Preparation method of photodiodes, photodiode and CMOS image sensor

A photodiode and lithography technology, applied in the direction of diodes, electric solid-state devices, circuits, etc., can solve problems such as output image quality degradation, white spots, and carrier residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

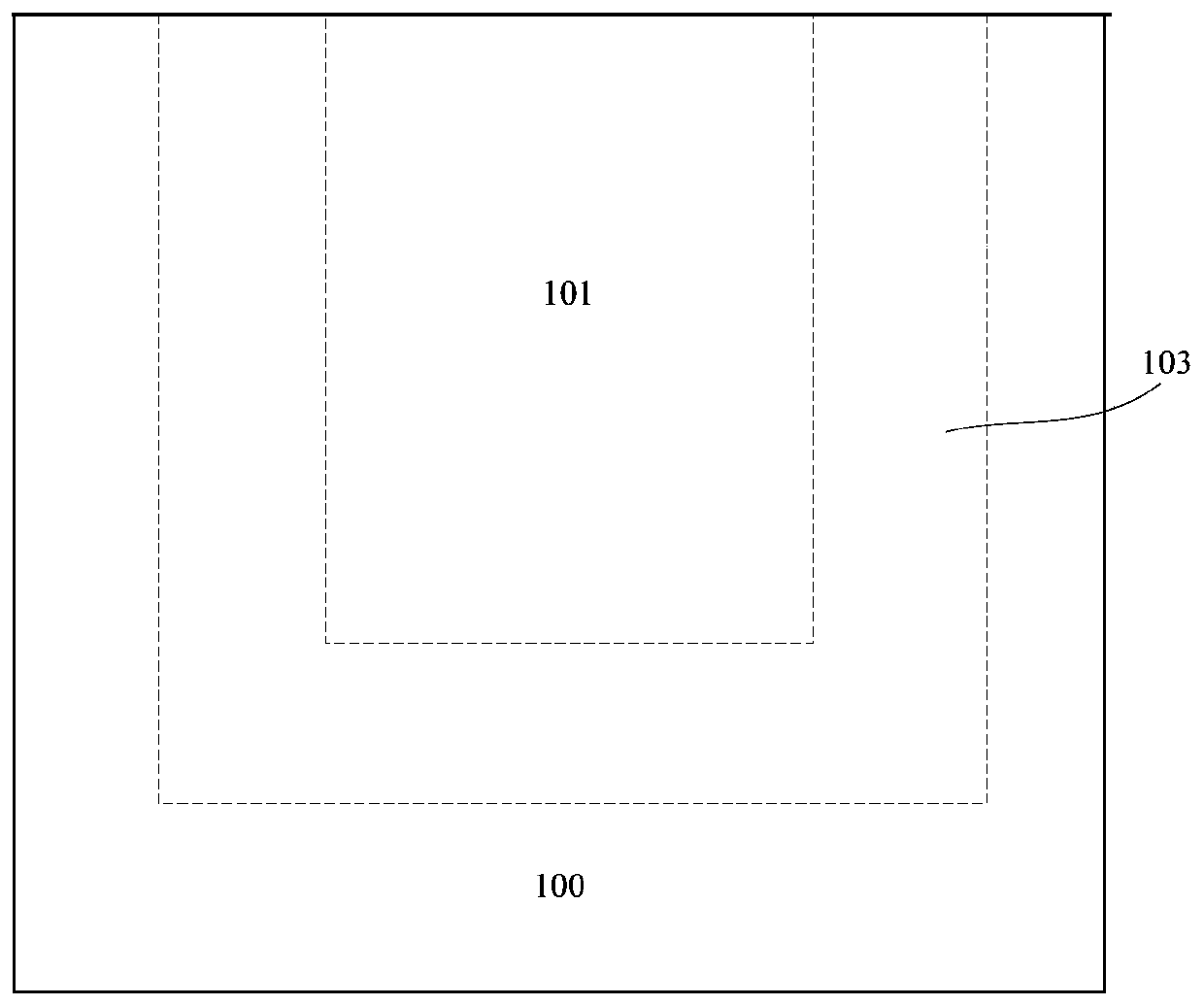

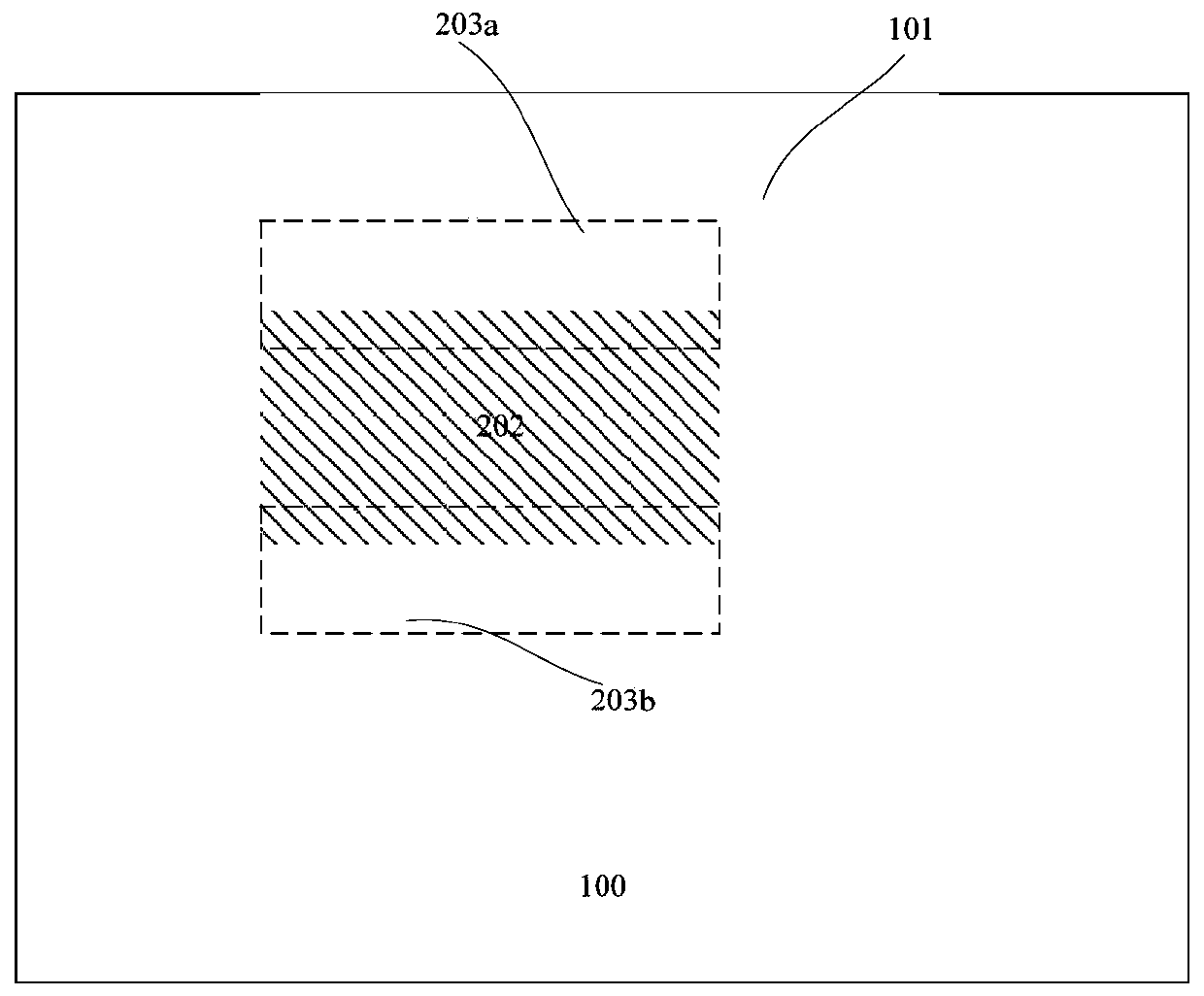

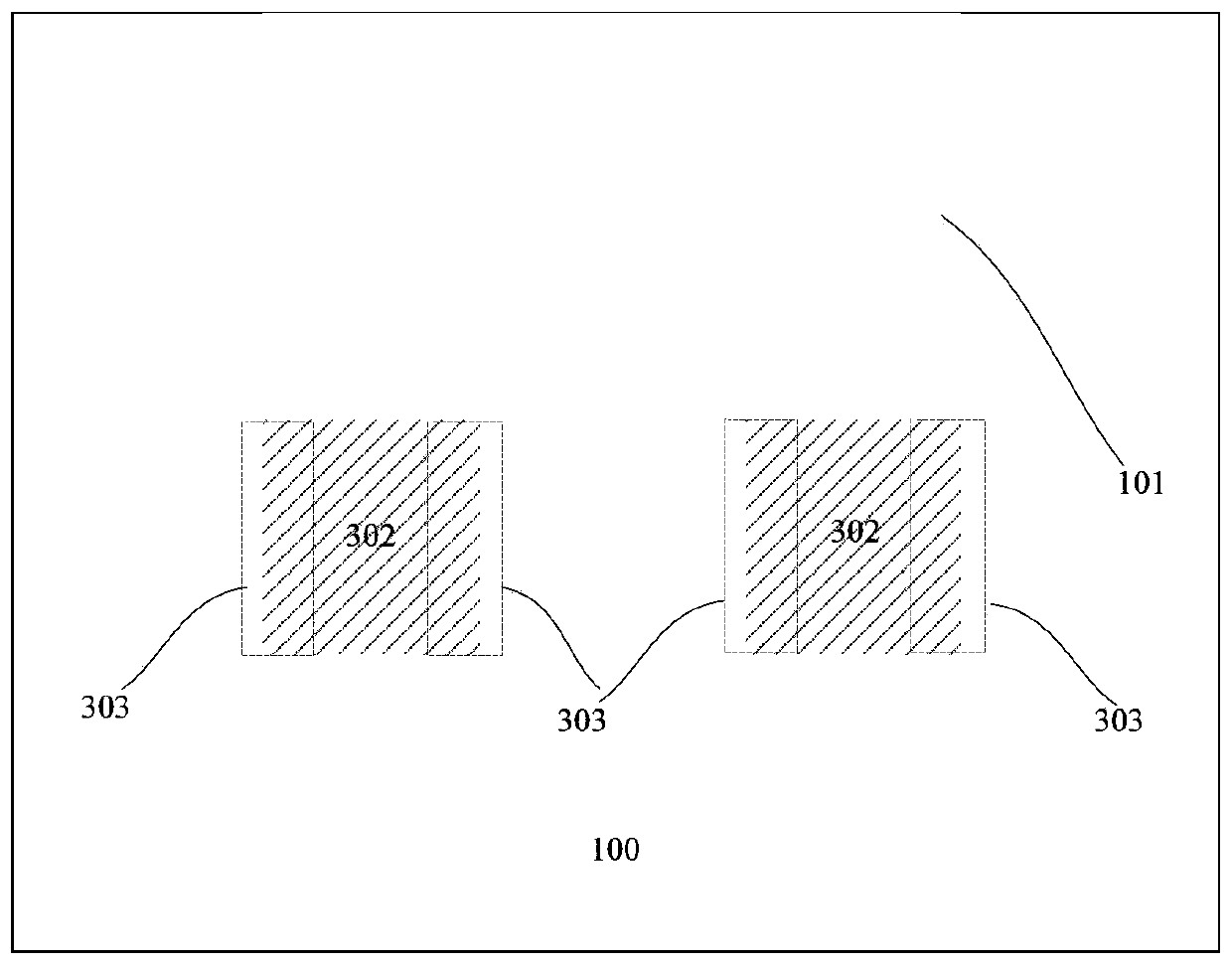

[0048] Figure 4 Schematic flow chart of the preparation method of the photodiode provided by the application Figure 1 . Figure 4 The execution subject of the shown method flow can be the preparation device of photodiode, such as Figure 4 As shown, the preparation method of the photodiode provided in this embodiment may include:

[0049] S401, forming a shielding layer on the substrate, the substrate has a first doping type, and a preset position is set on the substrate, the preset position is a position where the doping type is the second doping type, and the first doping type Different from the second doping type, the shielding layer is used to shield ions implanted into the substrate, and the shielding strength of the shielding layer is related to the thickness of the shielding layer.

[0050] The photodiode preparation device in this embodiment can be a device that integrates multiple functions such as coating, photolithography, etching, and ion implantation, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com