Crop straw fiber modification method

A technology for crop straw and fiber modification, which is used in fiber raw material processing, cellulose raw material pulping, textile and paper making, etc. Increase the property, enhance the physical and chemical binding effect, increase the effect of surface active points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

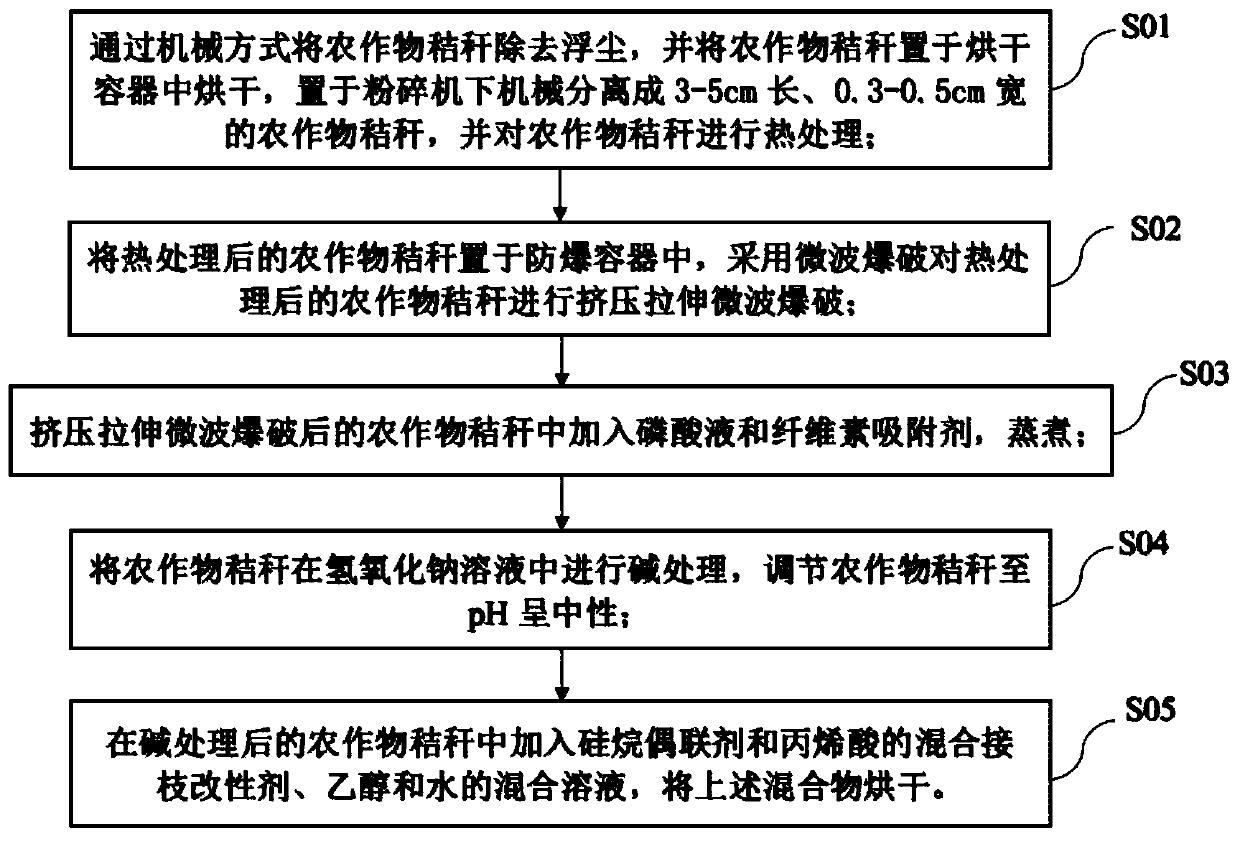

[0026] like figure 1 As shown, the method for modifying crop stalk fibers provided in this embodiment comprises the following steps:

[0027] Step S1: mechanically remove the floating dust from the crop straws, place the crop straws in a drying container to dry, place them under a pulverizer to mechanically separate them into crop straws with a length of 4 cm and a width of 0.4 cm, and heat-treat the straws; Heat treatment in the range of 180°C, after heat treatment, the adhesion force on the surface of crop straw fibers will be improved, spherulites will appear on the surface, the roughness will increase, and the diffusion of low molecular substances will be promo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com