Flocculating agent for underwater non-dispersing concrete

A concrete and flocculant technology, applied in the field of concrete admixtures, can solve the problems of large slump loss, low strength, and large water demand of the mixture, and achieve good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

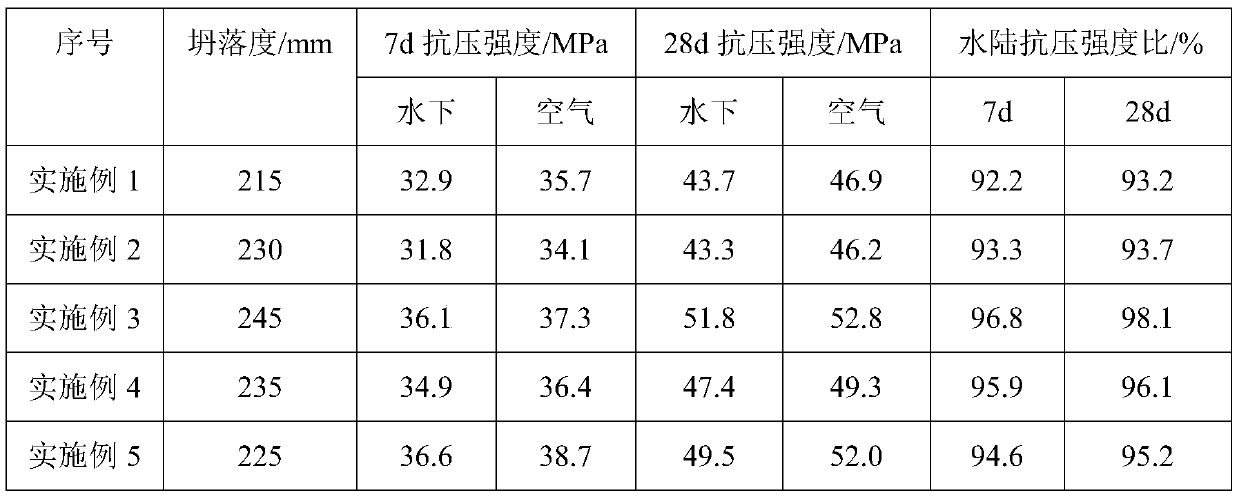

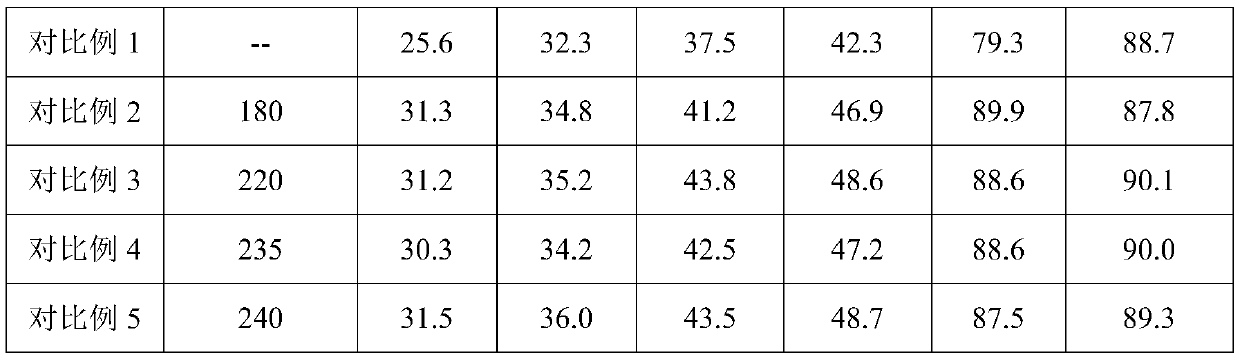

Examples

Embodiment 1

[0016] A flocculant for underwater non-dispersible concrete, consisting of the following parts by weight: 10 parts of grafted modified konjac flour, 8 parts of polyethylene glycol (molecular weight 2000) dilaurate, 10 parts of dispersant, 3 parts of sodium nitrilotriacetate, 3 parts of lithium polystyrene sulfonate, 50 parts of wollastonite.

[0017] The preparation method of the graft modified konjac flour is as follows: (1) mix itaconic acid, N-methylolacrylamide and molecular weight regulator, then add itaconic acid and N-methylolacrylamide total weight 8 1 times the deionized water, stir to dissolve, heat up to 70°C, add the initiator solution dropwise, the initiator solution is added dropwise in 3 hours, and keep warm for 30 minutes to obtain A; (2) add konjac powder to 100 times the deionized water, Use formic acid to adjust the pH value to 4, stir and heat up to 70°C to obtain B; (3) Mix the above two products evenly at a mass ratio of 1:2, adjust the temperature to 70°...

Embodiment 2

[0023] A flocculant for underwater non-dispersible concrete, consisting of the following parts by weight: 30 parts of grafted modified konjac flour, 3 parts of polyethylene glycol (molecular weight 5000) dilaurate, 20 parts of dispersant, 1 part of sodium nitrilotriacetate, 8 parts of lithium polystyrene sulfonate, and 20 parts of wollastonite.

[0024] The preparation method of the grafted modified konjac flour is as follows: (1) mix itaconic acid, N-methylolacrylamide and molecular weight regulator, then add itaconic acid and N-methylolacrylamide total weight 15 1 times the amount of deionized water, stirred and dissolved, heated up to 50°C, added dropwise the initiator solution, the initiator solution was added dropwise after 4 hours, and kept for 30 minutes to obtain A; (2) konjac powder was added to 50 times the amount of deionized water, Use oxalic acid to adjust the pH value to 6, stir and heat up to 50°C to obtain B; (3) Mix the above two products evenly at a mass rati...

Embodiment 3

[0030] A flocculant for underwater non-dispersible concrete, consisting of the following parts by weight: 20 parts of grafted modified konjac flour, 5 parts of polyethylene glycol (molecular weight 4000) dilaurate, 15 parts of dispersant, 2 parts of sodium nitrilotriacetate, 5 parts of lithium polystyrene sulfonate, and 30 parts of wollastonite.

[0031] The preparation method of the grafted modified konjac flour is as follows: (1) mix itaconic acid, N-methylolacrylamide and molecular weight regulator, then add itaconic acid and N-methylolacrylamide total weight 12 times the amount of deionized water, stir to dissolve, heat up to 60°C, add the initiator solution dropwise, the initiator solution is added dropwise in 3.5 hours, and keep warm for 30 minutes to obtain A; (2) add konjac powder to 80 times the amount of deionized water , adjust the pH value to 5 with p-toluenesulfonic acid, stir and heat up to 60°C to obtain B; (3) Mix the above two products evenly according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com