Automobile steering knuckle resisting transgranular fracture failure mode and manufacturing method of automobile steering knuckle

An automobile steering knuckle and failure mode technology, which is applied to the automobile steering knuckle and its manufacturing field, can solve the problems of poor torsion resistance, high processing cost, and lack of comprehensive improvement of the application performance of aluminum alloys, and achieves resistance to axial tensile extrusion. Strong ability, simple and fast casting, excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An automobile steering knuckle anti-transgranular fracture failure mode, the steering knuckle has a porosity of 0%-0.2%, and the overall grain growth direction is horizontal from the outermost edge to the center of the axis, and the material used is ZL203;

[0027] The manufacturing method of the above-mentioned anti-transgranular fracture failure mode of the automobile steering knuckle comprises the following steps:

[0028] 1) Preparation before manufacturing

[0029] ① Raw material preparation: Prepare sufficient quantities to design the corresponding aluminum-copper alloy master ingot for casting;

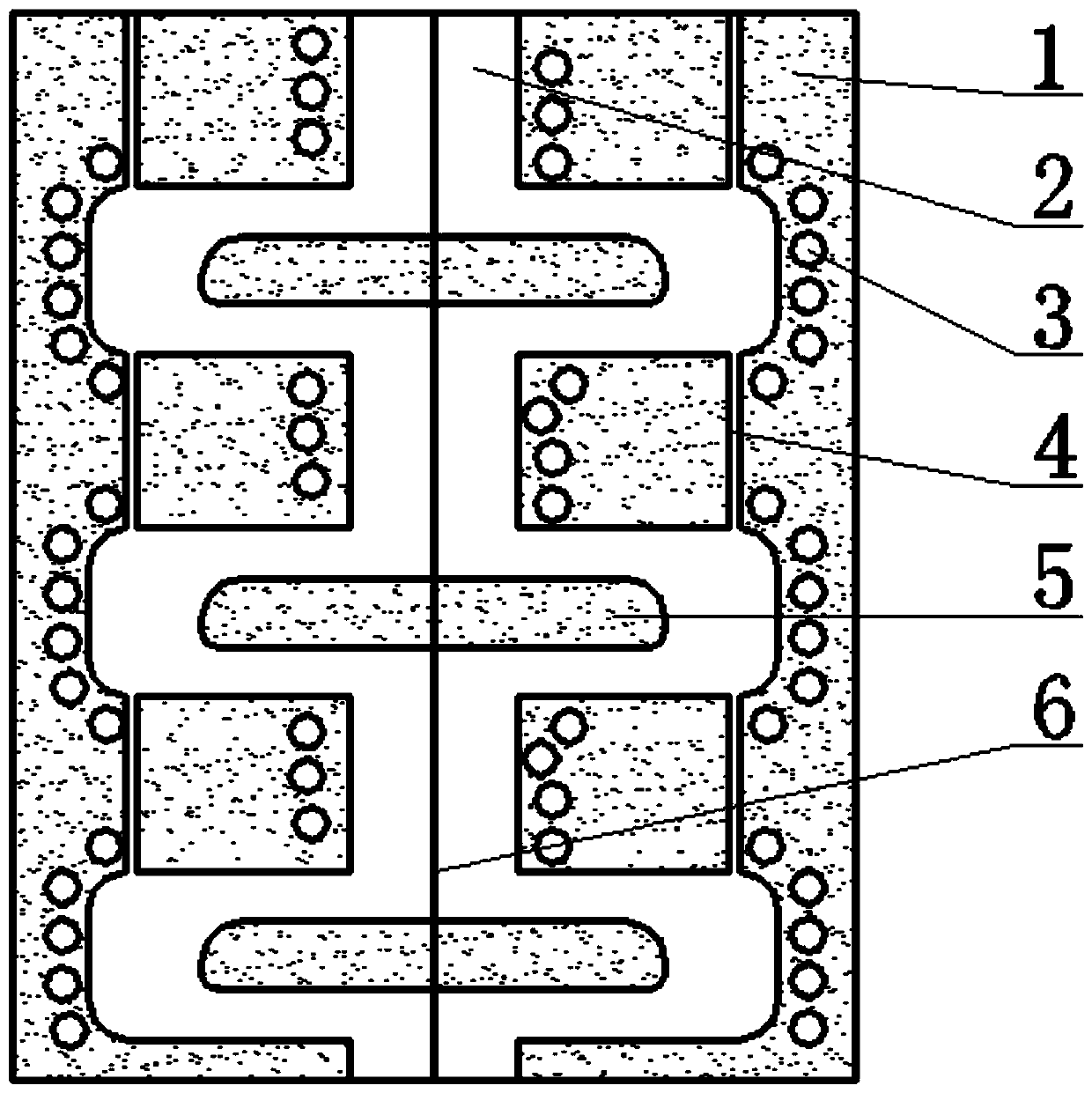

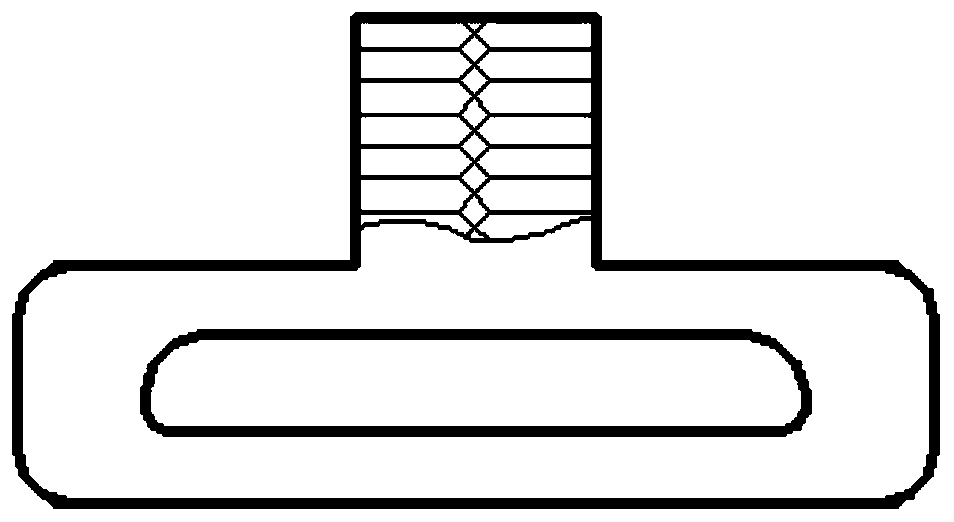

[0030] ② Tooling preparation: Prepare a water-cooled copper mold rotary casting mold. The mold is composed of two half-moulds. The parting surface 6 is located on the center line of the symmetrical sides. The mold entity is a solid copper base 1, which is made of pure copper. In the road 2, the part corresponding to the center shaft of the steering knuckle is designed a...

Embodiment 2

[0040] The whole is consistent with Example 1, the difference is:

[0041] The material used for the steering knuckle is ZL202;

[0042] The manufacturing method of the above-mentioned anti-transgranular fracture failure mode of the automobile steering knuckle comprises the following steps:

[0043] 1) Preparation before manufacturing

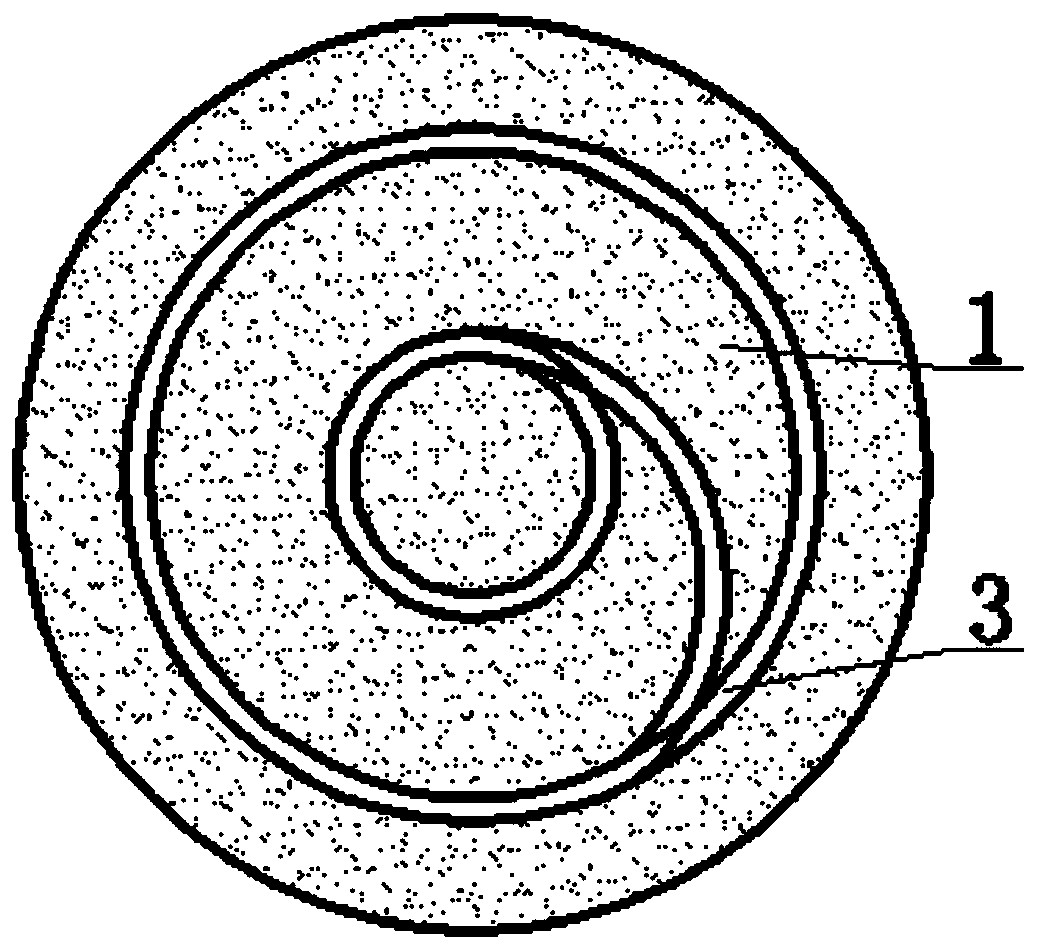

[0044] ② Tooling preparation: the solid copper substrate 1 is provided with a water-cooling pipe 3 on the radially outer side of the runner 2 and close to the runner 1.2cm; prepare a single-section inner cavity size that is 3% larger than the design outline size of the steering knuckle, and the inner surface is 10 layers 0.1mm stainless steel strip;

[0045] 2) casting

[0046] ① After spraying the parting agent on the inner cavity of the water-cooled copper mold rotary casting mold, after merging and assembling, install and fix it on the rotating chassis in the furnace to correspond to the automatic casting mechanism, and the gate is at a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com