Pretreatment method for oily sludge on horizontal screw filter pressing type offshore platform

An offshore platform and pretreatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. and other problems, to achieve the effect of high dehydration rate, low energy consumption, and continuous operation of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, features and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

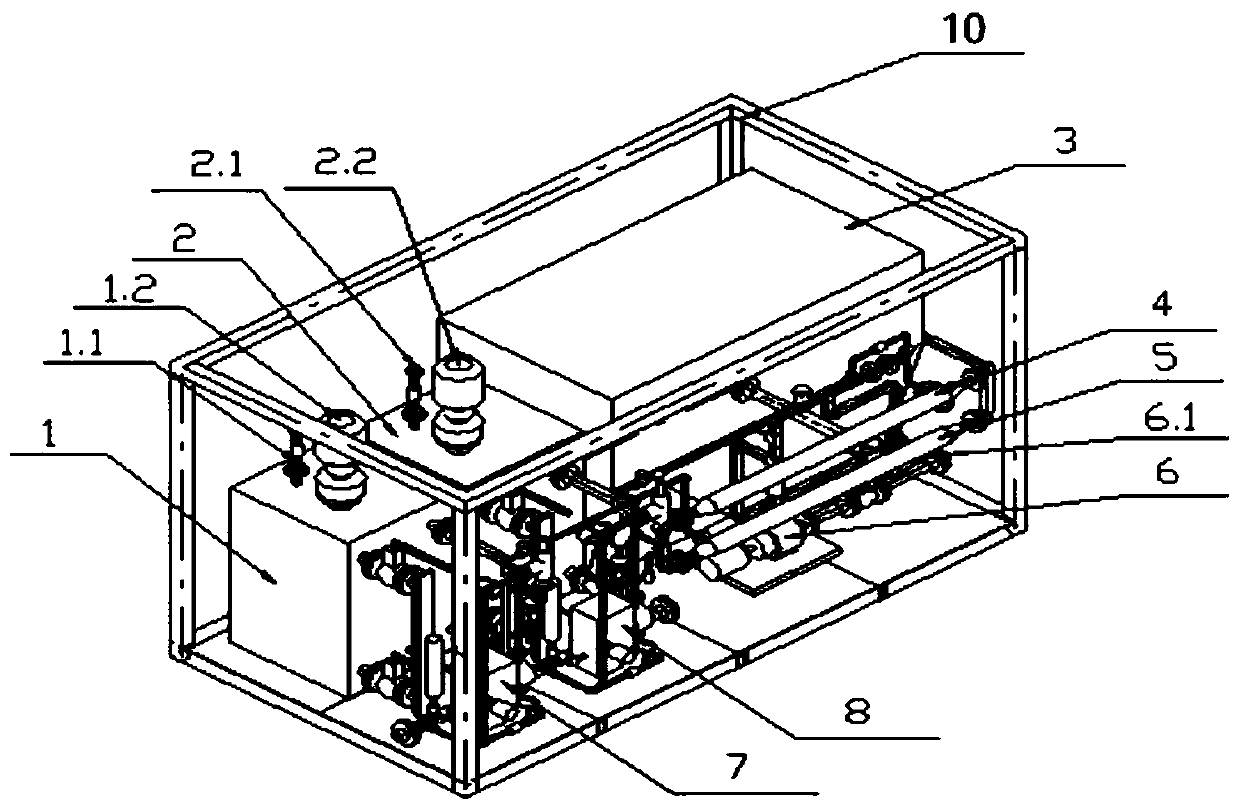

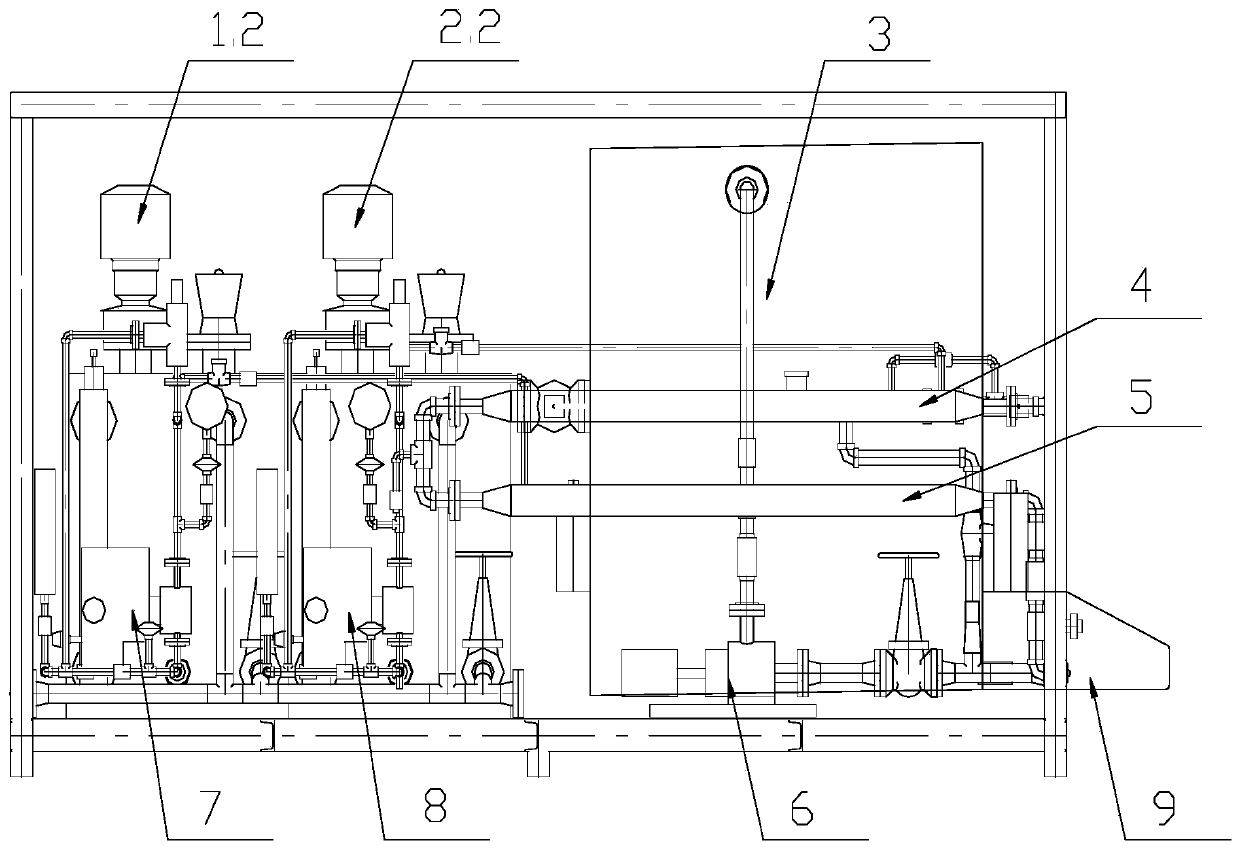

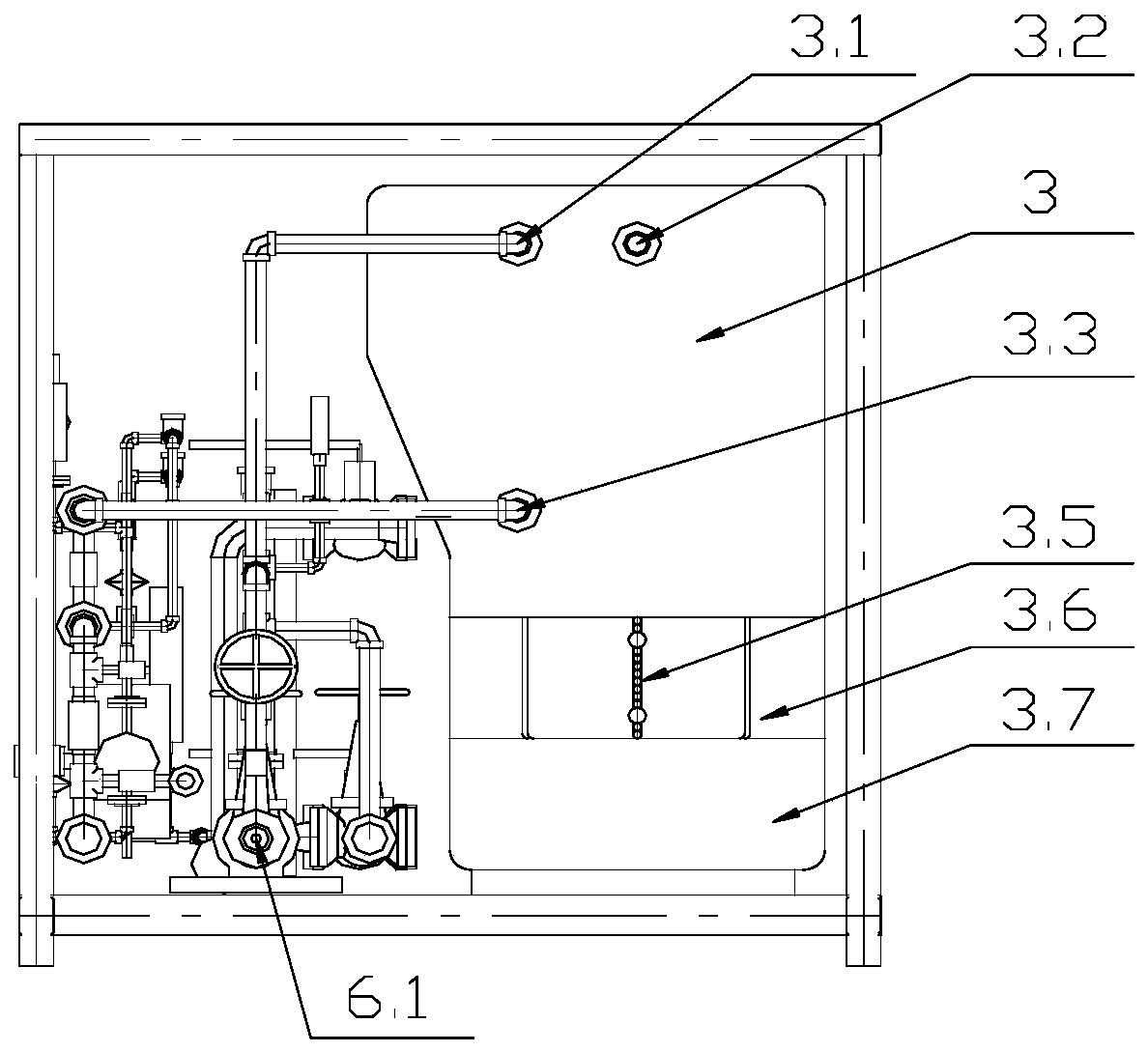

[0025] Such as Figure 1 to Figure 4 As shown, the horizontal screw press type offshore platform oily sludge pretreatment device of the present invention includes a fixed shell 10, and the fixed shell 10 is provided with a medicament A storage box 1, a medicament B storage box 2, a dosing pump A7, a dosing pump A7, Medicine pump B8, pipeline mixer A4, pipeline mixer B5, feed pump 6, medicine mixing reactor 3.

[0026] The medicament A storage box 1 is provided with a medicament A inlet 1.1 and a medicament A agitator 1.2, and is connected to the dosing pump A7 through a pipeline. The medicament B storage box 2 is provided with a medicament B inlet 2.1 and a medicament B agitator 2.2, and is connected to a dosing pump B8 through a pipeline. Both the dosing pump A7 and the dosing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com