Light absorption coating used for increasing melting depth of aluminum-copper dissimilar metal laser welding and laser welding process method

A technology of dissimilar metals and light-absorbing coatings, applied in the welding of aluminum-copper dissimilar metals, laser welding of aluminum-copper dissimilar metals, and new energy power batteries, can solve problems such as complex processes, low production efficiency, and low laser utilization, and achieve Improve mechanical properties, improve production efficiency and penetration, and increase utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in combination with specific embodiments.

[0026] 1. Production of graphite coating:

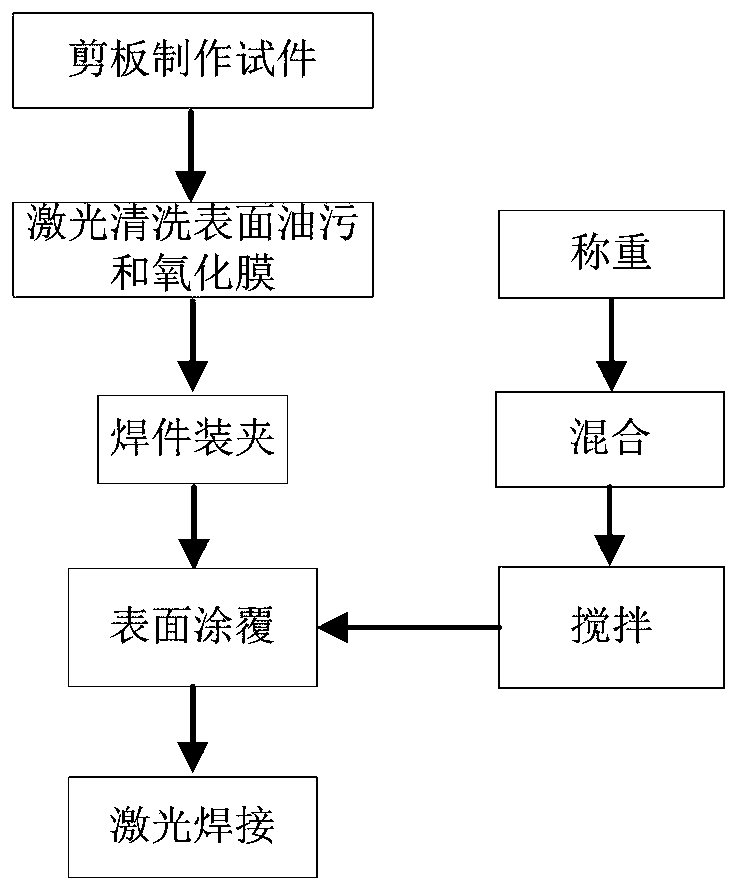

[0027] Production of graphite coating: Weigh 90% of graphite, 5% of acrylate, 3% of rubber, and 2% of borax with a balance by weight percentage, put them in a beaker for mixing, stir evenly and then use for coating;

[0028] 2. Make the test piece by shearing plate: use the CNC shearing machine with the width and length of the shearing plate not less than 1mm to cut copper T2 and aluminum 1060 with a thickness of 0.3mm, and the size is 100mm×20mm;

[0029] 3. Laser cleaning of the surface of the workpiece to be welded: use laser cleaning equipment with an average power of not less than 200W and a pulse frequency of 105Hz to remove oil stains and oxide films on the surface of the workpiece to be welded, see metallic luster;

[0030] 4. Clamping of welding parts: place the aluminum plate under the copper plate, and press ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com