Method for treating landfill leachate with aerobic granular sludge membrane and its membrane bioreactor

An aerobic granular sludge and membrane bioreactor technology, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, polluted groundwater/leachate treatment, etc., can solve the problem of increasing the cost of landfill leachate treatment , water environmental hazards, degradation of pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

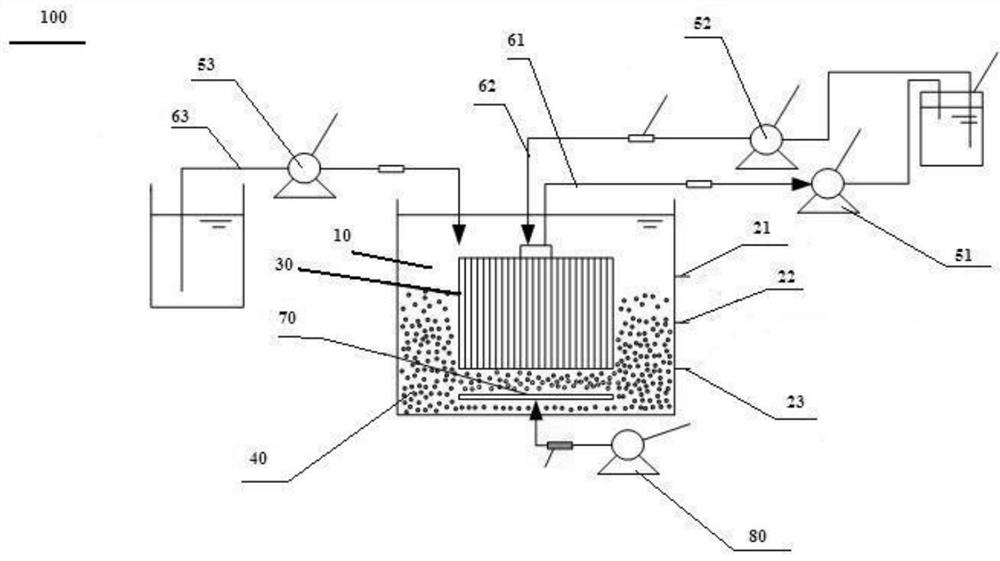

[0022] A method for treating landfill leachate using an aerobic granular sludge membrane, comprising the steps of cultivating the aerobic granular sludge and domesticating the reactor:

[0023] (1) Cultivation of aerobic granular sludge: Put ordinary activated sludge with a concentration of 3400mg / L into the reactor, control the aeration rate of the reactor to 0.8L / min, and use simulated sewage to carry out water inflow cultivation in an intermittent manner , 6 hours of hydraulic retention in the reactor is a cycle, and the reactor is re-fed when each cycle begins, and the reactor is drained at the end, and the water inflow is equal to the discharge; the sedimentation time of the sludge is divided into three stages during the cultivation process. stage, wherein: the cultivation time of the first stage is 7 days, drain water after 5 minutes of settlement, and wash out a large amount of sludge with poor settleability; the cultivation time of the second stage is 9 days, and drain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com