Composite oxide and preparation method thereof

A composite oxide and composite hydroxide technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of limitation, low specific surface area of aging products, energy consumption, etc., and achieve short heating time, Excellent pore size distribution and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment prepares Y 2 o 3 -ZrO 2 -Al 2 o 3 composite oxide, the composite oxide, Y 2 o 3 The mass percentage is 15%, ZrO 2 The mass percentage is 35%, Al 2 o 3 The mass percentage is 50%, and the preparation steps are as follows:

[0030] (1) According to Y in the composite oxide 2 o 3 , ZrO 2 、Al 2 o 3 Weigh yttrium nitrate, zirconium nitrate and aluminum nitrate, then prepare yttrium nitrate, zirconium nitrate and aluminum nitrate at room temperature with water to make a salt solution with a total mass concentration of 5%, then add Y 2 o 3 , ZrO 2 、Al 2 o 3 Total mass 10% polyvinyl alcohol was stirred at room temperature for 2 hours;

[0031] (2) The buffer solution (pH=12) that will add the saline solution of polyvinyl alcohol and ammoniacal liquor and ammonium bicarbonate composition is in jacketed reactor at room temperature at the stirring speed of 400 rev / mins and is titrated concurrently, adding polyvinyl alcohol The titration rate of t...

Embodiment 2

[0052] This embodiment is the same as the composite oxide prepared in Example 1, and the preparation steps are as follows:

[0053] Step (1) and (2) are with embodiment 1 step (1) and (2);

[0054] (3) After the titration, divide the generated composite hydroxide slurry into six samples, and rapidly raise the temperature of the six samples to 50°C, 55°C, 60°C, 70°C, 75°C and 80°C, and continue Stir for 2 hours, replenish the buffer solution composed of ammonia water and ammonium bicarbonate to keep the pH value of the composite hydroxide slurry at 9, then cool to room temperature and let stand for 1 day;

[0055] Steps (4), (5) are the same as Steps (4) and (5) of Example 1, except that the 6 samples are only calcined at 1000° C. for 5 hours.

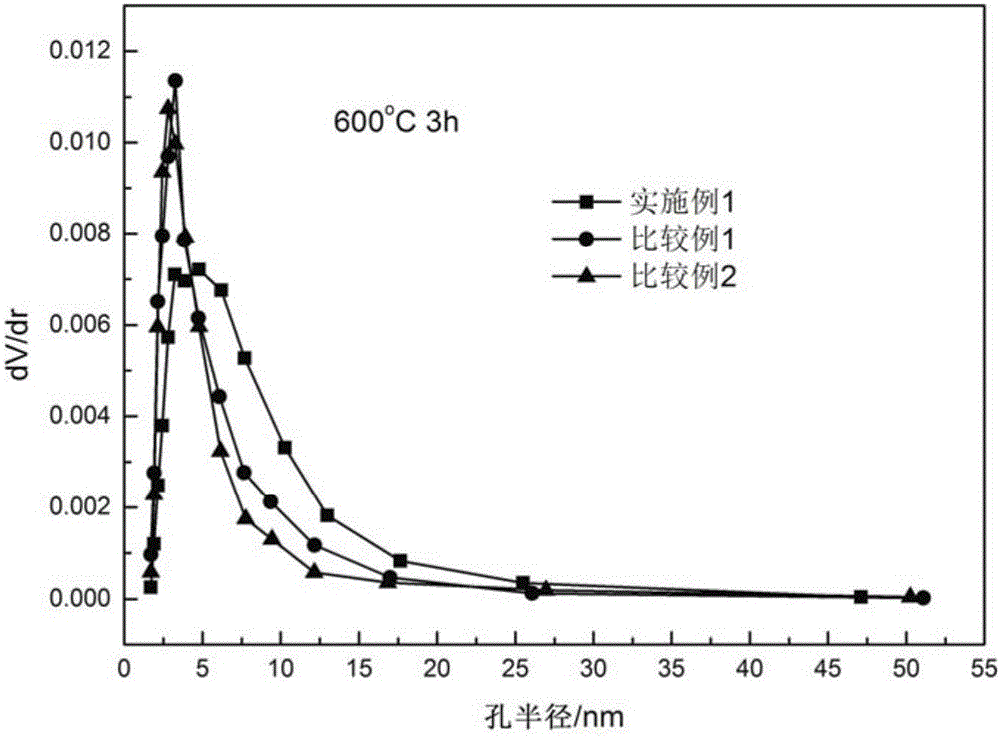

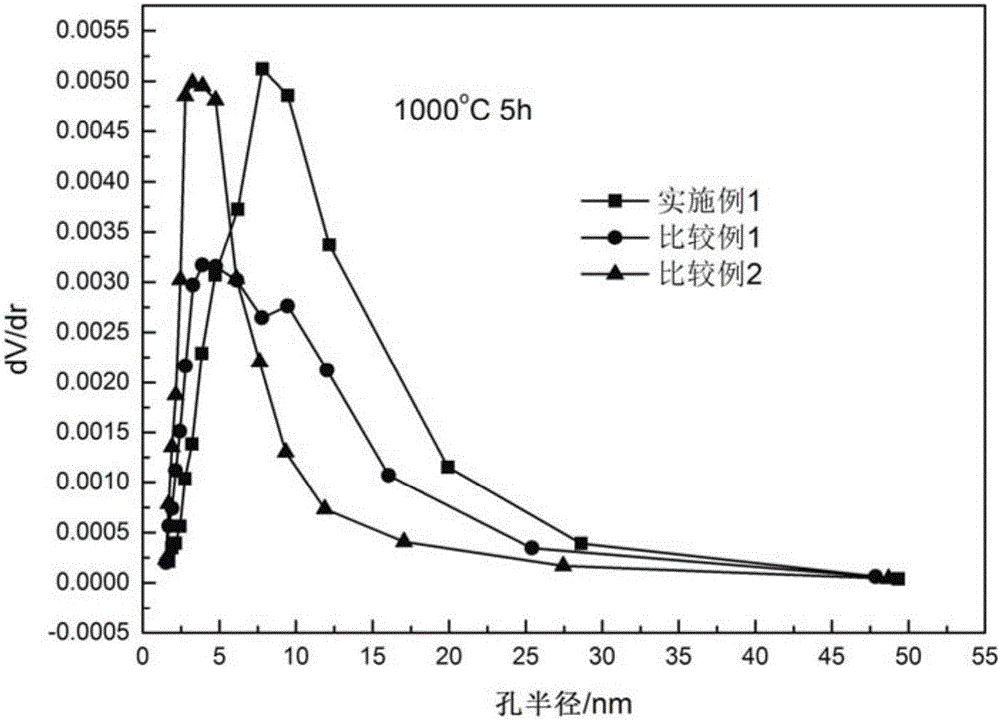

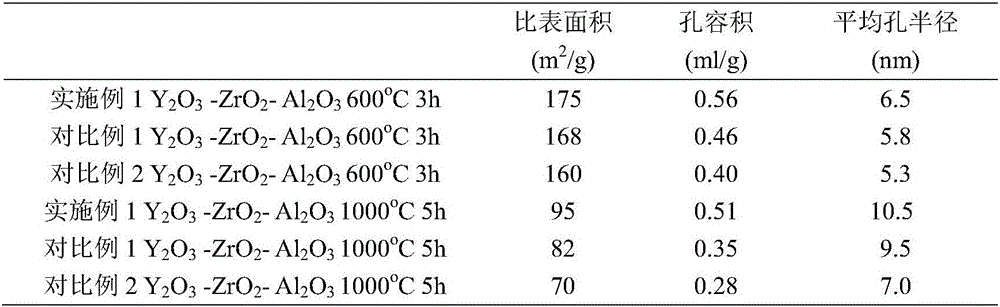

[0056] 6 parts of 15% Y prepared at different temperatures after titration 2 o 3 -35% ZrO 2 -50%Al 2 o 3 Composite oxides were used in low temperature N 2 The texture properties were measured by adsorption-desorption, and the res...

Embodiment 3

[0061] The preparation process conditions of this embodiment and embodiment 1 are the same, the difference is that this embodiment according to the stoichiometric ratio Y 2 o 3 :ZrO 2 :Al 2 o 3 =20:15:65 (wt) take by weighing yttrium nitrate, zirconium nitrate and aluminum nitrate, the composite oxide obtained is 20%Y 2 o 3 -15% ZrO 2 -65% Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average hole radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com