Hole dredging device for coal-bed gas well continuous perforation

A coalbed methane well and perforation technology, applied in the field of auxiliary desilting equipment components for coalbed methane wells, can solve the problems of sediment retention, adhesion on the perforation hole and the inner wall of the wellbore, obstacles to stable and continuous drainage of coalbed methane wells, and small coverage areas. Achieve the effects of avoiding sudden drop in gas production, improving dredging effect, and increasing mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and example the present invention will be further described:

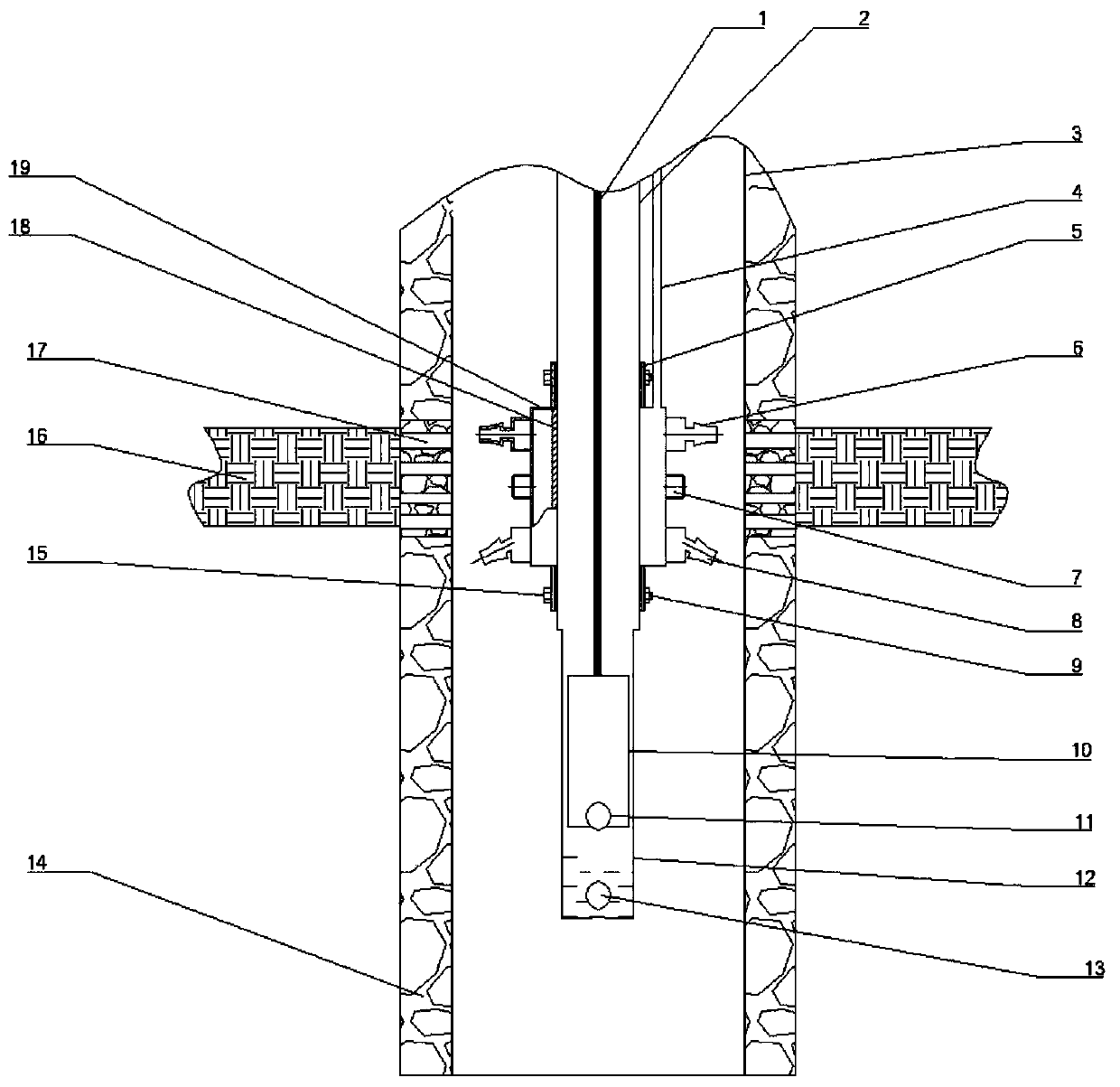

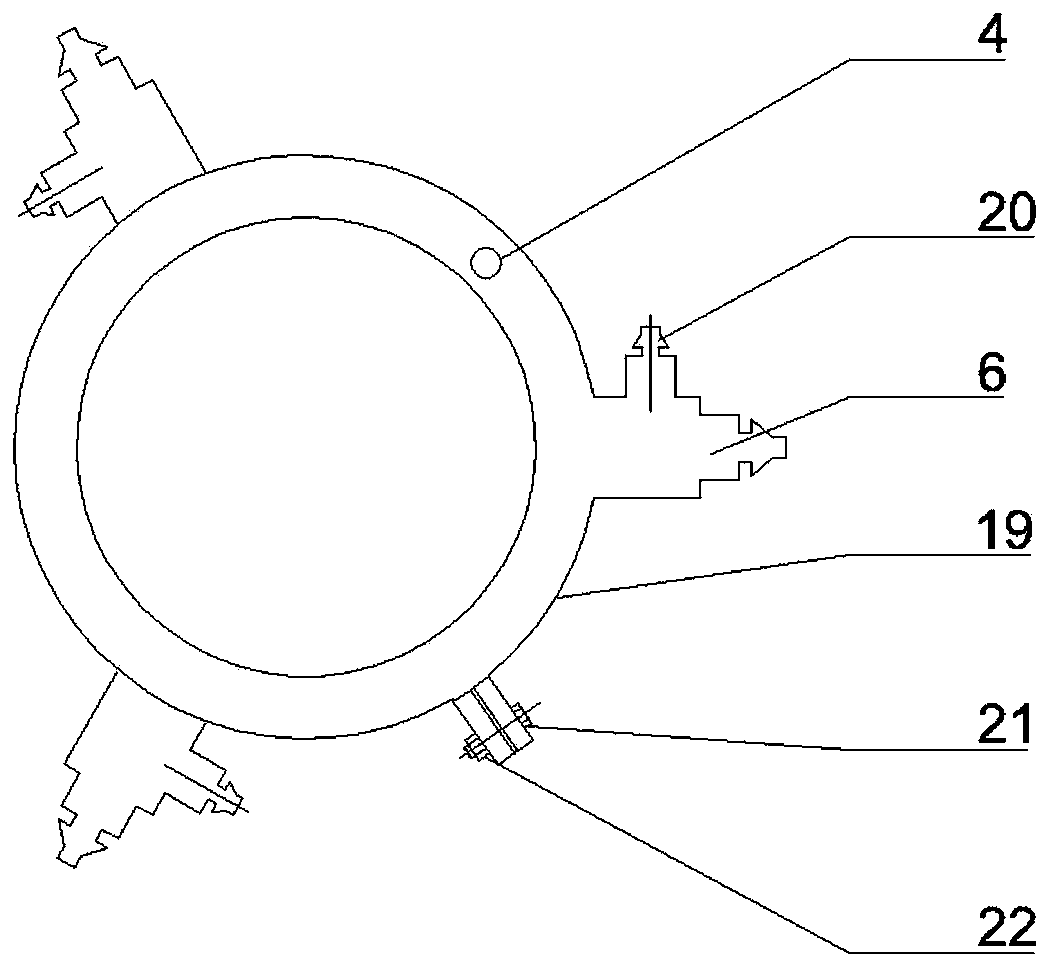

[0016] Such as Figure 1 to Figure 2 As shown: the present invention includes sucker rod 1, oil pipe 2, casing 3, high-pressure water injection pipe 4, rubber gasket 5, horizontal nozzle 6, threaded joint 7, multi-angle nozzle 8, positioning nut 9, plunger 10, swimming Moving valve 11, pump barrel 12, fixed valve 13, cementing cement layer 14, positioning bolt 15, coal reservoir 16, perforation hole 17, sliding bearing bush 18, water storage tank 19, rotary push nozzle 20, fastening bolt 21 , fastening nut 22, the device is connected by the sliding bearing 18 and the oil pipe 2 through the positioning bolt 14, the positioning nut 9 and the rubber gasket 5, the water storage bin 19 and the sliding bearing 18, the water storage bin 19 is threaded with the horizontal nozzle 6, the multi-angle nozzle 8, and the rotary push nozzle 20 through the threaded joint 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com