Method for treating leachate of garbage transfer station

A waste transfer station and treatment method technology, which is applied in the field of leachate treatment of waste transfer stations, can solve the problems of inconvenient operation and management, increased operating costs, and high investment costs, and achieve improved treatment quality, treatment effect and quality, and improved treatment efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

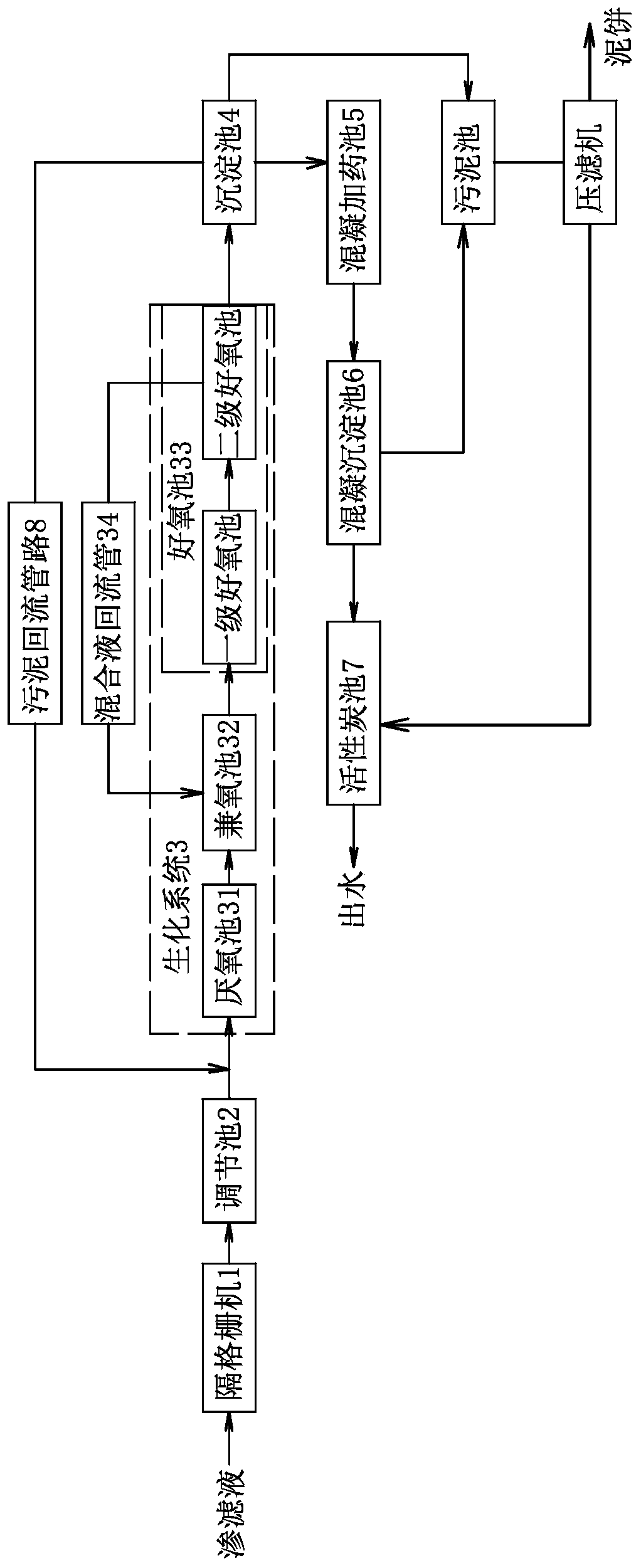

Image

Examples

Embodiment 1

[0071] The leachate of the garbage transfer station has a daily treatment capacity of 5 tons, a COD content of 7500 mg / L, an ammonia nitrogen content of 160 mg / L, a total phosphorus content of 120 mg / L, a suspended solid concentration of 305 mg / L, and a pH of 5.4.

[0072] According to the leachate characteristics of the above garbage transfer station, the technical solutions include:

[0073] S1. The leachate generated by the garbage transfer station first passes through the screen machine to separate high-concentration suspended solids and pollutants with large particle sizes in the water body, and then flows into the regulating tank.

[0074] S2. The wastewater from the regulating tank enters the biochemical system through the lift pump.

[0075] S3. The effluent from the biochemical system flows into the sedimentation tank.

[0076] S4. The effluent from the sedimentation tank flows into the coagulation dosing and coagulation sedimentation unit. After coagulation and sedi...

Embodiment 2

[0086] The leachate of the garbage transfer station has a daily treatment capacity of 20t, a COD content of 16650mg / L, an ammonia nitrogen content of 280mg / L, a total phosphorus content of 270mg / L, a suspended solid concentration of 445mg / L, and a pH of 6.

[0087] According to the leachate characteristics of the above garbage transfer station, the technical solutions include:

[0088] S1. The leachate generated by the garbage transfer station first passes through the screen machine to separate high-concentration suspended solids and pollutants with large particle sizes in the water body, and then flows into the regulating tank.

[0089] S2. The wastewater from the regulating tank enters the biochemical system through the lift pump.

[0090] S3. The effluent from the biochemical system flows into the sedimentation tank.

[0091] S4. The effluent from the sedimentation tank flows into the coagulation dosing and coagulation sedimentation unit, and after coagulation and sediment...

Embodiment 3

[0101] The leachate of the garbage transfer station has a daily treatment capacity of 50t, a COD content of 28500mg / L, an ammonia nitrogen content of 450mg / L, a total phosphorus content of 320mg / L, a suspended solid concentration of 530mg / L, and a pH of 6.5.

[0102] According to the leachate characteristics of the above garbage transfer station, the technical solutions include:

[0103] S1. The leachate generated by the garbage transfer station first passes through the screen machine to separate high-concentration suspended solids and pollutants with large particle sizes in the water body, and then flows into the regulating tank.

[0104] S2. The wastewater from the regulating tank enters the biochemical system through the lift pump.

[0105] S3. The effluent from the biochemical system flows into the sedimentation tank.

[0106] S4. The effluent from the sedimentation tank flows into the coagulation dosing and coagulation sedimentation unit, and after coagulation and sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com