Deep denitrification process for low-concentration total nitrogen wastewater

A deep denitrification, low-concentration technology, applied in water pollutants, biological water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem that the total nitrogen in the effluent is not easy to meet the standard, and achieve good re-adsorption performance and increase biomass. , the effect of increasing the abundance ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

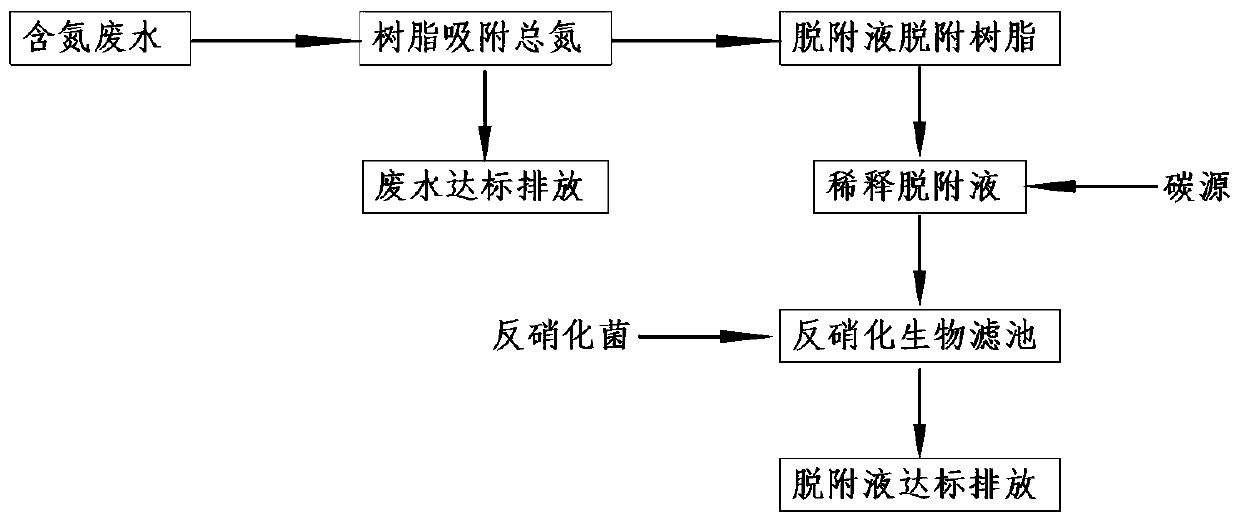

[0026] refer to figure 1 As shown, this embodiment 1 discloses a deep denitrification process for low-concentration total nitrogen wastewater. This embodiment is aimed at collecting wastewater produced by a certain urban sewage treatment plant. After testing, the raw water quality of the wastewater has a TN content of 20- 30 mg / L, the specific treatment process is as follows:

[0027] 1) Low-concentration total nitrogen wastewater passes through the reactor equipped with ion exchange resin at a flow rate of 6 BV / h. After treatment, the total nitrogen in the wastewater is about 5 mg / L, which can reach the discharge standard;

[0028] a. Resin pretreatment: fill the resin column in the ion exchange resin reactor with resin. The resin is a macroporous styrene series strong base anion exchange resin. In this example, the resin uses D205 type resin as the selective denitrification resin ; Then soak 2 h with 12%NaCl resin desorption solution, enter pure water to rinse the resin co...

Embodiment 2

[0037] refer to figure 1 As shown, this embodiment 2 discloses a deep denitrification process for low-concentration total nitrogen wastewater. This embodiment is aimed at collecting wastewater produced by a certain urban sewage treatment plant. After testing, the raw water quality of the wastewater has a TN content of 18- 22 mg / L, the specific treatment process is as follows:

[0038] 1) Low-concentration total nitrogen wastewater passes through the reactor equipped with ion exchange resin at a flow rate of 6 BV / h. After treatment, the total nitrogen in the wastewater is about 4 mg / L, which can reach the discharge standard;

[0039]a. Resin pretreatment: fill the resin column in the ion exchange resin reactor with resin. The resin is a macroporous styrene series strong base anion exchange resin. In this example, the resin uses D205 type resin as the selective denitrification resin Then soak 2 h with 10%NaCl resin desorption solution, enter pure water to rinse the resin colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com