A kind of pretreatment method and carbon carrier of carbon carrier for battery catalyst

A carbon carrier and catalyst technology, which is applied in the field of hydrogen fuel cell material preparation, can solve the problems affecting the electron transport characteristics and strength of carbon carriers, too many carbon carriers, and damage to the structure of carbon carriers, so as to reduce the amount of deionized water and reduce the washing time. , Improve the effect of loading and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

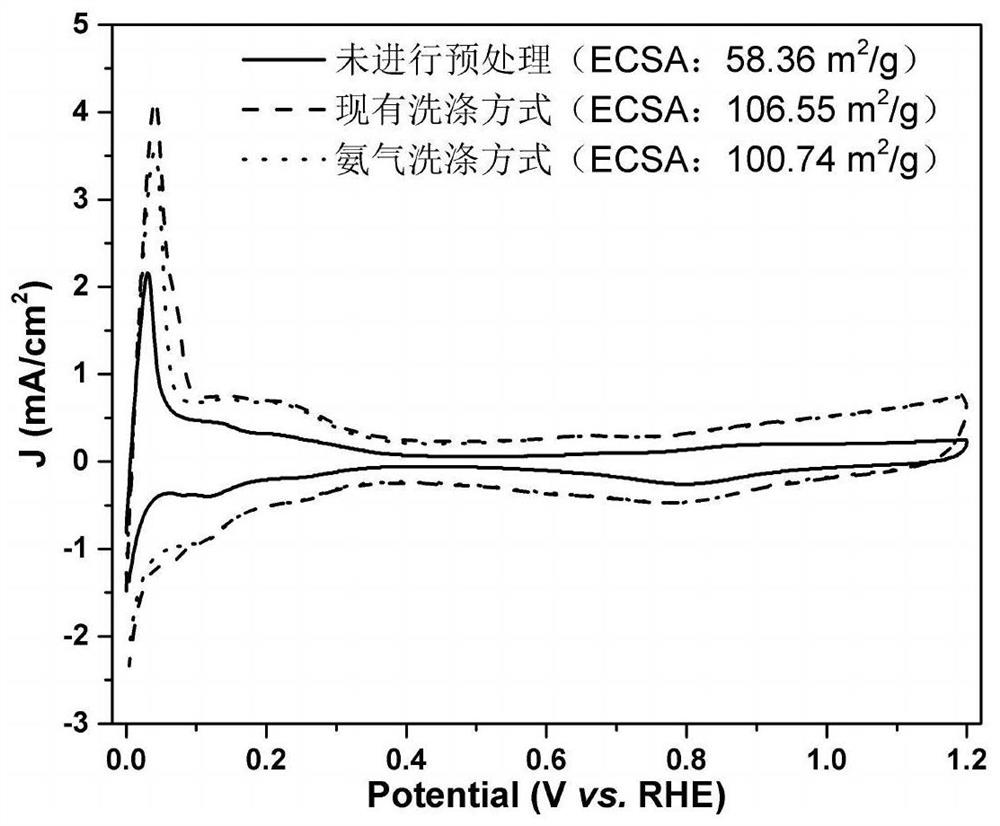

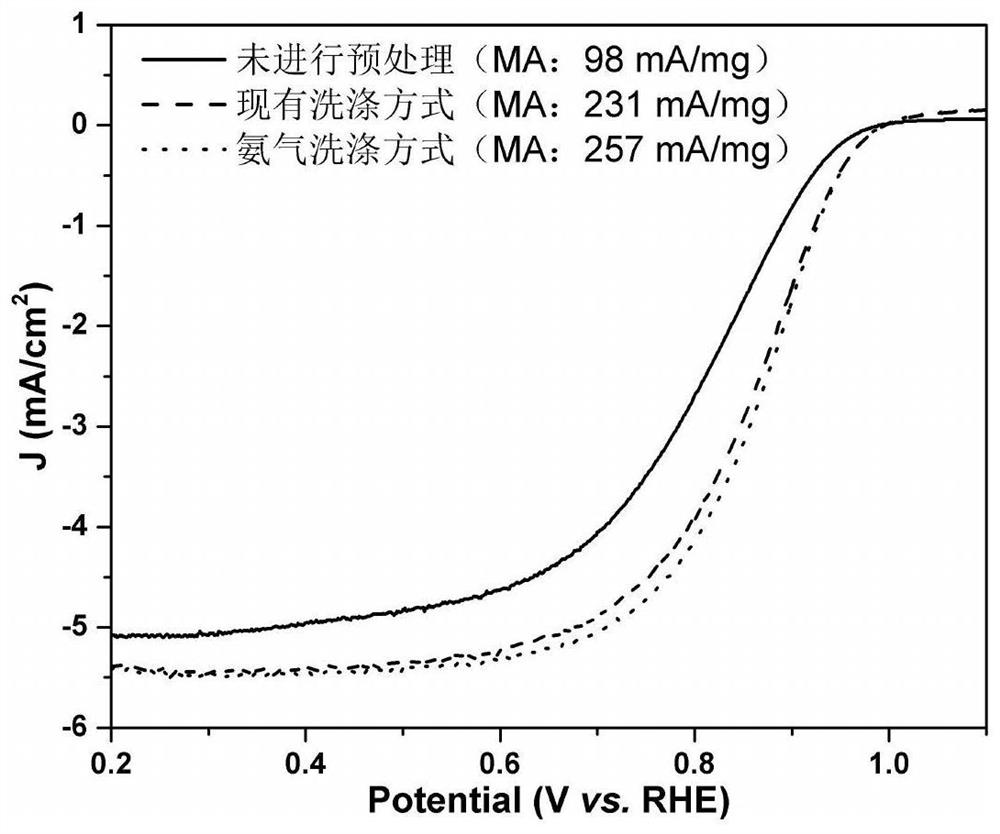

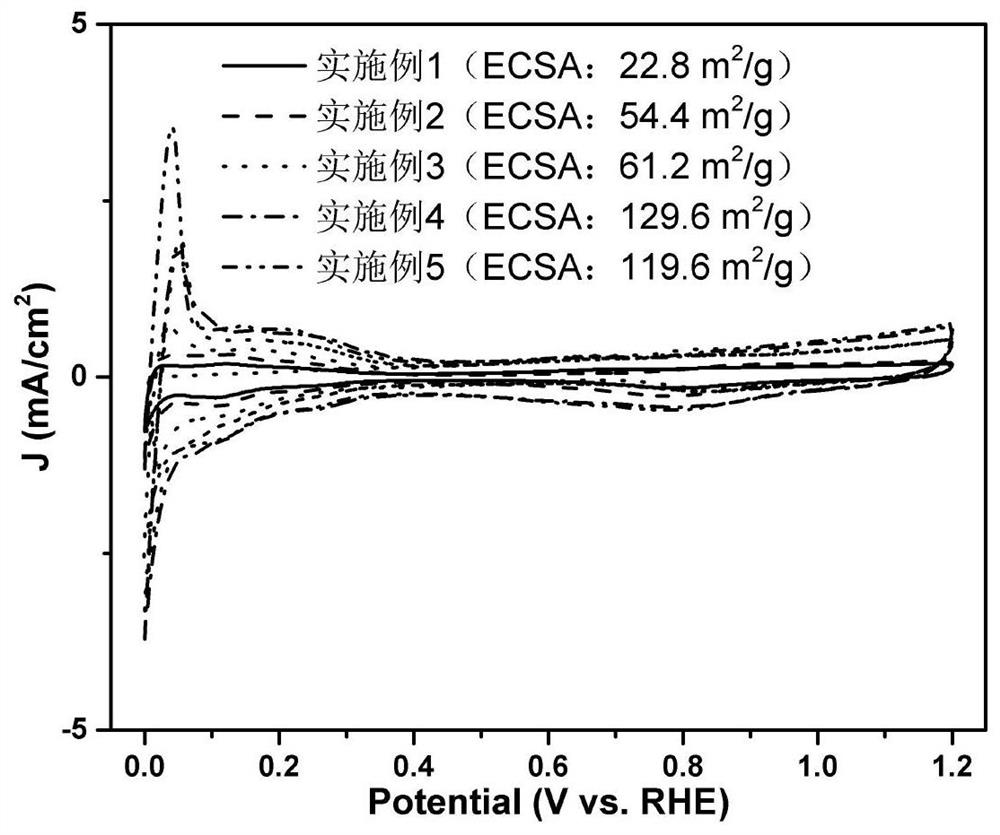

Embodiment 1

[0052] 1. Take 2g of original carbon carrier directly and crush it with a crusher.

[0053] 2. Directly take the broken original carbon carrier in step 1 and mix with an appropriate amount of chloroplatinic acid solution, stir and disperse for 60 minutes, then vacuum dry for 12 hours, and finally grind the dried sample into powder, and mix it in 3% nitrogen / hydrogen The catalyst was prepared by calcining at 400°C for 2 hours in air. The platinum metal loading in the catalyst was 40%.

[0054] 3. Weigh 7.6 mg of the catalyst obtained in step 2, add 7 milliliters of ultrapure water and 3 milliliters of isopropanol to it successively, disperse evenly by ultrasonic vibration for 30 minutes, and then add 40 microliters of Nafion membrane solution (mass. Fraction 5%, DuPont), and then ultrasonically shake in ice water for 10 minutes. Use a microsampler to draw 6.5 microliters and evenly coat it on a glassy carbon rotating disk electrode (inner core diameter: 5 mm), and spin dry in...

Embodiment 2

[0056] 1. Weigh 2g of original carbon carrier and 24g of acetone, and stir mechanically at room temperature for 5 hours;

[0057] 2. Remove the filtrate from the sample in step 1, rinse it with alcohol several times, and finally put it in an oven at 80°C for 12 hours;

[0058] 3. The dried sample in step 2 is crushed with a crusher;

[0059] 4. Directly take the broken carbon carrier in step 3 and mix it with an appropriate amount of chloroplatinic acid solution, stir and disperse for 60 minutes, then dry it in vacuum for 12 hours, and finally grind the dried sample into powder. The catalyst was prepared by calcining at 400°C for 2 hours. The platinum metal loading in the catalyst was 40%.

[0060] 5. Weigh 7.6 mg of the catalyst obtained in step 4, add 7 milliliters of ultrapure water and 3 milliliters of isopropanol to it successively, disperse evenly by ultrasonic vibration for 30 minutes, and then add 40 microliters of Nafion membrane solution (mass. Fraction 5%, DuPont...

Embodiment 3

[0062] 1. Take 2g of original carbon carrier directly and crush it with a crusher.

[0063] 2. Mix 1 g of the carbon carrier obtained in step 1 with 80 g of 0.5 M nitric acid solution, and stir at 60 ° C for 12 hours;

[0064] 3. Remove the filtrate from the sample in step 2, and wash it once with deionized water;

[0065] 4. Disperse the sample in step 3 in 60g of water and stir it mechanically for 30 minutes;

[0066] 5. Continuously feed NH into step 4 3 30 minutes to saturation, keep stirring during gas introduction;

[0067] 6. Pyrolyze the carbon carrier suspension obtained in step 5 at 200° C. for 10 minutes under vacuum. Then continue vacuum drying at 70° C. for 12 hours.

[0068] 7. Mix the dried powder in step 6 with an appropriate amount of chloroplatinic acid solution, stir and disperse for 60 minutes, then vacuum-dry for 12 hours, and finally grind the dried sample into powder, and bake it in 3% nitrogen / hydrogen mixed gas at 400°C The catalyst can be obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com