Liquid crystal on silicon (LCOS) chip and LCOS module

A chip and orientation layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of LCOS chips and LCOS modules difficult to apply high-energy laser imaging and modulation, and achieve simplified structure, improved anti-glare resistance, high efficiency The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

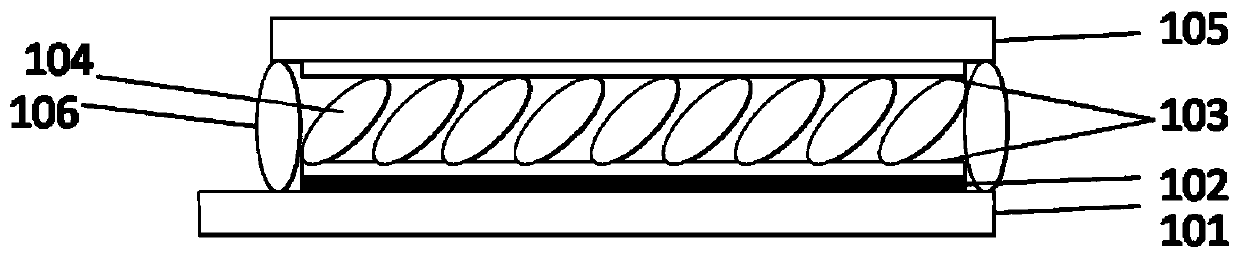

[0025] as attached figure 1 As shown, the LCOS chip 10 provided by this embodiment includes a silicon substrate 101, a dielectric film 102, an alignment layer 103, a liquid crystal 104, an alignment layer 103, and an ITO glass 105 from bottom to top, and the silicon substrate 101 and the ITO glass 105 are passed through epoxy Resin glue 106 bonds the package.

[0026] Optionally, the alignment layer 103 may be an organic alignment layer or an inorganic alignment layer.

[0027] Since the light damage threshold of the inorganic alignment layer is higher, it can withstand stronger laser irradiation than the organic alignment layer.

[0028] Specifically, the inorganic alignment layer is a silicon oxide material, and a small-angle silicon oxide thin film is prepared on the ITO glass 105 and the silicon substrate 101 coated with the dielectric film 102 by electron beam evaporation coating method and using an oblique evaporation process. The LCOS chip 10 is used for 810nm wavelen...

Embodiment 2

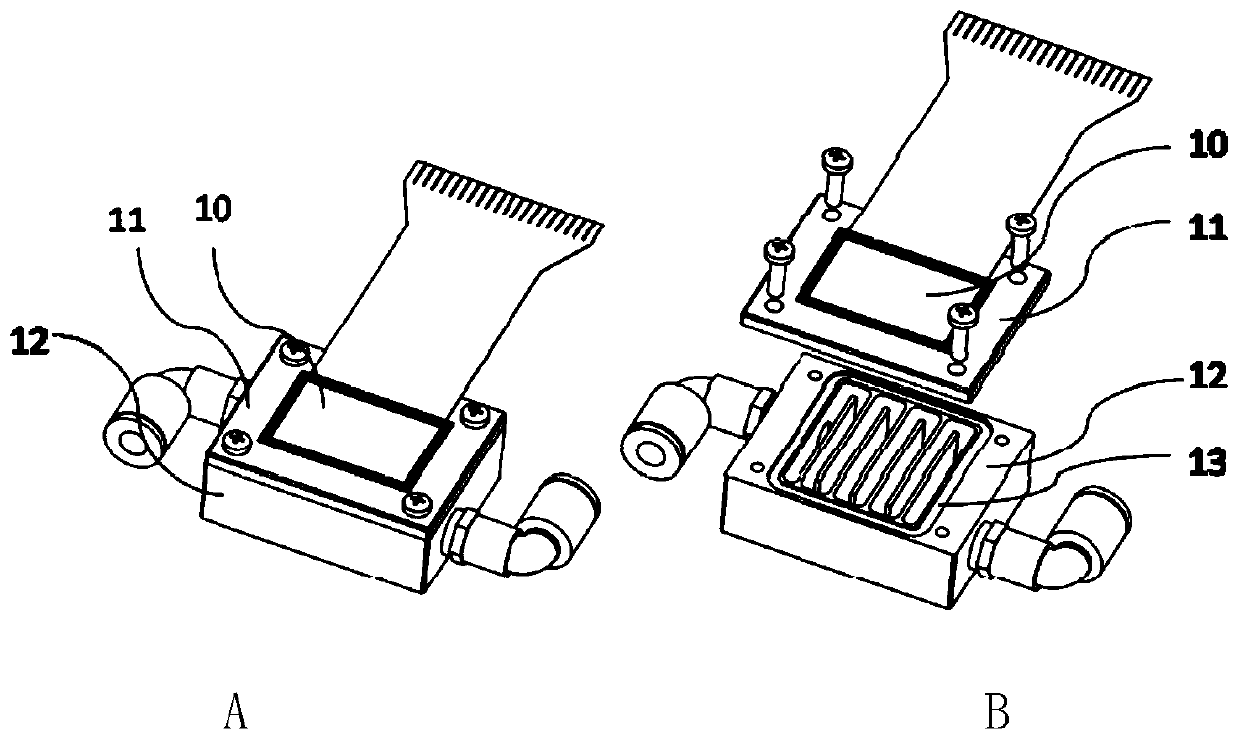

[0034] as attached Figure 2-3 As shown, in the LCOS module shown in the second embodiment, the LCOS module includes the LCOS chip shown in the first embodiment.

[0035] Optionally, in addition to the LCOS chip 10, the LCOS module also includes a water-cooled heat sink 12 and a cover plate 11, the LCOS chip 10 is embedded in the cover plate 11, and the lower surface of the cover plate 11 is attached to the water-cooled heat sink 12.

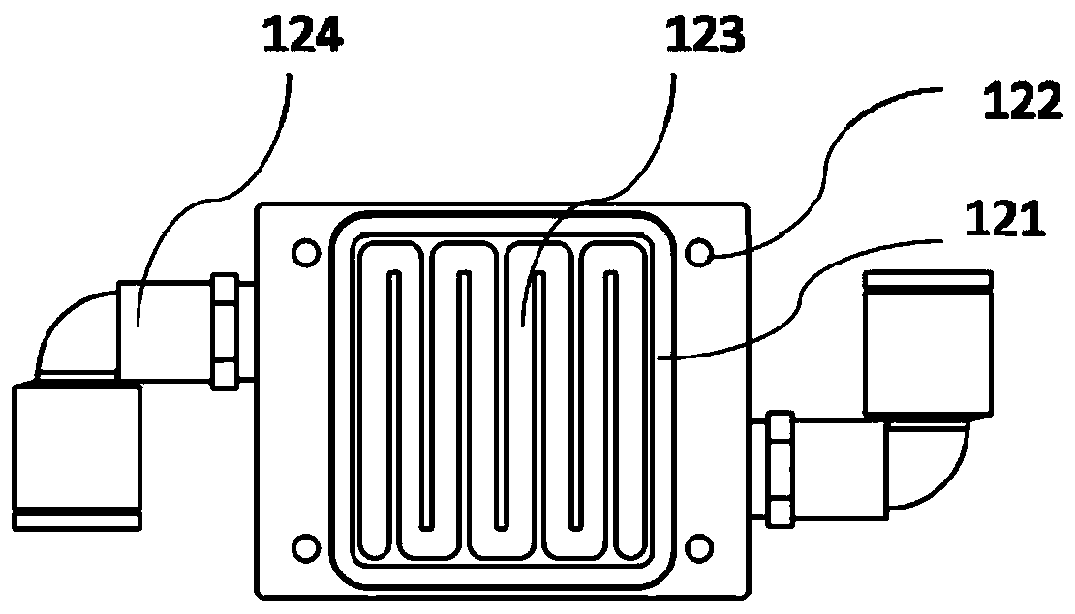

[0036] Please refer to figure 2 , which is a schematic structural diagram of a water-cooled heat sink 12 according to an embodiment of the present invention.

[0037] Such as figure 2 As shown, the water path in the water-cooled heat sink 12 is a "snake-like" microchannel structure 123. In the microchannel structure 123, the two ends of the microchannel are through holes connected to the outside world, and the outer through holes can be connected with the hose transfer valve 124 connect. The edge of the microchannel is a closed-loop groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com