Preparation method of graded mesoporous hydration aluminium oxide microsphere capable of controlling crystal forms

A pore hydrated alumina, grading technology, applied in the field of preparation of mesoporous hydrated alumina microspheres, to achieve good texture properties and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

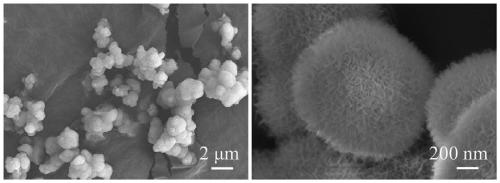

[0032] Dissolve 2.46g of sodium aluminate in 58mL of deionized water, and magnetically stir at 25°C for 15 minutes to form a sodium aluminate solution; then pipette 12mL of formamide into the above solution, and continue to magnetically stir for 1min to form a solution; Then quickly add the solution to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, put it in an oven at 25°C for 2 hours, and filter the resulting white precipitate, and wash it twice with deionized water , washed once with absolute ethanol, and then dried in a blast drying oven at 60° C. for 12 hours to obtain pseudo-boehmite microspheres.

[0033] as table 1 and figure 1 , Figure 8 , Figure 9 As shown, the obtained flower-like pseudo-boehmite microspheres assembled by nanosheets have an average particle size of 1.02 μm and a specific surface area of 154.8 m 2 / g, the pore volume is 0.26cm 3 / g, the average pore diameter is 5.3nm, and the pore size distribution is concentrated a...

Embodiment 2

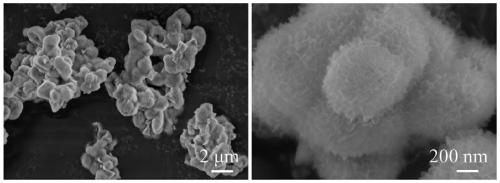

[0035]Dissolve 2.46g of sodium aluminate in 58mL of deionized water, and magnetically stir at 25°C for 15 minutes to form a sodium aluminate solution; then pipette 12mL of formamide into the above solution, and continue to magnetically stir for 1min to form a solution; Then quickly add the solution into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, put it in an oven at 25°C for 24 hours, and filter the resulting white precipitate, wash it twice with deionized water, Wash once with absolute ethanol, and then dry in a blast drying oven at 60° C. for 12 hours to obtain Bayerite microspheres.

[0036] as table 1 and figure 2 , Figure 8 , Figure 9 As shown, the obtained flower-shaped Bayerite microspheres assembled by nanosheets have an average particle size of 1.23 μm and a specific surface area of 122.8 m 2 / g, the pore volume is 0.20cm 3 / g, the average pore diameter is 5.3nm, and the pore size distribution is concentrated at 3.4nm.

Embodiment 3

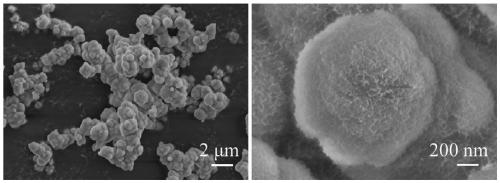

[0038] Dissolve 2.46g of sodium aluminate in 66mL of deionized water, and magnetically stir at 25°C for 15 minutes to form a sodium aluminate solution; then pipette 4mL of formamide into the above solution, and continue to magnetically stir for 1min to form a solution; Then quickly add the solution into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, put it in an oven at 25°C for 2 hours, and filter the resulting white precipitate, wash it twice with deionized water, Wash once with absolute ethanol, and then dry in a blast drying oven at 60° C. for 12 hours to obtain mixed microspheres of Bayerite and pseudoboehmite.

[0039] as table 1 and image 3 , Figure 8 , Figure 9 As shown, the obtained flower-shaped Bayerite and pseudo-boehmite microspheres assembled by nanosheets have an average particle size of 1.02 μm and a specific surface area of 103.7 m 2 / g, the pore volume is 0.2cm 3 / g, the average pore diameter is 5.2nm, and the pore size distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com