AB glue with high-refractive-index ultrathin intermediate bonding layer

A high-refractive-index, adhesive-layer technology, applied in the field of AB glue, can solve the problems of insufficient adhesion between high-viscosity materials and organic silica gel, insufficient softness of AB glue, and reduced light transmittance and refractive index of AB glue. To achieve the effect of increasing flexibility and deformability, excellent anti-aging performance, stable and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

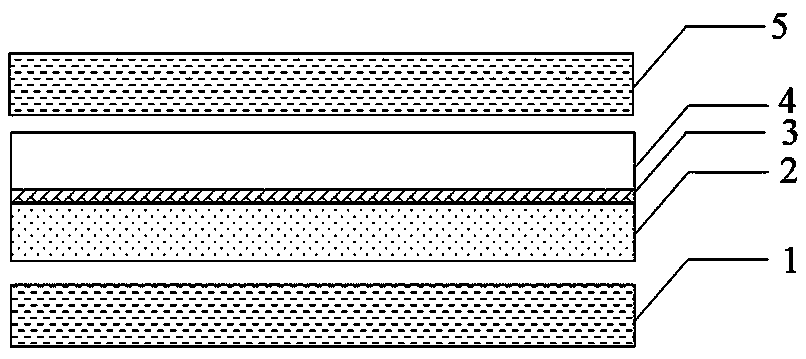

[0033] Such as figure 1 As shown, an AB glue with a high refractive index ultra-thin intermediate adhesive layer in this embodiment includes a high refractive index ultra-thin intermediate adhesive layer, and a layer of low-viscosity silica gel layer is attached to the upper surface of the intermediate adhesive layer. Then the lower surface of the layer is attached with a layer of high-viscosity layer, the lower surface of the high-viscosity layer is attached with a layer of organic silicon release film, and the upper surface of the silica gel layer is attached with a layer of pre-treated PET film; The high-refractive index ultra-thin intermediate bonding layer is to introduce inorganic nanoparticles with high refractive index into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com