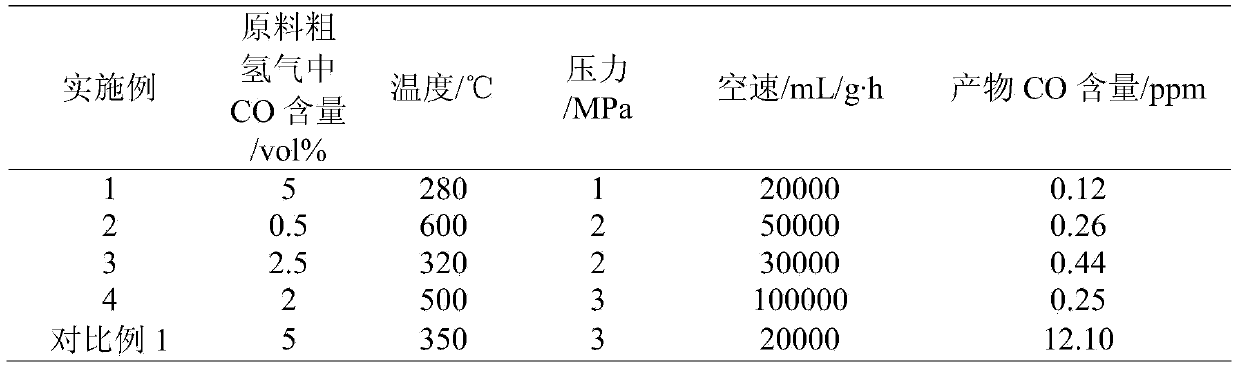

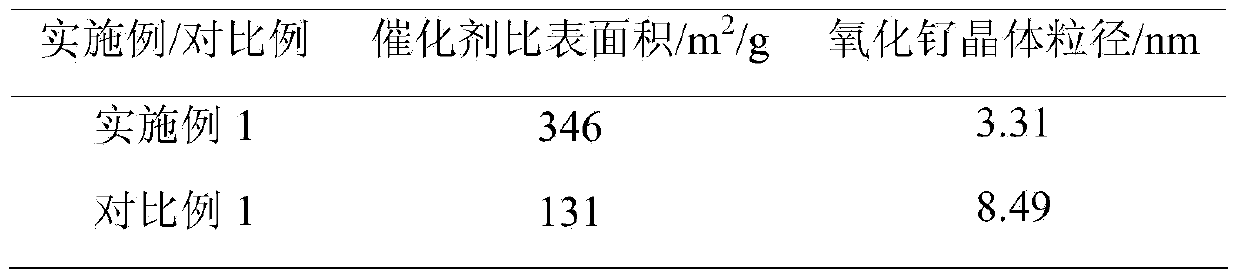

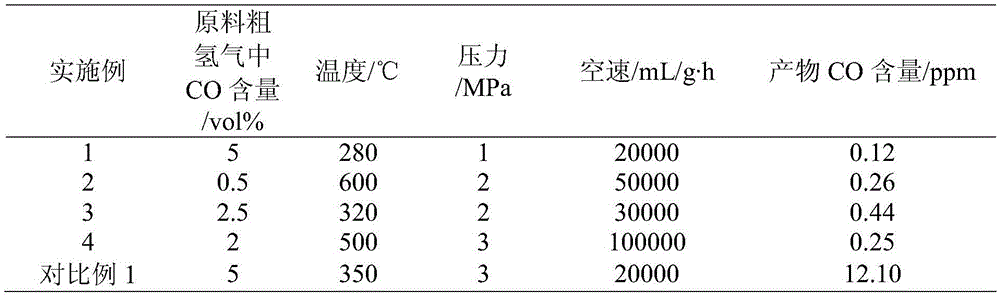

Precious metal methanation catalyst prepared by using solution combustion method and preparation method and applications thereof

InactiveCN103801290AImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

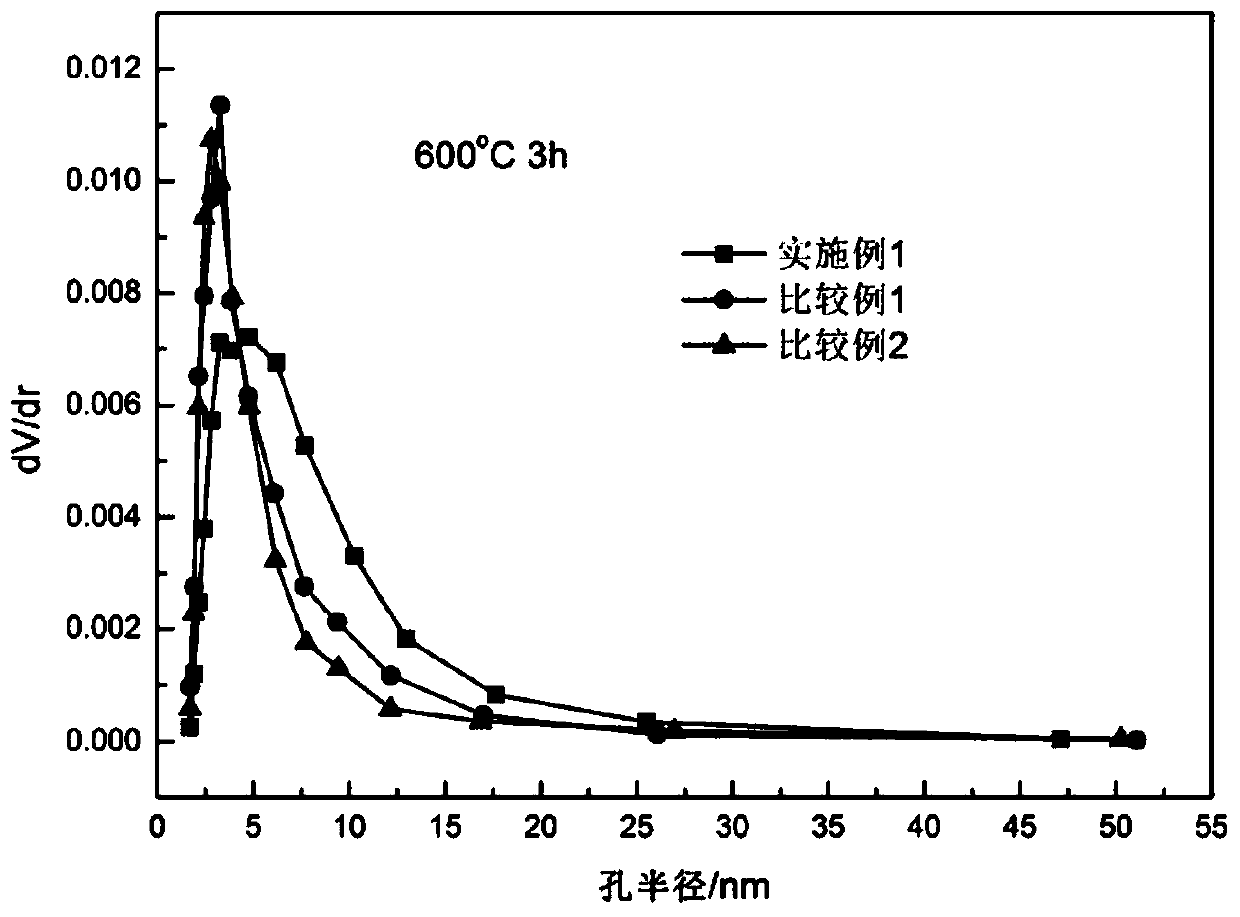

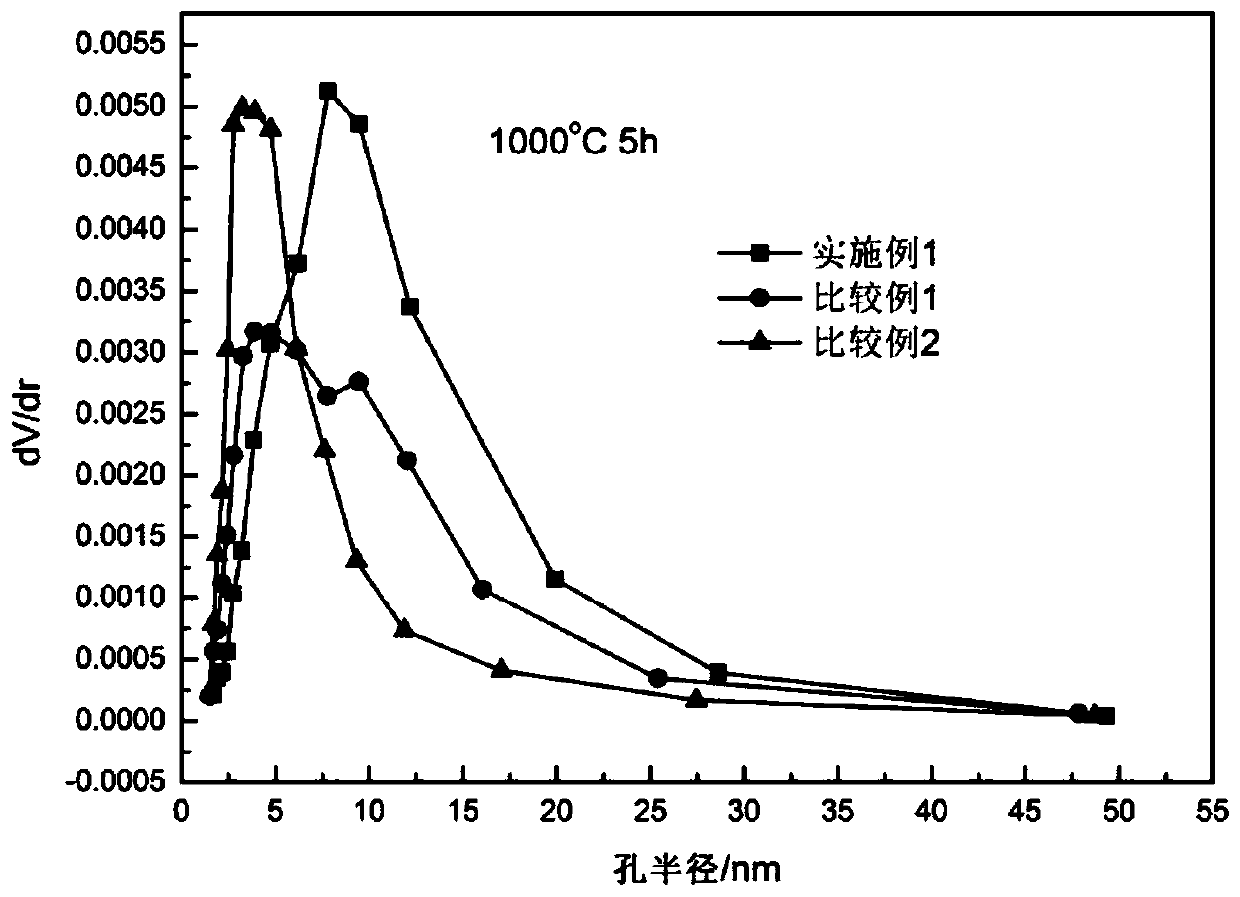

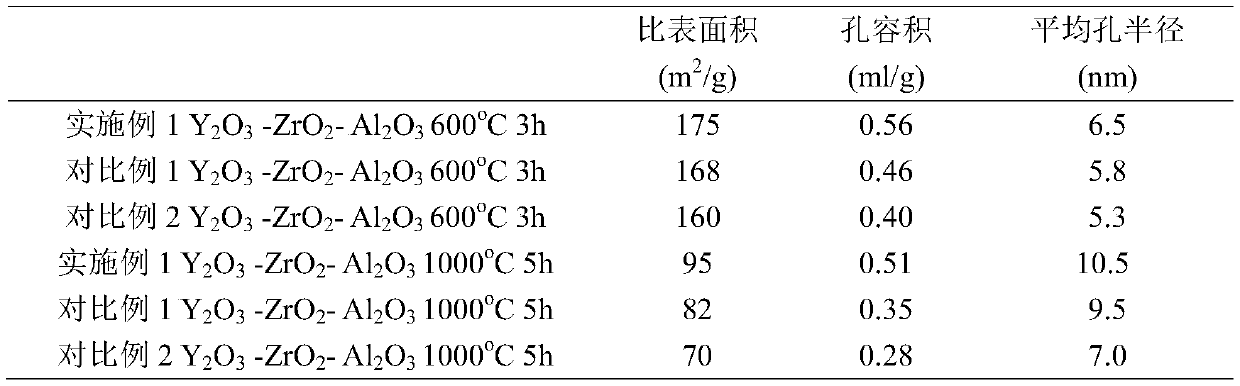

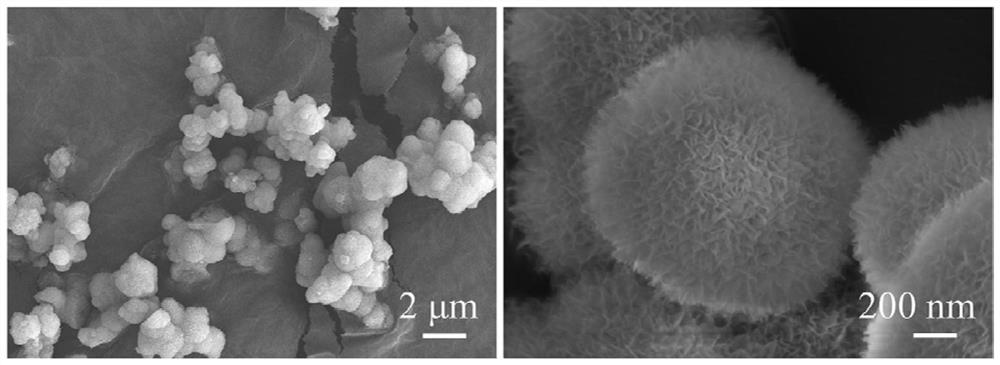

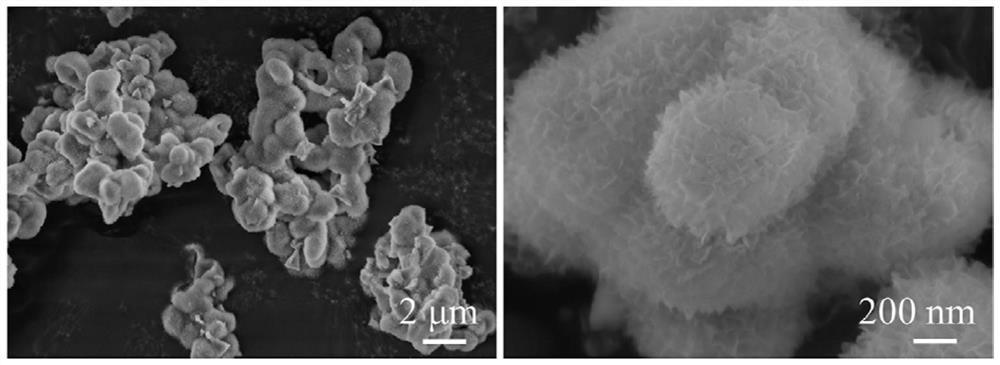

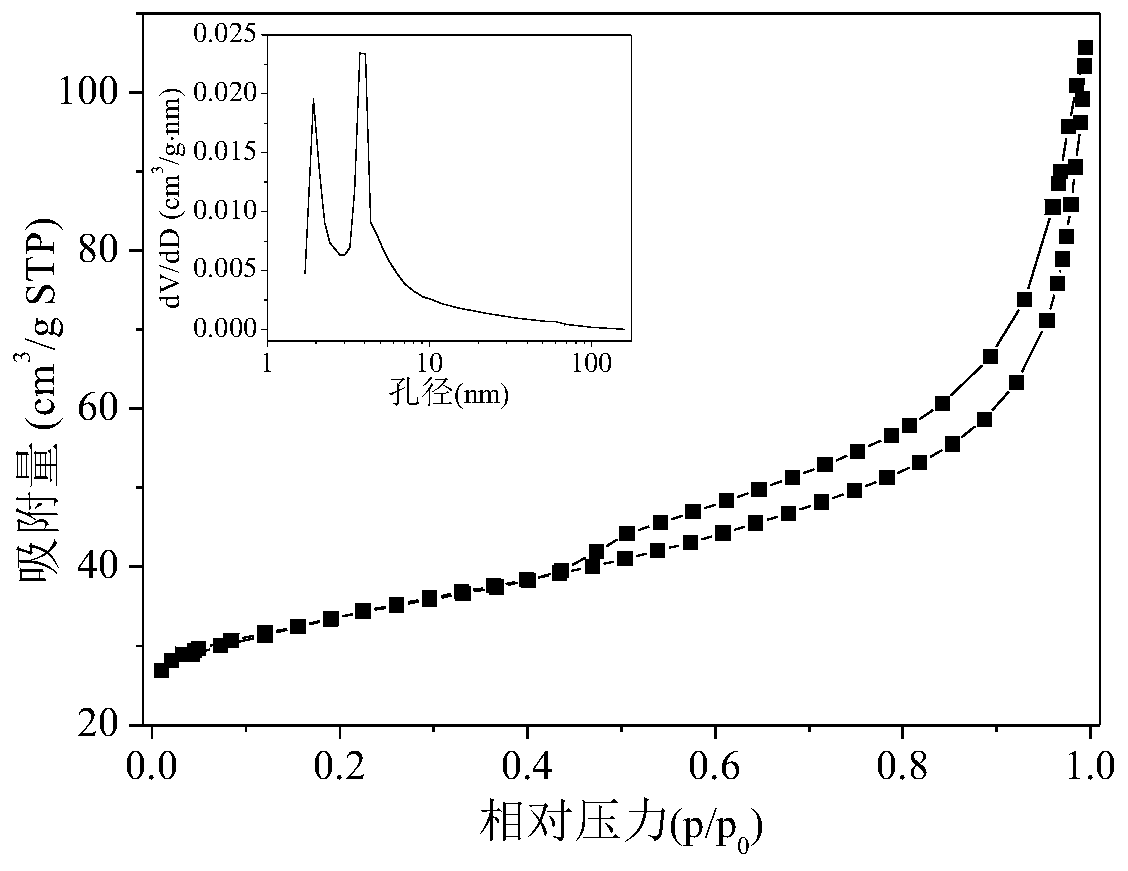

Composite oxide and preparation method thereof

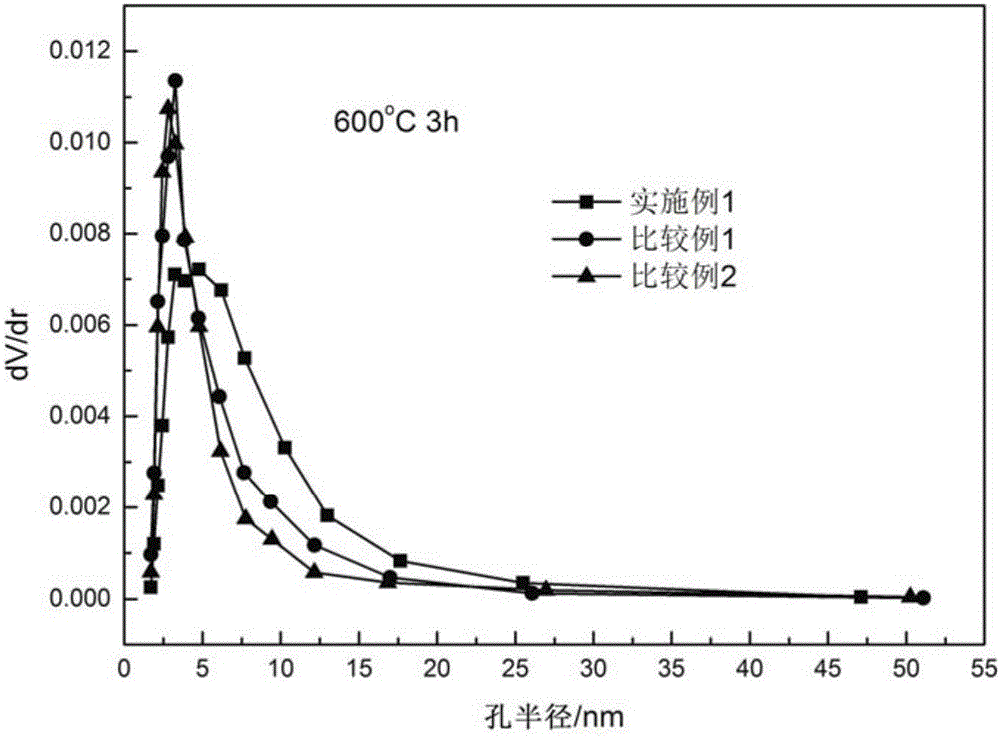

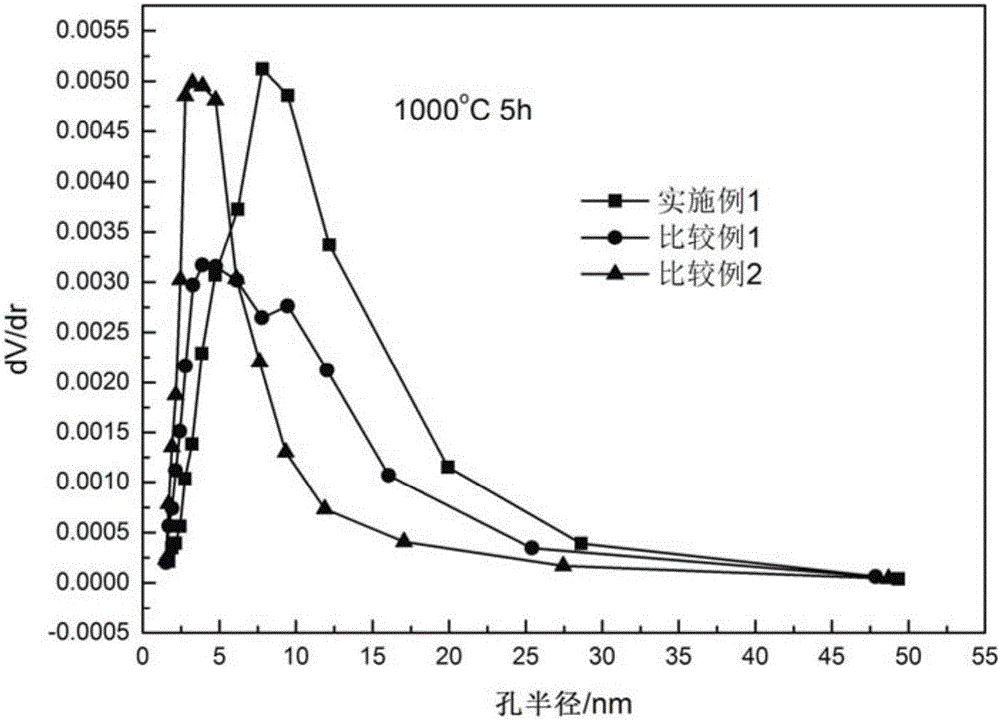

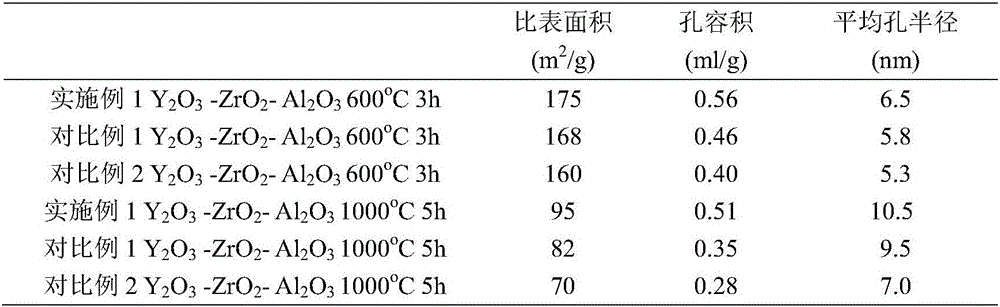

InactiveCN106824163AImprove thermal stabilityImprove texture propertiesHeterogenous catalyst chemical elementsDispersed particle separationComposite oxideOxide

The invention discloses a composite oxide and a preparation method thereof. The preparation method is characterized in that a precursor solution of the composite oxide is prepared; the precursor solution and an alkaline solution are subjected to titration reaction with high-speed stirring under room temperature according to a coprecipitation method, wherein the pH in the titration reaction is 8.5-9.5; composite oxide sizing obtained in the titration reaction is quickly heated to be 50-80 DEG C to enable the growing of crystal grains, and the composite oxide sizing is stirred for 1-3 hours under 50-80 DEG C; the alkaline solution is supplemented to maintain the pH of the composite oxide sizing; the composite oxide sizing is cooled to the room temperature and stood for 1-6 days to enable the slow developing of the crystal grains; then the composite oxide sizing is aged for 6-8 hours under the temperature of 90-95 DEG C to enable the developing of particles; finally, the composite oxide sizing is roasted at the temperature of 600-1000 DEG C to obtain the composite oxide. Compared with a sample prepared by a traditional constant-temperature titration reaction, the composite oxide prepared by the method has the characteristics of being high in specific surface area, high in pore volume, and wide in pore size distribution; the composite oxide can be used as a carrier material in exhaust cleaning of moving sources such as a motor vehicle, and treatment of solid sources such as catalytic combustion or volatile gas, and can also be directly used as a catalyst, so that the composite oxide is applicable to various application fields.

Owner:SICHUAN UNIV

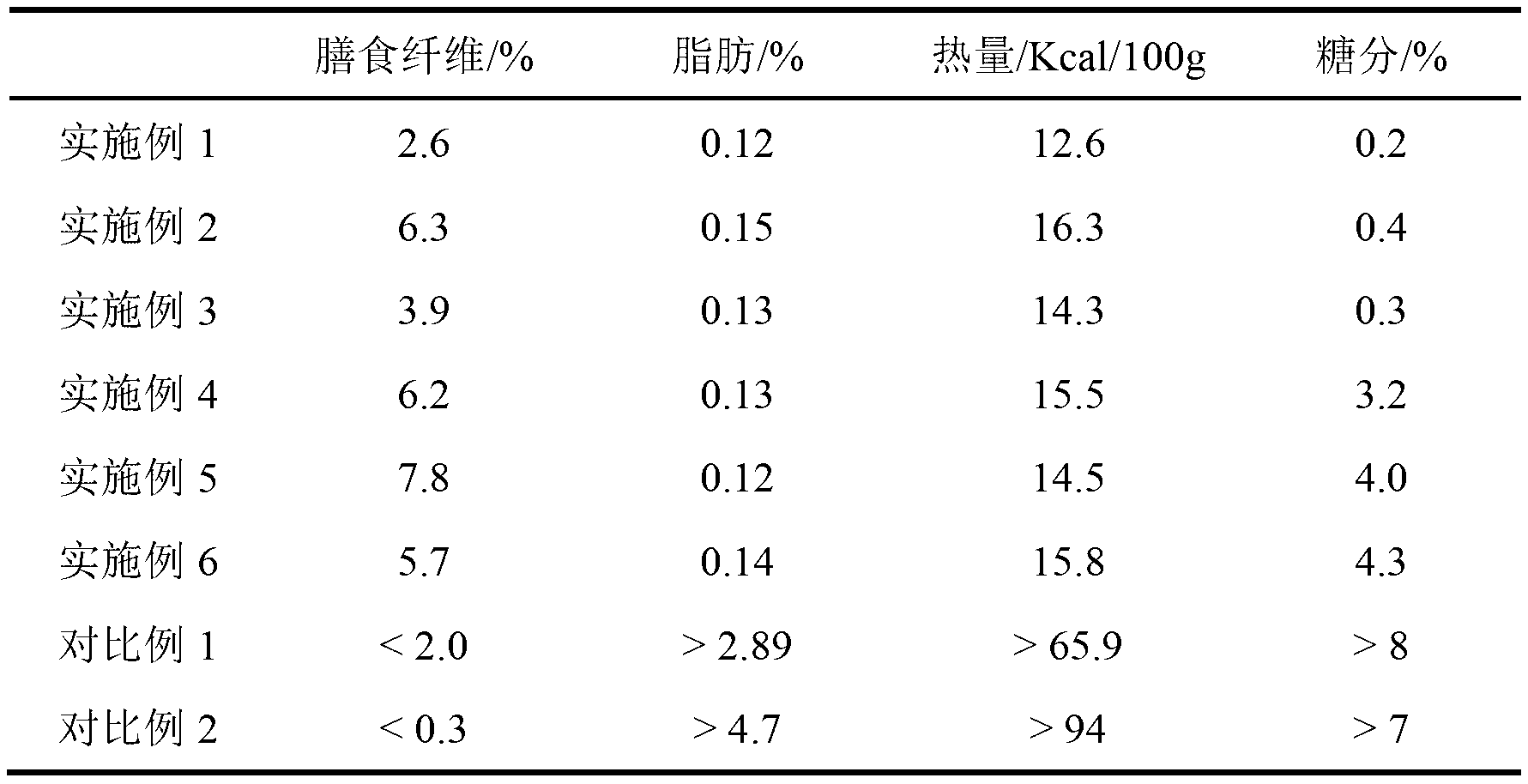

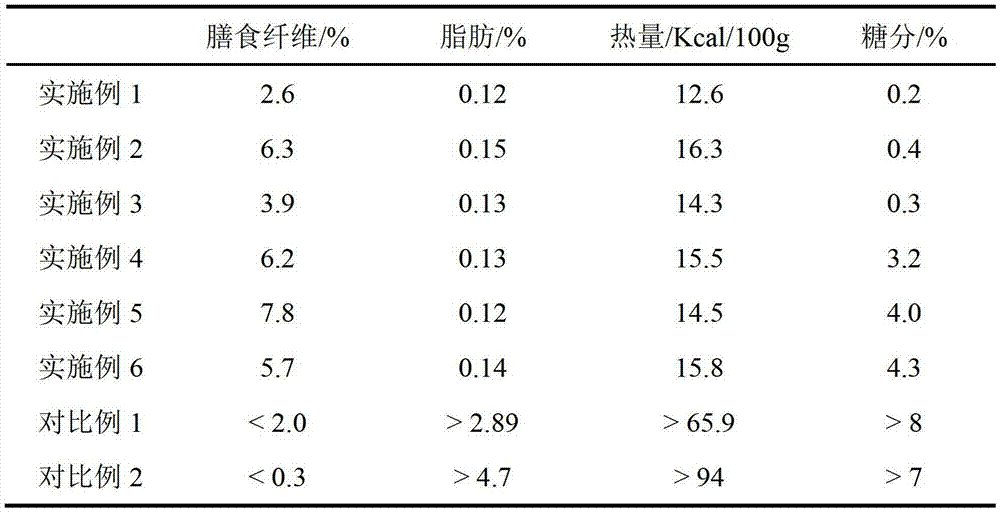

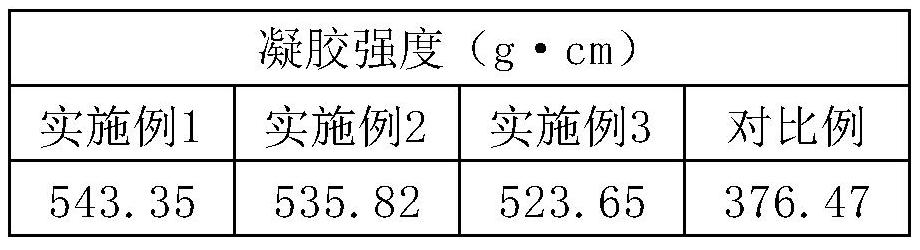

Inulin low-fat yogurt pudding and preparation method thereof

The invention discloses an inulin low-fat yogurt pudding and a preparation method thereof, and belongs to the technical field of food processing. The inulin low-fat yogurt pudding is prepared from the following components by weight percent: 30-40% of yogurt base, 2-10% of inulin, 0.05-0.5% of a thickener, 0.001-5% of a sweetening agent and the balance of water, wherein the inulin is a soluble dietary fiber, can selectively promote growth of colon probiotics, and has the functions of reducing blood sugar concentration, maintaining lipid metabolism balance, improving the bioavailability of mineral elements, enhancing the immunity of the organism, and the like. The inulin low-fat yogurt pudding disclosed by the invention contains the inulin dietary fiber, is low in fat content, and smooth in mouthfeel, has the functions of improving the intestinal microenvironment, controlling blood fat and blood sugar levels, reducing the energy, promoting absorption of a mineral substance and synthesis of vitamins, and is especially suitable for middle aged and elderly people with diseases such as constipation, obesity, hypertension, hyperlipidemia and diabetes mellitus.

Owner:HENAN UNIV OF SCI & TECH

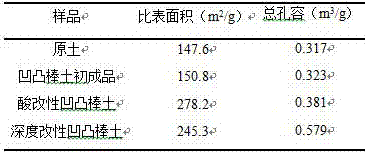

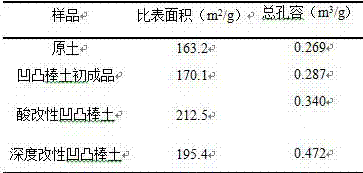

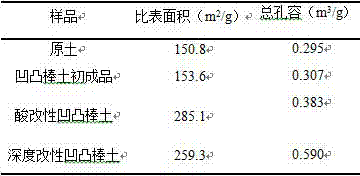

Method of deeply modifying attapulgite to prepare nano carrier material

ActiveCN107311188AImprove surface propertiesImprove texture propertiesSilicon compoundsNanometreChemistry

The invention discloses a method of deeply modifying attapulgite to prepare a nano carrier material; the method comprises the steps of crushing attapulgite, screening, rinsing with water, separating by settling, and drying to obtain primary attapulgite; subjecting the primary attapulgite to primary acid modification, filtering and separating, washing, and drying to obtain acid-modified attapulgite; subjecting the acid-modified attapulgite to secondary alkali modification in an ice-water bath under the protection of nitrogen, filtering, separating, washing, and drying to obtain deeply-modified attapulgite; cyclically modifying via filtrates obtained by the primary acid modification and secondary alkali modification and part of a washing liquor which fresh inorganic acids and alkaline salts are added, and neutralizing the rest washing liquor. Attapulgite is deeply modified via chemical redox at low temperature, further improvements on surface characteristics and texture performance of the attapulgite are promoted, modification wastewater is effectively treated, and the method is an efficient green thorough method of modifying attapulgite.

Owner:盱眙凹土能源环保材料研发中心

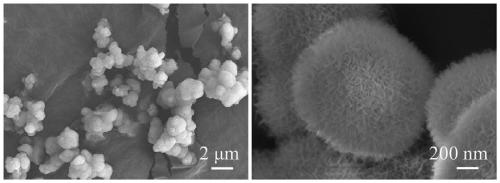

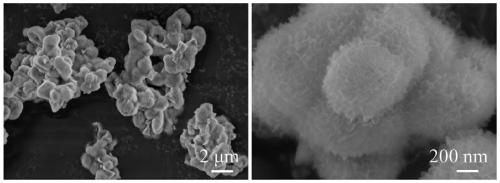

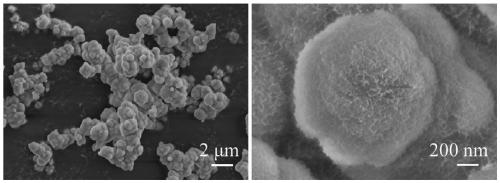

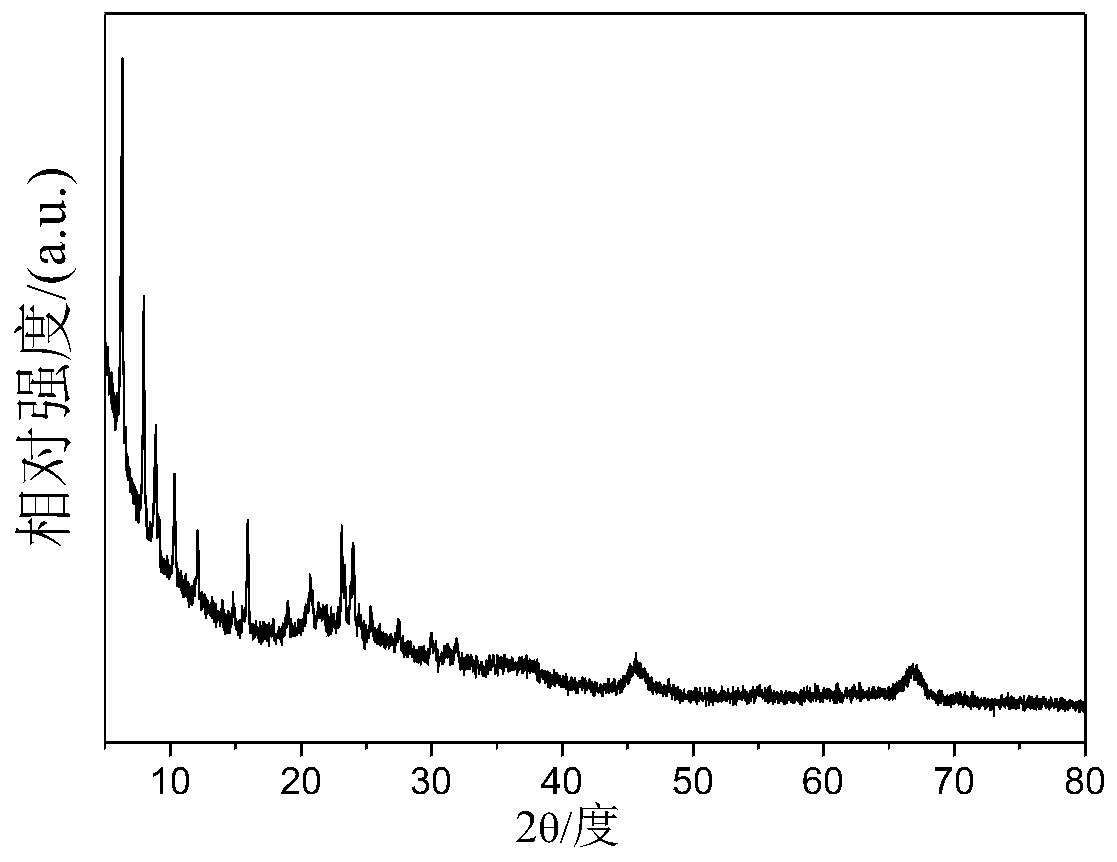

Preparation method of graded mesoporous hydration aluminium oxide microsphere capable of controlling crystal forms

ActiveCN110386613AHigh crystallinityGood dispersionMicroballoon preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydrated aluminaAlcohol

The invention relates to a preparation method of a graded mesoporous hydration aluminium oxide microsphere capable of controlling crystal forms. The preparation method comprises the following steps oftaking a certain formamide to quickly add a sodium aluminate solution, and evenly mixing; then quickly adding the solution into a hydrothermal kettle, heating to hydrolyze for a period of time, aftercooling, filtering generated white precipitate, adding water and absolute ethyl alcohol in sequence to clean, and obtain a filter cake; and drying the filter cake, and obtaining the flowerlike mesoporous hydration aluminium oxide microsphere with different crystal forms formed by assembling two-dimensional nanometer sheets. According to the flowerlike hydrated alumina microsphere with the different crystal forms, good texture property is achieved, hydrothermal time, a hydrothermal temperature and the formamide additive amount are changed, pore structural parameters of the microsphere can change under the following ranges: 103.7-250.1 m2 / g of a specific surface area, 0.20-0.35 cm3 / g of the pore volume and 4.3-5.4 nm of the average pore diameter, and concentration distribution of pore diameters is 3.3-5.2 nm.

Owner:GUANGZHOU UNIVERSITY

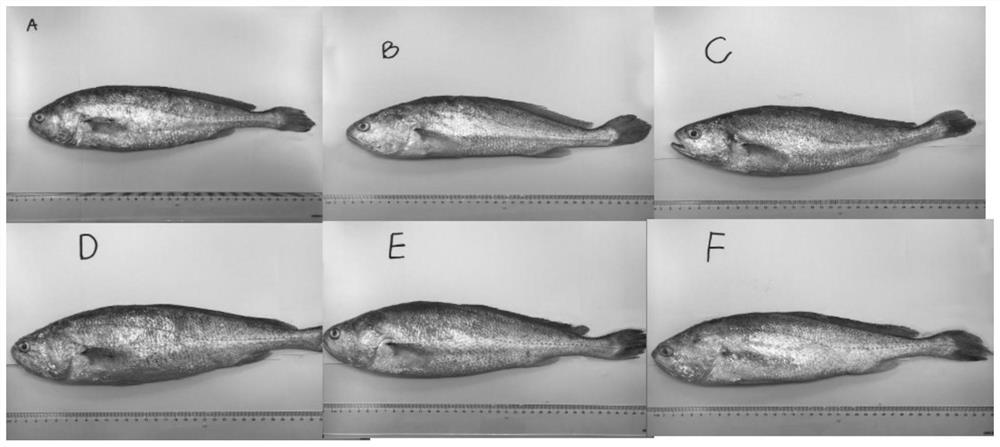

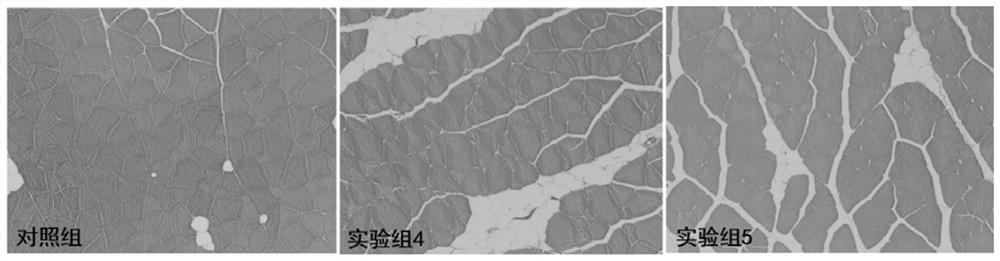

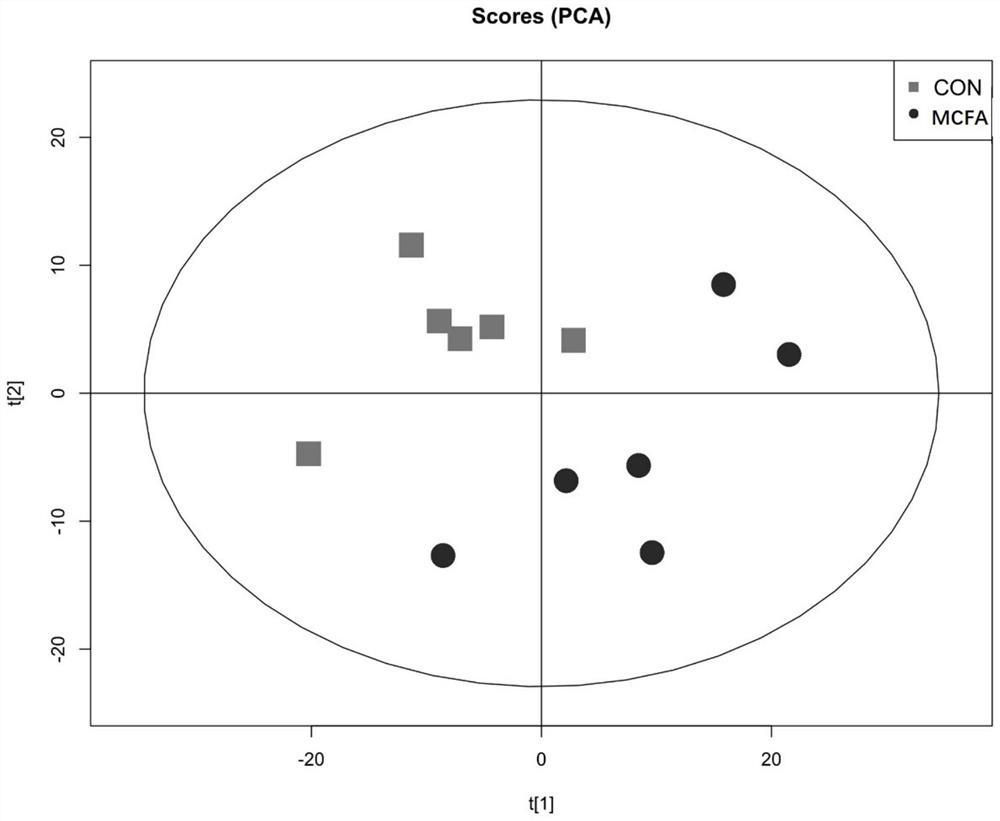

Application of compound feed additive in preparation of feed for improving muscle texture of cultured large yellow croakers

ActiveCN112042810AIncrease mRNA levelsImproved muscle fiber diameterFood processingClimate change adaptationProtein proteinGlycerol

The invention discloses application of a compound feed additive in preparation of feed for improving muscle texture of cultured large yellow croakers. Glycerol monolaurate, glycerol caprate and glycerol caprylate are used as feed additives and are added into the feed for culturing the large yellow croakers according to a ratio. According to the application disclosed by the invention, medium-chainfatty acid is applied through the feed additive, so that the mRNA level synthesized by muscle fibers in bodies of the cultured large yellow croakers can be effectively improved, and a metabolic pathway synthesized by protein and amino acid is up-regulated, and furthermore, the muscle texture and muscle fiber diameter of the large yellow croakers are improved. According to the application disclosedby the invention, the medium-chain fatty acid is applied through the feed additive, so that the content level of the amino acid, fatty acid and flavor substances in the muscles of the cultured largeyellow croakers can also be effectively improved, and furthermore, the flavor substances of the large yellow croakers are improved.

Owner:ZHEJIANG UNIV +1

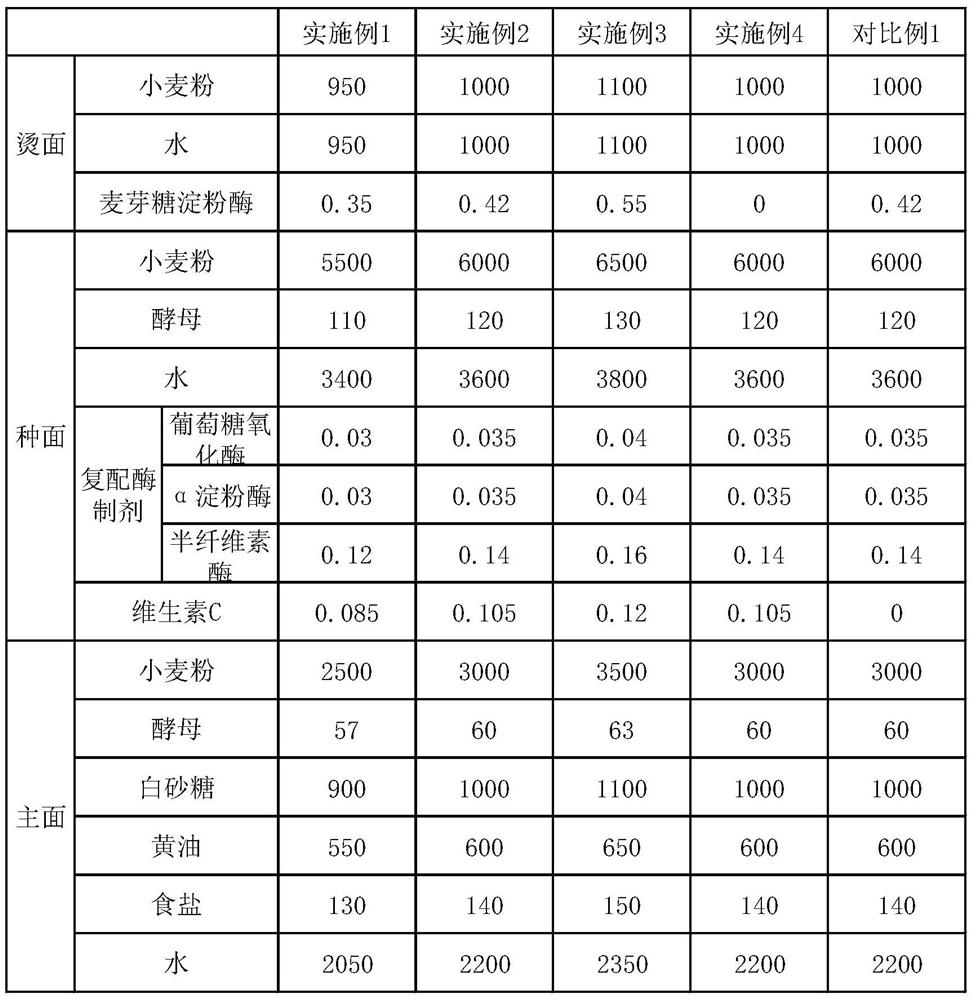

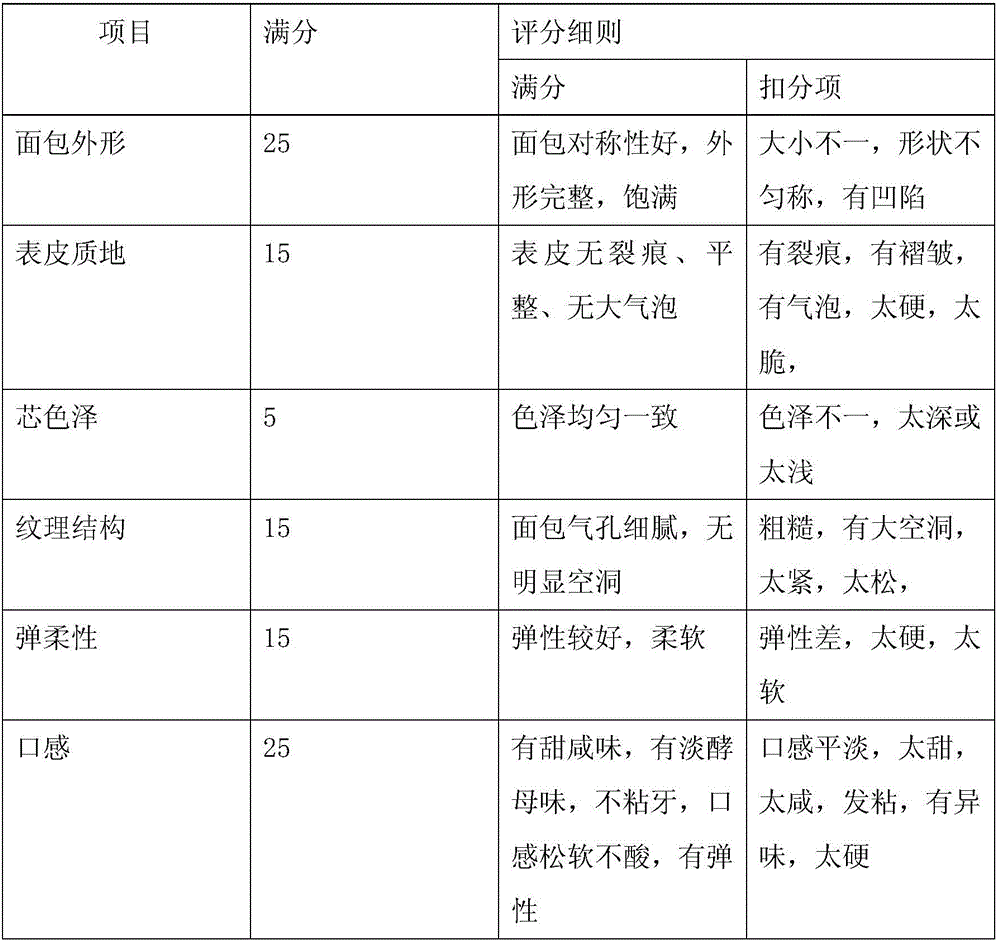

Biological enzyme-improved double-cooked toast and preparation process thereof

ActiveCN111758760AIngredient information is simpleAdapt to the concept of foodDough treatmentClimate change adaptationBiotechnologyVitamin C

The invention discloses biological enzyme-improved double-cooked toast and a preparation process thereof, belongs to the technical field of bread food preparation, and solves the problem that toast iseasy to age when an emulsifier is not used. The technical key points are as follows: the biological enzyme-improved double-cooked toast is prepared from the following components in parts by weight: dough made with boiling water: 950 to 1100 parts of wheat flour and 950 to 1100 parts of water; seed dough: 5500 to 6500 parts of wheat flour, 110 to 130 parts of yeast, 3400 to 3800 parts of water, 0.18 to 0.24 part of an enzyme preparation group and 0.085 to 0.12 part of vitamin C; and main dough: 2500 to 3500 parts of wheat flour, 57 to 63 parts of yeast, 900 to 1100 parts of white granulated sugar, 550 to 650 parts of butter, 130 to 150 parts of a edible salt and 2050 to 2350 parts of water. According to the scheme, the change rate of various texture data of the prepared double-cooked toastis effectively reduced, so that the change amplitudes of hardness, elasticity, chewiness and resilience of the double-cooked toast within the same time are effectively reduced, and the double-cookedtoast has relatively good ageing resistance.

Owner:武汉市仟吉食品有限公司

Yin-nourishing and dryness-moisturizing green tea-Lentinus edodes-lotus leaf steamed bun and preparation method thereof

InactiveCN105533424AStrengthen gluten structureHigh whitenessFood scienceMedicinal herbsToxic material

The present invention discloses a yin-nourishing and dryness-moisturizing green tea-Lentinus edodes-lotus leaf steamed bun and a preparation method thereof. The steamed bun is prepared from the following raw materials in parts by weight: 280-300 parts of wheat, 22-30 parts of fresh lotus leaves, 20-30 parts of Taigan (a kind of dry stemmed vegetable), 14-20 parts of Lentinus edodes, 7-10 parts of green tea, 28-30 parts of rice milk, 1-1.5 parts of gmelin sealavender herb, 1.4-1.5 parts of donkey-hide gelatin, 1-2 parts of Kadsura longipedunculata, a proper amount of white sugar and a proper amount of table salt. The steamed bun is bright in color and luster, chewy in texture and lingering in fragrance after entering the mouth, and the addition of gmelin sealavender herb, donkey-hide gelatin, Kadsura longipedunculata and other edible medicinal herbs makes the steamed bun have health-care benefits in clearing away heat and toxic material, enriching blood and tonifying qi, and nourishing yin and moisturizing dryness.

Owner:周比玥

Lotus-flavor steamed bun with effects of resolving depression, relieving uneasiness of mind and balancing Yin and Yang and preparation method of lotus-flavor steamed bun

The invention discloses a lotus-flavored steamed bun for relieving stagnation and calming the nerves, balancing yin and yang, which is made of the following raw materials in parts by weight: 280-300 parts of wheat, 22-30 parts of fresh lotus leaves, 10-13 parts of shallots, 6-10 parts of pig blood, and sharp peppers 3-5, 5-10 tomatoes, 1-1.4 grain buds, 1-2 sunflower leaves, 0.8-1 Albizia Julibrissin, appropriate amount of sugar and salt. The present invention has bright color, strong mouthfeel, long-lasting fragrance in the mouth, grain buds, sunflower leaves, Albizia julibrissin and other food and medicinal materials are added, which is rich in digestion and strengthening of the spleen, lowering blood pressure and calming the liver, relieving stagnation and calming the nerves, nourishing yin and tonifying yang health benefits.

Owner:WUHE TONGSHIFU FOOD

Composite oxide and preparation method thereof

InactiveCN106824163BImprove thermal stabilityImprove texture propertiesHeterogenous catalyst chemical elementsDispersed particle separationRoom temperatureCoprecipitation

The invention discloses a composite oxide and a preparation method thereof. A precursor solution of the composite oxide is prepared, and the precursor solution and an alkali solution are subjected to a titration reaction at room temperature using a co-precipitation method under high-speed stirring in an environment of pH=8.5 to 9.5. , the composite hydroxide slurry obtained by the titration reaction is rapidly heated to 50-80°C to grow the crystal grains, and is stirred at this temperature for 1-3 hours. Add alkali solution to maintain the pH value of the composite hydroxide slurry, and then cool to room temperature. The crystal grains are left to grow slowly for 1 to 6 days, and then the composite hydroxide slurry is aged at 90 to 95°C for 6 to 8 hours to grow the particles, and finally the composite oxide is obtained by roasting at 600 to 1000°C. The texture properties of the composite oxide prepared by the present invention have the characteristics of higher specific surface, larger pore volume and wider pore size distribution than the sample prepared by the traditional constant temperature titration reaction. It is suitable for mobile sources such as motor vehicle exhaust purification, stationary sources such as catalytic combustion or easy volatilization. It can be used as a carrier material in exhaust gas treatment or directly as a catalyst, so it has a wide range of applications.

Owner:SICHUAN UNIV

Denitration catalyst and preparation method thereof, and waste gas denitration method

ActiveCN113368865AImprove dispersionBalances Acidity and OxidationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganese oxideExhaust fumes

The invention provides a denitration catalyst and a preparation method thereof, and a waste gas denitration method, belonging to the field of waste gas treatment. The denitration catalyst comprises a core layer, a middle layer and a shell layer, wherein the core layer comprises titanium nanotubes, the middle layer comprises manganese oxide, and the shell layer comprises iron oxide. The preparation method of the denitration catalyst comprises the following steps: subjecting a manganese oxide precursor to reacting with the titanium nanotubes to obtain the titanium nanotubes loaded with the manganese oxide, and then modifying the titanium nanotubes loaded with the manganese oxide by using an iron source to obtain the denitration catalyst. According to the waste gas denitration method, waste gas denitration is carried out by using the denitration catalyst. The denitration catalyst provided by the invention has higher stability, activity, selectivity and sulfur resistance; raw materials used in the preparation method are environment-friendly and easily available, operation is simple and controllable, and expanded production is facilitated; and when the denitration catalyst is used for denitration treatment of waste gas, a denitration rate is high, selectivity is good, and stability is high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of frozen dough and its preparation method and application

The invention belongs to the technical field of food processing, and in particular relates to a frozen dough and its preparation method and application. The frozen dough of the present invention is made of the following raw materials in parts by weight: 1 to 5 parts of yeast, 180 to 230 parts of high-gluten flour, 10 to 30 parts of sugar, 1 to 5 parts of edible salt, 10 to 30 parts of inulin, 20 to 30 parts of 40 parts of eggs, 0.5-1 part of edible glycerin, 50-70 parts of water, 10-20 parts of butter. The dough made from the above raw materials is relaxed, proofed, divided and shaped, and then frozen to obtain the frozen dough of the present invention. Inulin and edible glycerin are added to the frozen dough of the invention, and the formula is simple and the cost is low. Moreover, the inulin and edible glycerin in the frozen dough of the present invention have a coordination effect after being mixed, can obviously improve the texture properties of the food, and improve its processing performance and nutritional value.

Owner:HENAN UNIV OF SCI & TECH

Lung-moistening heart-clearing steamed bun with arrowroot and lotus leaf and production method thereof

The invention discloses lung-moistening heart-clearing steamed bun with arrowroot and lotus leaf, made from the following materials according to parts by weight: 280-300 parts of wheat, 22-30 parts of fresh lotus leaf, 5-6 parts of banana peel, 8-10 parts of aloe peel, 11-12 parts of lemon pulp, 13-14 parts of candied dates, 1.2-2 parts of Radix Asparagi, 1.3-2 parts of Flos Trollii, 1.5-2 parts of arrowroot, and suitable white sugar and edible salt. The lung-moistening heart-clearing steamed bun with arrowroot and lotus leaf is bright in color and chewy, has aftertaste and is imparted the health effects of nourishing yin and promoting secretion of bodily fluid, moistening lung and clearing heat, and reinforcing stomach and relieving cough by adding the edible herbs such as Radix Asparagi, Flos Trollii and arrowroot.

Owner:WUHE TONGSHIFU FOOD

Green wheat bread and preparation method thereof

PendingCN105961498AImprove sensory qualityImprove texture propertiesDough treatmentBakery productsWheat breadSugar

The invention belongs to the technical field of food preparation, and particularly relates to a green wheat bread and a preparation method thereof. The green wheat bread is prepared from, by weight, 500 parts of green wheat flour, 70-80 parts of sugar, 3-5 parts of salt, 200-300 parts of water, 10 parts of yeast, 50-70 parts of eggs, 10-20 parts of milk powder and 25-35 parts of shortening, wherein the green wheat flour is obtained by mixing green wheatberry flour with flour, and the mass of the green wheatberry flour accounts for 5-30% of the mass of the green wheat flour. The green wheat bread is good in both organoleptic quality and texture property, the nutrient and taste are ensured, and the green wheat bread is simple in preparation process, suitable for industrial production and capable of being easily accepted by mass consumers.

Owner:HENAN ACAD OF AGRI SCI

A preparation method of graded mesoporous hydrated alumina microspheres with controllable crystal form

ActiveCN110386613BHigh crystallinityGood dispersionMicroballoon preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydrated aluminaMicrosphere

Owner:GUANGZHOU UNIVERSITY

Catalyst carrier and supported catalyst, preparation method and application thereof, and method for producing synthesis gas by dry reforming of methane

ActiveCN105562113BSimple processReduce manufacturing costHydrogenCatalyst carriersSolventCatalyst support

The invention relates to a preparation method of a catalyst carrier, a preparation method of a supported catalyst, the supported catalyst, a use of the supported catalyst and a method for producing synthetic gas through dry reforming of methane through the supported catalyst. According to the preparation method of the catalyst carrier, a sale carrier precursor such as pseudo-boehmite as a raw material is used, a carrier modification assistant is directly added into a glue solvent such as a dilute nitric acid solution, simultaneously, a pore forming agent and an extrusion aid are added into the solution, the mixture is mixed and is extruded to form strips and the strips are dried and roasted. The carrier is roasted once so that the carrier has excellent texture properties, has a large specific surface area and is conducive to active metal uniform dispersion. The carrier carries an active metal Ni to form the supported catalyst and the supported catalyst is used for a methane dry reforming catalytic reaction. Compared with the same type of the existing catalyst, the supported catalyst has higher catalytic activity and better resistance to carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

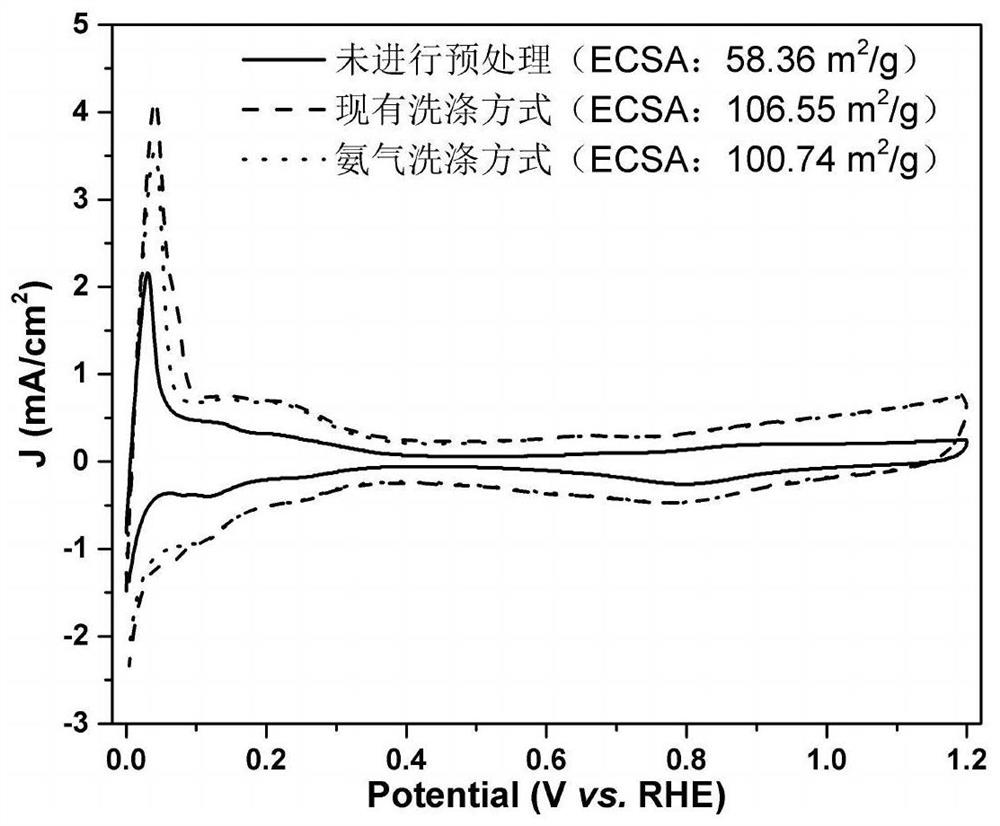

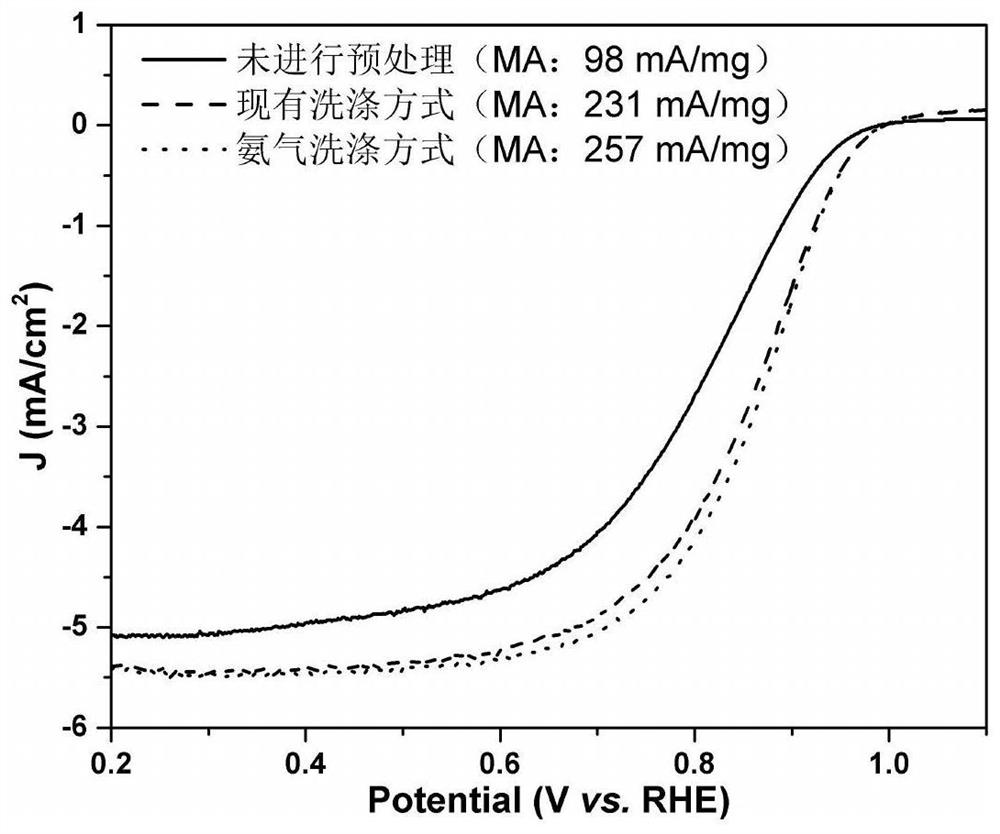

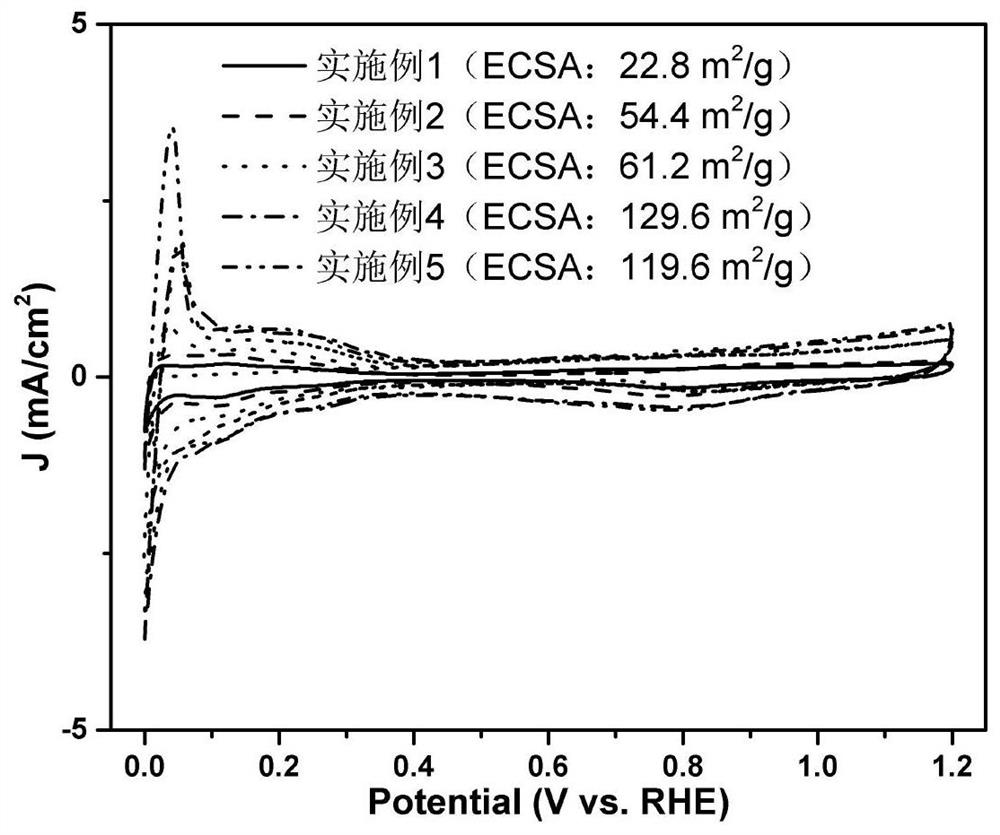

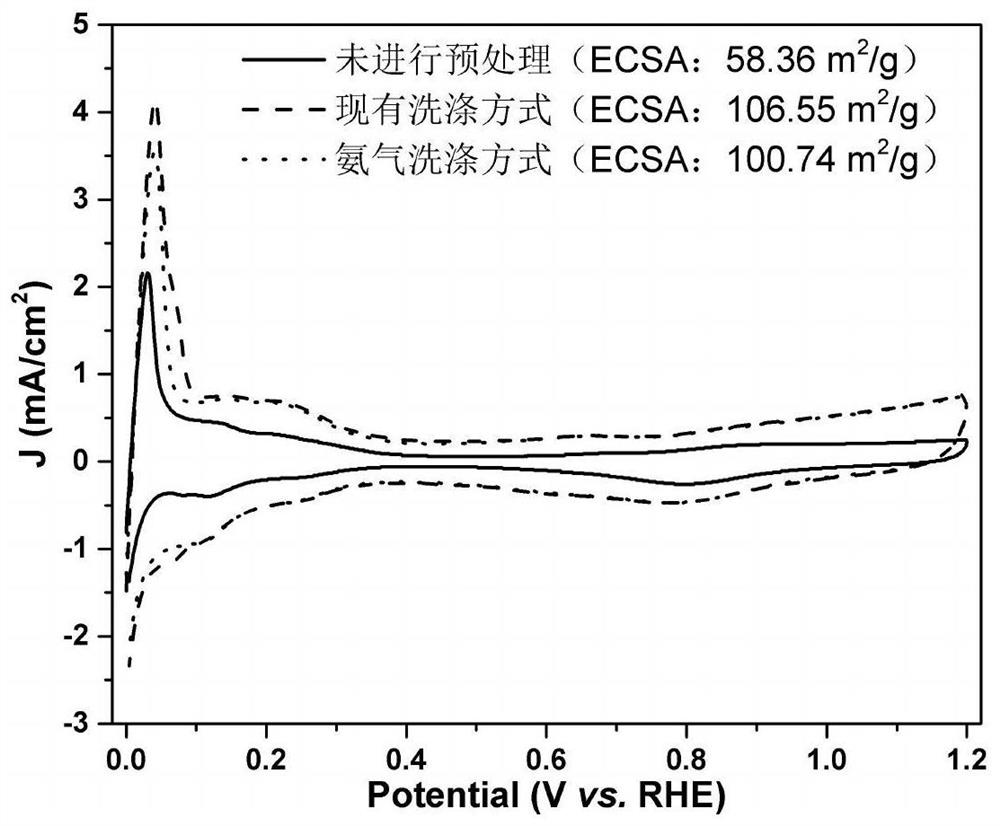

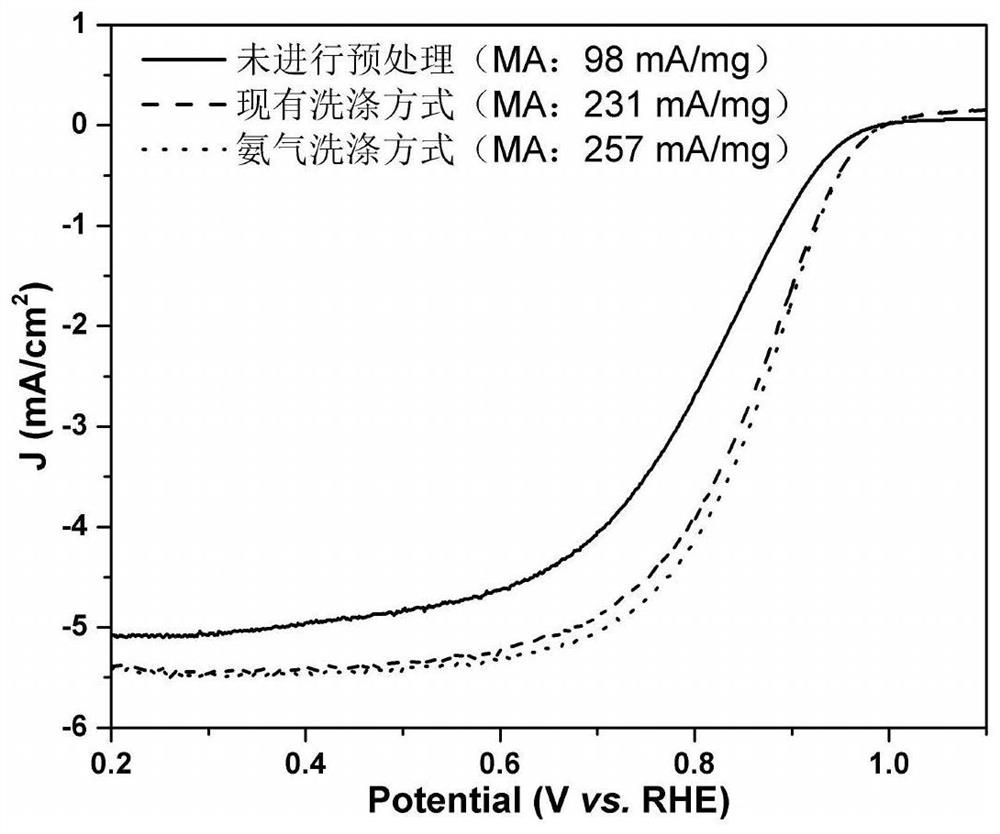

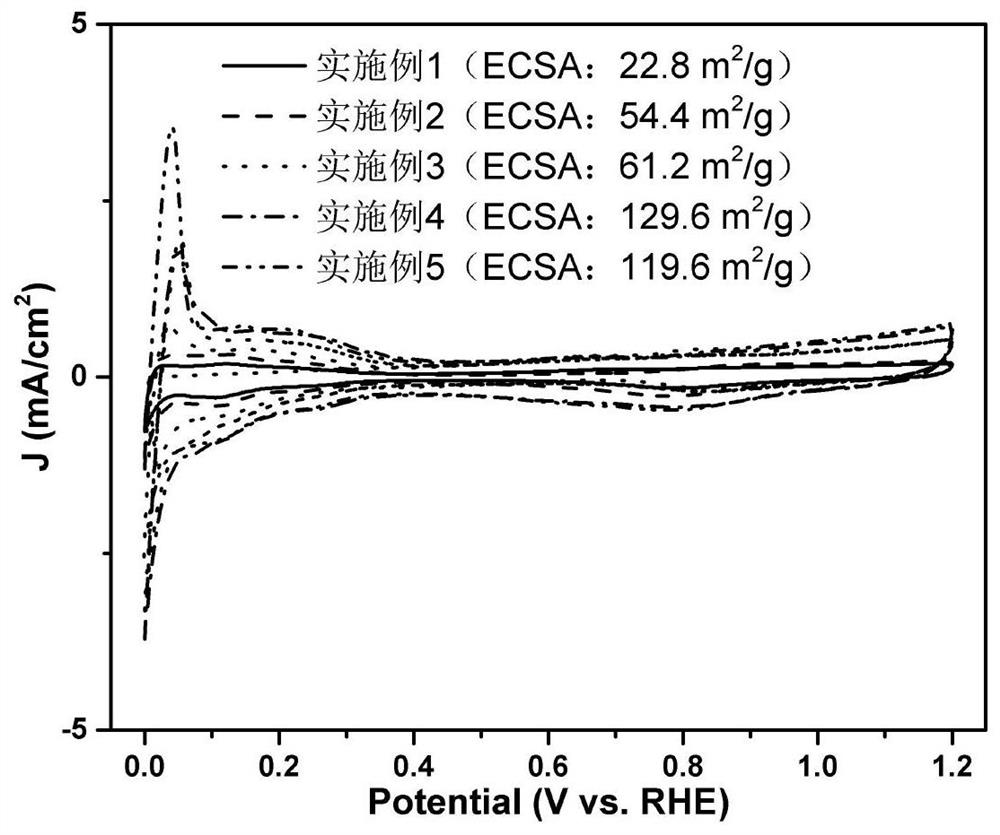

A kind of pretreatment method and carbon carrier of carbon carrier for battery catalyst

ActiveCN112331862BAvoid excessive oxidationImprove texture propertiesCell electrodesPtru catalystPretreatment method

The invention discloses a pretreatment method for a carbon carrier used in a battery catalyst and the carbon carrier. Including: washing the carbon carrier with an organic solvent, drying and crushing after filtering and rinsing, pickling with oxidative acid, dispersing in water after filtering and rinsing, introducing ammonia gas and stirring rapidly, drying, thermal decomposition, evaporating the suspension liquid to dryness, and obtaining The solid is ground into powder to make a carbon carrier for battery catalyst. The pretreatment method of the present invention can improve the texture properties and surface chemical properties of the original carbon carrier itself, and the prepared carbon carrier can increase the loading and dispersion of noble metal particles when preparing electrocatalysts; the pretreatment method can reduce the carbon carrier in the carbon carrier. Ash impurity content, the treatment method of the present invention reduces the carbon carrier washing time and deionized water consumption, and provides a more environmentally friendly, friendly and efficient pretreatment process for further industrial production.

Owner:SINOCAT ENVIRONMENTAL TECH

Small shrimp and fruit steamed bun with effects of protecting liver and promoting gallbladder and preparation method of small shrimp and fruit steamed bun

InactiveCN105982169AHigh in proteinTight textureNatural extract food ingredientsFood ingredient for microbe protectionTriticum turgidumSugar

The invention discloses a small shrimp and fruit steamed bun with effects of protecting the lever and promoting the gallbladder. The small shrimp and fruit steamed bun is prepared from the following raw materials in parts by weight: 280-300 parts of wheat, 22-30 parts of fresh Folium Nelumbinis, 18-19 parts of small shrimps, 6-8 parts of Jasmine tea juice, 14-16 parts of Fructus Rubi, 23-24 parts of Fericarpium Citri Limoniae, 0.9-1 part of Acacia catechu, 2-3 parts of Radix Peucedani, 1.3-2 parts of Caulis Kadsurae Coccineae, a proper amount of white sugar, and a proper amount of salt. The small shrimp and fruit steamed bun is bright in color, is chewy and has fragrance when a person eats the steamed bun, is added with medicinal materials such as Acacia catechu, Radix Peucedani and Caulis Kadsurae Coccineae, and therefore has health-care effects of protecting the liver and promoting the gallbladder, and promoting flow of Qi and blood.

Owner:WUHE TONGSHIFU FOOD

A kind of inulin low-fat yogurt pudding and preparation method thereof

Owner:HENAN UNIV OF SCI & TECH

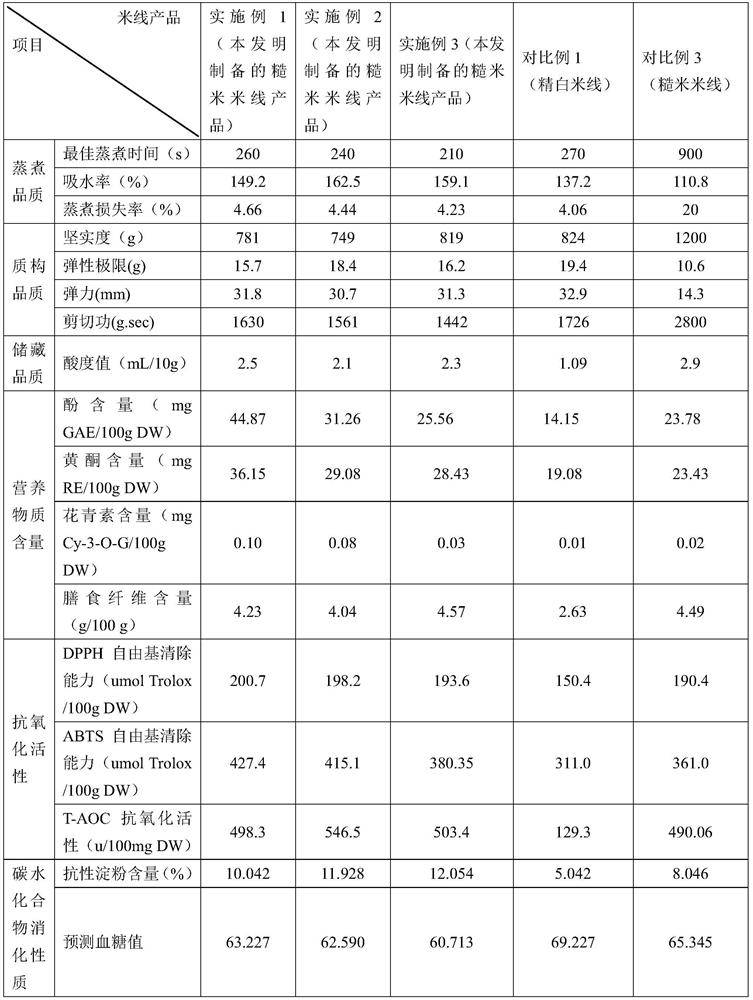

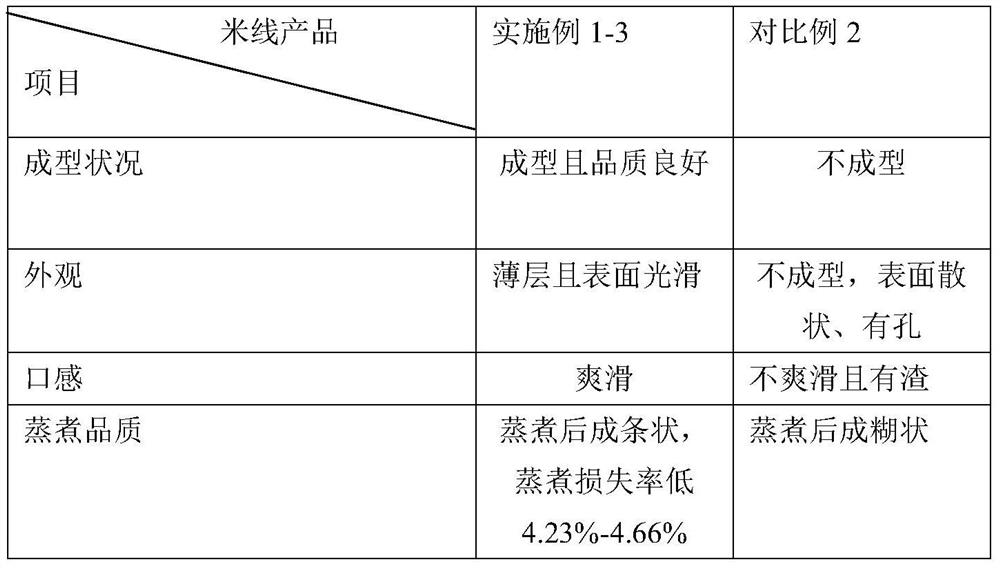

A preparation method of brown rice noodle with improved steaming and eating quality

The invention discloses a method for preparing brown rice noodles with improved cooking and eating quality. The method comprises grinding brown rice to obtain rice bran and white rice, rice bran stabilization treatment and soaking milling and refining, soaking white rice milling and refining, mixing rice bran flour slurry and white rice flour slurry for second refining, steaming flour, aging, cutting Stripping, drying and other steps are used to prepare brown rice noodles with improved cooking and edible quality. The method of the present invention adopts brown rice bran stabilization technology, mixed slurry secondary grinding technology and particle fineness control technology, and the prepared brown rice noodle has low breaking rate and loss rate, long shelf life, low digestion rate and low glycemic index. The content of phenolic substances and dietary fiber increased, which significantly improved the quality of brown rice noodles.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

Pretreatment method of carbon carrier for battery catalyst and carbon carrier

ActiveCN112331862AAvoid excessive oxidationImprove texture propertiesCell electrodesPtru catalystPretreatment method

The invention discloses a pretreatment method of a carbon carrier for a battery catalyst and the carbon carrier. The preparation method comprises the following steps: washing a carbon carrier with anorganic solvent, filtering and rinsing the carbon carrier, drying and crushing the carbon carrier, carrying out oxidative acid pickling, filtering and rinsing the carbon carrier, dispersing the carboncarrier in water, introducing ammonia gas, quickly stirring and drying the components, carrying out thermal decomposition, evaporating turbid liquid to dryness, and grinding the obtained solid into powder, thereby obtaining the carbon carrier for the battery catalyst. According to the pretreatment method, the texture property and the surface chemical property of the original carbon carrier can beimproved, and the loading capacity and the dispersity of noble metal particles can be improved when the prepared carbon carrier is used for preparing an electrocatalyst; according to the pretreatmentmethod, the content of ash impurities in the carbon carrier can be reduced, the washing time of the carbon carrier and the use amount of deionized water are reduced, and a pretreatment process whichis more environmentally friendly and higher in efficiency is provided for further industrial production.

Owner:SINOCAT ENVIRONMENTAL TECH

Precious metal methanation catalyst prepared by solution combustion method, preparation method and application

InactiveCN103801290BImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

A quality improver for recombined products of round toe crab meat and its preparation method

ActiveCN110050966BImprove the gel performanceImprove gelationFood ingredient as antioxidantFood ingredient as thickening agentBiotechnologySodium lactate

The invention discloses a quality improver for recombined products of fine-pointed round-toed crab meat, which consists of the following components in parts by weight: 5-7 parts of trehalose, 5-7 parts of sodium lactate, 0.02-0.03 parts of calcium peroxide, 0.3-0.5 parts of 0.1-0.15 parts of oxidized tea polyphenol modified konjac glucomannan, 0.3-0.5 parts of sucrose ester, 3-5 parts of β-cyclodextrin, and 3-5 parts of corn starch. The quality improver of the recombined product of the fine-pointed round-toed crabmeat of the present invention has a reasonable and scientific formula, simple components, and mutual cooperation among the groups, which can greatly improve the gel performance of the fine-pointed round-toed crabmeat mince and improve the texture properties. The invention also discloses a preparation method for the quality improver of the recombined product of fine-pointed round-toed crabmeat, which has simple process steps, strong operability and low requirements on production equipment.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Lotus-flavored steamed bun and production method thereof

The invention discloses a lotus-flavored steamed bun, which is made of the following raw materials in parts by weight: 280-300 parts of wheat, 22-30 parts of fresh lotus leaves, 9-14 parts of duck blood, 8-10 parts of bamboo shoots, 10-12 parts of distiller's grains, and 7 parts of bean dregs. 8. 1.6-2 apple blossoms, 1.8-2.2 ginseng leaves, 1-2 river willows, appropriate amount of sugar and salt. The present invention has bright color, strong mouthfeel and long-lasting fragrance in the mouth. It also adds food and medicinal materials such as apple blossom, ginseng leaf, and willow, etc., which enriches the present invention to invigorate qi and benefit the lungs, dispel heat and promote body fluid, moisten the lungs and delight the heart, promote body fluid and appetizer, Health benefits of nourishing blood and improving eyesight.

Owner:WUHE TONGSHIFU FOOD

Five-spice beef-tendon steamed buns capable of regulating qi and making method thereof

The invention discloses a spiced beef tendon regulating qi steamed bun, which is made of the following raw materials in parts by weight: 280-300 wheat, 22-30 fresh lotus leaves, 10-20 beef tendon, 2-3 chopped onions, and 10-12 five-spice powder , Kidney Meridian Herb 1.8-2.5, Radix Hessae 2-2.2, Radix Scutellariae Radix 2-3, appropriate amount of sugar and salt. The invention has bright color, strong mouthfeel, and long-lasting fragrance in the mouth. It is also added with edible and medicinal materials such as kidney meridian, red qi, and Radix Scutellariae Radix, which has the health-care effects of nourishing qi and strengthening the surface, regulating qi and relieving pain, strengthening the waist and tonifying the kidney.

Owner:WUHE TONGSHIFU FOOD

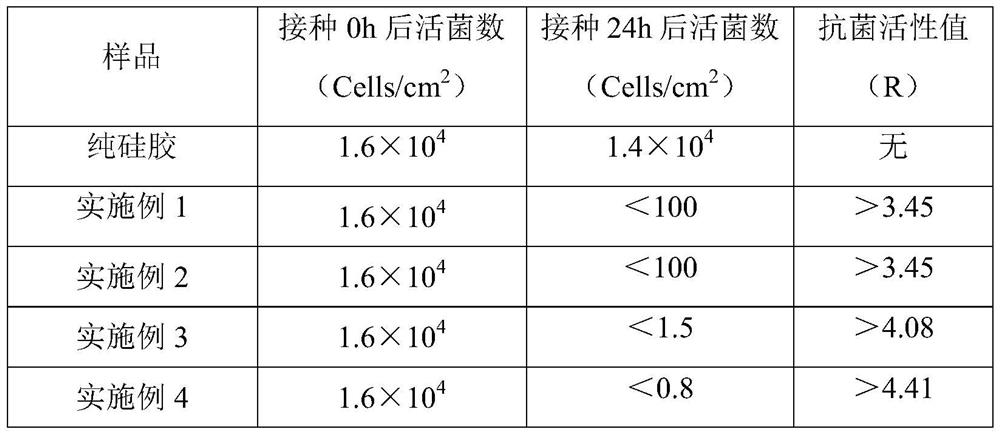

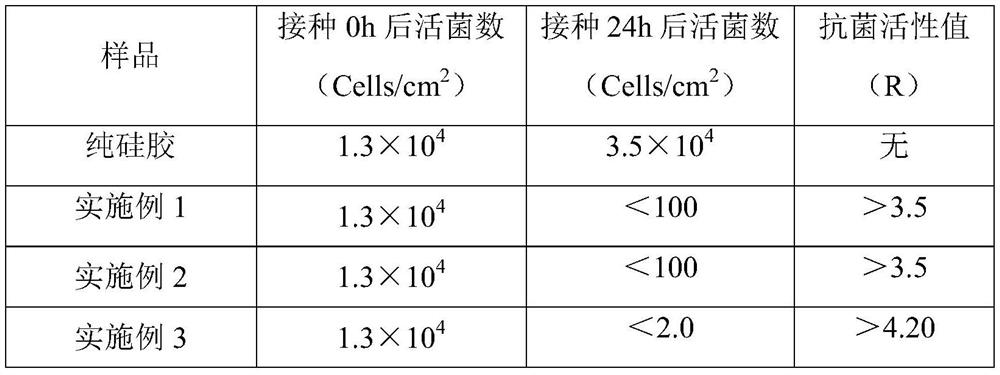

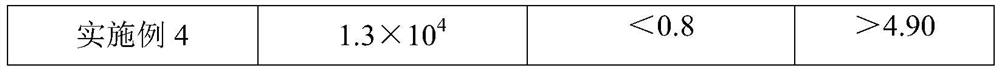

Antibacterial household dehumidifying rotating wheel and preparation method thereof

PendingCN114682045AMild reductionThe reduction process is stableGas treatmentDispersed particle separationChemistryActive agent

The invention relates to the technical field of rotating wheel preparation, in particular to an antibacterial household dehumidifying rotating wheel and a preparation method thereof.The preparation method comprises the steps that an inorganic fiber rotating wheel is pretreated, impregnated with a silicon source at the room temperature, dried and then impregnated in acid liquor for a water bath reaction; drying and roasting after washing to be neutral; dipping into an active agent, washing and drying; and soaking in a metal salt solution for reaction, soaking in a reduction reaction solution for water bath reaction after the reaction is finished, and washing and drying to obtain the antibacterial household dehumidifying rotating wheel. The prepared antibacterial household dehumidification rotating wheel comprises the metal particle-silica gel composite material, the antibacterial property can be effectively generated, the texture property of the material is improved, the water absorption capacity is increased, and the dehumidification performance of the rotating wheel is improved.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD +1

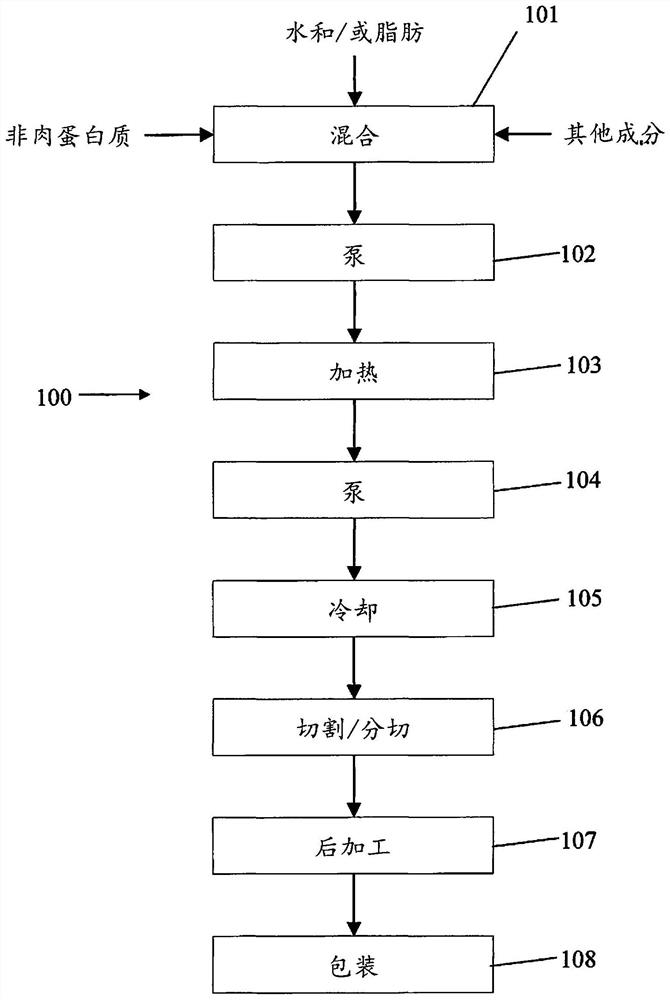

Non-meat food products with the appearance and texture of cooked meat

ActiveCN107105710BImprove texture propertiesImprove palatabilityDough treatmentVitamin food ingredientsBiotechnologyVegetable Proteins

The present invention provides a non-meat food product with the appearance and texture of cooked meat. A method of preparing such a non-meat food product is also provided. In one embodiment, a method comprises: mixing dry ingredients comprising vegetable protein with wet ingredients comprising water and / or oil to form a non-meat dough; heating the non-meat dough under pressure; maintaining said pressure while transferring the heated non-meat dough to a cooling device; and gradually cooling said heated non-meat dough while gradually reducing the pressure on said heated non-meat dough to form a non-meat dough food product. The mixing may be performed by a batch mixer or a continuous mixer; the heating may be performed by a device selected from a high shear emulsifier, a heat exchanger, and a dielectric heater; and the gradual cooling may be performed by a heat exchanger.

Owner:SOC DES PROD NESTLE SA

A kind of method that prepares high-efficiency anthraquinone hydrogenation catalyst by FCC waste catalyst

InactiveCN108465482BEmission reductionLow costMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesPtru catalyst

The invention relates to a method for preparing a high-efficiency anthraquinone hydrogenation catalyst from an FCC waste catalyst. The steps of the method are as follows: mix the FCC waste catalyst, NaOH and a small amount of water evenly and roast them at a certain temperature for a period of time; After sufficient grinding, sieve; add a certain amount of deionized water to the roasted material, raise the temperature to a certain temperature, stir and age for a period of time; after aging, raise the temperature to a certain temperature, stir and crystallize for a period of time; filter, wash and dry the resulting filter cake. That is 4A zeolite; use H 2 PdCl 4 The above-mentioned 4A zeolite is impregnated with an equal volume of the solution, and then excessively impregnated with NaOH solution, and then washed, dried and calcined in sequence to prepare the catalyst. The present invention uses FCC waste catalyst as raw material and obtains zeolite with higher purity at a lower activation temperature. When used as an anthraquinone hydrogenation catalyst carrier, it has the characteristics of catalyst activity and high anthraquinone recycling recovery rate.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com