Ruthenium oxide hydrate-ruthenium nanoparticle composite material, preparation method and application thereof

A technology of composite materials and nanoparticles, applied in the direction of nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of no interaction at the interface, large difference in surface properties, and no significant improvement in the stability of ruthenium-based materials and other problems to achieve the effect of improving dispersion and stability, helping to stabilize and disperse, and solving poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

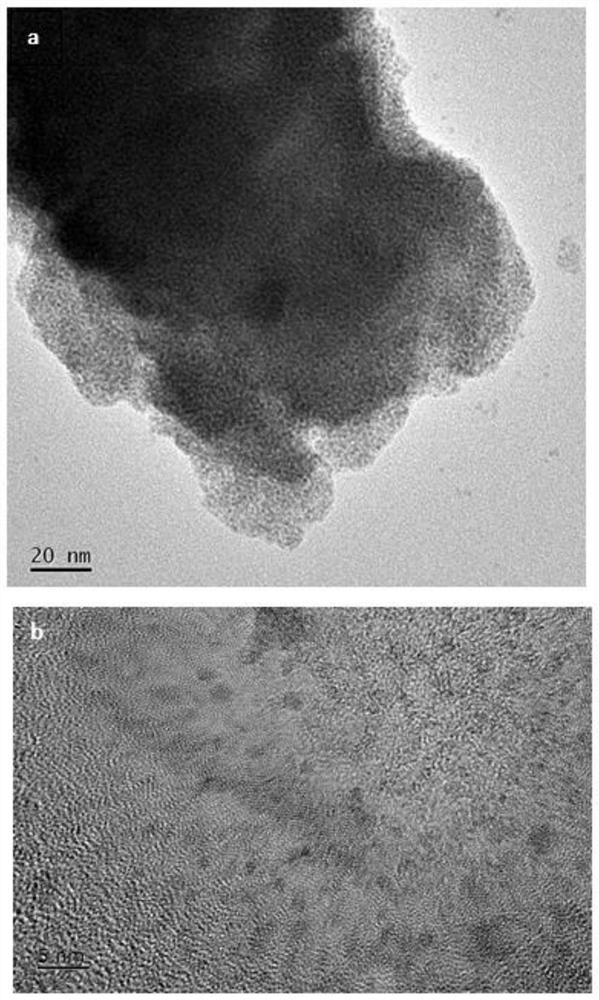

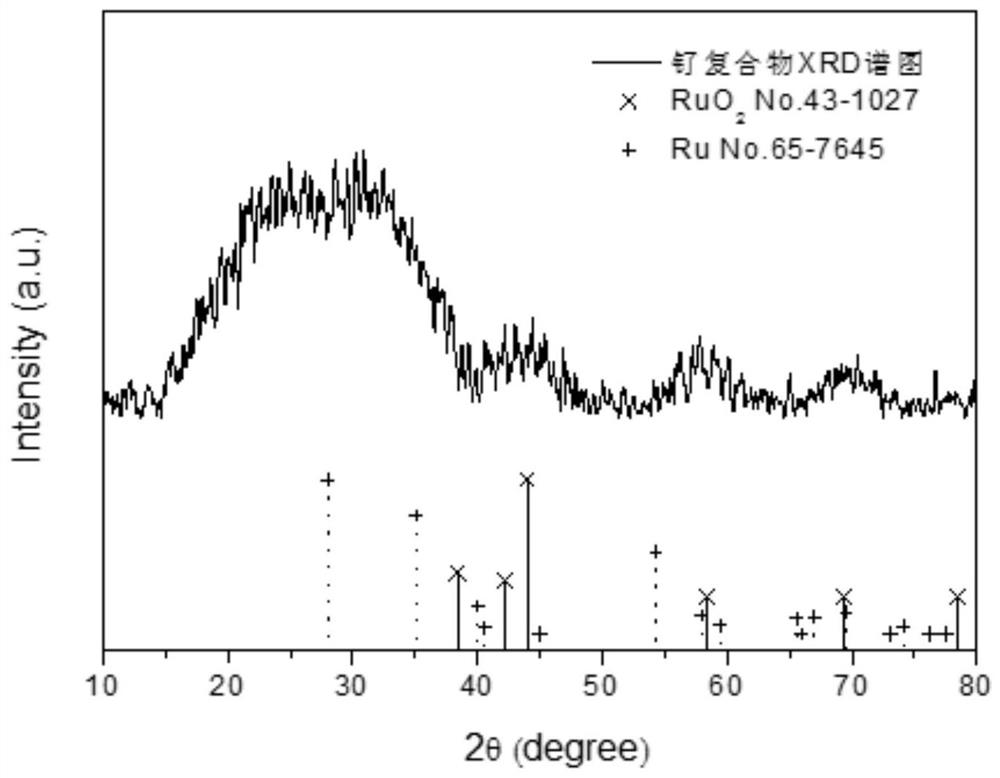

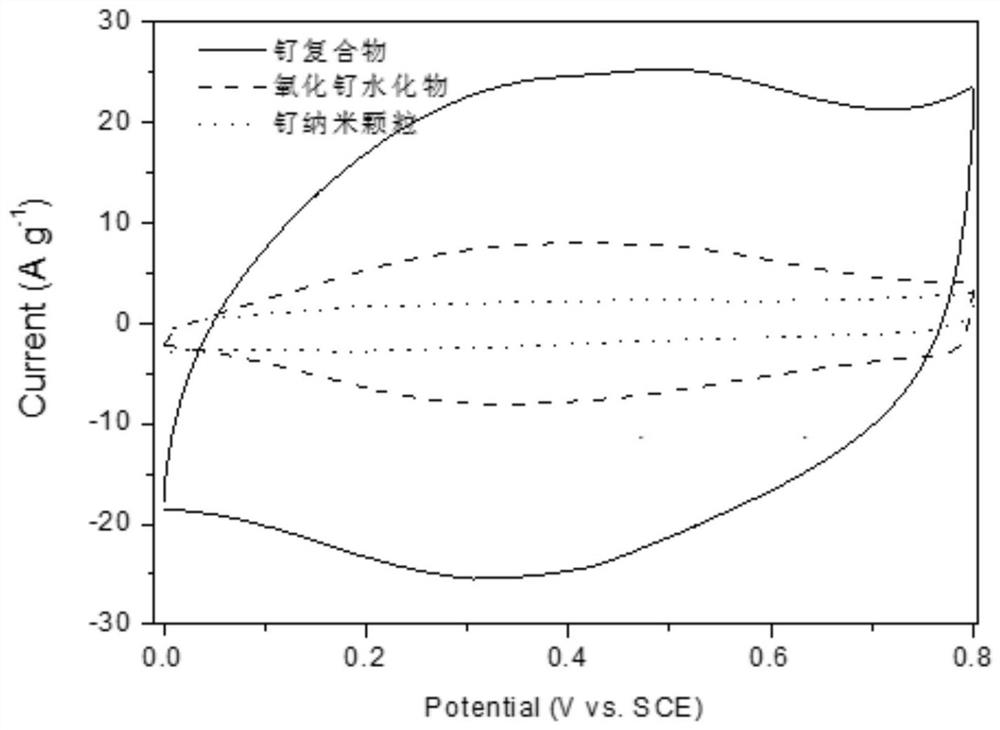

Image

Examples

Embodiment 1

[0031]Add 0.1 g of ruthenium trichloride trihydrate, 0.025 g of Tween-80 and 20 mL of water into a 25 mL hydrothermal reaction kettle, stir and dissolve, adjust the pH value to 7 with 3 mol / L sodium hydroxide solution, and conduct a hydrothermal reaction at 80 °C 2 hours. The precipitated product was suction-filtered, washed 3 times with 2 mL of deionized water, and dried at 40°C for 12 hours to obtain product I.

[0032] Add 0.1 g of ruthenium trichloride trihydrate, 0.2 g of carboxyhexanethiol and 20 mL of ethanol into a 50 mL beaker, stir and dissolve, then use 0.06 g of hydrazine hydrate for reduction reaction for 4 hours. Concentrate to 1 mL by rotary evaporation, centrifuge three times, and dry at 40°C for 12 hours to obtain product II.

[0033] Stir and mix the obtained product I, product II and 20mL water in a 25mL hydrothermal reaction kettle, adjust the pH=4 with 0.1mol / L dilute hydrochloric acid solution, perform a hydrothermal reaction at 60°C for 48 hours, and fi...

Embodiment 2

[0035] Add 0.3 g of ruthenium trichloride trihydrate, 0.05 g of Span-80 and 20 mL of water into a 25 mL hydrothermal reaction kettle. After stirring and dissolving, adjust the pH value to 6 with 3 mol / L sodium hydroxide solution. Hydrothermal reaction at 70 °C for 3 Hours. The precipitated product was suction-filtered, washed three times with 2 mL of deionized water, and dried at 40° C. for 24 hours to obtain product I.

[0036] Add 0.4 g of ruthenium trichloride trihydrate, 0.5 g of carboxybutanethiol and 20 mL of ethanol into a 50 mL beaker, stir and dissolve, then use 0.1 g of hydrazine hydrate for reduction reaction for 6 hours. Concentrate to 1 mL by rotary evaporation, centrifuge three times, and dry at 40°C for 24 hours to obtain product II.

[0037] Stir and mix the obtained product I, product II and 20 mL of water in a 25 mL hydrothermal reaction kettle, adjust the pH to 4 with 0.1 mol / L dilute hydrochloric acid solution, conduct a hydrothermal reaction at 70°C for 4...

Embodiment 3

[0039] Add 0.5 g of ruthenium trichloride trihydrate, 0.085 g of sorbitol and 20 mL of water into a 25 mL hydrothermal reaction kettle, stir and dissolve, adjust the pH value to 9 with 3 mol / L sodium hydroxide solution, and conduct a hydrothermal reaction at 90°C for 4 hours . The precipitated product was suction-filtered, washed three times with 2 mL of deionized water, and dried at 40° C. for 36 hours to obtain product I.

[0040] Add 0.2 g of ruthenium trichloride trihydrate, 0.1 g of carboxyhexanethiol and 20 mL of ethanol into a 50 mL beaker, stir to dissolve, and then use 0.02 g of hydrazine hydrate for reduction reaction for 12 hours. Concentrate to 1 mL by rotary evaporation, centrifuge three times, and dry at 40°C for 48 hours to obtain product II.

[0041] Stir and mix the obtained product I, product II and 20mL water in a 25mL hydrothermal reaction kettle, adjust the pH to 5 with 0.1mol / L dilute hydrochloric acid solution, conduct a hydrothermal reaction at 50°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com