Method and system for separately continuous sterilizing carbon source and nitrogen source in bacitracin zinc production

A technology of bacitracin zinc and carbon source, applied in the field of carbon source and nitrogen source separation and continuous sterilization method and system, can solve the problems of high energy consumption, destruction of nutrients in culture medium, etc., reduce energy consumption, relieve cooling pressure, The effect of fermentation unit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a carbon source and nitrogen source separation and continuous sterilization method in the production of bacitracin zinc, which sequentially includes a system emptying step, a nitrogen source sterilization step, a water sterilization step, a carbon source sterilization step, and a water sterilization step ,Specific steps are as follows:

[0036] (1) System decontamination step: simultaneously decontaminate the fermenter and the continuous sterilization system at 120-140°C and 0.1MPa-0.4MPa for 20-60 minutes.

[0037](2) Carbon source sterilization step: put the pre-prepared carbon source into the continuous sterilization system with a batching pump and maintain it for 1-20 minutes under the conditions of 120-150°C and 0.1MPa-0.5MPa for sterilization, and then quickly The temperature is lowered to 30-40 DEG C, and then enters the fermenter; the carbon source is composed of the following components by weight, 1-3% of glucose, 1-5% of starch, and the ...

Embodiment 2

[0042] A carbon source in the production of bacitracin zinc, nitrogen source separation continuous sterilization method, comprising system empty elimination step, nitrogen source sterilization step, water sterilization step, carbon source sterilization step, water sterilization step, detailed steps are :

[0043] (1) System decontamination step: simultaneously decontaminate the fermenter and the continuous sterilization system at 120-140°C and 0.1MPa-0.4MPa for 20-60 minutes;

[0044] (2) Carbon source sterilization step: inject the material in the pre-prepared carbon source tank into the inlet of the spiral plate heat exchanger Ⅰ through the batching pump, enter the spray heater from the exit of the spiral plate heat exchanger Ⅰ, and then pass through the spray After the heater is heated, it enters the maintenance tank for sterilization, and then enters the heating medium inlet of the spiral plate heat exchanger Ⅰ from the upper end of the maintenance tank to exchange heat wi...

Embodiment 3

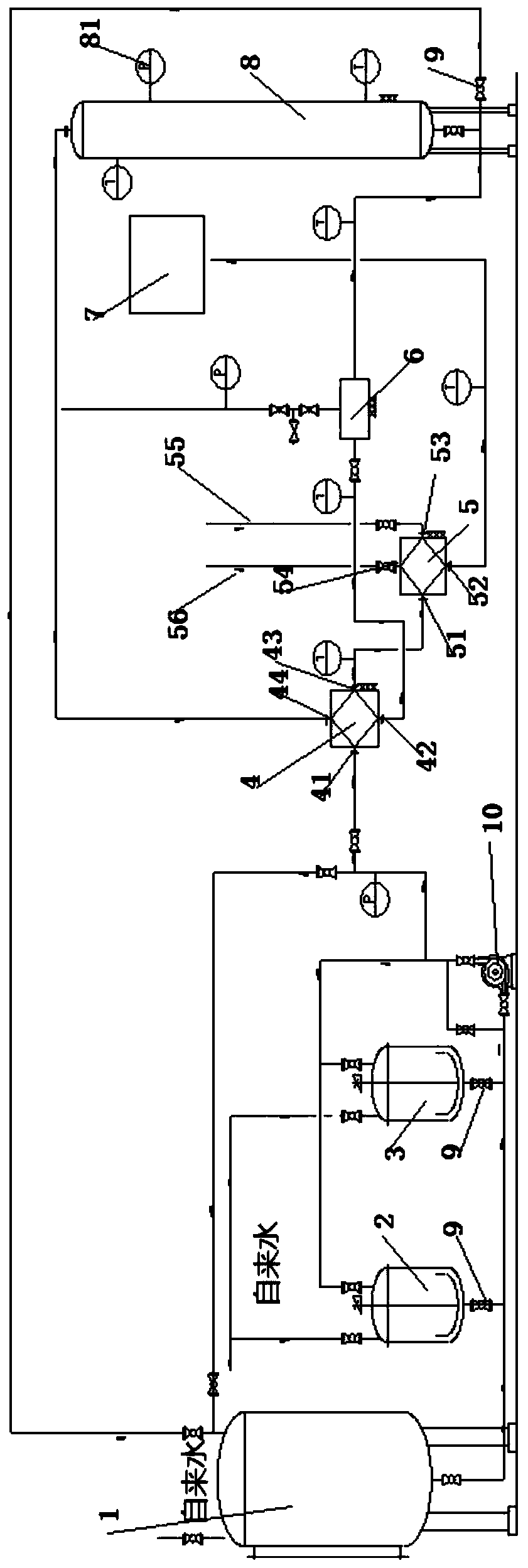

[0049] A carbon source and nitrogen source separation and continuous sterilization system in the production of bacitracin zinc, comprising a batching pump 10, the inlet of the batching pump 10 is used to connect the clean water tank 1, the carbon source tank 3, and the nitrogen source tank respectively through pipelines 2. Valves 9 are respectively set between the batching pump 10 and the clean water tank 1, the carbon source tank 3, and the nitrogen source tank 2; the outlet of the batching pump 10 is connected to the inlet 41 of the spiral plate heat exchanger I through a pipeline, and the spiral The outlet 41 of the plate heat exchanger I is connected to the jet heater 6, and the jet heater 6 is connected to the maintenance tank 8, and the outlet of the maintenance tank 8 is connected to the heating medium inlet 44 of the spiral plate heat exchanger I, and the spiral plate heat exchanger I The heating medium outlet 43 of the spiral plate heat exchanger II is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com