Application of compound feed additive in preparation of feed for improving muscle texture of cultured large yellow croakers

A compound feed, large yellow croaker technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of inability to satisfy consumers, decreased flavor, and high abdominal fat, and achieves improvement in muscle fiber diameter, mRNA level, and flavor substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Further, the preparation method of the above compound feed of the present application is also relatively convenient, and one of the preparation methods has the following steps:

[0054] The first step: pretreatment of raw materials, such as crushing and screening of fish meal and soybean meal.

[0055] Step 2: Weigh each raw material according to the mass ratio.

[0056] Step 3: Mix other solid raw materials except soybean lecithin, fish oil, and choline chloride. The mixing principle is as follows: mix uniformly and quantitatively step by step according to the proportion of raw materials, and then put the obtained mixture in the V-shaped Mix thoroughly in a mixer;

[0057] Step 4: Dissolve soybean lecithin in fish oil, and then continue to mix evenly with the well-mixed solid mixture.

[0058] Step 5: Dissolve choline chloride in water, then add the resulting aqueous solution into the above mixture (the amount of water is about 20% of the dry weight of the raw materi...

Embodiment 1

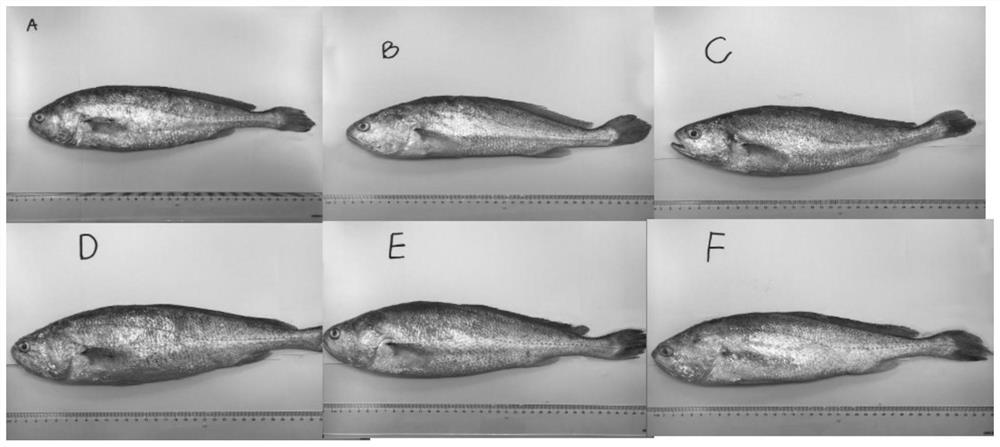

[0062] Before the formal breeding experiment, the large yellow croaker was temporarily raised in a seawater floating cage of 3.0×3.0×3.0m to adapt to the environment. Two weeks later, after starvation for 24 hours, the healthy and uniform large yellow croakers were selected and randomly divided into 6 groups (control group, experimental group 1, experimental group 2, experimental group 3, experimental group 4, and experimental group 5), and each group was divided into 6 groups. Each replicate was reared in a 1.5×1.5×2.0m floating cage, and each replicate had 30 tails. The control group was fed with basal feed, and the experimental groups 1, 2, 3, 4, and 5 added 900 mg / kg of compound feed additives on the basis of basal feed, and fed twice a day (05:00 and 17:30) . During the breeding period, the water temperature is 26.5-32.5°C, the salinity changes 32-36‰, the dissolved oxygen is greater than 6mg / L during the breeding period, and the breeding cycle is 45 days.

[0063] Acco...

Embodiment 2

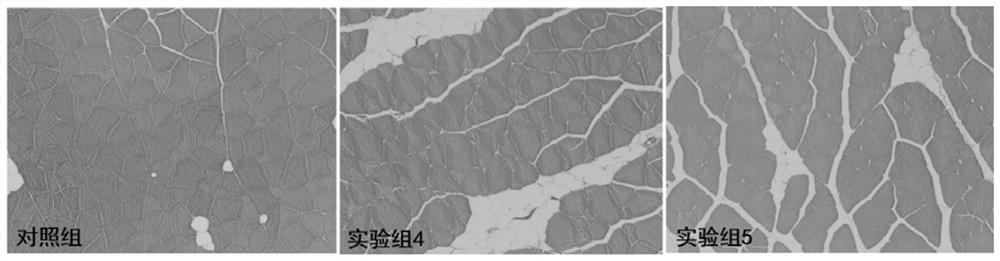

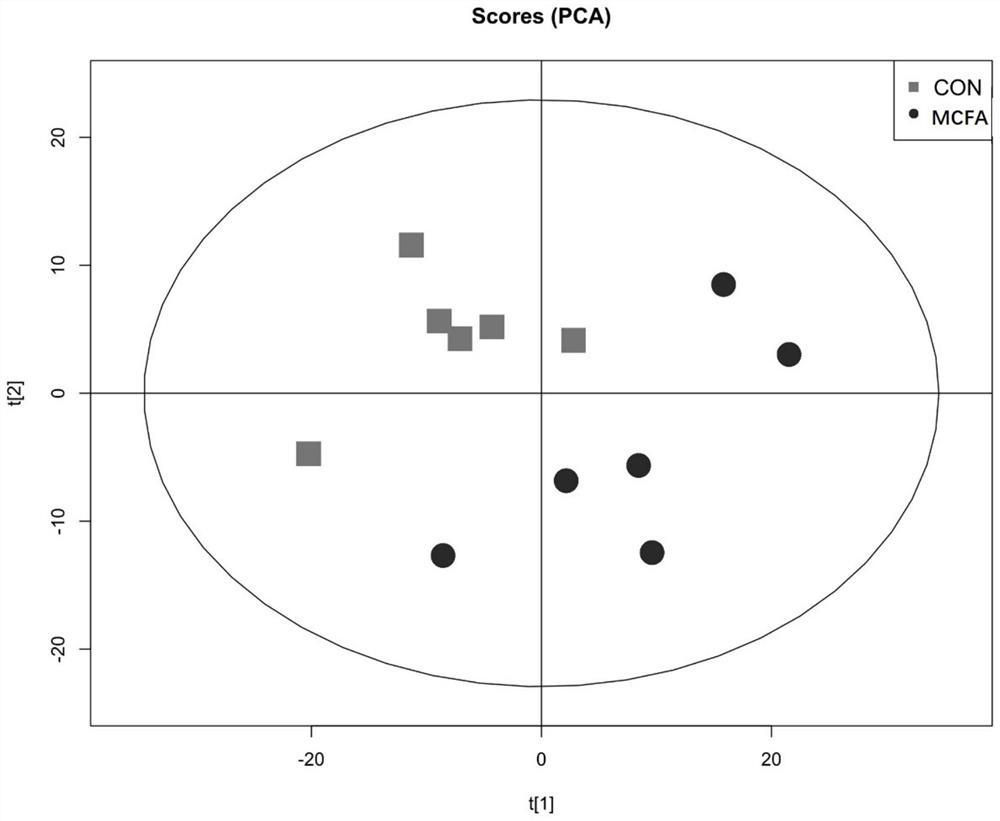

[0085] It can be seen from Example 1 that the fat and protein content of the cultured large yellow croaker body in experimental groups 4 and 5 obviously increased. In order to clarify the relationship between the increase in fat and protein content and the meat quality of large yellow croaker, Example 2 was designed. The large yellow croakers with strong physique and uniform size were selected and randomly divided into 3 groups (control group, experimental group 4, and experimental group 5). Each group had 6 replicates, and they were respectively raised in floating cages of 1.5×1.5×2.0m. 30 tails per replicate. The control group was fed with basal feed, and the experimental groups 4 and 5 added 900 mg / kg of feed additives on the basis of basal feed, respectively, and fed twice a day (05:00 and 17:30). During the breeding period, the water temperature is 26.5-32.5°C, the salinity changes 32-36‰, the dissolved oxygen is greater than 6mg / L during the breeding period, and the bree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com