Preparation method of polyvinylpyrrolidone/silver/silver telluride ternary flexible composite thermoelectric film

A technology of polyvinylpyrrolidone and thermoelectric film, which is applied in the manufacture/processing of thermoelectric devices, and the material of thermoelectric device junction leads, etc., can solve the problems of non-flexibility, low thermoelectric performance, and restrictions on the application of wearable electronic devices, and achieve The effect of excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

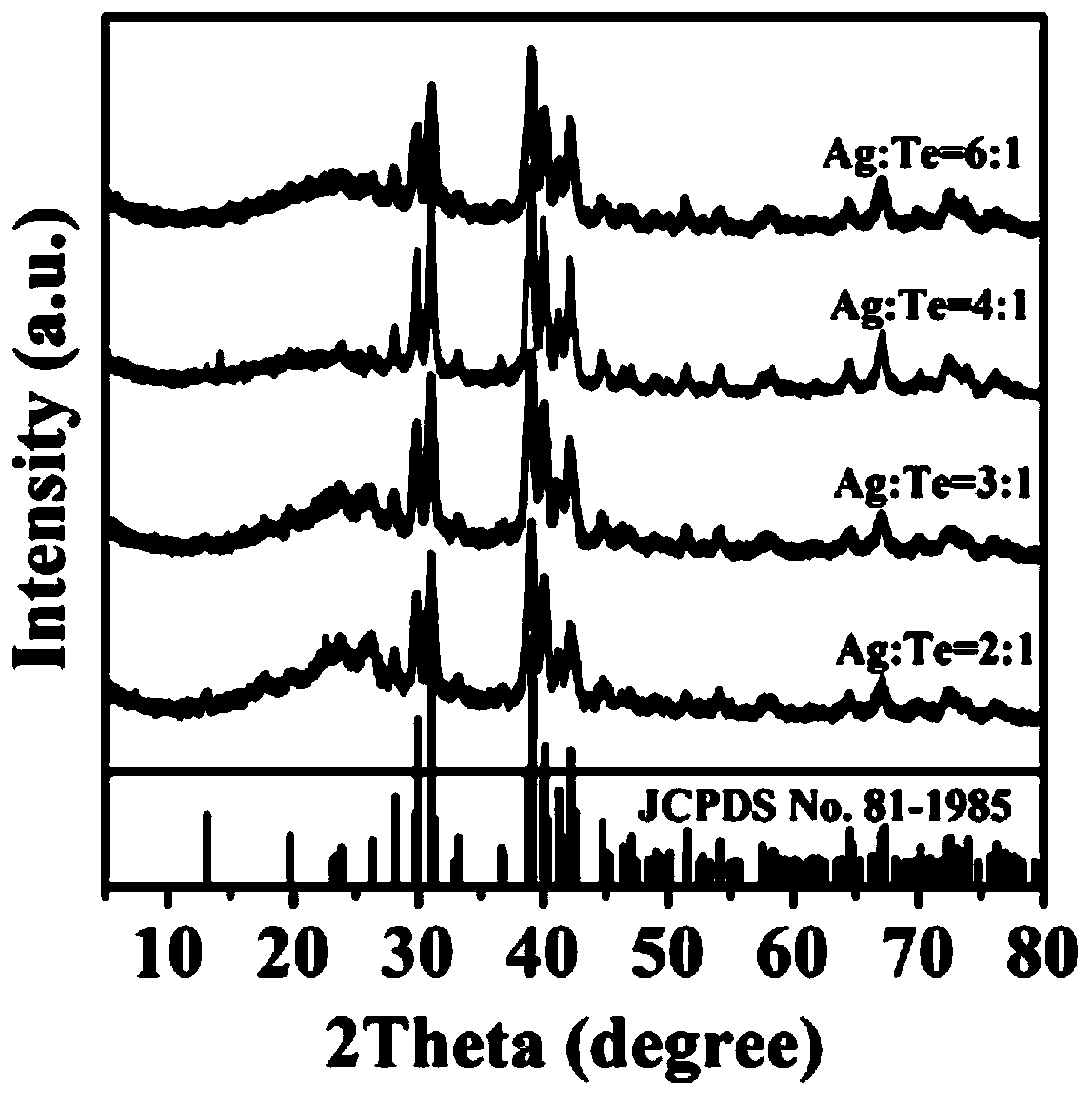

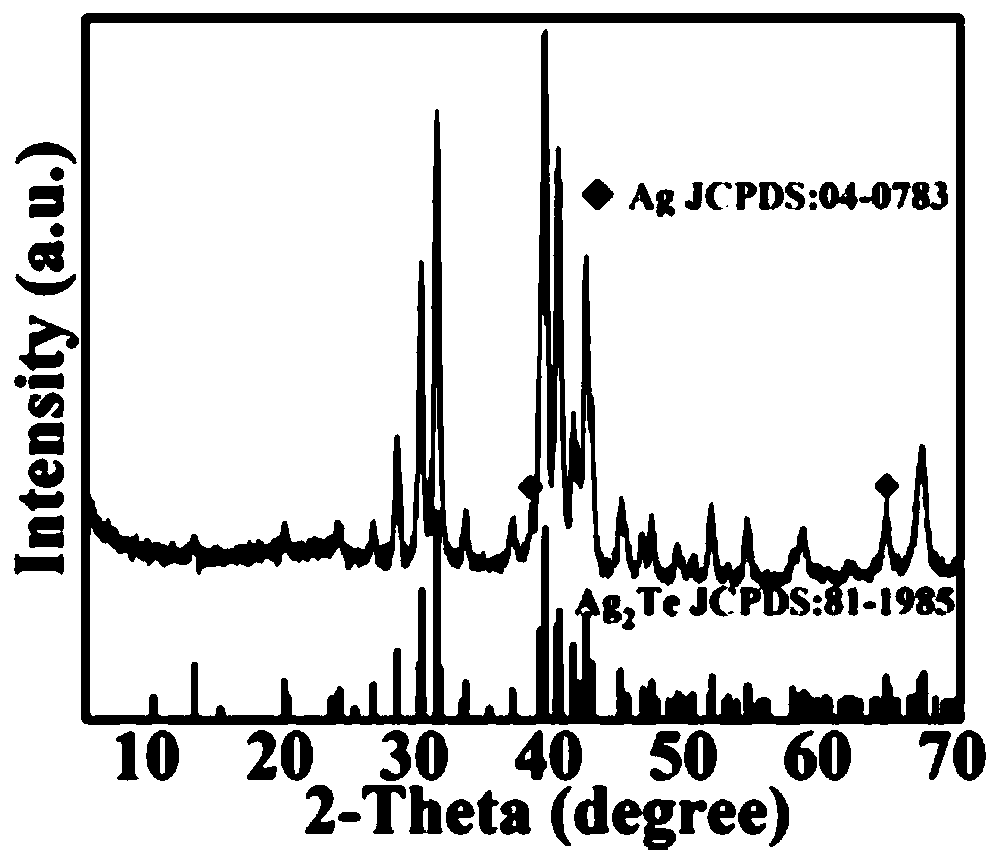

[0036] A preparation method of a polyvinylpyrrolidone / silver / silver telluride ternary flexible composite thermoelectric film. First, a PVP-coated tellurium nanowire is prepared. Then, the ethylene glycol solution of silver nitrate was slowly added dropwise to the PVP-coated tellurium nanowire dispersion, stirred at room temperature for 2 hours, centrifuged and washed alternately with deionized water and ethanol until the supernatant was colorless. The product was dispersed in a mixed solution of absolute ethanol and hydrazine hydrate, and the volume ratio of absolute ethanol and hydrazine hydrate was 10 / 1, and the product was stirred at room temperature overnight to remove excess PVP. After centrifuging the product, it was washed 5 times alternately with deionized water and ethanol. The precipitated product was dispersed in absolute ethanol and ultrasonicated for 2 h to obtain a uniform PVP-coated silver telluride nanowire ethanol dispersion. Using a nylon filter membrane as ...

Embodiment 2

[0044] A preparation method of a polyvinylpyrrolidone / silver / silver telluride ternary flexible composite thermoelectric film. First, a PVP-coated tellurium nanowire is prepared. Then, the ethylene glycol solution of silver nitrate was slowly added dropwise to the PVP-coated tellurium nanowire dispersion, stirred at room temperature for 2 hours, centrifuged and washed alternately with deionized water and ethanol until the supernatant was colorless. The product is dispersed in a mixed solution of absolute ethanol and hydrazine hydrate, and the volume ratio of absolute ethanol and hydrazine hydrate is 10 / 1. Stir overnight at room temperature to remove excess PVP. After centrifuging the product, it was washed 5 times alternately with deionized water and ethanol. The precipitated product was dispersed in absolute ethanol and ultrasonicated for 2 h to obtain a uniform PVP-coated silver telluride nanowire ethanol dispersion. Using a nylon filter membrane as a substrate, a PVP / silve...

Embodiment 3

[0052] A preparation method of a polyvinylpyrrolidone / silver / silver telluride ternary flexible composite thermoelectric film. First, a PVP-coated tellurium nanowire is prepared. Then, the ethylene glycol solution of silver nitrate was slowly added dropwise to the PVP-coated tellurium nanowire dispersion, stirred at room temperature for 2 hours, centrifuged and washed alternately with deionized water and ethanol until the supernatant was colorless. The product is dispersed in a mixed solution of absolute ethanol and hydrazine hydrate, and the volume ratio of absolute ethanol and hydrazine hydrate is 10 / 1. Stir overnight at room temperature to remove excess PVP. After centrifuging the product, it was washed 5 times alternately with deionized water and ethanol. The precipitated product was dispersed in absolute ethanol and ultrasonicated for 2 h to obtain a uniform PVP-coated silver telluride nanowire ethanol dispersion. Using a nylon filter membrane as a substrate, a PVP / silve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com