Antibacterial household dehumidifying rotating wheel and preparation method thereof

A runner, household technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor extract stability, high extraction cost, easy volatility, etc., achieve stable reduction process, improve dehumidification performance, Restorative mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

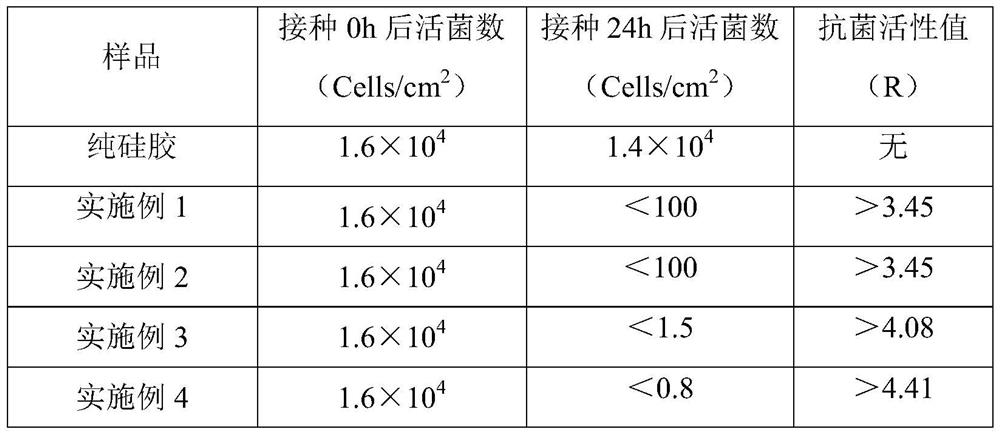

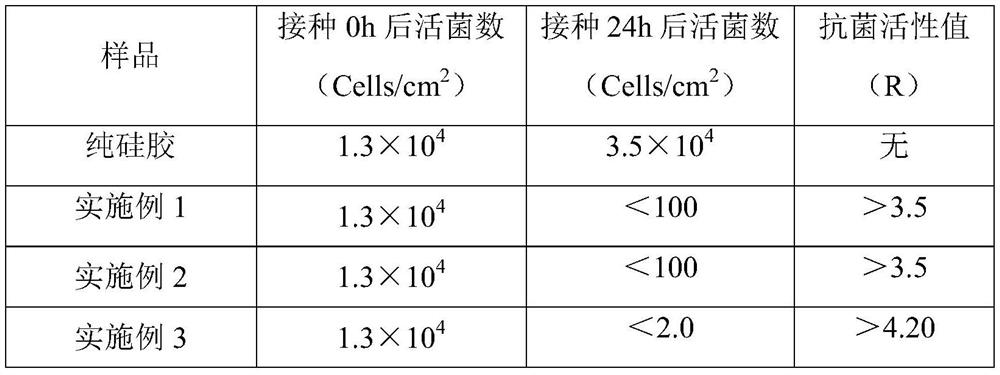

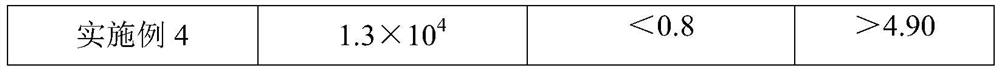

Examples

Embodiment 1

[0037] A preparation method of an antibacterial household dehumidification wheel, the method comprises the following steps:

[0038] S1: Dry the glass fiber runner at 100°C for 20min, purge to remove impurities, then immerse it in water glass with a concentration of 25% at room temperature, remove excess water glass after repeated pulling and dipping for 5min, and dry at 50°C 2h;

[0039] S2: Immerse the S1 product in sulfuric acid with a pH of 2, keep stirring in a water bath at 50°C, and react for 4h;

[0040] S3: after the reaction, the excess sulfuric acid is removed by the runner, washed with deionized water until neutral, dried and calcined at 150 °C for 3 hours;

[0041] S4: place the S3 product in a 0.1 mol / L sodium metaaluminate solution, wash and dry after immersion reaction for 10 min;

[0042] S5: Immerse the S4 product into ZnCl with a concentration of 0.8 mol / L 2 In the solution, the solution was stirred at 40 °C, and the runner was removed after the reaction ...

Embodiment 2

[0045] A preparation method of an antibacterial household dehumidification wheel, the method comprises the following steps:

[0046] S1: Dry the ceramic fiber runner at 100°C for 20min, purge to remove impurities, then immerse it in water glass with a concentration of 30% at room temperature, remove excess water glass after repeated pulling and dipping for 5min, and dry at 30°C 4h;

[0047] S2: Immerse the S1 product in sulfuric acid with a pH of 3, stir continuously in a water bath at 30°C, and react for 4h;

[0048] S3: after the reaction, the excess sulfuric acid is removed by the runner, washed with deionized water until neutral, dried and calcined at 120 °C for 6 h;

[0049] S4: place the S3 product in a 0.1 mol / L sodium metaaluminate solution, wash and dry after immersion reaction for 10 min;

[0050] S5: Immerse the S4 product into CuSO with a concentration of 0.5 mol / L 4 In the solution, stir the solution at 30 °C, and remove the excess CuSO after the reaction for 2...

Embodiment 3

[0053] A preparation method of an antibacterial household dehumidification wheel, the method comprises the following steps:

[0054] S1: Dry the glass fiber runner at 100 °C for 20 minutes, purge to remove impurities, then immerse it in water glass with a concentration of 30% at room temperature, remove excess water glass after repeated pulling and dipping for 5 minutes, and dry at 80 °C 1h;

[0055]S2: Immerse the S1 product in sulfuric acid with a pH of 1, keep stirring in a water bath at 70°C, and react for 2h;

[0056] S3: after the reaction, the excess sulfuric acid is removed by the runner, washed with deionized water until neutral, dried and calcined at 130 °C for 5 h;

[0057] S4: place the S3 product in a 0.1 mol / L sodium metaaluminate solution, wash and dry after immersion reaction for 10 min;

[0058] S5: Impregnate the S4 product into AgNO with a concentration of 0.6 mol / L 3 In the solution, the solution was stirred at 35 °C, and the excess AgNO was removed afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com