Graphene-coated conductive heat storage fabric and preparation process thereof

A graphene and water-based graphene technology, applied in the field of textile fabrics, can solve the problems of poor graphene dispersion, affecting the performance of glue, affecting the compatibility and dispersibility of graphene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

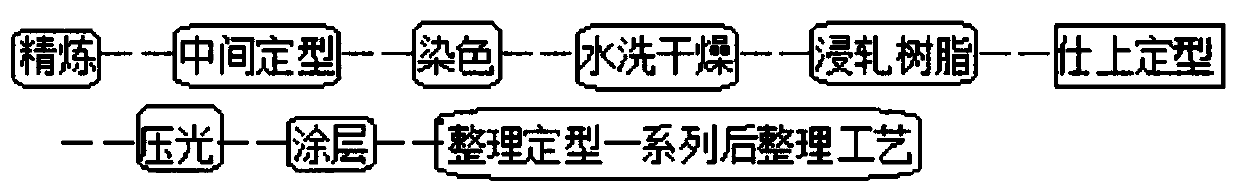

Method used

Image

Examples

specific Embodiment 1

[0031] A graphene coating glue, the component distribution ratio of the graphene coating glue is composed of the following parts by weight: 70 parts of water-based aliphatic polyurethane emulsion, 20 parts of water-based graphene emulsion, 5 parts of crosslinking agent, 5 parts of water 1 part, 1 part of acrylate polymer; wherein, the solid content of the aqueous aliphatic polyurethane emulsion is 50%, and the graphene content is 30%.

[0032] The viscosity of the graphene-coated glue is: 8000MPA*S.

[0033] A kind of preparation method according to described graphene coating glue, described graphene coating glue is prepared graphene coating with the mode of high-speed stirring by adding a certain amount of water-based graphene emulsion in water-based coating material glue;

[0034] The specific preparation process is as follows: Add ① water-based aliphatic polyurethane emulsion, ② water-based graphene emulsion, ③ crosslinking agent, ④ water, ⑤ acrylate polymer in the state o...

specific Embodiment 2

[0051] A graphene coating glue, the component distribution ratio of the graphene coating glue is composed of the following parts by weight: 80 parts of water-based aliphatic polyurethane emulsion, 30 parts of water-based graphene emulsion, 10 parts of crosslinking agent, 10 parts of water parts, 3 parts of acrylate polymer; wherein, the solid content of the aqueous aliphatic polyurethane emulsion is 50%, and the graphene content is 50%.

[0052] The viscosity of the graphene-coated glue is: 15000MPA*S.

[0053] A kind of preparation method according to described graphene coating glue, described graphene coating glue is prepared graphene coating with the mode of high-speed stirring by adding a certain amount of water-based graphene emulsion in water-based coating material glue;

[0054] The specific preparation process is as follows: Add ① water-based aliphatic polyurethane emulsion, ② water-based graphene emulsion, ③ crosslinking agent, ④ water, ⑤ acrylate polymer in the stat...

specific Embodiment 3

[0071] A graphene coating glue, the component distribution ratio of the graphene coating glue is composed of the following parts by weight: 75 parts of water-based aliphatic polyurethane emulsion, 26 parts of water-based graphene emulsion, 7 parts of crosslinking agent, 8 parts of water 2 parts, 2 parts of acrylate polymer; wherein, the solid content of the aqueous aliphatic polyurethane emulsion is 50%, and the graphene content is 40%.

[0072] The viscosity of the graphene-coated glue is: 12000MPA*S.

[0073] A kind of preparation method according to described graphene coating glue, described graphene coating glue is prepared graphene coating with the mode of high-speed stirring by adding a certain amount of water-based graphene emulsion in water-based coating material glue;

[0074] The specific preparation process is as follows: Add ① water-based aliphatic polyurethane emulsion, ② water-based graphene emulsion, ③ crosslinking agent, ④ water, ⑤ acrylate polymer in the stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com