A kind of cutting-lifting agent for gas stagnation plug and preparation method thereof

A technology of cutting agent and initiator, which is applied in the field of cutting agent and preparation for gas stagnation plugs, can solve the problems of insufficient temperature resistance of cutting agent, improve anti-collapse performance, improve gas retarding ability, and improve kinetic energy. The effect of plastic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

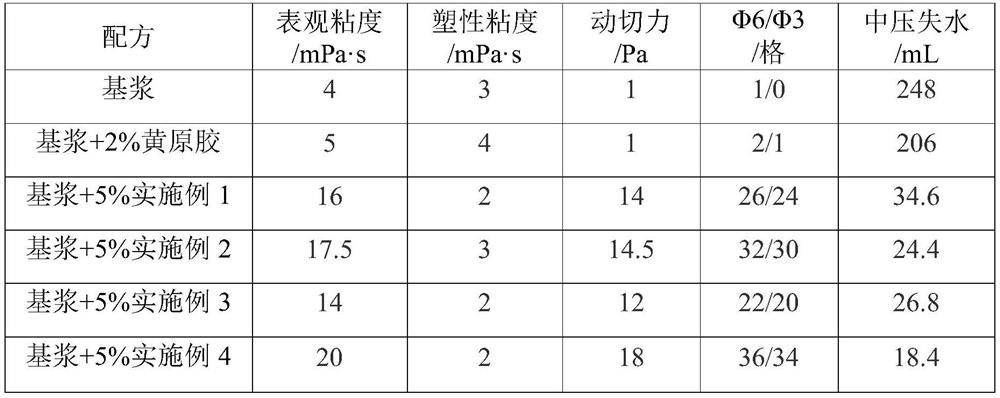

Examples

Embodiment 1

[0029] Add 20g of sepiolite and 0.5g of KH560 to 100mL of distilled water at a stirring speed of 300 rpm. After stirring for 40 minutes, add 3g of 2-acrylamide-2-methylpropanesulfonic acid under stirring, and use sodium hydroxide to Adjust the pH value to 6-7, then add 0.02g of ammonium persulfate and 0.015g of sodium bisulfite, heat at 60°C, keep the stirring speed for 4 hours, dry and pulverize the resulting mixture to obtain the final product.

Embodiment 2

[0031] Add 20g of attapulgite and 0.4g of KH550 to 100mL of distilled water at a stirring speed of 500 rpm. After stirring for 40 minutes, add 2g of 2-acrylamide-2-methylpropanesulfonic acid under stirring, and use sodium hydroxide Adjust the pH value to 6-7, then add 0.015g potassium persulfate and 0.015g sodium bisulfite, heat at 70°C, keep stirring for 4 hours, dry and pulverize the resulting mixture to obtain the final product.

Embodiment 3

[0033] Add 20g of sepiolite, 0.2g of KH560 and 0.2g of KH570 to 100mL of distilled water at a stirring speed of 600 rpm. After stirring for 30 minutes, add 1.5g of 2-acrylamide-2-methylpropanesulfonic acid under stirring, and Use sodium hydroxide to adjust the pH value to 6-7, then add 0.015g potassium persulfate and 0.015g sodium bisulfite, heat at 60°C, keep the stirring speed for 4 hours, dry and pulverize the obtained mixture to obtain the final product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com