Method of deeply modifying attapulgite to prepare nano carrier material

A technology of attapulgite and nano-carrier, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as waste water pollution, expand application fields, promote surface properties and texture properties, and maximize The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

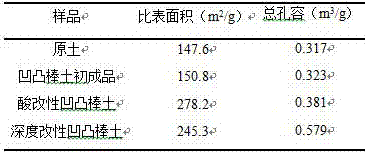

Embodiment 1

[0019] Example 1: According to the following steps, attapulgite is deeply modified to prepare nano-carrier materials

[0020] (1) 100g of attapulgite raw ore was crushed and sieved until the particle size was 60 mesh, added to 800g of water at 50°C and stirred for 2 hours, cooled and settled, and the middle layer slurry was filtered and dried to obtain 76g of attapulgite primary product;

[0021] (2) Grind and sieve the above 76g attapulgite primary product until the particle size is 100 mesh, add it to 456g, 80°C, 12.0wt% sulfuric acid aqueous solution and stir for 2.5 hours, filter to obtain 361g filtrate, wash the solids with water, Dried to obtain 42g acid-modified attapulgite, and collected pickling liquid 720g altogether simultaneously;

[0022] (3) Grind and sieve the above 42g of acid-modified attapulgite until the particle size is 80 mesh, put it into a three-necked flask and completely replace the air with nitrogen, prepare 63mL of 2mol / L sodium borohydride aqueous s...

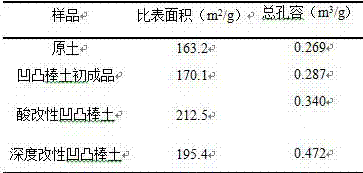

Embodiment 2

[0028] Example 2: According to the following steps, attapulgite is deeply modified to prepare nano-carrier materials

[0029] (1) 80g of attapulgite raw ore was crushed and sieved until the particle size was 200 mesh, added to 400g of water at 80°C and stirred for 1 hour, cooled and settled, and the middle layer slurry was filtered and dried to obtain 65g of attapulgite primary product;

[0030] (2) Crush and sieve the above 65g attapulgite primary product until the particle size is 60 mesh, add it to 325g, 60°C, 6.0wt% nitric acid aqueous solution and stir for 2 hours, filter to obtain 260g filtrate, wash the solids with water, Dried to obtain 48g acid-modified attapulgite, while collecting pickling liquid 640g altogether;

[0031] (3) Grind and sieve the above 48g of acid-modified attapulgite until the particle size is 100 mesh, add it into a three-necked flask and completely replace the air with nitrogen, prepare 96mL of 0.5mol / L sodium metaaluminate aqueous solution, In a...

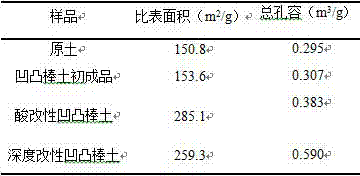

Embodiment 3

[0037] Example 3: According to the following steps, attapulgite is deeply modified to prepare nano-carrier materials

[0038] (1) 50g of attapulgite raw ore was crushed and sieved until the particle size was 100 mesh, added to 200g of water at 75°C and stirred for 3 hours, cooled and settled, and the middle layer slurry was filtered and dried to obtain 32g of attapulgite primary product;

[0039] (2) Crush and sieve the above 32g attapulgite primary product until the particle size is 80 mesh, add it to 96g, 50°C, 15.0wt% hydrochloric acid aqueous solution and stir for 1 hour, filter to obtain 51g of filtrate, wash the solids with water, Dry to obtain 17g acid-modified attapulgite, and collect the pickling liquid 660g altogether simultaneously;

[0040] (3) Crush and sieve the above 17g of acid-modified attapulgite until the particle size is 60 mesh, add it to a three-necked flask and completely replace the air with nitrogen, and prepare a mixture of 1.0mol / L potassium borohydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com