A kind of method that prepares high-efficiency anthraquinone hydrogenation catalyst by FCC waste catalyst

A technology for hydrogenation catalysts and spent catalysts, which is applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc. It can solve the problems of complex process waste catalysts, low utilization of silicon and aluminum elements, and incomplete removal of heavy metals. Achieve the effects of high recycling rate of anthraquinone, low cost and good texture properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

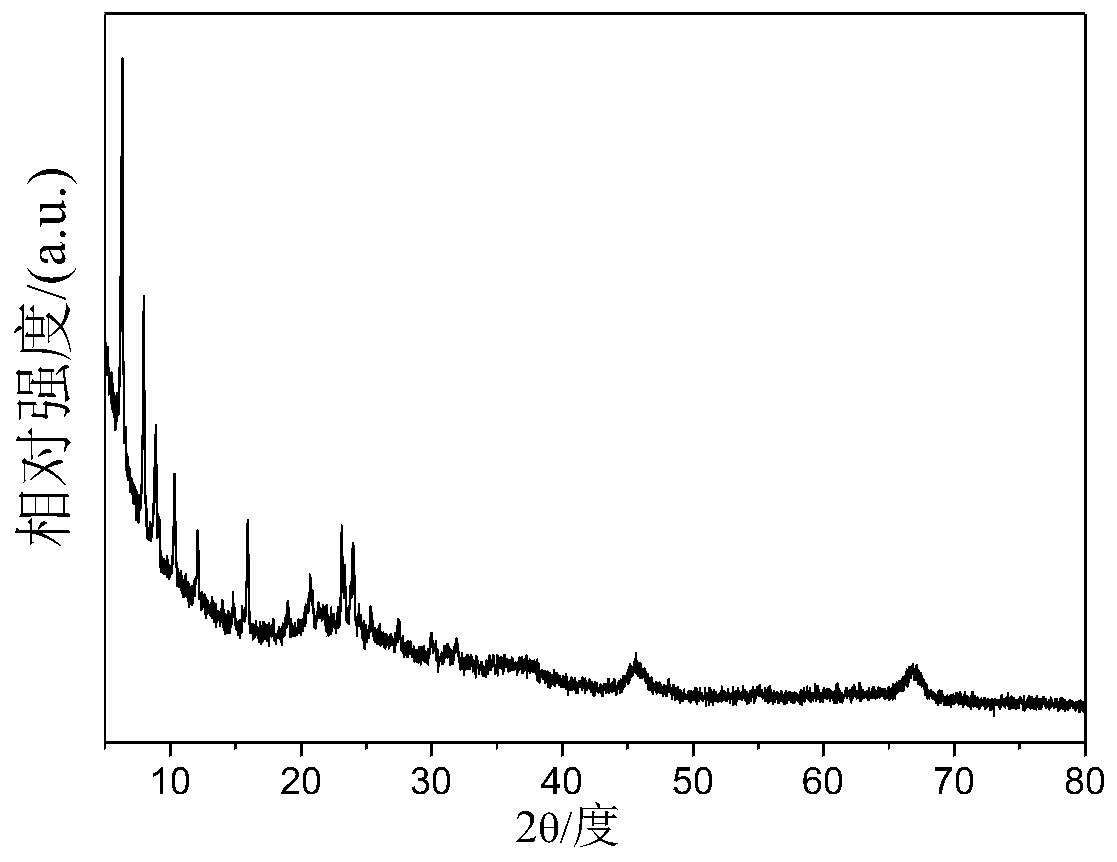

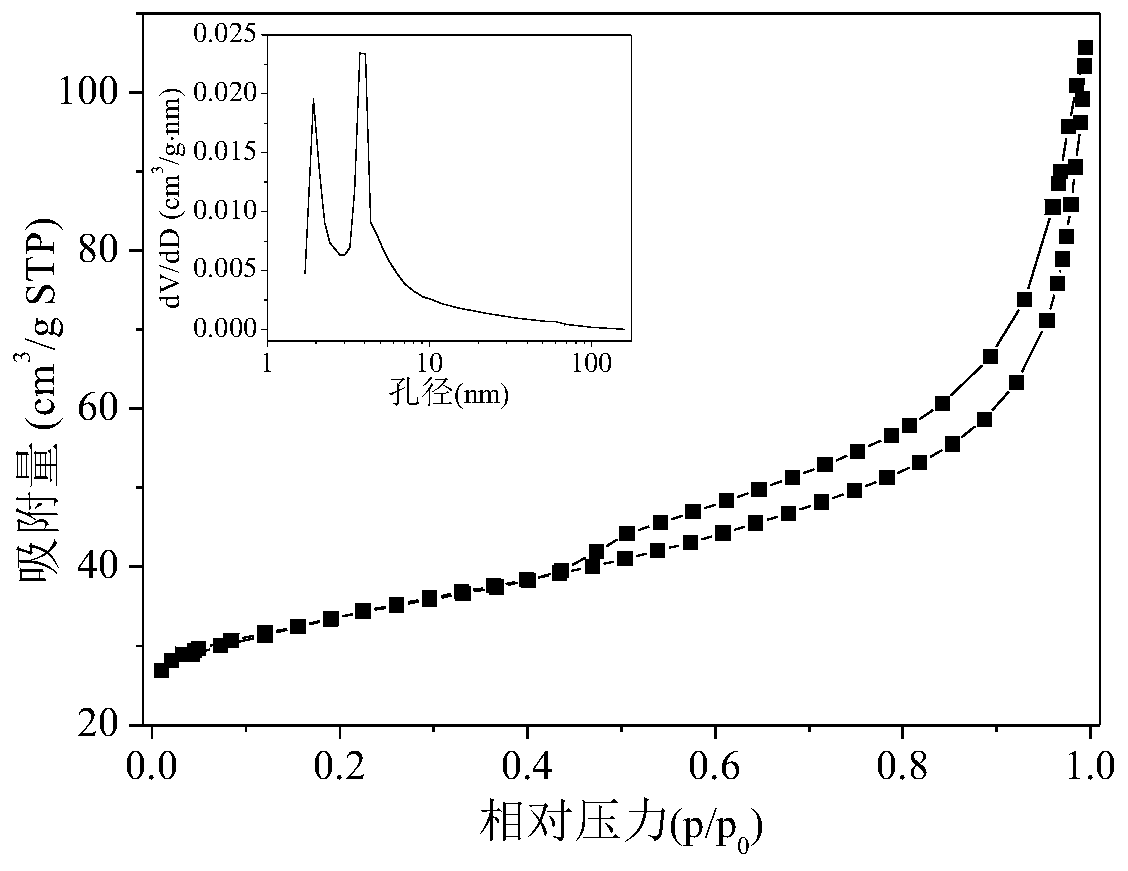

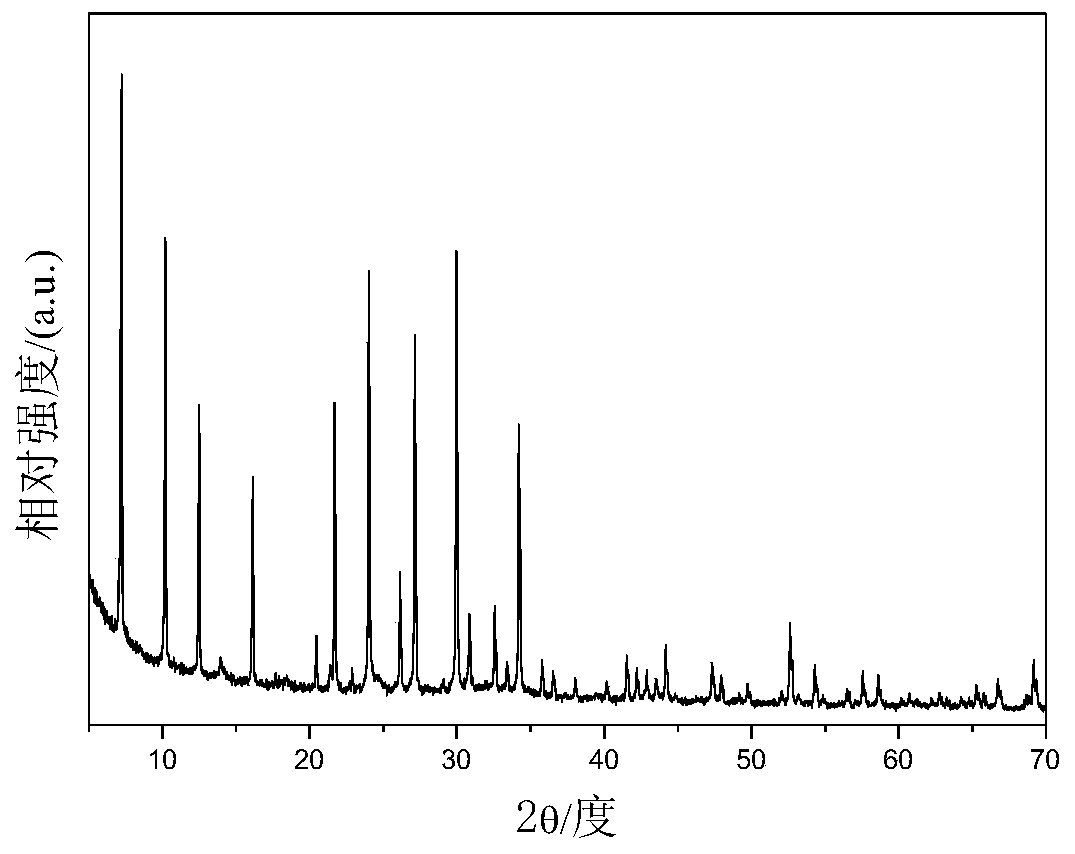

[0037] Weigh 3g of spent FCC catalyst and place it in a crucible, add 4.25g of solid NaOH and 2.1ml of deionized water, and bake at 400°C for 2h. Fully grind the roasted material through a 200-mesh sieve, add 52.55ml of deionized water to it, first stir and age at 60°C at 180r / min for 1h, after aging, raise the temperature to 90°C, and stir at 180r / min After crystallization for 4 hours, the mixture was filtered, and the filter cake was washed with deionized water until pH≤11, and dried at 105° C. for 2 hours to obtain 4A zeolite. The calcium ion exchange capacity of the resulting 4A zeolite is 305mgCaCO 3 / g-dry basis, the specific surface area is 9.9m2 / g, and the pore volume is 0.032cm 3 / g, the average pore diameter is 10.5nm.

[0038] Take 1.0g of the above 4A zeolite, mix 0.0050g of PdCl 2 The powder is dissolved in hydrochloric acid with a mass concentration of 0.003wt% and pH=3 to obtain H 2 PdCl 4 solution, the amount of hydrochloric acid is required to be equal to...

Embodiment 2

[0040]Weigh 3g of spent FCC catalyst and place it in a crucible, add 3.84g of solid NaOH and 1.8ml of deionized water, and bake at 400°C for 2h. Fully grind the calcined material through a 200-mesh sieve, add 47.54ml of deionized water to it, stir and age at 60°C and 180r / min for 1h, after aging, raise the temperature to 90°C, Stir and crystallize for 4 hours, filter the mixture, wash the filter cake with deionized water until pH≤11, and further dry at 105° C. for 2 hours to obtain zeolite 4A. The calcium ion exchange capacity of the resulting 4A zeolite is 288mg CaCO 3 / g-dry basis, the specific surface area is 10.8m 2 / g, the pore volume is 0.032cm 3 / g, the average pore diameter is 10.3nm.

[0041] The loading process is the same as in Example 1.

[0042] The highest hydrogenation efficiency of the obtained catalyst in the self-made slurry bed is 9.82g / L working solution, and the anthraquinone recycling rate is 100.0%.

Embodiment 3

[0044] Weigh 3g of spent FCC catalyst and place it in a crucible, add 3.84g of solid NaOH and 1.8ml of deionized water, and bake at 400°C for 2h. Fully grind the roasted material through a 200-mesh sieve, add 43.22ml of deionized water to it, stir and age at 60°C and 180r / min for 2 hours, after the aging is over, raise the temperature to 90°C, Stir and crystallize for 3 hours, filter the mixture, wash the filter cake with deionized water until pH≤11, and dry at 105° C. for 2 hours to obtain 4A zeolite. The calcium ion exchange capacity of the resulting 4A zeolite is 285mg CaCO 3 / g-dry basis, the specific surface area is 15.3m 2 / g, the pore volume is 0.041cm 3 / g, the average pore diameter is 9.4nm.

[0045] The loading process is the same as in Example 1.

[0046] The highest hydrogenation efficiency of the obtained catalyst measured in a self-made slurry bed is 9.53g / L working fluid, and the anthraquinone recycling rate is 94.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com