Plane static pressure driving structure and inclined shaft plunger pump or motor comprising same

A technology of driving structure and driving spindle, which is applied in the direction of variable displacement pump parts, parts of pumping devices for elastic fluid, pumps, etc., can solve the problem of short service life, large pump or motor size, bearing machining accuracy and assembly accuracy Advanced problems, to achieve the effect of improving work reliability and working life, increasing working pressure and working speed, and improving the ratio of power per unit mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

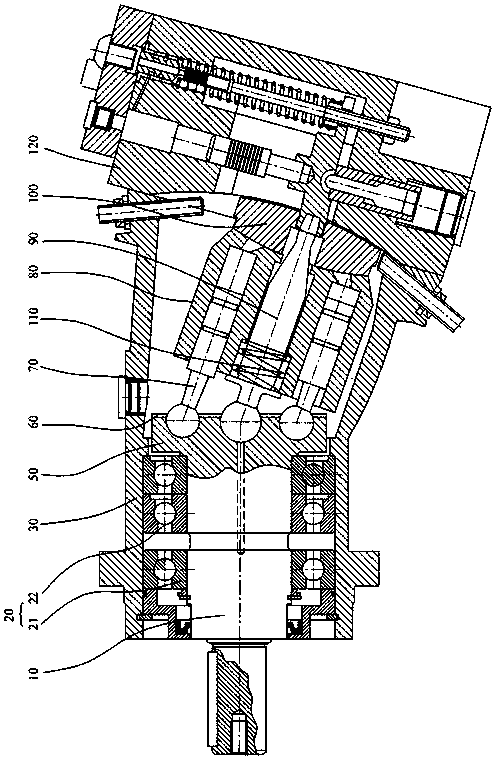

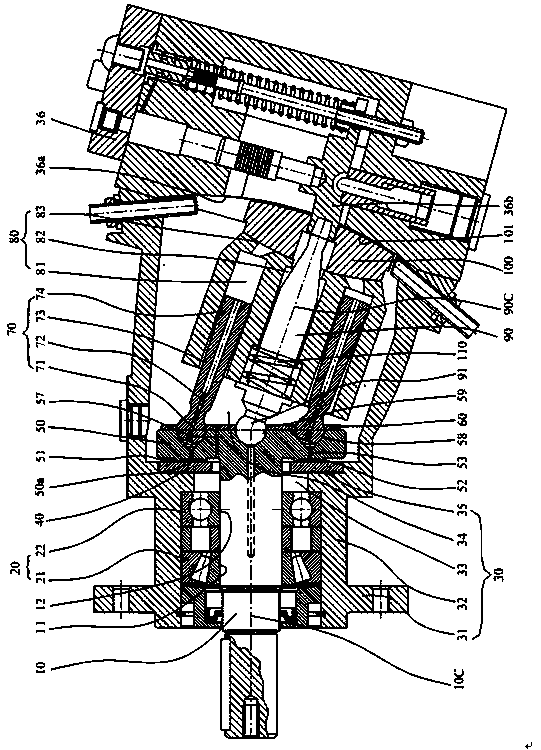

[0042] Such as Figure 2-7 Shown is an embodiment of a planar hydrostatic drive structure of an inclined-axis plunger pump of the present invention. In the preferred embodiment shown, the inclined-axis plunger pump or motor includes a drive main shaft 10, a bearing 20, Housing 30 , liner 40 , drive plate 50 , pressure plate 60 , plunger 70 , cylinder 80 , central shaft 90 , and distribution plate 100 . The axis 10C of the drive spindle and the axis 90C of the central axis form a certain angle, and the drive spindle 10 is supported by the casing 30 via a bearing 20 in a state where one end is arranged inside the casing 30 and can rotate around its own axis. The other end face of the drive spindle 10 is coaxially connected to the drive disc 50 , and a plurality of plunger support ball sockets 58 and a center shaft support ball socket 59 are arranged on the end face of the drive disc 50 facing the cylinder body 80 . The plunger supporting ball sockets 58 are evenly distributed o...

Embodiment 2

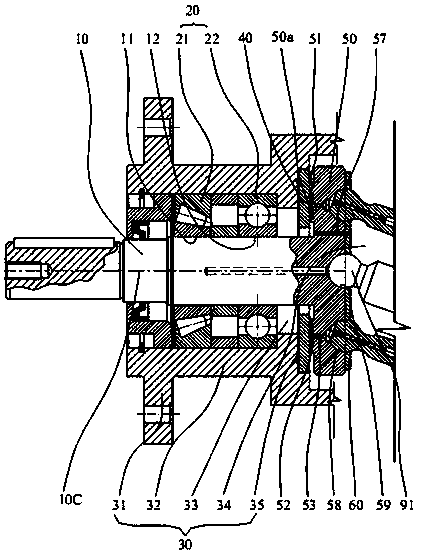

[0068] Such as Figure 8-10 As shown, it shows the inclined-axis plunger pump or motor of Embodiment 2 of the present invention. The difference from Embodiment 1 lies in the structure of the static pressure bearing surface of the drive disc 50 on the side connected to the drive spindle 10 and the interposition For the structure of the liner 40 between the drive plate 50 and the housing 30 , other structures may refer to the structure described in Embodiment 1.

[0069] Such as Figure 8 and 9 As shown, the structure of the liner 40 sandwiched between the drive plate 50 and the housing 30 is shown. The high-pressure oil chamber 42, that is, only the high-pressure oil chamber 42 is provided, and the high-pressure oil chamber 42 communicates intermittently with the corresponding plunger hole 81 on the high-pressure oil side through the oil through hole 53, and the oil through hole 53 introduces the oil High pressure oil chamber 42. Alternatively, at least one high-pressure oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com