Artificial synthetic stone composite magnesium oxysulfate binding material and preparation method and application thereof

A technology of artificial granite and magnesium oxysulfide glue, which is applied in the field of magnesium oxysulfide cementitious materials and can solve problems such as difficulty in improving material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Test raw materials:

[0033] The magnesium sulfate heptahydrate was purchased from Fangchenggang Wuxing Chemical Reagent Factory, industrial grade, and its chemical composition is shown in Table 1.

[0034] The light-burned magnesia powder is produced in Haicheng, Liaoning, and its activity is determined to be 66.72% by hydration test. The chemical composition is shown in Table 2.

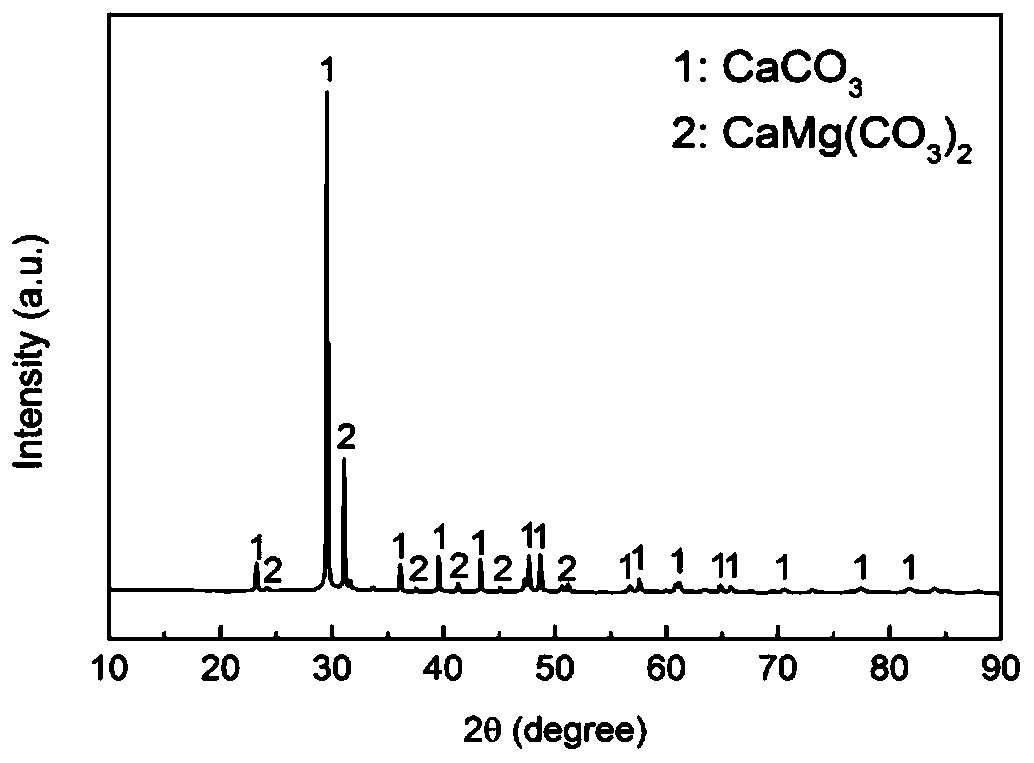

[0035] The artificial granite waste slag is taken from Hezhou, Guangxi. After drying and grinding, it is a white powder with a whiteness of 85.7%. XRD analysis sees figure 1 , and its chemical composition is shown in Table 2.

[0036] The citric acid was purchased from Nanning Lantian Chemical Reagent Company and was chemically pure.

[0037]The aggregate is ISO standard sand, and the water is tap water.

[0038] The chemical composition (unit: %) of table 1 technical grade magnesium sulfate heptahydrate

[0039]

[0040] Table 2 Granite waste slag and lightly burned MgO compositio...

Embodiment 2

[0068] On the basis of test number 2 and 3 of table 3 in embodiment 1, add the fly ash of 10-15% of the sum of artificial granite and active MgO quality respectively again, constitute 5% artificial granite waste slag-10% Fly ash and 10% artificial granite-15% fly ash are two kinds of composite magnesium oxysulfide cementitious materials. The said fly ash is class I class F of the thermal power station. The place of origin is Gongyi, Henan. The chemical composition of the fly ash is shown in the table 7.

[0069] Table 7 fly ash composition (unit: %)

[0070]

[0071] Sample preparation and test method are with reference to embodiment 1, find through test, and fly ash particle size is less, and mostly is spherical (such as Figure 11 shown), the SEM image of the magnesium oxysulfide cement slurry sample mixed with 5% artificial stone waste residue + 10% fly ash is shown Figure 12 shown. The addition of fly ash can play a role in lubricating and supplementing the lack of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com