A platinum/titanium dioxide catalyst for dehydrogenation of dodecahydroethylcarbazole and preparation method thereof

A technology of dodecahydroethylcarbazole and titanium dioxide is applied in the field of organic liquid hydride hydrogen storage to achieve the effects of low preparation cost, mild preparation conditions and mild reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

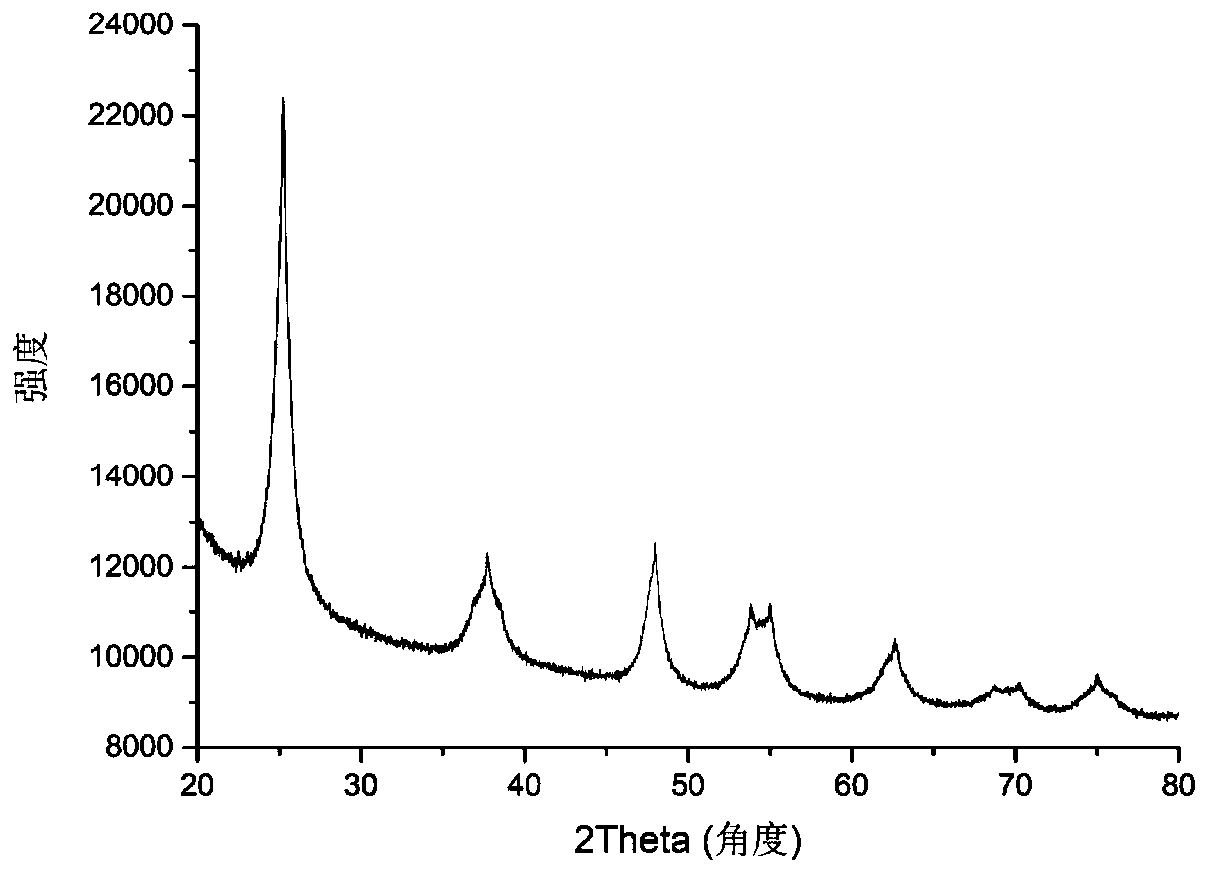

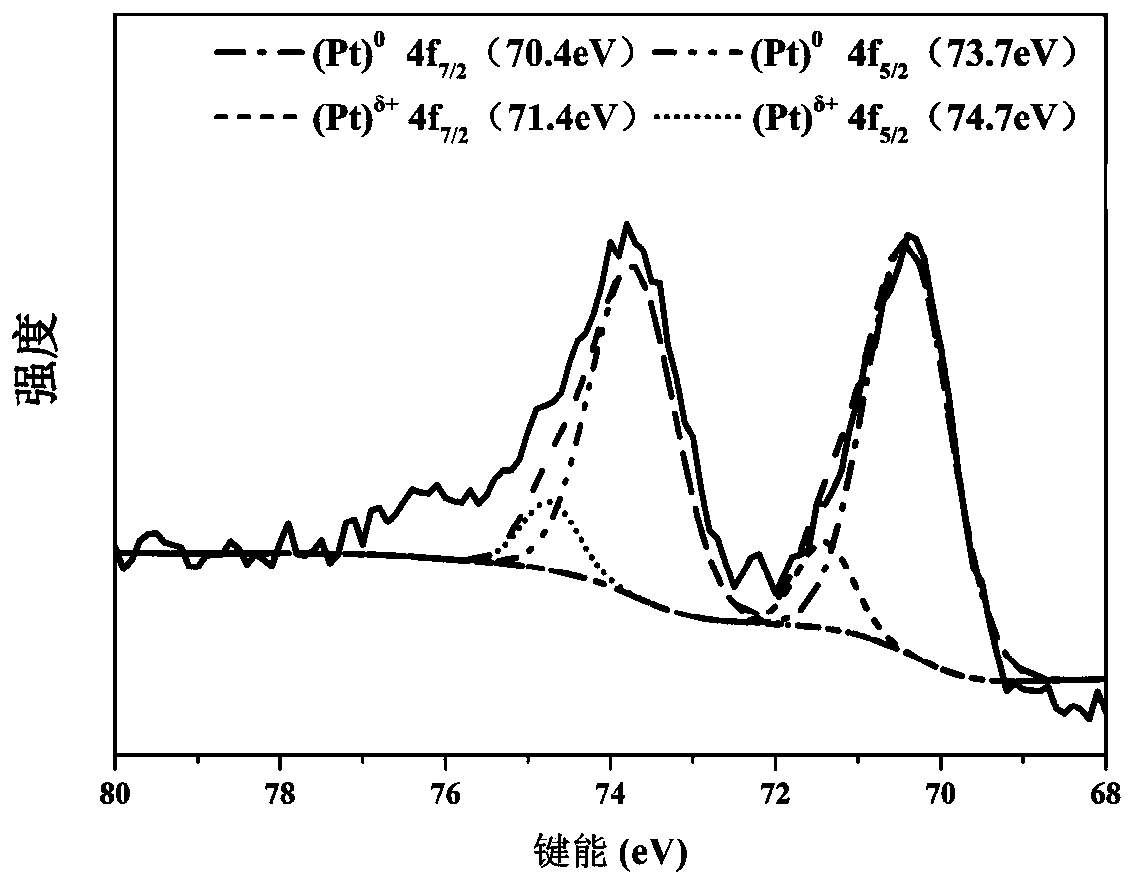

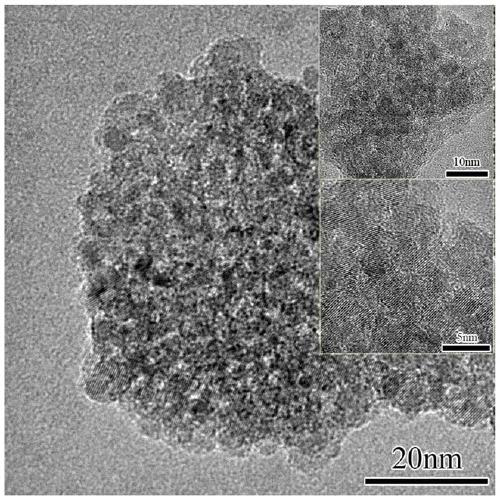

[0033] In this example, a platinum / titanium dioxide catalyst used for dehydrogenation of dodecahydroethylcarbazole, 1.5 g of titanium dioxide and 30 ml of ethylene glycol were added to a container, and the mixture was placed on a magnetic stirrer and stirred for 20 minutes. Then the temperature was raised to 120°C and kept for 20 min, then the heating was stopped and cooled to room temperature. Then the above-mentioned cooled mixture was filtered, rinsed with deionized water and absolute ethanol so that no ethylene glycol remained, and dried in an oven at 60° C. for 6 h. Grind after complete drying, weigh 1.0g for later use.

[0034] Pour 20ml of ethylene glycol into the container, then add 0.0249g of potassium chloroplatinate, place it on a magnetic stirrer and stir for 3h, then add 1.0g of pretreated titanium dioxide that has been weighed to the above mixture of ethylene glycol and platinum , continue stirring for 0.5h, then weigh 0.249g of sodium citrate and add it to the ...

Embodiment 2

[0042] In this example, a platinum / titanium dioxide catalyst used for dehydrogenation of dodecahydroethylcarbazole, 1.0 g of titanium dioxide and 20 ml of ethylene glycol were added to a container, and the mixture was placed on a magnetic stirrer and stirred for 15 minutes. Then the temperature was raised to 120°C and kept for 10 min, then the heating was stopped and cooled to room temperature. Then the above mixture was filtered, rinsed with deionized water and absolute ethanol so that no ethylene glycol remained, and dried in an oven at 70° C. for 8 hours. Grind after complete drying, weigh 0.4g for later use.

[0043] Pour 8ml of ethylene glycol into the container, then add 0.0248g of potassium chloroplatinate, place it on a magnetic stirrer and stir for 3h, then add the weighed 0.4g of pretreated titanium dioxide to the above mixture of ethylene glycol and platinum , continue stirring for 0.5h, then weigh 0.248g of sodium citrate and add it to the above mixture, raise the...

Embodiment 3

[0047] In this example, a platinum / titanium dioxide catalyst used for dehydrogenation of dodecahydroethylcarbazole, 0.8 g of titanium dioxide and 16 ml of ethylene glycol were added to a container, and the mixture was placed on a magnetic stirrer and stirred for 30 minutes. Then the temperature was raised to 130°C and kept for 12 minutes, then the heating was stopped and cooled to room temperature. Then the above mixture was filtered, rinsed with deionized water and absolute ethanol so that no ethylene glycol remained, and dried in an oven at 110° C. for 6 h. Grind after complete drying, weigh 0.5g for later use.

[0048] Pour 10ml of ethylene glycol into the container, then add 0.0655g of potassium chloroplatinate, place it on a magnetic stirrer and stir for 3h, then add the weighed 0.5g of pretreated titanium dioxide to the mixture of ethylene glycol and platinum , continue stirring for 0.5h, then weigh 0.524g of sodium citrate and add it to the above mixture, raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com