Isocyanate-crosslinked polyethylene glycol-polyglycerol sebacate bioelastomer and its preparation method and application

A technology of polyglycerol sebacate and polyethylene glycol, which is applied in pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the complex cross-linking conditions of polyglycerol sebacate, poor hydrophilicity, and soft tissue use. Limited performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

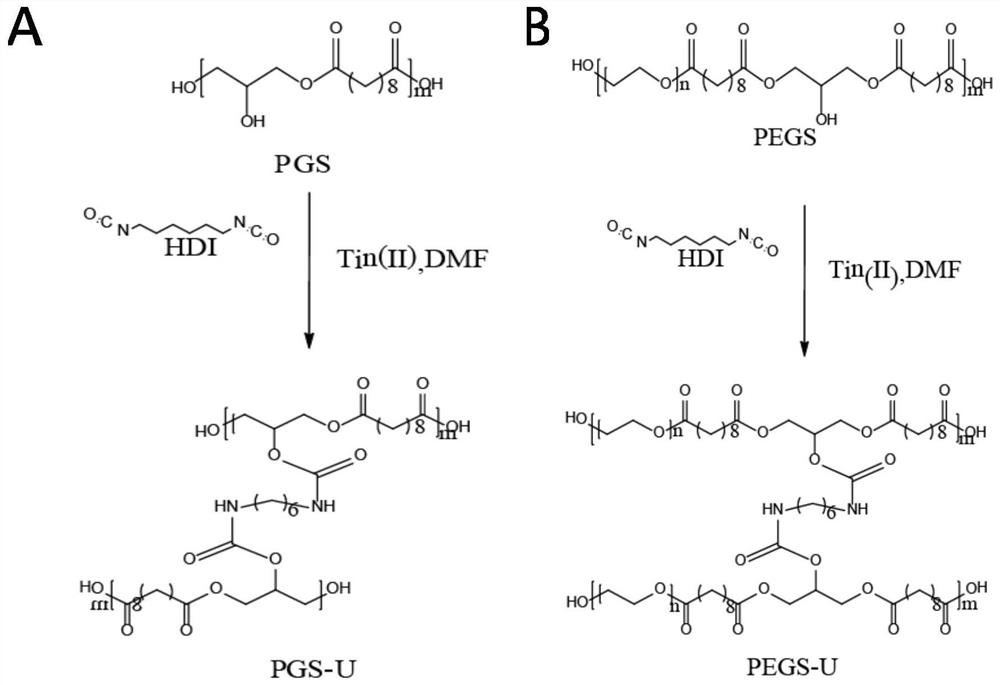

Method used

Image

Examples

Embodiment 1

[0102] The present embodiment relates to the synthesis and purification of PEGSO

[0103] PEGSO prepolymers were synthesized by a two-step method:

[0104] (a) In an argon atmosphere, sebacic acid and glycerol with a molar ratio of 1:1 were reacted at 130 °C for 24 hours;

[0105] (b) The product of step a) was further reacted at 150° C. under vacuum conditions for 6 hours to obtain a PEGSO prepolymer.

[0106]The prepolymerized product is purified by repeated ethanol dissolution-water precipitation operation to remove unreacted monomers and small molecules to obtain purified PEGSO prepolymer (polyglycerol sebacate). The number average molecular weight is 6023Da, and the dispersibility coefficient is 3.21.

Embodiment 2

[0108] This example relates to the synthesis and purification of PEGS20 (20% polyethylene glycol-polyglycerol sebacate)

[0109] (i) 14.14 g of sebacic acid and 20.00 g of PEG (number-average molecular weight of 1000 g / mol) were reacted at 130° C. for 2 hours under an argon atmosphere;

[0110] (ii) continuing to react the product of step (a) at 130° C. under vacuum conditions for 24 hours to obtain a linear prepolymer of sebacic acid and PEG;

[0111] (iii) 7.36 g of glycerol and 14.14 g of sebacic acid were added to the product of step (b), and the reaction was continued for 48 hours at 130° C. under vacuum conditions. In this reaction, the molar content of PEG relative to glycerol was 20%, and the molar ratio of hydroxyl group to carboxyl group in the total reaction was 1.

[0112] The prepolymerized product was purified by repeated ethanol dissolution-water precipitation operation to remove unreacted monomers and small molecules to obtain a purified PEGS20 prepolymer. Th...

Embodiment 3

[0114] This example relates to the synthesis and purification of PEGS80 (80% polyethylene glycol-polyglycerol sebacate)

[0115] (a) Under an argon atmosphere, 16.18 g of sebacic acid and 80.00 g of PEG (number-average molecular weight of 1000 g / mol) were reacted at 130° C. for 2 hours;

[0116] (b) continuing to react the product of step (a) at 130° C. under vacuum conditions for 24 hours to obtain a linear prepolymer of sebacic acid and PEG;

[0117] (c) 1.8414g of glycerol and 6.0675g of sebacic acid were added to the product of step (b), and the reaction was continued for 48 hours at 130° C. under vacuum conditions. In this reaction, the molar content of PEG relative to glycerol was 80%, and the molar ratio of hydroxyl groups to carboxyl groups in the total reaction was 1:1.

[0118] The prepolymerized product was purified by repeated ethanol dissolution-water precipitation operation to remove unreacted monomers and small molecules to obtain a purified PEGS80 prepolymer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

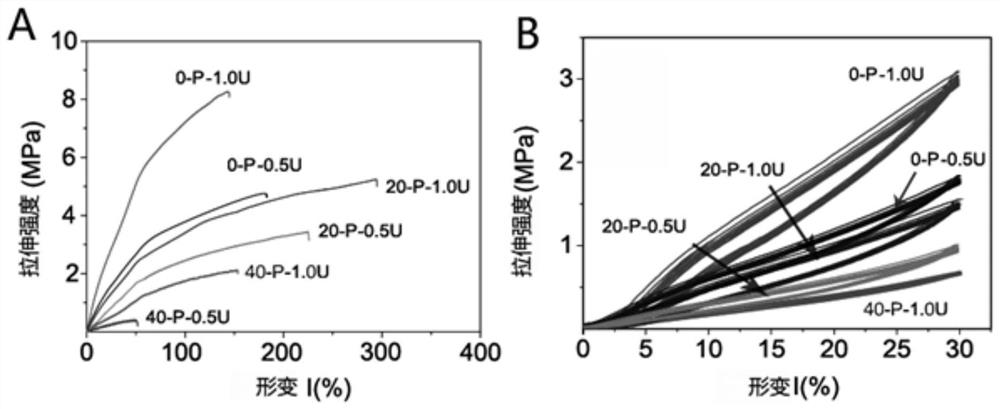

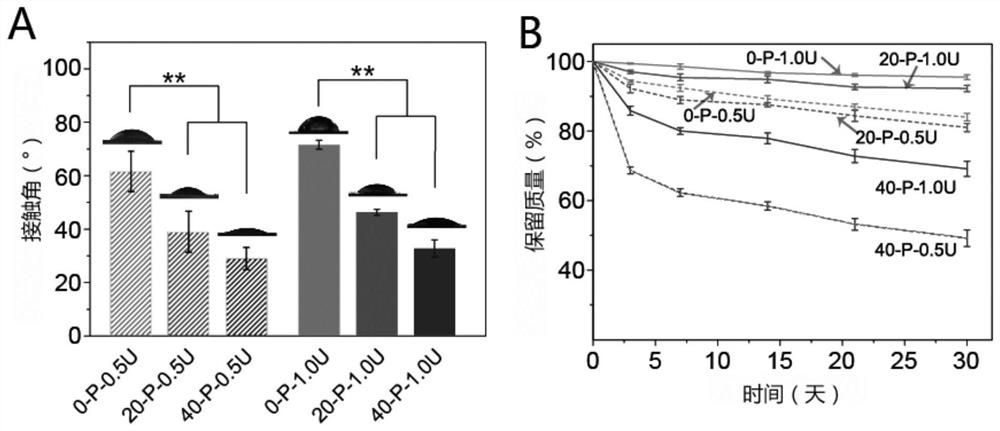

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com