A kind of flame-retardant regenerated cellulose fiber and its preparation method

A technology of regenerated cellulose and cellulose, which is used in the manufacture of fire-retardant and flame-retardant filaments, rayon in cellulose solutions, etc., can solve the problems of difficulty in taking into account the flame-retardant properties and mechanical properties of cellulose fibers and easy loss. Achieve the effect of solving the difficulty of taking into account flame retardancy and mechanical properties, reducing dosage, excellent mechanical properties and wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

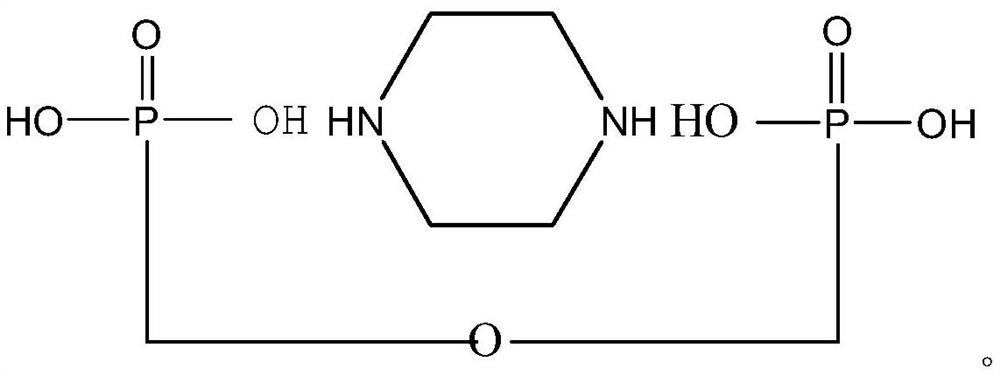

[0034] (1) Wood pulp cellulose (DP=550, α-cellulose content is 88%) is pulverized into the flake of 2cm * 2cm, weighs the wood pulp cellulose of 230g pulverization; Disperses 73g piperazine pyrophosphate to 500g50% NMMO and ground on a ball mill for 8 hours to obtain the flame retardant mother liquor, after testing, the average particle diameter of the flame retardant is 1.6 μm; the pulverized wood pulp cellulose, flame retardant mother liquor and 2260g50% NMMO solvent are added to Mix in the dissolving tank, let it stand for swelling for 30 minutes, then vacuumize and dehydrate at 90°C and stir mechanically to completely dissolve the cellulose to obtain a spinning solution;

[0035] (2) The above-mentioned spinning solution is metered by a metering pump under a nitrogen pressure of 0.3MPa and then extruded from the micropores of the spinneret. After passing through an air section, it enters a water coagulation bath with a temperature of 20°C. After drawing, washing, After dry...

Embodiment 2

[0037](1) wood pulp cellulose (DP=800, α-cellulose content 96.6%) is pulverized into small pieces of 2cm × 2cm, and 230g of pulverized wood pulp cellulose is weighed; 58g of piperazine pyrophosphate is dispersed into 500g of 50% In NMMO and ground on a ball mill for 8 hours to obtain the flame retardant mother liquor, after testing, the average particle size of the flame retardant is 1.8 μm; the pulverized wood pulp cellulose, flame retardant mother liquor and 2260g50% NMMO solvent are added to dissolve Mix in the kettle, let stand to swell for 30min, then vacuumize and dehydrate at 90°C and stir mechanically to completely dissolve the cellulose to obtain the spinning solution;

[0038] (2) The above-mentioned spinning solution is measured by a metering pump under a nitrogen pressure of 0.4 MPa and then extruded from the spinneret micropores. After passing through an air section, it enters a water coagulation bath with a temperature of 20 ° C. After drawing, washing, After dry...

Embodiment 3

[0040] (1) Wood pulp cellulose (DP=550, α-cellulose content is 88%) is pulverized into the flake of 2cm * 2cm, weighs the wood pulp cellulose of 230g pulverization; Disperses 44g piperazine pyrophosphate to 500g50% In NMMO and ground on a ball mill for 8 hours to obtain the flame retardant mother liquor, after testing, the average particle diameter of the flame retardant is 1.8 μm; the NMMO solvent of the pulverized wood pulp cellulose, flame retardant mother liquor and 2260g50% is added to Mix in the dissolving kettle, let it stand for swelling for 30 minutes, then vacuumize and dehydrate at 90°C and stir mechanically to completely dissolve the cellulose to obtain the spinning solution;

[0041] (2) The above-mentioned spinning solution is metered by a metering pump under a nitrogen pressure of 0.3MPa and then extruded from the micropores of the spinneret. After passing through an air section, it enters a water coagulation bath with a temperature of 20°C. After drawing, washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com