Method of preparing multicomponent titanium dioxide pigment mainly from wollastonite

A wollastonite and multi-component technology is applied in the field of preparation of multi-component titanium dioxide pigments, which can solve the problems of incomplete coating, low titanium dioxide and incomplete titanium dioxide coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

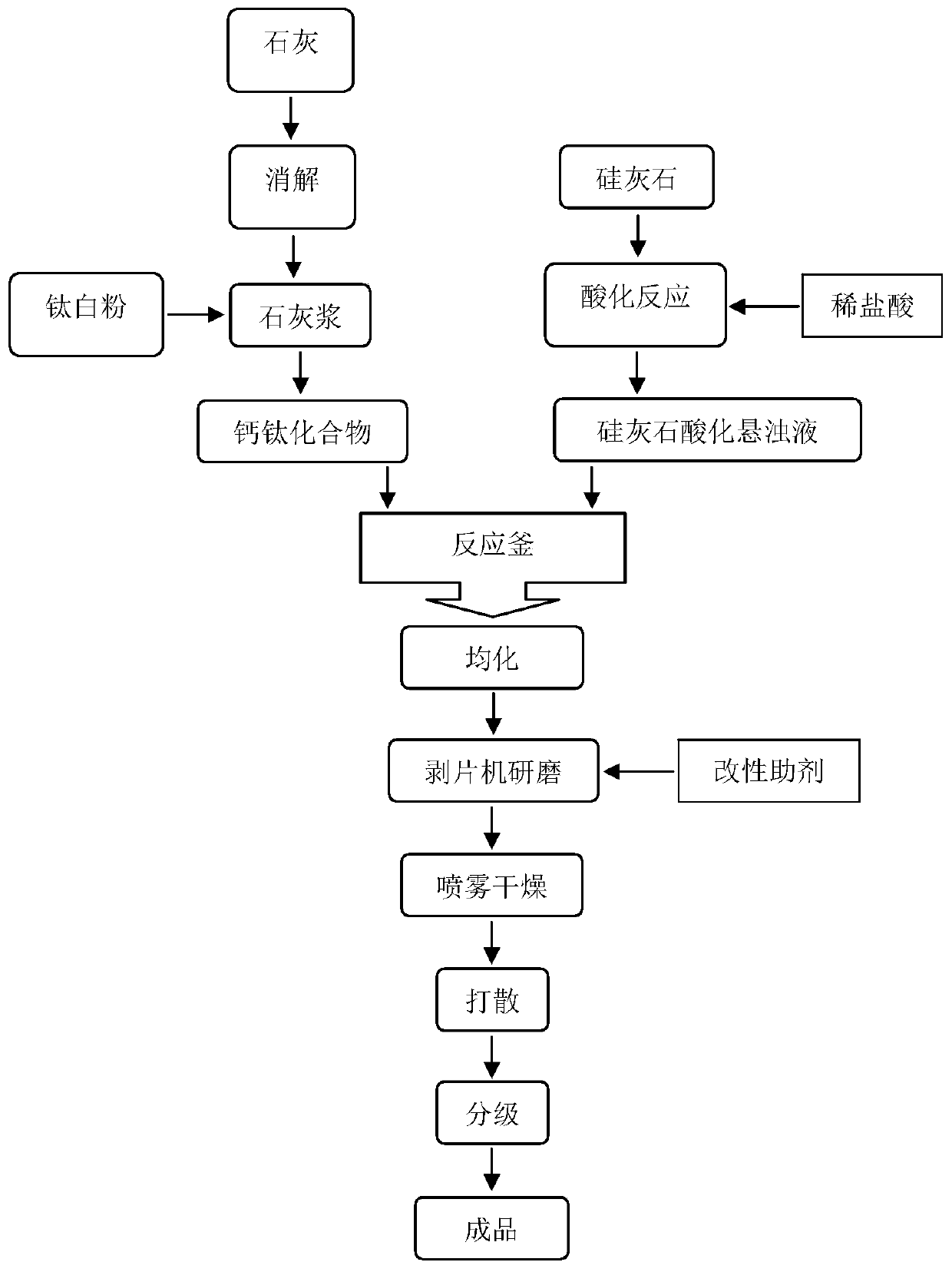

Method used

Image

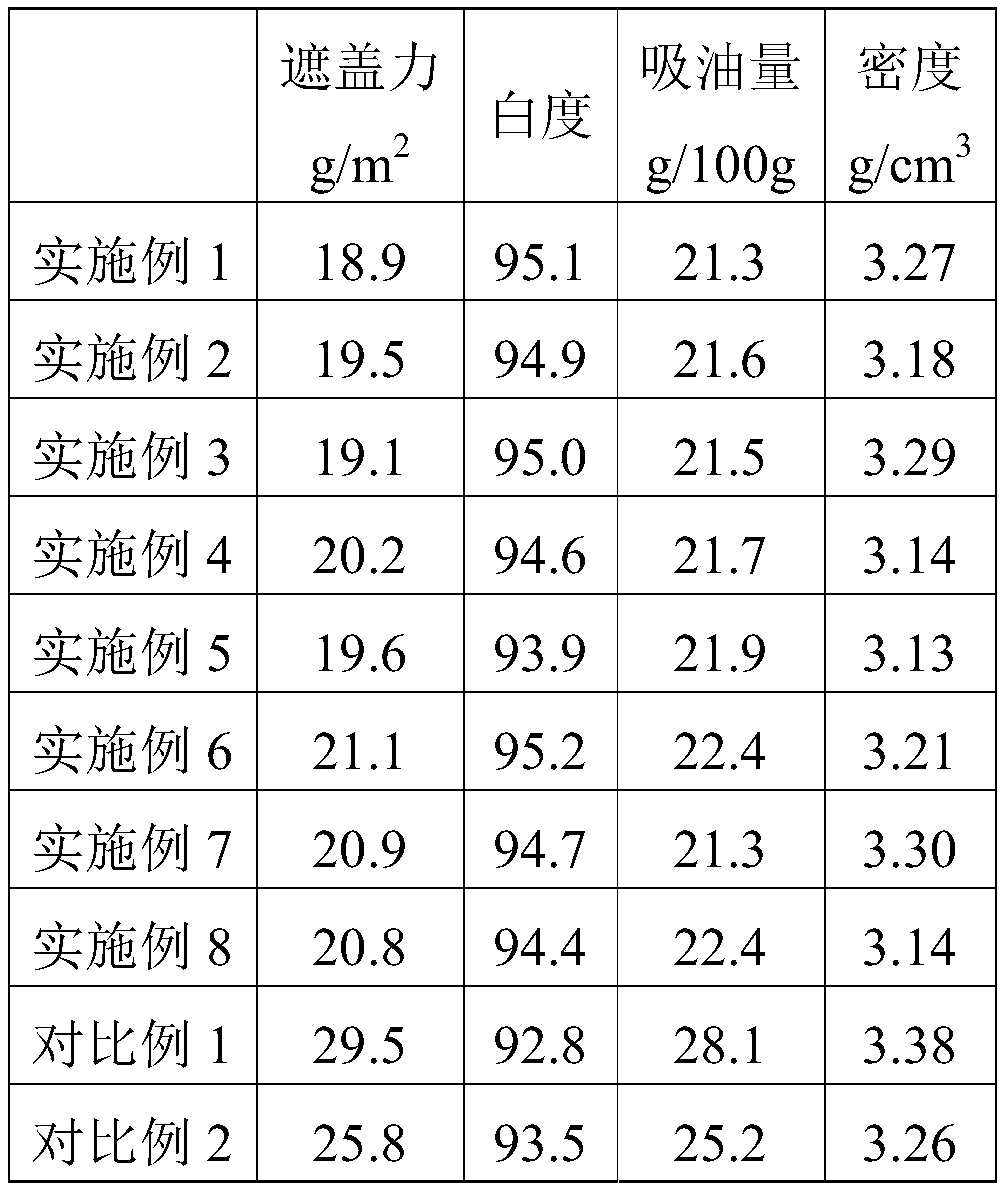

Examples

Embodiment 1

[0027] A kind of preparation method of the multi-element titanium dioxide pigment with wollastonite as main ingredient, described preparation method comprises the following steps:

[0028] (1) Take industrial-grade quicklime with a CaO content of 91.5%, add water to 14.8 times the quality of quicklime, put it into a reactor for slurrying and disperse it, and age it for 17 hours at a temperature of 110°C to obtain Ca(OH) with a concentration of 12.0%. 2 slurry;

[0029] (2) Get particle size 12 μ m rutile type titanium dioxide, its consumption is 85% of CaO quality, drop in the reactor of step (1);

[0030] (3) Prepare wollastonite with a particle size of 30 μm into an aqueous suspension with a mass fraction of 12%, heat it to 55° C., and add hydrochloric acid with a concentration of 2 mol / L under constant stirring, and control the reaction system to maintain a pH value of 4;

[0031] (4) pump the wollastonite suspension of step (3) into the reactor of step (2), carry out neut...

Embodiment 2

[0038] A kind of preparation method of the multi-element titanium dioxide pigment with wollastonite as main ingredient, described preparation method comprises the following steps:

[0039] (1) Take industrial-grade quicklime with a CaO content of 85%, add water to 10 times the mass of quicklime, put it into a reactor for slurrying and disperse, and age at a temperature of 100°C for 15 hours to obtain a Ca(OH) concentration of 11.55%. 2 slurry;

[0040](2) get particle size 15 μm rutile type titanium dioxide, its consumption is 80% of CaO quality, drop in the reactor of step (1);

[0041] Steps (3)-(9) are the same as in Example 1.

Embodiment 3

[0043] A kind of preparation method of the multi-element titanium dioxide pigment with wollastonite as main ingredient, described preparation method comprises the following steps:

[0044] (1) Take industrial-grade quicklime with a CaO content of 93%, add water to 20 times the mass of quicklime, put it into a reactor for slurrying and disperse it, and age it at a temperature of 120°C for 20 hours to obtain a concentration of 6.23% Ca(OH) 2 slurry;

[0045] (2) get particle size 8 μ m rutile type titanium dioxide, its consumption is 90% of CaO quality, drop in the reactor of step (1);

[0046] Steps (3)-(9) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com