Green wheat bread and preparation method thereof

A green wheat and bread technology, which is applied in the field of green wheat bread and its preparation, can solve problems such as the integration of green wheat, and achieve the effects of simple production process, high nutritional value, excellent sensory quality and texture properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

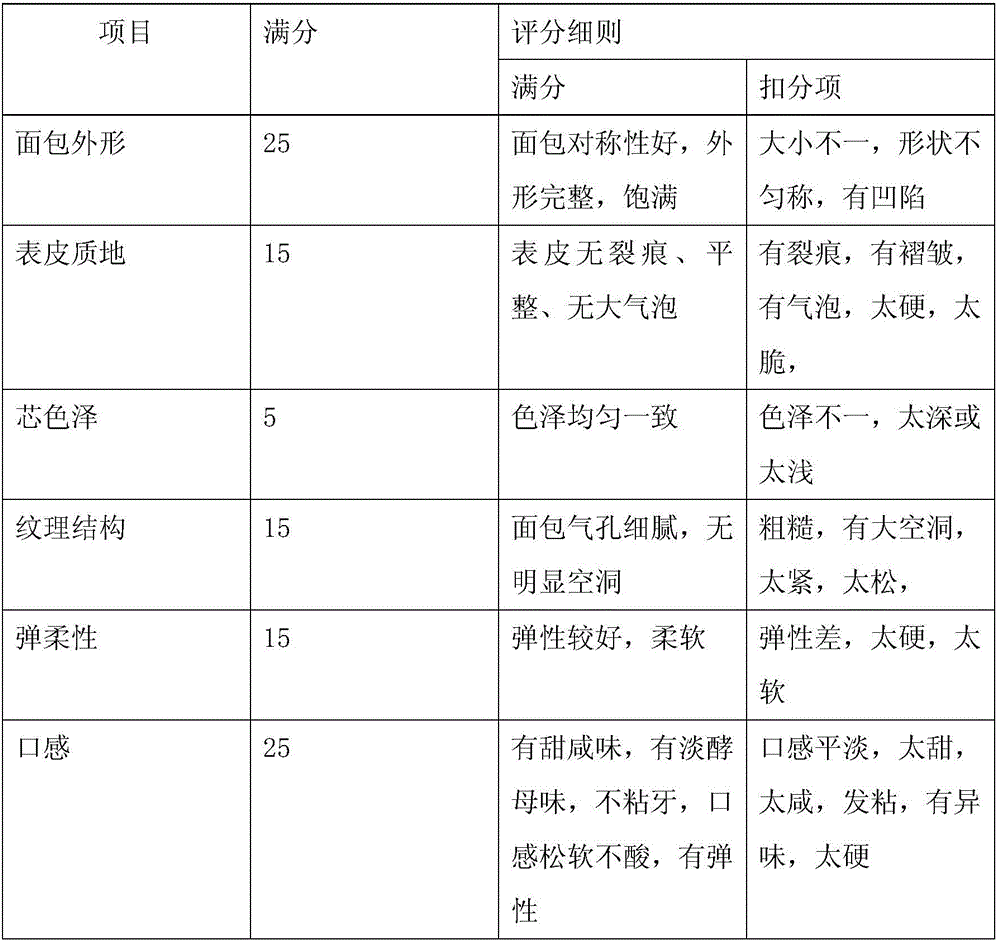

Method used

Image

Examples

Embodiment 1

[0041] Green wheat bread, raw materials are as follows:

[0042] Green wheat kernel powder 50g, bread flour 450g, sugar 70g, salt 4g, water 255g, egg 1, milk powder 20g, shortening 30g, yeast 10g.

[0043] The preparation method is as follows:

[0044] 1) Preparation of green wheat flour: thaw the finished green wheat kernels, remove impurities, drain, put them in a vacuum freeze-drying box, freeze at -30°C for 2 hours, remove moisture in a vacuum until the water content is 5%, take them out, and crush them until they are over 60°C. The purpose is to add 5% gluten powder of the green wheat kernel powder quality; the green wheat kernel powder and bread flour are fully mixed to obtain green wheat flour;

[0045]2) sugar-salt solution: take sugar and salt respectively, be placed in the 500ml beaker, add 200ml distilled water and constantly stir to make sugar and salt dissolve completely;

[0046] 3) Yeast pretreatment: put the yeast into the remaining water, fully stir, place i...

Embodiment 2

[0054] Green wheat bread, raw materials are as follows:

[0055] Green wheat kernel powder 100g, bread flour 400g, sugar 75g, salt 4g, water 260g, yeast 10g, egg 1, milk powder 15g, shortening 30g.

[0056] The preparation method is as follows:

[0057] Step 1)-4) with embodiment 1;

[0058] 5) Fermentation: Take out the dough, put it into a small pot, and place it in a proofing box; the proofing conditions are temperature 35°C, relative humidity 85%, and time 60 minutes;

[0059] 6) Shaping: Take out the dough, discharge the dough gas, use a tablet machine to form a piece three times, then roll up the dough piece, compact it as much as possible during the rolling process, with the interface facing down, put it into a bread tin coated with a little oil middle;

[0060] 7) Proofing: put the bread tin with dough into a proofing box with a temperature of 35°C and a relative humidity of 85%, and proof for 45 minutes;

[0061] 8) Baking: put the bread tin with the dough into th...

Embodiment 3

[0064] Green wheat bread, raw materials are as follows:

[0065] Green wheat kernel powder 150g, bread flour 350g, sugar 80g, salt 4g, water 265g, yeast 10g, egg 1, milk powder 10g, shortening 30g.

[0066] The preparation method is as follows: steps 1)-4) are the same as in Example 1;

[0067] 5) Fermentation: Take out the dough, put it into a small pot, and place it in a proofing box; the proofing conditions are temperature 34°C, relative humidity 83%, and time 55 minutes;

[0068] 6) Shaping: Take out the dough, discharge the dough gas, use a tablet machine to form a piece three times, then roll up the dough piece, compact it as much as possible during the rolling process, with the interface facing down, put it into a bread tin coated with a little oil middle;

[0069] 7) Proofing: put the bread tin with dough into a proofing box with a temperature of 34°C and a relative humidity of 84%, and proof for 40 minutes;

[0070] 8) Baking: put the bread tin with dough into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com